Introduction: Navigating the Global Market for bottle cap diameter

In today’s dynamic global market, sourcing the right bottle cap diameter is a critical challenge for B2B buyers looking to ensure product integrity and enhance consumer safety. The precise fit between bottle caps and neck finishes is essential not only for preventing leakage but also for maintaining the quality of the contents within. This comprehensive guide delves into the intricate world of bottle cap diameters, examining various types, applications, and the nuances of selecting the appropriate cap for different bottle designs.

Through this guide, international buyers—particularly from Africa, South America, the Middle East, and Europe—will gain valuable insights into the complexities of cap sizing, including the significance of thread styles and their impact on functionality. We will also cover essential considerations for supplier vetting, cost analysis, and market trends that influence purchasing decisions. By equipping buyers with knowledge about the diverse range of options available, this guide empowers them to make informed choices that align with their specific business needs.

Whether you are navigating the intricacies of sourcing caps for beverages, pharmaceuticals, or personal care products, understanding bottle cap diameters is crucial for optimizing your supply chain. With actionable insights and expert recommendations, this guide serves as a strategic tool for enhancing your procurement process and ensuring product compatibility in a competitive marketplace.

Artikel navigatie

- Top 9 Bottle Cap Diameter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle cap diameter

- Understanding bottle cap diameter Types and Variations

- Key Industrial Applications of bottle cap diameter

- 3 Common User Pain Points for ‘bottle cap diameter’ & Their Solutions

- Strategic Material Selection Guide for bottle cap diameter

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle cap diameter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle cap diameter’

- Comprehensive Cost and Pricing Analysis for bottle cap diameter Sourcing

- Alternatives Analysis: Comparing bottle cap diameter With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle cap diameter

- Navigating Market Dynamics and Sourcing Trends in the bottle cap diameter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle cap diameter

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for bottle cap diameter

Understanding bottle cap diameter Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| 28-410 Cap | 28mm diameter, 1.5 thread turns | Beverage, personal care products | Voordelen: Versatile, widely used; Minpunten: Common size may lead to oversupply issues. |

| 24-410 Cap | 24mm diameter, suitable for smaller bottles | Cosmetics, pharmaceuticals | Voordelen: Compact size; Minpunten: Limited capacity for larger volumes. |

| 20-400 Cap | 20mm diameter, often used for squeeze bottles | Condiments, sauces | Voordelen: Ideal for dispensing; Minpunten: Less durable under pressure. |

| 38-400 Cap | 38mm diameter, thicker walls for sturdiness | Industriële chemicaliën, reinigingsmiddelen | Voordelen: Robust design; Minpunten: Higher cost due to materials. |

| 63-400 Cap | 63mm diameter, larger opening for bulk products | Food packaging, large beverages | Voordelen: Suitable for large volumes; Minpunten: May require specific bottling equipment. |

What are the Characteristics of the 28-410 Cap and Its Applications?

The 28-410 cap is one of the most prevalent sizes in the market, featuring a diameter of 28mm and 1.5 thread turns. Its versatility makes it suitable for a broad range of applications, particularly in the beverage and personal care sectors. B2B buyers appreciate its compatibility with numerous bottles, providing ease of sourcing. However, its popularity can lead to market saturation, potentially affecting pricing and availability.

How Does the 24-410 Cap Differ in Use?

With a diameter of 24mm, the 24-410 cap is ideal for smaller bottles often used in cosmetics and pharmaceuticals. Its compact design allows for efficient use of space, making it a favorite among brands focusing on premium products. Buyers should consider that while its size is advantageous, it may limit the volume of contents, which can be a drawback for certain applications.

What Makes the 20-400 Cap Popular for Dispensing?

The 20-400 cap, characterized by its 20mm diameter, is frequently used for squeeze bottles, making it a go-to choice for condiments and sauces. Its design facilitates easy dispensing, appealing to consumers looking for convenience. However, B2B buyers should be cautious about its durability under pressure, as it may not be suitable for carbonated beverages.

Why Choose the 38-400 Cap for Industrial Applications?

The 38-400 cap features a robust design with a 38mm diameter, making it suitable for industrial chemicals and cleaning agents. Its thicker walls provide added sturdiness, which is essential for products that may be subject to rigorous handling. While this cap offers durability, buyers should be prepared for a higher cost due to the materials used in its construction.

What are the Advantages of the 63-400 Cap for Large Volume Products?

The 63-400 cap, with a diameter of 63mm, is designed for larger openings, accommodating bulk products in food packaging and large beverages. This cap allows for efficient filling and dispensing, which is critical for high-volume production lines. However, B2B buyers must ensure they have the appropriate bottling equipment, as this size may require specialized machinery.

Key Industrial Applications of bottle cap diameter

| Industrie/sector | Specific Application of bottle cap diameter | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Beverage Industry | Carbonated soft drinks and beer packaging | Ensures airtight sealing, preventing carbonation loss | Must match cap diameter with bottle neck finish for optimal fit |

| Pharmaceutical Sector | Bottling of liquid medications | Maintains product integrity and extends shelf life | Compliance with international standards for safety and sealing |

| Eten en drinken | Sauces and condiments packaging | Provides tamper-evident seals, enhancing consumer trust | Availability of diverse sizes and styles for various products |

| Cosmetics & Personal Care | Packaging of lotions and creams | Facilitates controlled dispensing and prevents leakage | Considerations for cap designs that enhance user experience |

| Chemical Industry | Storage of industrial liquids | Prevents contamination and ensures safe handling | Need for caps that meet specific chemical compatibility standards |

How is Bottle Cap Diameter Critical in the Beverage Industry?

In the beverage industry, particularly for carbonated drinks and beer, the precise diameter of bottle caps is crucial for maintaining carbonation levels. An improper fit can lead to gas escape, affecting product quality and shelf life. Buyers must ensure that the cap’s inner diameter matches the bottle’s neck finish, such as the common 28-410 size. This attention to detail can lead to improved customer satisfaction and reduced product returns.

What Role Does Bottle Cap Diameter Play in the Pharmaceutical Sector?

In the pharmaceutical sector, the diameter of bottle caps is essential for ensuring the integrity of liquid medications. Caps that fit correctly prevent contamination and protect against leakage, which is vital for maintaining product efficacy. International buyers should consider sourcing caps that comply with global safety standards, ensuring that they meet regulations in their respective markets, such as those in Europe and the Middle East.

Why is Bottle Cap Diameter Important for Food and Beverage Packaging?

Food packaging, especially for sauces and condiments, relies on the correct bottle cap diameter to provide tamper-evident seals. This feature is increasingly important for consumer trust and safety. Buyers should focus on sourcing caps that not only fit their bottles but also offer various sizes and styles to accommodate diverse product lines. This can enhance brand reputation and ensure compliance with food safety regulations.

How Can Bottle Cap Diameter Enhance Cosmetics and Personal Care Products?

For cosmetics and personal care products, the diameter of bottle caps influences dispensing control and prevents leakage. A well-fitting cap ensures that products are delivered effectively without waste, which is especially important for lotions and creams. Sourcing considerations should include the design of the cap, as innovative features can enhance user experience and differentiate products in a competitive market.

What Are the Safety Considerations Related to Bottle Cap Diameter in the Chemical Industry?

In the chemical industry, the diameter of bottle caps plays a significant role in ensuring safe storage of industrial liquids. Caps must fit securely to prevent contamination and accidental spills. Buyers in this sector should prioritize sourcing caps that meet specific compatibility standards with the chemicals being stored. This ensures safety and compliance with industry regulations, minimizing risks associated with hazardous materials.

3 Common User Pain Points for ‘bottle cap diameter’ & Their Solutions

Scenario 1: Misalignment Between Cap and Bottle Neck Sizes

Het probleem: A common challenge faced by B2B buyers is the misalignment between the cap size and the neck finish of bottles. This issue often arises during procurement when buyers select caps without verifying the specific neck finish measurements of their bottles. Misalignment can lead to significant operational inefficiencies, including product contamination, leakage, and the need for costly rework or replacements. In industries such as food and beverage, where quality control is paramount, these errors can result in wasted resources and potential regulatory issues.

De oplossing: To mitigate this problem, buyers should implement a thorough verification process before finalizing their cap orders. Start by measuring the neck finish of the bottles using precise calipers to ascertain both the outer diameter and the thread style. For example, if the measurement indicates a 28mm outer diameter with a 410 thread style, then the correct cap would be labeled as 28-410. Additionally, maintain an organized database of all bottle specifications and their corresponding caps to streamline future orders. Collaborating with suppliers who offer sample caps can also provide buyers with the opportunity to test for fit and compatibility before making bulk purchases.

Scenario 2: Inconsistent Quality of Caps Across Suppliers

Het probleem: B2B buyers often encounter issues with inconsistent quality when sourcing caps from different suppliers. Variations in manufacturing tolerances can lead to discrepancies in the inside diameter of caps, which may not fit as expected on the bottles. This inconsistency can disrupt production lines, cause delays, and lead to financial losses, particularly in high-volume operations where efficiency is critical.

De oplossing: To address quality inconsistency, buyers should prioritize sourcing caps from reputable suppliers with established quality assurance processes. Conducting a thorough supplier evaluation is essential; this includes checking for certifications such as ISO standards that ensure manufacturing precision. Additionally, implement a rigorous incoming inspection protocol for caps received, measuring the inside diameter and checking for any deformities. By maintaining a close relationship with suppliers and communicating any quality concerns, buyers can work collaboratively to ensure consistent cap production that meets their specifications.

Scenario 3: Limited Knowledge of Cap Sizes and Thread Styles

Het probleem: Many B2B buyers, especially those new to the packaging industry, may lack comprehensive knowledge about cap sizes and thread styles, leading to confusion during the purchasing process. This lack of understanding can result in ordering caps that are either too large or too small, causing packaging problems that impact product integrity and customer satisfaction.

De oplossing: To overcome this knowledge gap, buyers should invest time in educating themselves about bottle cap specifications. This can be achieved through resources such as industry webinars, training sessions, and detailed product catalogs from suppliers that clearly outline cap sizes and thread styles. Buyers should also consider consulting with packaging engineers or industry experts who can provide tailored advice based on specific needs. Creating a reference guide that includes common cap sizes and their applications can also serve as a valuable tool for quick decision-making during procurement. By equipping themselves with the right knowledge, buyers can make informed choices that enhance their packaging operations.

Strategic Material Selection Guide for bottle cap diameter

When selecting materials for bottle caps, it is essential to consider the specific requirements of the application, including compatibility with the contents, environmental conditions, and manufacturing processes. Below, we analyze four common materials used in the production of bottle caps, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Plastic Bottle Caps?

Plastic (Polypropylene and Polyethylene)

Plastic caps, particularly those made from polypropylene (PP) and polyethylene (PE), are widely utilized due to their lightweight and versatile nature. They offer good chemical resistance and can withstand a temperature range of -40°C to 120°C. These materials are generally resistant to moisture and provide a secure seal, making them suitable for beverages and other liquid products.

Voor- en nadelen

The primary advantages of plastic caps include their low cost, ease of manufacturing, and customization options in terms of color and design. However, they may not be suitable for high-temperature applications or for products requiring long-term storage, as they can degrade over time when exposed to UV light. Additionally, they may not be as durable as metal options.

Invloed op toepassing

Plastic caps are ideal for carbonated beverages and non-carbonated liquids. However, they may not be suitable for products that require a hermetic seal, as they can allow for some gas permeation over time.

How Do Metal Bottle Caps Compare in Performance?

Metal (Aluminum and Steel)

Metal caps, particularly aluminum and steel, provide excellent sealing capabilities and are often used for carbonated beverages and food products. They can withstand higher pressures and temperatures compared to plastic caps, making them suitable for products requiring a robust seal.

Voor- en nadelen

The key advantage of metal caps is their durability and resistance to corrosion, which ensures a longer shelf life for the contents. However, they are generally more expensive than plastic caps and may require more complex manufacturing processes, such as stamping and coating. Additionally, metal caps can be heavier, impacting shipping costs.

Invloed op toepassing

Metal caps are particularly effective for beverages that undergo pasteurization or require a vacuum seal. They are also preferred for products that need to be stored for extended periods, as they provide a superior barrier against oxygen and moisture.

What Considerations Should International Buyers Keep in Mind?

Glass (for Crown Caps)

Glass caps, often used in conjunction with crown caps, are primarily utilized in the beer and beverage industry. They provide an excellent seal and are fully recyclable, making them an environmentally friendly option.

Voor- en nadelen

The main advantage of glass caps is their inert nature, which means they do not react with the contents. However, they are fragile and can break easily, posing challenges in handling and transportation. Additionally, glass caps are generally more expensive and require specialized bottling equipment.

Invloed op toepassing

Glass caps are suitable for high-quality beverages where taste and purity are paramount. They are often used in premium products, but the fragility can limit their use in high-volume production environments.

International Compliance and Preferences

When sourcing materials for bottle caps, international B2B buyers must consider compliance with local regulations and standards such as ASTM, DIN, and JIS. For instance, buyers in Europe may prioritize recyclable materials due to stringent environmental regulations, while those in the Middle East may focus on durability and resistance to high temperatures.

Summary Table of Material Selection for Bottle Caps

| Materiaal | Typical Use Case for bottle cap diameter | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Kunststof | Non-carbonated beverages, personal care products | Lichtgewicht en kosteneffectief | Less durable, UV degradation risk | Laag |

| Metal | Carbonated beverages, food products | Excellent sealing and durability | Higher cost, heavier | Medium |

| Glas | Premium beverages, craft beers | Inert and recyclable | Fragile, requires specialized handling | Hoog |

| Composite | Specialty products requiring unique properties | Versatile and customizable | Higher manufacturing complexity | Medium to High |

This guide provides a comprehensive overview of the considerations that B2B buyers must keep in mind when selecting materials for bottle caps, ensuring they choose the most suitable option for their specific applications and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bottle cap diameter

What Are the Main Stages of Manufacturing Bottle Caps?

The manufacturing process for bottle caps involves several crucial stages, each ensuring the final product meets strict quality and usability standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Materiaalvoorbereiding

The first step involves selecting suitable materials, typically high-density polyethylene (HDPE) or polypropylene (PP). These plastics are chosen for their durability, chemical resistance, and ease of molding. Raw materials are often subjected to a series of tests to confirm their quality and compliance with international standards. This may include checking for consistency in resin quality and ensuring the absence of contaminants. -

Forming Techniques

The forming stage utilizes various techniques, including injection molding and compression molding. In injection molding, heated plastic is injected into a mold that shapes the cap. This method allows for high precision, ensuring that the internal diameter aligns with the corresponding bottle neck. For compression molding, materials are placed into a heated mold where they are compressed to form the cap. This method is often used for larger caps and can produce thicker products. -

Assembly Processes

Once formed, caps are assembled with additional components such as liners and seals, which are crucial for ensuring leak-proof functionality. The assembly process may also involve the application of tamper-evident features, which are increasingly important in the global market for safety and compliance. -

Finishing Operations

The final stage includes quality checks, surface treatments, and packaging. Finishing operations might involve printing or labeling, which provides branding and essential information to consumers. Caps are typically packaged in bulk for shipping, but they can also be individually packaged depending on client requirements.

How Is Quality Assurance Managed in Bottle Cap Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every batch of bottle caps meets specified standards. International standards such as ISO 9001 are often adopted, providing a framework for quality management systems.

-

What Are the Relevant International Standards?

Companies in the bottle cap manufacturing sector frequently adhere to ISO 9001, which emphasizes a process-oriented approach to quality management. Additionally, industry-specific standards like CE marking for compliance in Europe and API standards for petroleum products may be relevant, depending on the intended use of the caps. Adhering to these standards not only enhances product reliability but also builds trust with international buyers. -

Wat zijn de belangrijkste controlepunten voor kwaliteitscontrole?

Quality control (QC) checkpoints are established at various stages of the manufacturing process. These include:

- Inkomende kwaliteitscontrole (IQC): Raw materials are inspected upon arrival to ensure they meet specified criteria.

- Kwaliteitscontrole tijdens het proces (IPQC): Ongoing checks during the manufacturing process ensure that each phase adheres to quality standards.

- Finale kwaliteitscontrole (FQC): The final product is tested for functionality, dimensions, and aesthetic quality before packaging.

- What Testing Methods Are Commonly Used?

Testing methods may include dimensional checks, tensile strength tests, and leak tests. Dimensional checks ensure that the cap’s diameter and thread style match the specifications required for compatibility with bottles. Tensile strength tests assess the material’s durability, while leak tests verify that the caps can securely seal the contents of the bottle.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure consistent product quality.

-

Conducting Audits

Buyers should conduct on-site audits of potential suppliers. This allows them to assess the manufacturing processes, quality control systems, and overall operational standards. Audits provide insight into the supplier’s adherence to international quality standards and their commitment to continuous improvement. -

Reviewing Quality Reports

Suppliers should provide detailed quality reports that outline testing results and compliance with industry standards. These reports should include data on material specifications, testing outcomes, and any corrective actions taken for non-compliance. -

Utilizing Third-Party Inspections

Engaging third-party inspection services can add an additional layer of assurance. These independent bodies can conduct quality checks and audits, providing an unbiased evaluation of the supplier’s quality control processes. This is particularly beneficial for buyers in regions where local regulations may differ.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing bottle caps internationally, B2B buyers need to be aware of specific quality control and certification nuances.

-

Regional Compliance Requirements

Different regions may have distinct compliance requirements, such as food safety standards in the EU or specific labeling laws in the Middle East. Buyers should ensure that suppliers are familiar with these regulations and can provide documentation proving compliance. -

Cultural and Logistical Considerations

Cultural differences can influence quality perceptions. Buyers should engage in discussions with suppliers about quality expectations and ensure that communication is clear regarding specifications. Logistical considerations, such as shipping times and customs regulations, also play a role in maintaining product quality during transport. -

Building Long-term Relationships

Establishing long-term partnerships with reliable suppliers can lead to improved quality assurance. Regular communication and collaboration on quality improvements can help both parties adapt to changing market demands and regulatory requirements.

By understanding the manufacturing processes and quality assurance protocols for bottle cap diameter, B2B buyers can make informed decisions that ensure product reliability and compliance in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle cap diameter’

Inleiding

This guide provides a step-by-step checklist for B2B buyers seeking to procure the correct bottle cap diameter for their products. Understanding the specific requirements of bottle cap sizes and neck finishes is essential to ensure compatibility, maintain product integrity, and optimize supply chain efficiency. This checklist will help you navigate the complexities of sourcing bottle caps effectively.

1. Identify Your Bottle Specifications

Begin by clearly defining the specifications of your bottles, including the neck finish and diameter. This is crucial as the cap must fit the bottle securely to prevent leakage and contamination.

– Key Measurements: Measure the outside diameter of the bottle neck and the thread style. Common sizes include 28-410 or 20-400.

– Compatibility Check: Ensure the diameter of the cap matches the neck finish of the bottle.

2. Research Cap Types and Styles

Familiarize yourself with different cap types and styles available in the market. Each type serves specific functions and may vary in design, such as child-resistant features or dispensing capabilities.

– Common Styles: Understand the thread styles (e.g., 410, 415) and their applications.

– Material Considerations: Consider the material of the cap (plastic, metal) based on the product being bottled.

3. Leverancierscertificeringen evalueren

Before selecting a supplier, verify their certifications to ensure product quality and compliance with industry standards. Certifications can indicate a commitment to quality management and safety.

– Quality Standards: Look for ISO certifications or other relevant industry certifications.

– Compliance: Ensure that the supplier adheres to regulations applicable in your target regions, such as FDA or EU standards.

4. Monsters aanvragen voor testen

Always request samples from potential suppliers to assess the quality and fit of the caps. This step is vital to confirm that the caps function properly with your bottles.

– Fit Testing: Test the samples on your bottles to ensure a secure fit.

– Durability Assessment: Evaluate the material and design for durability under your product conditions.

5. Analyze Pricing and Volume Discounts

Review the pricing structure and inquire about volume discounts. Understanding the cost implications can help you manage your budget effectively while maximizing your procurement strategy.

– Cost per Unit: Compare prices across different suppliers for similar quality products.

– Bulk Purchase Savings: Discuss potential savings for larger orders, which can significantly reduce overall costs.

6. Assess Lead Times and Delivery Options

Evaluate the lead times and delivery options offered by suppliers. Timely delivery is crucial to maintaining your production schedule and meeting market demands.

– Production Timeframes: Confirm how long it takes for the supplier to produce your caps once an order is placed.

– Shipping Options: Discuss shipping methods and costs, especially for international transactions, to ensure you can plan accordingly.

7. Duidelijke communicatiekanalen opzetten

Finally, ensure that you have established clear communication channels with your chosen supplier. This is essential for addressing any issues that may arise during the procurement process.

– Contact Points: Identify key contacts for order updates, issues, and inquiries.

– Response Times: Agree on expected response times to ensure smooth communication throughout the partnership.

By following this checklist, B2B buyers can effectively source the right bottle cap diameter, ensuring product compatibility and quality while optimizing their supply chain.

Comprehensive Cost and Pricing Analysis for bottle cap diameter Sourcing

What Are the Key Cost Components in Sourcing Bottle Cap Diameters?

When sourcing bottle caps, understanding the cost structure is vital for effective budgeting and strategic purchasing. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materialen: The type of plastic or metal used significantly impacts costs. For instance, high-density polyethylene (HDPE) or polypropylene are common materials for plastic caps, while aluminum might be used for metal caps. Variations in material quality can lead to price fluctuations.

-

Arbeid: Labor costs can vary based on the region. For example, labor is generally more affordable in emerging markets such as parts of Africa and South America compared to Europe. Understanding local labor costs can help buyers negotiate better prices.

-

Productie Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, translating to lower prices for buyers.

-

Gereedschap: Custom caps often require specialized tooling, which can be a significant upfront investment. Buyers should factor this into their total cost of ownership, particularly if they require unique sizes or designs.

-

Kwaliteitscontrole: Ensuring product quality through robust QC processes can add to costs but is essential for maintaining standards, especially in regulated markets.

-

Logistiek: Transportation costs can be a major expense, particularly for international shipments. This includes shipping fees, customs duties, and handling charges. Buyers should consider these costs when comparing suppliers.

-

Marge: Suppliers will add a margin to cover their costs and profit. Understanding typical margin rates in your industry can aid in negotiation.

How Do Price Influencers Affect Bottle Cap Sourcing?

Several factors influence the pricing of bottle caps, making it crucial for buyers to understand these dynamics.

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to negotiate favorable terms.

-

Specificaties en aanpassingen: Custom designs or specific thread styles may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materialen en kwaliteitscertificaten: Premium materials and certifications (e.g., FDA compliance for food-grade caps) can drive up costs. Buyers should balance their need for quality with budget constraints.

-

Factoren van leveranciers: The supplier’s reputation, reliability, and production capacity can impact pricing. Established suppliers may charge higher rates but offer better reliability and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for clarifying responsibilities regarding shipping, insurance, and duties. This knowledge can help buyers avoid hidden costs and ensure smooth transactions.

What Are the Best Negotiation Strategies for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings.

-

Research and Comparison: Always conduct thorough market research to understand standard pricing and identify potential suppliers. Compare prices and services from multiple vendors to leverage competition.

-

Long-Term Relationships: Building long-term relationships with suppliers can lead to better pricing and favorable terms over time. Consider establishing partnerships rather than one-off transactions.

-

Totale eigendomskosten (TCO): Evaluate the TCO rather than just the initial price. This includes all associated costs such as shipping, storage, and potential product returns. A higher upfront cost may be justified if it results in lower overall expenses.

-

Culturele overwegingen: Be mindful of cultural differences in negotiation styles. Understanding local business practices can facilitate smoother negotiations and foster goodwill.

Disclaimer over indicatieve prijzen

While indicative prices can be provided based on current market trends, they are subject to change based on various factors such as market demand, material costs, and geopolitical influences. Buyers should always seek updated quotes and consider current economic conditions when making purchasing decisions.

Alternatives Analysis: Comparing bottle cap diameter With Other Solutions

Exploring Alternatives to Bottle Cap Diameter

When it comes to securing bottle contents, the diameter of the bottle cap is a fundamental factor. However, various alternative solutions exist that can also fulfill the requirements for sealing and preserving the integrity of bottled products. Understanding these alternatives can help B2B buyers make informed decisions based on their specific needs, such as cost-effectiveness, implementation ease, and maintenance demands.

Comparison of Alternatives

| Vergelijkingsaspect | Bottle Cap Diameter | Alternative 1: Screw-On Caps | Alternative 2: Cork Stoppers |

|---|---|---|---|

| Prestaties | Reliable seal; prevents leakage | Strong seal; versatile for various liquids | Effective for wine; allows for cork aging |

| Kosten | Moderate; varies by size and material | Generally lower; price per unit decreases with volume | Higher initial cost; varies based on quality |

| Gemak van implementatie | Requires matching diameter with bottle neck | Easy to use; can be automated in bottling processes | Manual application; requires additional tools |

| Onderhoud | Low maintenance; replace as needed | Minimal maintenance; durable | Requires careful handling; potential for cork taint |

| Beste gebruikscasus | Ideal for various beverages; standardization across industries | Suitable for soft drinks, oils, and other liquids | Best for wines and spirits; adds a premium feel |

In-Depth Analysis of Alternative Solutions

1. Screw-On Caps

Screw-on caps provide a strong seal and are versatile for a wide range of products, from beverages to oils. They are generally more cost-effective than traditional bottle caps, especially when purchased in bulk. Their ease of use allows for quick application, often automated in production lines, which can significantly enhance efficiency. However, they may not provide the same aesthetic appeal as other options, and their manual application can be less efficient in small-scale operations.

2. Cork Stoppers

Cork stoppers are favored in the wine industry for their ability to allow for gradual aging of the contents, enhancing flavor profiles. While they offer an effective seal, cork stoppers come with higher costs, especially for high-quality corks. The manual application process can be cumbersome, requiring specialized equipment. Additionally, there’s a risk of cork taint, which can compromise the quality of the product. Despite these drawbacks, corks provide a premium perception and are often associated with high-end products.

Making the Right Choice for Your Business Needs

Selecting the appropriate sealing solution requires careful consideration of various factors, including the nature of the product, target market, and budget constraints. While bottle cap diameter remains a reliable choice for many beverages, alternatives like screw-on caps and cork stoppers present unique advantages. Businesses should evaluate their specific requirements—such as performance expectations, cost implications, and ease of use—to determine the best fit for their operations. By aligning the sealing method with product characteristics and consumer preferences, B2B buyers can enhance product quality and marketability.

Essential Technical Properties and Trade Terminology for bottle cap diameter

When selecting bottle caps, understanding the technical properties and terminology associated with bottle cap diameter is crucial for ensuring compatibility and efficiency in packaging operations. Below are essential specifications and commonly used trade terms that every B2B buyer should be familiar with.

What Are the Key Technical Properties of Bottle Cap Diameter?

-

Inside Diameter (ID)

The inside diameter of a cap is the primary measurement that determines compatibility with the bottle’s neck. This measurement ensures that the cap fits snugly onto the bottle, preventing leakage and contamination. For example, a cap labeled as 28-410 has an inside diameter of 28mm, which must match the bottle’s neck finish to ensure a proper seal. -

Outside Diameter (OD)

The outside diameter is equally important, especially when selecting capping equipment. The OD is usually 2-3mm greater than the ID for small to medium caps, and significantly larger for child-resistant caps. This measurement helps determine the correct capping chuck size, which is vital for efficient production processes. -

Thread Style

The second number in a cap size designation (like 410 in 28-410) refers to the thread style, which affects how many turns the cap makes around the bottle’s neck. Common thread styles include 400, 410, and 415, with variations in height and turns. Understanding thread styles is essential for ensuring that caps seal properly and for compatibility with various dispensing methods. -

Materiaalklasse

Caps can be made from various materials, including polyethylene, polypropylene, and metal. Each material has distinct properties such as durability, chemical resistance, and recyclability. Choosing the appropriate material is crucial for maintaining the integrity of the bottle’s contents, especially in industries like food and pharmaceuticals. -

Tolerance Levels

Tolerance levels define the allowable variation in measurements, ensuring that caps are manufactured within specific limits. High precision in tolerances is critical for maintaining compatibility and preventing issues during production. Inconsistent tolerances can lead to increased waste, production downtime, and customer dissatisfaction. -

Sealing Mechanism

The sealing mechanism, such as foam liners or induction seals, plays a significant role in the cap’s performance. Different sealing options provide varying levels of protection against leakage and contamination. Understanding these mechanisms is vital for selecting the right cap for specific applications, particularly in sensitive industries.

Which Trade Terms Are Commonly Used in the Bottle Cap Industry?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are used in another company’s final product. In the context of bottle caps, OEMs may provide customized caps designed to meet specific client requirements. -

MOQ (minimale bestelhoeveelheid)

MOQ denotes the smallest quantity of product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and control costs, especially when dealing with specialized caps. -

RFQ (Offerteaanvraag)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ for bottle caps can help compare offers from different suppliers and secure the best deal. -

Incoterms (internationale handelsvoorwaarden)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs, which are essential for global procurement of bottle caps. -

Doorlooptijd

Lead time refers to the duration from placing an order to receiving the product. Understanding lead times is essential for effective supply chain management, ensuring that production schedules are met without delays. -

Kwaliteitscontrole (QC)

QC is a systematic process to ensure that products meet specified standards. For bottle cap suppliers, implementing robust QC measures is essential to guarantee that the caps perform as required, reducing the risk of product recalls or customer complaints.

Incorporating these technical properties and trade terms into your procurement strategy can enhance decision-making and ensure that your operations run smoothly, particularly in diverse international markets.

Navigating Market Dynamics and Sourcing Trends in the bottle cap diameter Sector

What Are the Current Market Dynamics and Key Trends in the Bottle Cap Diameter Sector?

The bottle cap diameter sector is witnessing significant changes driven by evolving consumer preferences, technological advancements, and regulatory requirements. Globally, there is a growing demand for standardization in cap sizes to ensure compatibility across diverse bottling systems. This trend is particularly relevant for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where various bottling practices exist.

Emerging technologies, such as automated capping systems and smart manufacturing, are transforming how businesses manage their supply chains. These innovations improve efficiency and reduce costs, which is vital for businesses operating in competitive markets. Additionally, advancements in e-commerce platforms are enabling B2B buyers to source caps in smaller quantities, catering to niche markets and reducing inventory risks.

Sourcing trends are also shifting towards local suppliers as businesses aim to reduce lead times and transportation costs. This shift is essential in regions where logistics can be challenging, such as parts of Africa and South America. Moreover, the rise of customization in cap design and materials is prompting manufacturers to offer more tailored solutions to meet specific market demands, enhancing brand differentiation.

How Can Sustainability and Ethical Sourcing Impact the Bottle Cap Diameter Sector?

Sustainability is becoming a crucial factor in the bottle cap diameter sector, with increasing scrutiny on environmental impacts and ethical sourcing practices. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recyclable materials and minimizing waste. This trend is particularly relevant in markets like Europe and the Middle East, where consumers are increasingly conscious of their environmental footprint.

The use of ‘green’ certifications and materials is gaining traction, with many manufacturers opting for biodegradable or recyclable cap options. These materials not only reduce environmental impact but also appeal to eco-conscious consumers, offering businesses a competitive edge. Additionally, adopting ethical supply chain practices ensures transparency and accountability, which are increasingly demanded by stakeholders.

B2B buyers should actively seek suppliers who adhere to sustainability standards and can provide evidence of their environmental initiatives. This alignment not only enhances brand reputation but also fosters long-term relationships with suppliers who share similar values.

How Has the Bottle Cap Diameter Sector Evolved Over Time?

The evolution of the bottle cap diameter sector can be traced back to the increasing demand for beverage packaging solutions that ensure safety and functionality. Initially, caps were primarily designed for compatibility with specific bottle types, but as the beverage market expanded, so did the need for standardization in cap sizes.

Throughout the years, manufacturers have innovated in materials and designs, leading to the development of various cap types, such as child-resistant caps and tamper-evident designs. These advancements were not only driven by consumer safety concerns but also by regulatory requirements that aim to protect public health.

Today, the sector continues to evolve with a focus on sustainability and technological integration, shaping the future of bottle cap manufacturing and sourcing. B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with market demands and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle cap diameter

-

How do I ensure the correct bottle cap diameter for my product?

To ensure the correct bottle cap diameter, start by measuring the neck finish of your bottles. The diameter should match the inside diameter of the cap. Common sizes include 28mm, 20mm, and 18mm, with the thread style also being crucial. Use a caliper for precision and consult with suppliers to confirm compatibility. If you’re sourcing internationally, verify that the cap dimensions meet your local standards, as regulations may vary. -

What is the best bottle cap size for my beverage type?

The best bottle cap size depends on the beverage and bottle type. For carbonated drinks, a cap with a secure seal, like a 28-410, is ideal to prevent leakage. For non-carbonated beverages, you might consider a 20-400 cap. Evaluate your product’s viscosity and carbonation level to select the most suitable cap size, and discuss options with your supplier to ensure compatibility with your production process. -

What are the common thread styles for bottle caps, and why do they matter?

Common thread styles include 410, 415, and 400, each differing in the number of turns and height. The thread style affects how tightly the cap seals on the bottle, which is crucial for maintaining product integrity. Choosing the correct thread style ensures compatibility with your bottling equipment and prevents leaks or contamination. Always match the thread style to your bottle’s neck finish to avoid issues during production. -

What should I consider when vetting suppliers for bottle caps?

When vetting suppliers, check for certifications that demonstrate compliance with international quality standards, such as ISO or FDA. Review their production capabilities and material sourcing to ensure they can meet your specifications. Request samples to evaluate quality and fit. Additionally, consider their logistics and shipping capabilities, particularly if you’re importing to regions like Africa or South America, where delays can occur. -

What customization options are available for bottle caps?

Customization options for bottle caps include size, color, material, and printing. You can request specific diameters or thread styles to match your bottles, as well as custom colors for branding purposes. Some suppliers also offer printed designs or logos on caps. Discuss your needs with potential suppliers to explore their customization capabilities and minimum order quantities to ensure they align with your production goals. -

What is the minimum order quantity (MOQ) for bottle caps, and how does it vary by supplier?

Minimum order quantities (MOQs) for bottle caps can vary significantly between suppliers, often ranging from 1,000 to 10,000 units or more. Smaller suppliers may offer lower MOQs, while larger manufacturers typically have higher thresholds. When sourcing, inquire about MOQs upfront, especially if you’re testing a new product line. Some suppliers may allow flexibility on MOQs for first-time orders or ongoing partnerships. -

What payment terms should I expect when sourcing bottle caps internationally?

Payment terms can vary by supplier, but common options include advance payment, net 30, or letter of credit. Be prepared to negotiate terms based on your purchasing volume and relationship with the supplier. When importing, ensure you understand any additional fees such as customs duties or taxes that may apply. Establishing clear payment terms upfront can help avoid misunderstandings and ensure smoother transactions. -

How can I ensure quality assurance (QA) for my bottle caps?

To ensure quality assurance for bottle caps, establish a clear QA process that includes specifications for size, material, and sealing performance. Request documentation of quality tests from suppliers, such as material safety data sheets and compliance certificates. Conduct periodic audits of your suppliers and consider third-party inspections to verify that the caps meet your standards. By prioritizing QA, you can minimize risks associated with product recalls or customer dissatisfaction.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 9 Bottle Cap Diameter Manufacturers & Suppliers List

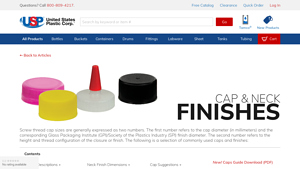

1. US Plastic – Cap and Neck Finishes

Domein: usplastic.com

Geregistreerd: 1996 (29 jaar)

Inleiding: Cap and Neck Finishes: Screw thread cap sizes are expressed as two numbers. The first number refers to the cap diameter (in millimeters) and the corresponding Glass Packaging Institute (GPI)/Society of the Plastics Industry (SPI) finish diameter. The second number refers to the height and thread configuration of the closure or finish. Common dimensions include: “T” Dimension (outside diameter of t…

2. Midwest Bottles – Plastic Bottle Caps

Domein: midwestbottles.com

Geregistreerd: 2006 (19 jaar)

Inleiding: Plastic Caps by Size: 15-415 Bottle Caps, 18-410 Bottle Caps, 18-415 Bottle Caps, 20-400 Bottle Caps, 20-410 Bottle Caps, 20-415 Bottle Caps, 22-400 Bottle Caps, 22-410 Bottle Caps, 22-415 Bottle Caps, 24-400 Bottle Caps, 24-410 Bottle Caps, 24-415 Bottle Caps, 25 mm Bottle Caps, 28 mm Bottle Caps, 28-400 Bottle Caps, 28-410 Bottle Caps, 28-415 Bottle Caps, 33-400 Bottle-Jar Caps, 38-400 Bottle-Ja…

3. Qorpak – Cap Measurement Guide

Domein: shop.qorpak.com

Geregistreerd: 1996 (29 jaar)

Inleiding: This company, Qorpak – Cap Measurement Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. HomebrewTalk – Bottle Cap Sizes

Domein: homebrewtalk.com

Geregistreerd: 2004 (21 jaar)

Inleiding: Bottle Cap Size: 26mm crown caps are used for both long-neck and stubby bottles. European bottles may use a 29mm size. The caps on stubby bottles may not crimp well due to the design of the bottle neck, which can lead to weaker seals. A bench capper is recommended for better sealing compared to a two-handed capper.

5. SKS Bottle – Caps and Closures

Domein: sks-bottle.com

Geregistreerd: 1997 (28 jaar)

Inleiding: Caps and closures available in various sizes including: 12 mm & 13 mm, 15 mm, 18 mm, 20 mm & 22 mm, 24 mm, 28 mm, 33 mm, 38 mm, 43 mm & 45 mm, 48 mm, 53 mm, 58 mm, 70 mm, 82 mm – 89 mm, 100 mm and 120 mm. Types include plastic caps, metal caps, dispensing caps, child resistant caps, tamper evident caps, and specialty closures. Specific caps for lip balm tubes are also available.

6. Crown Cap – 26 mm Universal Cap

Domein: gwkent.com

Geregistreerd: 1999 (26 jaar)

Inleiding: {“product_name”:”Crown Cap 26 mm”,”description”:”Universal crown cap size in 26 mm that fit standard beer bottles or soda bottles.”,”sizes”:”26 mm”,”colors”:[“Yellow”,”Red”],”quantity_per_box”:10000,”catalog_numbers”:[“2304-6″,”2304-2″],”regular_price”:268.69,”sale_price”:214.95,”weight_lb”:50.0}

7. Fermentaholics – 26 mm Bottle Caps

Domein: fermentaholics.com

Registered: 2016 (9 years)

Inleiding: This company, Fermentaholics – 26 mm Bottle Caps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. MoreBeer – 2-Day Delivery

Domein: morebeer.com

Geregistreerd: 1997 (28 jaar)

Inleiding: This company, MoreBeer – 2-Day Delivery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. Answers – Bottle Cap Size

Domein: answers.com

Geregistreerd: 1996 (29 jaar)

Inleiding: The diameter of a 2-liter bottle cap is typically around 28-33 millimeters.

Strategic Sourcing Conclusion and Outlook for bottle cap diameter

How Can Strategic Sourcing Enhance Your Bottle Cap Procurement?

In summary, the strategic sourcing of bottle cap diameters is crucial for maintaining product integrity and ensuring compatibility with your packaging. Understanding the relationship between cap size and neck finish not only minimizes leakage and contamination risks but also enhances operational efficiency. As B2B buyers, particularly in emerging markets like Africa and South America, it is essential to prioritize suppliers who offer a wide range of cap sizes and styles tailored to your specific needs. This can lead to cost savings and improved supply chain reliability.

Moreover, investing in high-quality caps can significantly impact your brand’s reputation and customer satisfaction. As industries evolve, the demand for sustainable and innovative packaging solutions will continue to grow. Therefore, it is imperative for international buyers to stay informed about the latest trends and technologies in bottle cap manufacturing.

As you navigate your sourcing strategy, consider leveraging partnerships with trusted suppliers who can provide not just the caps you need but also valuable insights into market dynamics. Embrace the future of packaging by aligning your sourcing strategies with innovative solutions that can propel your business forward. Your proactive approach today will set the stage for lasting success in tomorrow’s competitive marketplace.