Introduction: Navigating the Global Market for 2 fl oz bottle

In today’s competitive global market, sourcing the right packaging solutions can be a daunting task for B2B buyers, especially when it comes to the versatile 2 fl oz bottle. Whether you’re looking for glass, plastic, or soft-sided options, the challenge lies not just in finding a supplier but also in ensuring that the product meets your specific application needs—be it for essential oils, skincare serums, or condiments. This comprehensive guide aims to demystify the complexities of sourcing 2 fl oz bottles by providing insights into various types, applications, and the essential criteria for supplier vetting.

Navigating through the myriad of choices available, this guide will empower international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—to make informed purchasing decisions. You’ll find detailed sections on cost considerations, material specifications, and the importance of selecting the right closures and dispensing options for your products. Additionally, we will explore market trends and regulatory factors that may impact your sourcing strategy.

Arming yourself with the right information can significantly reduce your risk and enhance your brand’s presentation. By the end of this guide, you will be equipped to confidently select the best 2 fl oz bottle solutions that align with your business goals, ensuring both quality and aesthetic appeal while optimizing your supply chain.

기사 탐색

- Top 7 2 Fl Oz Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 2 fl oz bottle

- Understanding 2 fl oz bottle Types and Variations

- Key Industrial Applications of 2 fl oz bottle

- 3 Common User Pain Points for ‘2 fl oz bottle’ & Their Solutions

- Strategic Material Selection Guide for 2 fl oz bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 2 fl oz bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘2 fl oz bottle’

- Comprehensive Cost and Pricing Analysis for 2 fl oz bottle Sourcing

- Alternatives Analysis: Comparing 2 fl oz bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 2 fl oz bottle

- Navigating Market Dynamics and Sourcing Trends in the 2 fl oz bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 2 fl oz bottle

- 중요 고지 사항 및 이용 약관

- Strategic Sourcing Conclusion and Outlook for 2 fl oz bottle

Understanding 2 fl oz bottle Types and Variations

| 유형 이름 | 주요 차별화 기능 | 주요 B2B 애플리케이션 | 구매자를 위한 간략한 장단점 |

|---|---|---|---|

| Glass Boston Round Bottles | Available in various colors (amber, clear, frosted) | Essential oils, skincare products | 장점: Aesthetic appeal, chemical resistance. 단점: Heavier, fragile. |

| HDPE Plastic Cylinder Bottles | Lightweight, durable, and available in multiple neck finishes | Body care products, cleaning supplies | 장점: Cost-effective, shatterproof. 단점: Less premium feel than glass. |

| Soft-Sided Condiment Bottles | Flexible design, easy to refill, often with flip-top lids | Food service, travel applications | 장점: Space-saving, lightweight. 단점: Limited to non-carbonated liquids. |

| Dropper Bottles | Includes dropper tops for precise dispensing | Pharmaceuticals, essential oils | 장점: Accurate dosing, minimizes waste. 단점: May require additional parts. |

| Fine Mist Spray Bottles | Compatible with mist sprayers for even application | Toners, room sprays | 장점: Controlled application, versatile. 단점: Requires separate sprayer purchase. |

What Are the Key Characteristics of Glass Boston Round Bottles?

Glass Boston round bottles are a popular choice for businesses seeking high-quality, visually appealing packaging. They come in various finishes, including amber and frosted, which not only enhance brand presentation but also provide protection against UV light, making them ideal for sensitive products like essential oils and skincare serums. When considering these bottles, B2B buyers should note that while they offer a premium feel and chemical resistance, their weight and fragility can pose challenges in shipping and handling.

How Do HDPE Plastic Cylinder Bottles Compare?

HDPE plastic cylinder bottles are known for their lightweight and durable nature. These bottles are versatile and can accommodate a variety of liquid products, including body washes and cleaning supplies. Their cost-effectiveness makes them an attractive option for bulk orders, especially for businesses looking to reduce packaging costs. However, buyers should consider that while these bottles are shatterproof, they may not convey the same premium image as glass options.

What Advantages Do Soft-Sided Condiment Bottles Offer?

Soft-sided condiment bottles are designed for convenience and ease of use. Their flexible structure allows for easy refilling and makes them ideal for food service or travel applications. These bottles typically come with flip-top lids, enhancing user experience. However, they are not suitable for carbonated liquids, which limits their application scope. Buyers should weigh the benefits of their space-saving design against the limitations in product compatibility.

Why Choose Dropper Bottles for Precision?

Dropper bottles are specifically designed for accurate dispensing, making them essential for products where dosage precision is critical, such as pharmaceuticals and essential oils. These bottles often come with droppers that minimize waste and enhance user experience. B2B buyers must consider that while the precision of dropper bottles is a significant advantage, they may require additional components, such as separate dropper tops, which could complicate the supply chain.

What Makes Fine Mist Spray Bottles Essential for Certain Products?

Fine mist spray bottles are ideal for products that require a controlled application, such as toners and room sprays. Their compatibility with mist sprayers allows for an even distribution of liquid, enhancing user satisfaction. When purchasing these bottles, businesses should be aware that the sprayers are often sold separately, which may affect overall cost and inventory management. Despite this, the versatility and effectiveness of fine mist spray bottles make them a valuable addition to many product lines.

Key Industrial Applications of 2 fl oz bottle

| 산업/섹터 | Specific Application of 2 fl oz bottle | 비즈니스를 위한 가치/혜택 | 이 애플리케이션의 주요 소싱 고려 사항 |

|---|---|---|---|

| 화장품 및 퍼스널 케어 | Packaging for serums and essential oils | Enhances product appeal and preserves formulation integrity | Material quality, compatibility with droppers/sprayers |

| 식음료 | Portion control for sauces and condiments | Convenient for travel and sampling, reduces waste | Food-grade materials, leak-proof design |

| 제약 | Packaging for liquid medications or supplements | Ensures dosage accuracy and product safety | Compliance with regulations, child-resistant features |

| 청소 제품 | Packaging for concentrated cleaners | Cost-effective for bulk supply, minimizes storage space | Durability, compatibility with various dispensing caps |

| Industrial Chemicals | Packaging for specialty chemicals or lubricants | Provides secure containment and reduces risk of spills | Chemical compatibility, bulk purchasing options |

How are 2 fl oz bottles utilized in the cosmetics and personal care industry?

In the cosmetics and personal care sector, 2 fl oz bottles are ideal for packaging high-value products like serums and essential oils. These bottles not only enhance the visual appeal of the product but also preserve the integrity of sensitive formulations. For international buyers, sourcing bottles that are compatible with droppers or fine mist sprayers is crucial to ensure ease of use and customer satisfaction. Additionally, the choice of glass versus plastic may depend on brand positioning and sustainability goals.

What role do 2 fl oz bottles play in food and beverage packaging?

In the food and beverage industry, 2 fl oz bottles serve as an effective solution for portion control, particularly for sauces and condiments. Their compact size makes them perfect for travel, catering, or sampling, thus minimizing waste. Buyers need to prioritize food-grade materials and leak-proof designs to comply with health regulations and ensure customer safety. Sourcing these bottles in bulk can also lead to significant cost savings.

Why are 2 fl oz bottles important for the pharmaceutical industry?

Pharmaceutical companies utilize 2 fl oz bottles for packaging liquid medications and dietary supplements, ensuring accurate dosage and product safety. These bottles can be designed with child-resistant features to comply with stringent safety regulations. International buyers should focus on sourcing bottles that meet local compliance standards, as well as those that can withstand temperature variations during transportation.

How do 2 fl oz bottles benefit cleaning product manufacturers?

For cleaning product manufacturers, 2 fl oz bottles are a cost-effective packaging solution for concentrated cleaners. Their small size allows for efficient storage and transportation, while also appealing to consumers looking for convenience. When sourcing, businesses should consider the durability of the materials used, as well as compatibility with various dispensing caps to enhance user experience.

What are the advantages of using 2 fl oz bottles for industrial chemicals?

In the industrial sector, 2 fl oz bottles are commonly used for packaging specialty chemicals and lubricants. They provide secure containment that minimizes the risk of spills, which is critical in maintaining workplace safety. Buyers should ensure that the bottles are made from materials that are compatible with the chemicals being stored, as well as explore options for bulk purchasing to streamline supply chain management.

3 Common User Pain Points for ‘2 fl oz bottle’ & Their Solutions

Scenario 1: Packaging for Diverse Product Lines

문제: A B2B buyer in the beauty and personal care sector faces the challenge of sourcing 2 fl oz bottles that can accommodate various product types such as serums, oils, and toners. Each product requires different dispensing mechanisms—some need droppers for precise application while others benefit from fine mist sprayers. This complexity can lead to increased costs and logistical headaches when managing multiple suppliers and packaging solutions.

솔루션: To streamline your packaging process, consider selecting a versatile supplier that offers a wide range of customizable 2 fl oz bottles compatible with different dispensing options. Look for suppliers that provide bottles with interchangeable caps and closures, allowing you to order in bulk while maintaining flexibility for various product lines. When placing your order, specify the types of products you plan to package and inquire about multi-cap options to optimize your inventory. This approach not only simplifies logistics but also ensures a cohesive brand presentation across your product range.

Scenario 2: Ensuring Product Integrity During Shipping

문제: An international B2B buyer shipping cosmetic products faces concerns about product integrity during transport. The buyer has experienced incidents of leaks and breakage, resulting in financial losses and customer dissatisfaction. With varying regulations and shipping conditions across regions like Africa and Europe, maintaining product quality while reducing shipping costs becomes a daunting task.

솔루션: To mitigate these risks, invest in high-quality, durable 2 fl oz bottles made from materials that can withstand different shipping environments. Opt for glass or high-density polyethylene (HDPE) bottles, which offer superior protection against breakage and leaks. Additionally, use appropriate packaging materials such as bubble wrap or cushioning to further secure bottles during transit. Collaborate with your shipping partner to understand the best practices for packaging liquids and ensure compliance with regional regulations. Implementing these strategies will enhance product safety during shipping and improve customer satisfaction.

Scenario 3: Compliance with Regional Packaging Regulations

문제: A B2B buyer in the health supplement industry encounters challenges navigating the regulatory landscape regarding packaging for 2 fl oz bottles. Different regions, such as South America and the Middle East, have specific labeling and material requirements that can lead to delays in product launches and increased compliance costs if not adhered to properly.

솔루션: To effectively manage compliance, conduct thorough research on the packaging regulations specific to each target market. Partner with suppliers who are knowledgeable about international standards and can provide guidance on compliant materials and labeling practices. When sourcing your 2 fl oz bottles, request samples that meet the required specifications and ensure that your labels are designed according to local regulations. Additionally, consider investing in a compliance management software to track and manage your packaging requirements across different regions. This proactive approach will not only streamline your product launches but also protect your brand from potential legal challenges.

Strategic Material Selection Guide for 2 fl oz bottle

What are the Key Properties of Glass Bottles for 2 fl oz Applications?

Glass is a favored material for 2 fl oz bottles, particularly for products like essential oils and cosmetics. Its key properties include excellent chemical resistance, allowing it to safely contain a variety of liquids without leaching harmful substances. Glass bottles also have a high-temperature tolerance, making them suitable for heat-sensitive products. However, they are more fragile than plastic alternatives, which can be a concern during transportation and handling.

장점: Glass bottles offer superior aesthetics and can enhance brand perception due to their premium feel. They are recyclable, aligning with sustainability trends.

단점: The higher cost of production and the weight of glass can increase shipping expenses. Additionally, they require careful handling to prevent breakage.

애플리케이션에 미치는 영향: Glass is ideal for high-value products that require a premium presentation. Its compatibility with a wide range of media, including oils and alcohol-based solutions, makes it a versatile choice.

해외 구매자를 위한 고려 사항: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider the availability of glass recycling facilities in their regions, as this can affect sustainability practices.

How Does Plastic Compare as a Material for 2 fl oz Bottles?

Plastic, particularly high-density polyethylene (HDPE) and polyethylene terephthalate (PET), is commonly used for 2 fl oz bottles. These materials provide excellent durability and impact resistance, making them less prone to breakage compared to glass. They also have good chemical resistance, though not as extensive as glass.

장점: Plastic bottles are lightweight and cost-effective, which can reduce shipping costs significantly. They are also versatile, available in various colors and finishes.

단점: Plastics can be perceived as less premium than glass, potentially affecting brand image. Additionally, some plastics may leach chemicals into products, especially when exposed to heat.

애플리케이션에 미치는 영향: Plastic is suitable for a wide range of products, including lotions, shampoos, and cleaning supplies. However, it may not be ideal for products that require long shelf lives or high-quality presentation.

해외 구매자를 위한 고려 사항: Buyers should ensure that the chosen plastic meets local regulations regarding food and cosmetic safety. The availability of recycling programs for plastics in their region can also influence material selection.

What are the Advantages of Using Soft-Sided Bottles for 2 fl oz Applications?

Soft-sided bottles, often made from laminated polypropylene, are gaining popularity for their flexibility and ease of use. These bottles are particularly effective for condiments and other liquid products that require controlled dispensing.

장점: They are lightweight, squeezable, and easy to refill, making them user-friendly. Their design allows for efficient use of product, minimizing waste.

단점: Soft-sided bottles may not offer the same level of protection against external factors as rigid containers. They can also be less suitable for products requiring long-term storage.

애플리케이션에 미치는 영향: Ideal for travel and outdoor use, these bottles are perfect for sauces and other liquid condiments. Their flexibility makes them suitable for various applications, although they may not be suitable for all product types.

해외 구매자를 위한 고려 사항: Buyers should consider the durability of soft-sided bottles in their specific applications, especially in regions with varying climate conditions. Compliance with relevant safety standards is also essential.

How Do Different Materials Affect the Cost and Manufacturing Complexity of 2 fl oz Bottles?

The cost and complexity of manufacturing 2 fl oz bottles vary significantly by material. Glass production generally involves higher costs due to raw materials and processing. In contrast, plastic and soft-sided bottles can be produced more economically and with less energy, making them attractive for bulk orders.

장점: Lower manufacturing complexity for plastic and soft-sided bottles can lead to faster production times and reduced costs.

단점: The initial investment in glass molds and production lines can be significant, affecting pricing strategies for businesses.

애플리케이션에 미치는 영향: The choice of material directly influences the pricing strategy and market positioning of the product. Businesses targeting premium markets may opt for glass, while those focused on cost-effectiveness might prefer plastic.

해외 구매자를 위한 고려 사항: Understanding local manufacturing capabilities and material costs is crucial for international buyers. They should also be aware of tariffs and import regulations that may affect pricing.

| 재료 | Typical Use Case for 2 fl oz bottle | 주요 이점 | 주요 단점/제한 사항 | 상대적 비용(낮음/중간/높음) |

|---|---|---|---|---|

| 유리 | Essential oils, cosmetics | Excellent chemical resistance | Fragile, higher shipping costs | 높음 |

| HDPE 플라스틱 | Lotions, cleaning supplies | Lightweight, cost-effective | Perceived as less premium | 낮음 |

| PET 플라스틱 | Beverages, personal care | Good clarity and strength | 화학 물질 침출 가능성 | Medium |

| Soft-Sided Polypropylene | Condiments, travel products | Flexible, easy to dispense | Less protective, not for long-term storage | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for 2 fl oz bottle

What Are the Key Stages in the Manufacturing Process of a 2 fl oz Bottle?

The manufacturing of 2 fl oz bottles, whether made from glass or plastic, involves several critical stages that ensure quality and functionality.

1. 자료 준비

The first stage involves selecting the appropriate raw materials, which could be glass or high-density polyethylene (HDPE) for plastic bottles. For glass bottles, manufacturers often use high-quality silica sand, soda ash, and limestone. In the case of plastic bottles, HDPE is favored for its durability and resistance to chemicals. These materials undergo rigorous quality checks to ensure they meet industry standards before moving to the next stage.

2. 형성

In this phase, the prepared materials are shaped into the desired bottle form. For glass bottles, this typically involves melting the raw materials in a furnace at high temperatures (around 1,600 degrees Celsius) and then forming them using blow molding techniques. Plastic bottles are produced through injection or blow molding processes, where molten plastic is injected into molds to create the desired shape. This stage is crucial as it determines the bottle’s structural integrity and aesthetic appeal.

3. 조립

After forming, the next step is assembly, where various components such as caps and closures are added. For 2 fl oz bottles, this may include screw caps, droppers, or mist sprayers. The assembly must be precise to ensure that each component fits well and functions correctly. This stage often involves automated machinery to streamline the process and minimize human error.

4. 마무리

The final stage is finishing, which includes cleaning, labeling, and packaging the bottles. For glass bottles, this may involve polishing and applying coatings to enhance durability and appearance. In contrast, plastic bottles might undergo additional processes like printing or labeling directly onto the surface. This stage ensures that the products are visually appealing and ready for distribution.

How Is Quality Assurance Implemented in Bottle Manufacturing?

Quality assurance (QA) is integral to the manufacturing of 2 fl oz bottles to ensure they meet both safety and performance standards.

국제 및 산업별 표준

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This certification helps ensure that products consistently meet customer and regulatory requirements. Additionally, for markets in Europe, CE marking may be required, indicating compliance with health, safety, and environmental protection standards.

In the pharmaceutical and cosmetic industries, compliance with regulations from the American Petroleum Institute (API) or similar organizations is critical. These standards help ensure that bottles are suitable for containing sensitive substances like essential oils or skincare products.

품질 관리 체크 포인트

Quality control (QC) includes several checkpoints throughout the manufacturing process:

-

수신 품질 관리(IQC): This initial checkpoint involves inspecting raw materials before they enter production. It ensures that only high-quality materials are used, reducing the risk of defects later in the process.

-

IPQC(인프로세스 품질 관리): During manufacturing, various tests are conducted to monitor the production process. This may include checking the temperature and pressure during molding and ensuring that the dimensions of the bottles meet specifications.

-

최종 품질 관리(FQC): After the bottles are finished, they undergo rigorous testing, which may include leak testing, pressure testing, and visual inspections for defects. This final checkpoint is crucial to ensure that only products meeting quality standards are shipped to customers.

품질 보증에 사용되는 일반적인 테스트 방법에는 어떤 것이 있나요?

B2B buyers should be aware of the common testing methods employed in the QC of 2 fl oz bottles:

-

Dimensional Inspection: This method checks the physical dimensions of the bottles to ensure they meet specified tolerances. Tools such as calipers and micrometers are commonly used.

-

Visual Inspection: A thorough visual examination is performed to identify any surface defects, including scratches, bubbles, or inconsistencies in color.

-

누수 테스트: This is particularly important for bottles designed to hold liquids. Various methods, including vacuum testing and pressure decay testing, are used to ensure that the bottles do not leak.

-

재료 테스트: Chemical resistance tests may be conducted to ensure that the materials used for the bottles can withstand the contents they will hold, particularly for essential oils and other sensitive products.

B2B 구매자는 공급업체의 품질 관리를 어떻게 확인할 수 있나요?

When sourcing 2 fl oz bottles from international suppliers, B2B buyers must take proactive steps to verify the quality control measures in place.

감사 수행

Requesting a factory audit is one of the most effective ways to assess a supplier’s quality control processes. An audit can reveal the supplier’s adherence to international standards and their ability to maintain consistent product quality. During an audit, buyers should evaluate the manufacturing environment, employee training, and equipment used in the production process.

품질 보고서 검토

Buyers should ask suppliers for quality control documentation, including inspection reports, testing results, and certifications. These documents provide insight into the supplier’s QC practices and their compliance with industry standards.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can add an additional layer of assurance. These independent organizations can conduct comprehensive inspections at various stages of the manufacturing process, ensuring that the bottles meet the specified quality standards before shipment.

해외 B2B 구매자를 위한 품질 관리의 뉘앙스는 무엇인가요?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate several nuances when it comes to quality control in the bottle manufacturing process.

Understanding Regional Regulations

Buyers should be aware of the regulatory requirements specific to their region. For instance, cosmetic and pharmaceutical packaging regulations differ significantly between the European Union and countries in Africa or South America. Understanding these regulations helps buyers ensure compliance and avoid potential legal issues.

Cultural Considerations in Quality Expectations

Cultural differences can influence quality expectations. For example, buyers from Europe may have higher expectations regarding product aesthetics and packaging, while those in emerging markets may prioritize functionality and cost-effectiveness. Clear communication regarding quality expectations and standards is essential to bridge these cultural gaps.

Building Long-Term Relationships

Establishing long-term relationships with reliable suppliers can enhance quality assurance. By fostering collaboration and open communication, buyers can work closely with suppliers to address quality concerns and continuously improve processes.

결론

Understanding the manufacturing processes and quality assurance measures for 2 fl oz bottles is crucial for B2B buyers looking to source high-quality products. By familiarizing themselves with the stages of production, quality control standards, and verification methods, buyers can make informed decisions that align with their business needs and regulatory requirements. Investing time in supplier verification and quality assurance will ultimately contribute to successful and sustainable business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2 fl oz bottle’

In this guide, we provide a comprehensive checklist for B2B buyers interested in sourcing 2 fl oz bottles. Whether for essential oils, skincare products, or other liquid applications, understanding the key factors in procurement can streamline your purchasing process and ensure you select the best options for your business needs.

1단계: 기술 사양 정의

Establishing clear technical specifications is critical to ensure the bottles meet your product requirements. Consider factors such as material (glass, plastic, etc.), neck size (e.g., 20-410), and intended use (e.g., with droppers or sprayers). This clarity helps suppliers provide accurate options that align with your needs.

2단계: Assess Material Quality and Compatibility

Evaluate the materials used in the bottles. Glass and high-density polyethylene (HDPE) are common choices, each offering unique benefits. For example, glass provides a premium feel and better preservation of sensitive liquids, while HDPE is lightweight and resistant to impacts. Ensure the material is compatible with your product’s chemical composition to avoid leaching or degradation.

3단계: Determine Design and Aesthetic Preferences

The design of your packaging can significantly impact brand perception. Decide if you prefer amber, clear, or colored bottles based on the product’s light sensitivity and marketing strategy. A visually appealing design can enhance your brand’s marketability, so consider how the bottle will look on shelves or in promotional materials.

4단계: 잠재적 공급업체 평가

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, product samples, and references from other businesses in similar industries. Pay attention to their production capabilities, lead times, and customer service responsiveness. A reliable supplier should also provide information on their quality control processes and certifications.

5단계: Verify Compliance with International Standards

Ensure that the bottles you select comply with the relevant international packaging standards, particularly if you are exporting products. Different regions may have specific regulations regarding materials and safety. Verify that suppliers can provide documentation to prove compliance with standards such as ISO or FDA regulations, depending on your market.

6단계: Request Bulk Pricing and Shipping Options

When sourcing bottles, inquire about bulk pricing to optimize your procurement costs. Many suppliers offer discounts for larger orders, which can significantly reduce your overall expenses. Additionally, confirm the shipping options available, including costs, estimated delivery times, and any potential customs implications for international shipping.

7단계: Finalize Your Order and Establish Terms

Once you have selected a supplier, finalize your order details, including quantity, pricing, and delivery schedules. Clearly outline payment terms, return policies, and warranty conditions in your agreement. Establishing these terms upfront can prevent misunderstandings and ensure a smoother transaction process.

By following this practical sourcing checklist, B2B buyers can confidently navigate the procurement process for 2 fl oz bottles, ensuring they select the best products to support their business objectives.

Comprehensive Cost and Pricing Analysis for 2 fl oz bottle Sourcing

What Are the Key Cost Components for Sourcing 2 fl oz Bottles?

When sourcing 2 fl oz bottles, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

자료: The choice of materials significantly impacts the price. Glass bottles typically range from $0.37 to $0.58 per unit based on color and finish, while plastic options like HDPE can be as low as $0.13 per unit when ordered in bulk. Material quality affects durability and aesthetic appeal, which can influence buyer perception and brand image.

-

노동: Labor costs vary by region and manufacturing process. In countries with higher labor costs, such as Germany, expect a higher overall price. Conversely, sourcing from regions with lower labor costs may provide a more competitive pricing structure.

-

제조 오버헤드: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which is beneficial for both the manufacturer and the buyer.

-

툴링: Custom tooling for specific bottle designs or features can lead to significant upfront costs. However, these costs can be amortized over larger production runs, making them more manageable.

-

품질 관리(QC): Ensuring product quality is essential, especially for brands focusing on premium markets. Investing in QC can incur additional costs but is necessary to avoid potential recalls and maintain customer trust.

-

물류: Shipping and handling costs vary based on the origin and destination of the bottles. International shipping can be particularly expensive due to freight fees, customs duties, and insurance.

-

마진: Suppliers typically add a profit margin to cover their expenses and desired profit. This margin can vary widely depending on the supplier’s market position and the level of service they provide.

How Do Price Influencers Impact the Cost of 2 fl oz Bottles?

Several factors influence the pricing of 2 fl oz bottles, making it essential for buyers to consider these elements when negotiating:

-

볼륨/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders generally lead to lower per-unit costs, making bulk purchases more economical.

-

사양 및 사용자 지정: Custom designs, colors, and finishes can significantly increase costs. Standard options usually offer more competitive pricing, so buyers should weigh the benefits of customization against budget constraints.

-

재료 및 품질 인증: Higher quality materials or certifications (like FDA compliance for food-grade bottles) can raise costs. Buyers must assess whether these certifications are necessary for their products.

-

공급업체 요인: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge a premium for their services, but they often provide superior quality and support.

-

인코텀즈: The choice of Incoterms affects shipping costs and responsibilities. Buyers should negotiate these terms to optimize their total costs.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of 2 fl oz Bottles?

International B2B buyers can leverage several strategies to enhance cost efficiency in sourcing 2 fl oz bottles:

-

협상: Build strong relationships with suppliers and negotiate terms to secure better pricing. Understanding the supplier’s cost structure can provide leverage during negotiations.

-

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis that considers not just the purchase price, but also shipping, handling, storage, and potential waste. This comprehensive view can highlight hidden costs.

-

해외 구매자를 위한 가격 책정 뉘앙스: Be aware of currency fluctuations, tariffs, and import duties that can impact overall costs. Consider sourcing from countries with favorable trade agreements to minimize these expenses.

-

Stay Informed: Keep abreast of market trends and pricing changes in the bottle manufacturing industry. This knowledge can help anticipate price increases and identify better sourcing opportunities.

결론

Understanding the comprehensive cost structure and pricing influences of 2 fl oz bottles is vital for international B2B buyers. By focusing on the outlined cost components, recognizing key pricing influencers, and employing strategic sourcing tips, buyers can make informed decisions that align with their business objectives. Always remember that prices may fluctuate, and it’s prudent to request indicative quotes to ensure alignment with current market conditions.

Alternatives Analysis: Comparing 2 fl oz bottle With Other Solutions

Introduction: Exploring Alternatives to the 2 Fl Oz Bottle

When it comes to packaging solutions for liquid products, the 2 fl oz bottle is a popular choice due to its versatility and functionality. However, businesses often seek alternatives that may better meet specific needs or preferences. In this analysis, we will compare the 2 fl oz bottle against two viable alternatives: soft-sided condiment bottles and HDPE plastic bottles. By examining these options, B2B buyers can make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

비교 표

| 비교 측면 | 2 Fl Oz Bottle | Soft-Sided Condiment Bottle | HDPE Plastic Bottle |

|---|---|---|---|

| 성능 | Durable, ideal for various liquids | Flexible, suitable for sauces and condiments | Lightweight, good for cleaning supplies |

| 비용 | Moderate, bulk pricing available | Higher per unit, but reusable | Low cost, especially for bulk orders |

| 구현의 용이성 | Requires selection of appropriate closures | Easy to fill and refill | Simple design, easy to package |

| 유지 관리 | Minimal, easy to clean | Requires thorough cleaning to prevent clogs | Low maintenance, durable material |

| 모범 사용 사례 | Essential oils, skincare products | Travel-friendly condiment storage | Lotions, shampoos, cleaning solutions |

대안에 대한 자세한 분석

Soft-Sided Condiment Bottles

Soft-sided condiment bottles are designed for easy dispensing of sauces and liquids. They are particularly advantageous for businesses in the food industry or those that require portable packaging solutions. The flexible material allows for easy squeezing, making it easy to control the amount dispensed. However, their higher cost per unit and the need for thorough cleaning after each use can be a drawback for some businesses. While they are reusable, buyers should consider whether the benefits of flexibility and portability outweigh the maintenance requirements.

HDPE Plastic Bottles

HDPE (High-Density Polyethylene) plastic bottles are a cost-effective solution for packaging a variety of liquid products. These bottles are lightweight and durable, making them suitable for products such as lotions, shampoos, and cleaning supplies. The straightforward design allows for easy packaging and labeling, which can streamline operations. However, while they offer low upfront costs, the environmental impact of plastic may be a concern for some companies focused on sustainability. Businesses should weigh the benefits of affordability and functionality against potential environmental implications.

Conclusion: Making the Right Choice for Your Business

Choosing the right packaging solution ultimately depends on the specific needs of your business. The 2 fl oz bottle excels in durability and versatility, making it ideal for high-end products like essential oils and skincare items. On the other hand, soft-sided condiment bottles provide flexibility for the food sector, while HDPE plastic bottles offer a budget-friendly option for a range of liquid products. B2B buyers should assess their product requirements, budget constraints, and brand values to select the packaging solution that best aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for 2 fl oz bottle

What Are the Essential Technical Properties of a 2 fl oz Bottle?

When sourcing 2 fl oz bottles for your business, understanding their technical properties is vital. Here are the key specifications to consider:

-

머티리얼 구성: 2 fl oz bottles are typically made from glass or high-density polyethylene (HDPE). Glass offers excellent chemical resistance and an upscale appearance, making it suitable for premium products like essential oils and skincare serums. HDPE, on the other hand, is lightweight and resistant to impact, making it ideal for everyday products such as lotions and cleaning supplies. Choosing the right material impacts both product safety and brand presentation.

-

Neck Finish: The neck finish, often described using terms like “20-410” or “20-400,” refers to the diameter and threading of the bottle’s opening. This specification is crucial for compatibility with closures and dispensing systems. A proper fit ensures leak-proof seals and easy application, which can enhance user experience and minimize product waste.

-

용량: The stated capacity of 2 fl oz (approximately 59 ml) is a standard size for various applications, from personal care products to food items. Understanding capacity is critical for inventory management and ensuring your products meet market demand.

-

Tolerance: Tolerance refers to the allowable variation in the dimensions of the bottle. For instance, a tolerance of ±0.5 mm for the neck diameter is common. This specification is important for ensuring that caps fit securely and that the bottles can withstand filling and handling processes without compromising quality.

-

Finish and Coating: Bottles may come with various finishes, such as frosted or UV-coated. Frosted finishes provide a premium look and can enhance grip, while UV coatings protect sensitive contents from light degradation. Selecting the appropriate finish is crucial for maintaining product integrity and aesthetic appeal.

-

무게: The weight of the bottle can influence shipping costs and handling. Lightweight options reduce freight expenses, which is particularly important for international shipping. Buyers should evaluate the trade-off between sturdiness and weight to optimize both cost and product protection.

What Are Common Trade Terminologies Relevant to 2 fl oz Bottles?

Familiarizing yourself with industry jargon can facilitate smoother transactions and better negotiations. Here are essential terms to know:

-

OEM(주문자 상표 부착 생산): This term refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM relationships can help you identify potential suppliers who can provide customized 2 fl oz bottles tailored to your specifications.

-

MOQ(최소 주문 수량): MOQ is the smallest number of units a supplier is willing to sell. Being aware of the MOQ can aid in budgeting and inventory planning, ensuring that you don’t overcommit to stock that may not sell.

-

견적 요청(RFQ): An RFQ is a standard business process where a buyer requests price quotes from suppliers. This is particularly useful for comparing costs and terms when sourcing 2 fl oz bottles from multiple manufacturers.

-

인코텀즈(국제 상거래 약관): These are standardized trade terms used in international shipping that define the responsibilities of buyers and sellers. Familiarity with Incoterms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), is essential for understanding shipping costs and liabilities.

-

사용자 지정 옵션: This term refers to the ability to modify bottles in terms of size, shape, color, and labeling. Understanding customization options can help your brand stand out in a competitive market and meet specific customer needs.

-

리드 타임: This is the amount of time it takes from placing an order to receiving the product. Knowing the lead time is crucial for planning marketing campaigns and ensuring timely product launches.

By grasping these technical specifications and trade terms, international B2B buyers can make informed decisions when sourcing 2 fl oz bottles, ultimately enhancing their business operations and product offerings.

Navigating Market Dynamics and Sourcing Trends in the 2 fl oz bottle Sector

What Are the Current Market Dynamics and Key Trends in the 2 fl oz Bottle Sector?

The global market for 2 fl oz bottles is experiencing notable growth, driven by a surge in demand across various industries, including cosmetics, pharmaceuticals, and food and beverage. As international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe (notably Nigeria and Germany), navigate this evolving landscape, understanding market dynamics is crucial. Key trends include the increasing preference for glass bottles due to their recyclability and premium appearance, which enhances brand perception. Moreover, the rise of e-commerce has accelerated the need for efficient packaging solutions that are both attractive and functional.

Emerging technologies such as automated packaging processes and smart inventory management systems are transforming how businesses source and manage their bottle supplies. These innovations not only streamline operations but also reduce costs, allowing companies to maintain competitiveness in an increasingly crowded marketplace. Additionally, customization options are becoming more prevalent, enabling brands to differentiate themselves through unique designs and functionalities tailored to specific products, such as essential oils or skincare serums.

How Is Sustainability Influencing B2B Sourcing for 2 fl oz Bottles?

Sustainability is no longer just a trend; it is a necessity that influences sourcing decisions in the 2 fl oz bottle sector. As environmental concerns grow, international buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. The use of eco-friendly materials, such as recycled glass or biodegradable plastics, is becoming a key consideration in procurement strategies.

Moreover, businesses are seeking suppliers that provide certifications for sustainability, such as ISO 14001 or Forest Stewardship Council (FSC) certification. These certifications assure buyers that their products are sourced responsibly, minimizing environmental impact. Companies that invest in sustainable practices not only enhance their corporate responsibility but also appeal to environmentally conscious consumers, ultimately driving sales and brand loyalty.

What Is the Historical Context of 2 fl oz Bottle Development in B2B Markets?

The evolution of the 2 fl oz bottle sector is rooted in the broader trends of packaging innovation and consumer demand. Initially, these bottles were primarily used in pharmaceuticals and cosmetics, where small quantities were essential for dosage accuracy and product preservation. Over the decades, as industries expanded and e-commerce gained traction, the versatility of the 2 fl oz bottle made it a staple across various sectors, including food and beverage.

The shift towards sustainability in recent years has prompted manufacturers to explore alternative materials and eco-friendly designs, further driving innovation within the sector. This historical context underscores the importance of adaptability and forward-thinking in sourcing strategies for international buyers, as the market continues to evolve in response to consumer preferences and environmental considerations.

In summary, understanding these market dynamics, sustainability imperatives, and historical developments equips B2B buyers with the insights needed to make informed sourcing decisions in the thriving 2 fl oz bottle sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 2 fl oz bottle

-

How do I choose the right 2 fl oz bottle for my product?

Selecting the right 2 fl oz bottle depends on your product type and branding needs. Consider the material—glass offers a premium feel and better protection for sensitive liquids, while plastic is lightweight and cost-effective. Think about the closure type as well; droppers and fine mist sprayers are ideal for precision dispensing. Assess color options too; amber and green bottles protect contents from UV light, while clear bottles showcase product visibility. Evaluate your target market’s preferences and regulations in your region to finalize the best choice. -

What are the minimum order quantities (MOQ) for 2 fl oz bottles?

Minimum order quantities for 2 fl oz bottles can vary significantly based on the supplier and the material. Generally, glass bottles have higher MOQs due to manufacturing costs, often starting from 500 to 1,000 units. Plastic bottles may have lower MOQs, sometimes around 250 to 500 units. When negotiating with suppliers, inquire about bulk discounts and the possibility of combining different bottle types or colors within the same order to meet MOQ requirements while maximizing variety. -

How can I ensure the quality of the 2 fl oz bottles I purchase?

To ensure quality, always vet potential suppliers by requesting samples before placing a bulk order. Check for certifications that indicate compliance with international standards, especially if your products are intended for food or pharmaceuticals. Look for reviews or testimonials from other B2B buyers. Establish clear quality assurance (QA) processes, including inspections during production and before shipping. Communicate your quality expectations explicitly to the supplier to avoid misunderstandings. -

What payment terms should I expect when ordering 2 fl oz bottles internationally?

Payment terms for international orders typically vary by supplier but often include options like net 30, 50% upfront, and the remaining balance before shipping. Some suppliers may offer letters of credit or escrow services for larger transactions, providing additional security. Be aware of currency fluctuations and potential fees associated with international transactions. It’s advisable to discuss payment terms upfront and ensure they are documented in your purchase agreement to prevent disputes later. -

What customization options are available for 2 fl oz bottles?

Many suppliers offer customization options such as color, size, and closure types for 2 fl oz bottles. You can also opt for custom labeling, which is essential for branding. Some manufacturers may provide silk screening or labeling services for your logo directly on the bottles. When considering customization, discuss lead times and potential costs involved, as bespoke orders may require longer production times and higher MOQs. -

What logistics considerations should I keep in mind when importing 2 fl oz bottles?

When importing 2 fl oz bottles, consider shipping methods, costs, and delivery times. Air freight is faster but more expensive than sea freight, which is cost-effective for larger shipments. Be aware of customs regulations and import duties in your country; ensure all paperwork is in order to avoid delays. Partnering with a logistics provider experienced in international trade can help streamline the process and mitigate risks associated with shipping. -

How do I handle potential issues with my 2 fl oz bottle supplier?

Open communication is key to resolving issues with suppliers. If you encounter quality concerns or delays, address them directly and promptly. Document all correspondence and agreements to provide clarity. Establish a dispute resolution process in your contract, which may include mediation or arbitration. Building a strong relationship with your supplier can also help in navigating challenges, as they may be more willing to accommodate your needs and concerns. -

What regulations should I be aware of when sourcing 2 fl oz bottles?

Regulations vary by country and product type. For cosmetic or food products, ensure that the materials used for your bottles comply with safety standards and regulations, such as the FDA in the United States or EU regulations in Europe. If you are exporting to certain regions, familiarize yourself with labeling requirements and any necessary certifications. Consulting with a regulatory expert can help ensure compliance and facilitate smoother import/export processes.

중요 고지 사항 및 이용 약관

⚠️ 중요 고지 사항

제조업체, 기술 사양 및 시장 분석에 관한 내용을 포함하여 이 가이드에서 제공하는 정보는 정보 제공 및 교육 목적으로만 사용됩니다. 전문적인 조달 자문, 재무 자문 또는 법률 자문으로 간주되지 않습니다.

당사는 정보의 정확성과 시의성을 보장하기 위해 최선을 다했지만, 오류, 누락 또는 오래된 정보에 대해서는 책임을 지지 않습니다. 시장 상황, 회사 세부 정보 및 기술 표준은 변경될 수 있습니다.

B2B 구매자는 독립적이고 철저한 실사를 수행해야 합니다. 구매 결정을 내리기 전에 충분히 검토하세요. 여기에는 공급업체에 직접 연락하고, 인증을 확인하고, 샘플을 요청하고, 전문가 상담을 받는 것이 포함됩니다. 이 가이드의 정보에 의존하는 데 따른 위험은 전적으로 독자가 부담합니다.

Top 7 2 Fl Oz Bottle Manufacturers & Suppliers List

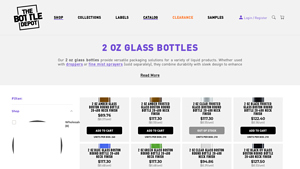

1. The Bottle Depot – 2 oz Glass Bottles

도메인: thebottledepot.co

등록: 2019 (6년)

소개: 2 oz Glass Bottles – Available in amber, clear, black, green, and blue finishes. Designed for versatile packaging solutions for liquid products. Compatible with droppers and fine mist sprayers (sold separately). Ideal for essential oils, skincare serums, toners, and room sprays. Sold wholesale, allowing bulk purchases to reduce costs. Boston Round design with a 20-400 neck finish. Units per box va…

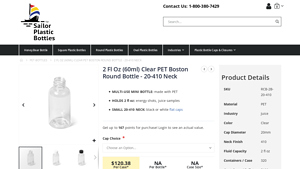

2. Sailor Plastics – Clear PET Boston Round Bottle

도메인: sailorplastics.com

등록: 1999년(26년)

소개: {‘name’: ‘Clear PET Boston Round Bottle’, ‘capacity’: ‘2 fl oz (60ml)’, ‘material’: ‘PET’, ‘color’: ‘Clear’, ‘neck_finish’: ’20-410′, ‘cap_options’: ‘black or white flat caps’, ‘sku’: ‘RCB-2B-20-410’, ‘containers_per_case’: 320, ‘bottle_diameter’: ‘1.875″‘, ‘bottle_height’: ‘3.937″‘, ‘bottle_circumference’: ‘4.500″‘, ‘max_fill_temp’: ‘140° F’, ‘bpa_free’: ‘Yes’, ‘country_of_manufacture’: ‘United S…

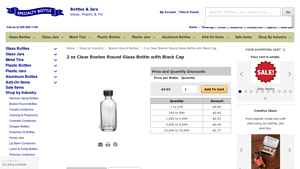

3. Specialty Bottle – 2 oz Clear Boston Round Glass Bottle

도메인: specialtybottle.com

등록: 1998년(27년)

소개: {‘name’: ‘2 oz Clear Boston Round Glass Bottle’, ‘capacity’: ‘2 oz’, ‘closure’: ’20/400 black phenolic cap’, ‘case_quantity’: ‘240’, ‘width’: ‘1.5 inches’, ‘height’: ‘3.75 inches’, ‘price’: ‘$0.89’, ‘description’: ‘Cleanly label or easily showcase the contents of this Boston round bottle with classic clear glass construction. The modest 2-ounce size is just right for saving shelf space or carry-on…

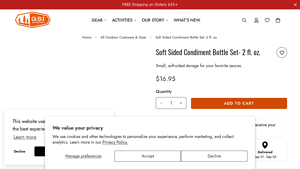

4. GSI Outdoors – Soft-Sided Condiment Bottle Set

도메인: gsioutdoors.com

등록: 1999년(26년)

소개: Soft-Sided Condiment Bottle Set, 2 fl oz, ideal for sauces and condiments, flexible design for easy dispensing, includes multiple bottles for various condiments, perfect for outdoor activities and picnics.

5. The Cary Company – 2 oz. Black HDPE Cylinder Bottle

도메인: thecarycompany.com

등록: 1999년(26년)

소개: {“product_name”: “2 oz. Black HDPE Plastic Cylinder Bottle”, “capacity”: “2 oz.”, “material”: “HDPE”, “color”: “Black”, “bottle_type”: “Cylinder”, “neck_size”: “20mm 20-410”, “weight”: “9 grams”}

6. Piping Rock – Amber Glass Dropper Bottle 2 fl oz

도메인: m.pipingrock.com

등록: 1998년(27년)

소개: Product Name: Dropper Bottle, 2 fl oz (59 mL) Glass Amber Dropper Bottle

Capacity: 2 fl oz (59 mL)

Material: Glass

Color: Amber

Features: Protects contents from harmful UV rays, suitable for storing essential oils, portable for on-the-go use or home storage.

Price: $2.29

Satisfaction Guarantee: 1 Year 100% No-Risk Satisfaction Guarantee

Shipping: Shipped from the USA

Customer Rating: 4.9 out of 5 …

7. Target – 2 oz Baby Bottles

도메인: target.com

등록: 1997년(28년)

소개: This company, Target – 2 oz Baby Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 2 fl oz bottle

In conclusion, the strategic sourcing of 2 fl oz bottles represents a significant opportunity for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The versatility of these bottles—ranging from glass to plastic—enables businesses to cater to a wide array of liquid products, from essential oils to skincare serums. Emphasizing quality and aesthetic appeal not only enhances product presentation but also builds brand credibility.

Buyers should focus on sourcing options that offer customization, bulk purchasing, and compatibility with various closures and dispensing methods. This ensures that packaging aligns with product requirements while optimizing costs. As the demand for sustainable and reliable packaging continues to rise, leveraging local suppliers and establishing strong partnerships can yield competitive advantages.

Looking ahead, it is crucial for international buyers to remain proactive in evaluating market trends and supplier capabilities. Engaging in strategic sourcing now will not only streamline operations but also position businesses favorably in an increasingly competitive landscape. Embrace this opportunity to enhance your product offerings and strengthen your market presence by sourcing high-quality 2 fl oz bottles tailored to your specific needs.