Introduction: Navigating the Global Market for can you put water bottles in the microwave

In today’s fast-paced world, the question of whether you can put water bottles in the microwave often arises, particularly for international B2B buyers seeking efficient solutions for their operations. Understanding the complexities of microwaving water bottles is crucial, as it impacts product safety, customer satisfaction, and ultimately, brand reputation. This comprehensive guide delves into the nuances of various water bottle types—including plastic, stainless steel, and other materials—while addressing their microwave safety and practical applications.

By exploring the essential considerations around sourcing, supplier vetting, and cost implications, this guide equips businesses from Africa, South America, the Middle East, and Europe—including markets like Vietnam and Germany—with the knowledge needed to make informed purchasing decisions. We will also cover the regulatory standards governing microwave-safe materials, helping you navigate potential liabilities and compliance issues effectively.

As you engage with this guide, you’ll gain insights into best practices for selecting water bottles that meet both consumer demands and safety standards. In doing so, you will empower your business to offer high-quality, reliable products that resonate with your target market, ultimately enhancing your competitive edge in the global marketplace.

Artikel navigatie

- Top 9 Can You Put Water Bottles In The Microwave Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for can you put water bottles in the microwave

- Understanding can you put water bottles in the microwave Types and Variations

- Key Industrial Applications of can you put water bottles in the microwave

- 3 Common User Pain Points for ‘can you put water bottles in the microwave’ & Their Solutions

- Strategic Material Selection Guide for can you put water bottles in the microwave

- In-depth Look: Manufacturing Processes and Quality Assurance for can you put water bottles in the microwave

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you put water bottles in the microwave’

- Comprehensive Cost and Pricing Analysis for can you put water bottles in the microwave Sourcing

- Alternatives Analysis: Comparing can you put water bottles in the microwave With Other Solutions

- Essential Technical Properties and Trade Terminology for can you put water bottles in the microwave

- Navigating Market Dynamics and Sourcing Trends in the can you put water bottles in the microwave Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of can you put water bottles in the microwave

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for can you put water bottles in the microwave

Understanding can you put water bottles in the microwave Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Plastic waterflessen | Typically made from PET (#1) plastic, lightweight and flexible. | Consumer goods, promotional products | Voordelen: Affordable, widely available. Minpunten: May leach chemicals if heated improperly. |

| Stainless Steel Water Bottles | Durable, insulated, and often vacuum-sealed. | Corporate gifts, outdoor activities | Voordelen: Long-lasting, retains temperature. Minpunten: Unsafe for microwaving, potential for pressure buildup. |

| Glazen waterflessen | Non-reactive, microwave-safe when labeled, often elegant design. | Health-conscious markets, premium products | Voordelen: Safe for microwaving, aesthetic appeal. Minpunten: Fragile, heavier than plastic. |

| Microwave-Safe Plastic Bottles | Specifically labeled as microwave-safe, often BPA-free. | Catering, food service, healthcare | Voordelen: Safe for heating, versatile. Minpunten: Limited durability compared to stainless steel. |

| Aluminum Bottles | Lightweight, often insulated but not microwave-safe. | Sports, outdoor activities, branding | Voordelen: Lightweight, good for branding. Minpunten: Reflects microwaves, can cause damage. |

What are the Characteristics of Plastic Water Bottles for Microwaving?

Plastic water bottles, particularly those made from polyethylene terephthalate (PET), are common in consumer markets. They are lightweight, flexible, and generally inexpensive, making them appealing for promotional products and bulk purchases. However, B2B buyers must ensure that the bottles are labeled as microwave-safe to avoid potential health risks associated with chemical leaching when heated. Furthermore, the durability of these bottles is lower than that of stainless steel or glass options.

How Do Stainless Steel Water Bottles Differ in Microwave Use?

Stainless steel water bottles are known for their durability and insulation properties, making them ideal for outdoor activities and corporate gifting. However, they are not microwave-safe due to their reflective properties, which can cause sparks and damage to microwave appliances. B2B buyers should consider the implications of this when marketing or distributing these products, as they may need to educate customers about proper usage to avoid safety hazards.

Why Choose Glass Water Bottles for Microwave Use?

Glass water bottles are appealing in premium markets due to their aesthetic appeal and non-reactive nature. Many glass bottles are labeled as microwave-safe, allowing for convenient heating without chemical concerns. They cater to health-conscious consumers and can be utilized in catering or food service settings. However, their fragility and weight compared to plastic options may deter some buyers, making it essential to assess market needs when considering glass products.

What Are Microwave-Safe Plastic Bottles and Their Applications?

Microwave-safe plastic bottles are designed specifically for heating and often come labeled as BPA-free. They are versatile and suitable for use in catering, food service, and healthcare environments where quick heating is necessary. The primary advantage is their safety for microwave use, but they tend to have a shorter lifespan compared to stainless steel options. B2B buyers should weigh the benefits of convenience against potential durability concerns when selecting these products.

Are Aluminum Bottles a Viable Option for Microwaving?

Aluminum bottles are lightweight and often used in sports and branding applications. However, they are not microwave-safe, as they reflect microwaves and can cause damage to appliances. B2B buyers should be cautious when promoting aluminum products for heating purposes, as this could lead to safety issues and customer dissatisfaction. Understanding the limitations of aluminum bottles is crucial for maintaining brand integrity and customer safety.

Key Industrial Applications of can you put water bottles in the microwave

| Industrie/sector | Specific Application of can you put water bottles in the microwave | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Eten en drinken | Heating water for tea or coffee in cafes and restaurants | Enhances customer satisfaction by providing quick service | Ensure containers are microwave-safe and durable |

| Gezondheidszorg | Preparing warm water for patient care in hospitals | Improves efficiency in healthcare delivery | Compliance with safety standards for medical use |

| Onderwijs | Using microwavable water bottles in schools for student hydration | Bevordert gezondheid en welzijn onder studenten | Sourcing BPA-free and safe materials |

| Gastvrijheid | Providing guests with access to hot water in hotel rooms | Increases guest comfort and satisfaction | Quality assurance for materials used in guest areas |

| Retail and Distribution | Selling microwave-safe water bottles in retail outlets | Captures health-conscious consumers | Focus on branding and safety certifications |

How is ‘Can You Put Water Bottles in the Microwave’ Used in the Food and Beverage Industry?

In cafes and restaurants, the ability to heat water quickly is crucial for preparing beverages like tea and coffee. By using microwave-safe water bottles, establishments can streamline their service, ensuring customers receive hot drinks promptly. This not only enhances the dining experience but also increases operational efficiency. Buyers in this sector should prioritize sourcing durable, microwave-safe materials that can withstand frequent use and maintain the quality of the beverages served.

What Role Does Microwaving Water Bottles Play in Healthcare Settings?

In hospitals, caregivers often need to prepare warm water for various patient care activities, including hydration and medication administration. Utilizing microwave-safe water bottles allows healthcare professionals to heat water quickly and safely, thus improving patient care efficiency. Buyers in the healthcare sector must consider sourcing bottles that meet stringent safety standards to ensure they are suitable for medical environments and do not leach harmful chemicals when heated.

How Can Educational Institutions Benefit from Microwave-Safe Water Bottles?

Schools and universities can promote student health by providing access to warm water through microwavable bottles. This initiative encourages hydration and supports wellness programs among students. When sourcing these products, educational institutions should focus on obtaining BPA-free materials to ensure safety for young users. Additionally, suppliers should offer bulk purchasing options to accommodate large student populations.

Why is Access to Hot Water Important in Hospitality?

Hotels can enhance guest satisfaction by providing microwave-safe water bottles in rooms for easy access to hot beverages. This small amenity can significantly improve the guest experience, making their stay more comfortable. When sourcing these bottles, hospitality businesses should ensure that the products are of high quality and aesthetically pleasing to align with their brand image while also being compliant with safety standards.

How Can Retailers Capitalize on the Demand for Microwave-Safe Water Bottles?

Retailers can tap into the growing trend of health-conscious consumers by offering a range of microwave-safe water bottles. This product line can attract customers looking for convenience and safety in their hydration solutions. Key sourcing considerations include ensuring that the products are properly branded and certified safe for microwaving, which can enhance consumer trust and loyalty.

3 Common User Pain Points for ‘can you put water bottles in the microwave’ & Their Solutions

Scenario 1: Ensuring Product Safety Compliance for Microwave Use

Het probleem: Many B2B buyers, particularly those in the beverage and food packaging sectors, are concerned about the safety and regulatory compliance of water bottles that can be microwaved. Misunderstandings about which materials are microwave-safe can lead to safety hazards, product recalls, or damage to consumer trust. For instance, a company might source water bottles made from the wrong type of plastic, like polycarbonate (recycling symbol #7), which can release harmful chemicals when heated. This not only poses a risk to end-users but also jeopardizes the brand’s reputation.

De oplossing: To mitigate these risks, B2B buyers should prioritize sourcing water bottles made from microwave-safe materials such as polyethylene terephthalate (PET), indicated by the recycling symbol #1. When specifying products, buyers should insist on certifications or testing results that confirm the materials are safe for microwave use. Additionally, it’s crucial to provide clear labeling on the product, indicating that the bottle is microwave-safe and includes instructions like removing the cap before microwaving. Implementing thorough supplier audits and requiring compliance documentation can further ensure product safety and enhance consumer confidence.

Scenario 2: Addressing Customer Misunderstandings About Microwave Compatibility

Het probleem: B2B buyers in retail or distribution often face challenges when customers misuse water bottles, believing that all types are microwave-safe. This misperception can lead to accidents, such as bottles bursting or leaking hot water, resulting in customer dissatisfaction and increased return rates. Companies may find themselves fielding numerous customer service inquiries related to misuse, which not only strains resources but also detracts from the overall customer experience.

De oplossing: To combat this issue, businesses should invest in customer education initiatives. This can include creating informative content such as brochures, videos, or infographics that clearly explain which types of water bottles are microwave-safe and why. Implementing a robust labeling system on packaging that outlines proper usage instructions and precautions can also help. Furthermore, offering training sessions for retail staff can empower them to provide accurate information to consumers. By proactively addressing these misunderstandings, companies can reduce misuse incidents and enhance customer satisfaction.

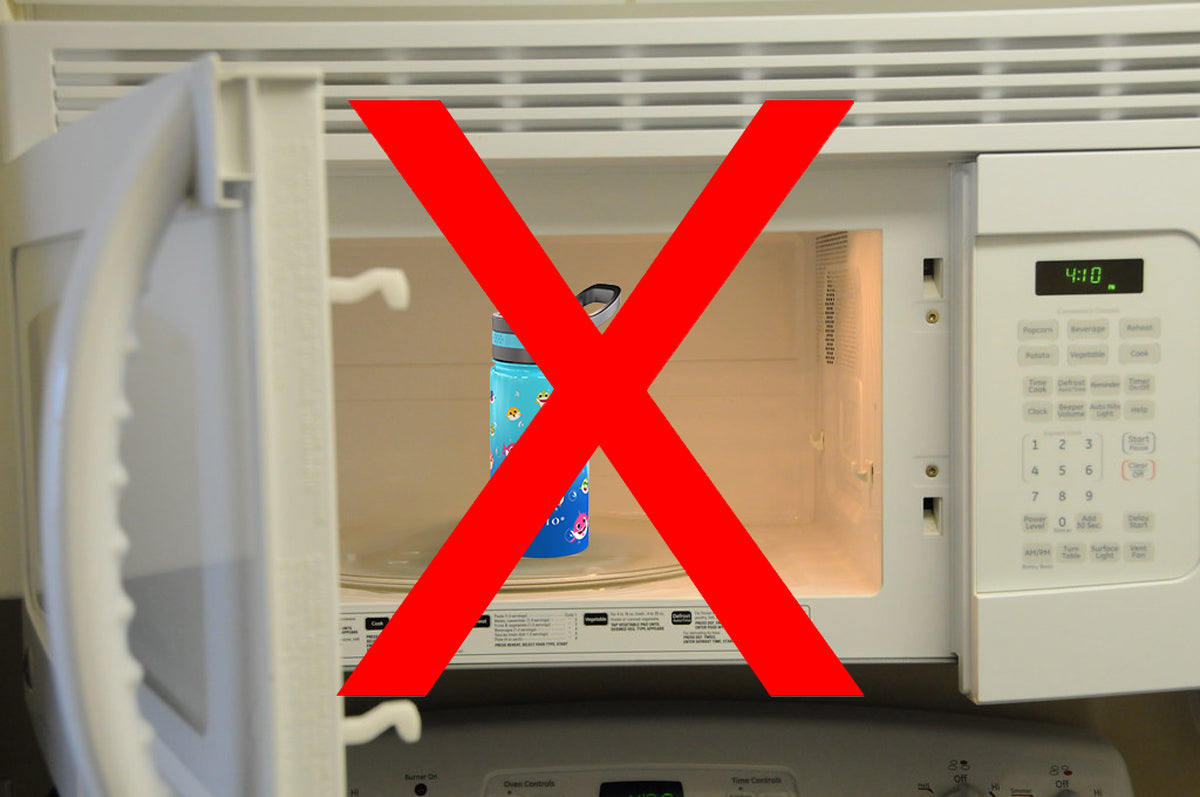

Scenario 3: Managing Risks with Stainless Steel Water Bottles in Microwaves

Het probleem: Companies that manufacture or distribute stainless steel water bottles often encounter confusion regarding their microwave safety. While many consumers believe stainless steel is a durable material that can handle heat, the truth is that microwaving these bottles can cause sparks, potential fires, and damage to appliances. This can lead to liability issues for businesses if consumers experience accidents due to improper usage.

De oplossing: To effectively manage these risks, businesses should clearly communicate that stainless steel water bottles are not microwave-safe. This can be achieved by placing bold warnings on product labels and marketing materials. Additionally, companies can offer alternative microwave-safe containers, such as glass or ceramic, as part of their product line. Providing educational resources that explain the dangers of microwaving metal, including the potential for electrical arcing and damage to both the bottle and microwave, can further protect consumers and the brand. By taking a proactive stance on educating the market, businesses can safeguard their reputation while enhancing customer safety.

Strategic Material Selection Guide for can you put water bottles in the microwave

What Are the Common Materials Used for Water Bottles and Their Microwave Compatibility?

When evaluating water bottles for microwave use, it is essential to consider the materials they are made from. Each material has unique properties, advantages, and disadvantages that can significantly influence their suitability for heating in a microwave. Below, we analyze four common materials: plastic, glass, stainless steel, and aluminum.

How Does Plastic Perform in Microwaves?

Plastic water bottles, particularly those made from polyethylene terephthalate (PET) and polypropylene (PP), are often microwave-safe. PET (recycling symbol #1) is known for its durability and resistance to impact, while PP (recycling symbol #5) can withstand higher temperatures without deforming. However, not all plastics are created equal; some can release harmful chemicals when heated.

Voordelen: Plastic bottles are lightweight, cost-effective, and less prone to breakage compared to glass. They are also versatile for various applications, from personal hydration to baby bottles.

Minpunten: The primary concern with plastic is its potential to leach chemicals when exposed to high temperatures, especially if the bottle is not specifically designed for microwave use. Additionally, repeated heating can degrade the material over time.

Considerations for B2B Buyers: International buyers should ensure compliance with local regulations regarding food safety and material safety standards, such as those set by the FDA in the U.S. or EFSA in Europe. Understanding the recycling codes and selecting products that meet safety standards is crucial.

Is Glass a Safe Option for Microwave Use?

Glass water bottles are generally microwave-safe, provided they are labeled as such. Borosilicate glass, in particular, is designed to withstand thermal shock, making it an excellent choice for microwave use.

Voordelen: Glass is non-reactive and does not leach chemicals, ensuring that the contents remain pure. It is also durable and can be recycled multiple times without losing quality.

Minpunten: While glass is resistant to thermal shock, it is still prone to breakage if dropped. Additionally, glass bottles tend to be heavier than their plastic counterparts, which may impact shipping costs.

Considerations for B2B Buyers: Buyers should look for glass bottles that comply with international standards such as ASTM or DIN for thermal resistance. Understanding local preferences for packaging materials can also guide product selection.

What About Stainless Steel Water Bottles?

Stainless steel water bottles are popular for their durability and insulation properties. However, they are not microwave-safe due to the metal reflecting microwave energy, which can lead to sparks and potential fire hazards.

Voordelen: Stainless steel is highly durable, resistant to corrosion, and can maintain the temperature of liquids for extended periods. It is also an environmentally friendly option due to its recyclability.

Minpunten: The main drawback is that stainless steel cannot be used in microwaves, limiting its versatility for heating liquids. Additionally, these bottles can be more expensive than plastic or glass options.

Considerations for B2B Buyers: Businesses should educate customers about the risks associated with microwaving stainless steel. Compliance with safety standards and educating consumers about proper use can enhance brand reputation.

Is Aluminum a Viable Choice for Microwave Use?

Aluminum water bottles, while lightweight and durable, are also not microwave-safe. The metal reflects microwaves, leading to similar issues as stainless steel.

Voordelen: Aluminum is lightweight, resistant to corrosion, and can be recycled. It is often used in outdoor and sports applications due to its portability.

Minpunten: Like stainless steel, aluminum cannot be microwaved, limiting its functionality for heating. Additionally, aluminum can react with acidic beverages, which may affect taste and safety.

Considerations for B2B Buyers: Buyers should ensure that aluminum products meet international safety standards and educate consumers about the limitations of microwaving aluminum.

Summary Table of Material Properties

| Materiaal | Typical Use Case for can you put water bottles in the microwave | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Kunststof | Personal hydration, baby bottles | Lichtgewicht en kosteneffectief | Potential chemical leaching | Laag |

| Glas | Home use, food service | Non-reactive and recyclable | Prone to breakage | Medium |

| Roestvrij staal | Insulated containers, outdoor use | Highly durable and insulated | Not microwave-safe | Hoog |

| Aluminium | Sports and outdoor applications | Lightweight and corrosion-resistant | Not microwave-safe | Medium |

In conclusion, selecting the right material for water bottles intended for microwave use requires careful consideration of their properties, advantages, and limitations. By understanding these factors, international B2B buyers can make informed decisions that align with safety standards and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for can you put water bottles in the microwave

What Are the Key Manufacturing Processes for Water Bottles Designed for Microwave Use?

The manufacturing process for water bottles that are deemed microwave-safe involves several critical stages, each ensuring the product meets safety and quality standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Microwave-Safe Water Bottles?

The first step in manufacturing microwave-safe water bottles involves selecting the appropriate materials. Common materials include polyethylene terephthalate (PET) for plastics, which is identified by the recycling symbol #1, and high-grade glass. These materials are chosen for their ability to withstand microwave energy without leaching harmful chemicals or melting.

Once the materials are selected, they undergo thorough quality checks to ensure they meet international safety standards. This includes checking for contaminants and ensuring consistency in material quality. Manufacturers may use spectrometers and other testing devices to confirm the integrity of the materials.

What Techniques Are Used in Forming Water Bottles?

In the forming stage, materials are shaped into bottles using various techniques. The most common methods include blow molding for plastics and glass forming.

- Blow Molding: This technique involves heating plastic until it becomes pliable and then inflating it into a mold using air pressure. This method is ideal for producing lightweight and durable bottles.

- Glass Forming: For glass bottles, techniques such as blow-blowing or press-blowing are employed, where molten glass is shaped into desired forms. Glass is inherently microwave-safe, making it a popular choice for consumers concerned about chemical leaching.

Each forming method is carefully monitored to ensure that the bottles maintain uniform thickness and structural integrity, which is crucial for safety during microwave use.

How Is Assembly Conducted for Microwave-Safe Water Bottles?

After forming, the bottles undergo assembly, where components such as caps and labels are added. The caps, which often contain seals to prevent leaks, must also be made from microwave-safe materials. During assembly, manufacturers must ensure that all components are compatible and fit securely to prevent accidents when heated.

Quality control at this stage involves visual inspections and functional tests to ensure that the seals are airtight and that the caps do not warp or degrade when exposed to heat.

What Finishing Processes Are Applied to Microwave-Safe Water Bottles?

The finishing stage involves several processes, including labeling, surface treatment, and packaging. Labels must be printed using inks that are also microwave-safe to prevent any chemical reactions when heated. Additionally, surface treatments may be applied to enhance durability and resistance to scratches.

Quality assurance measures during the finishing process include ensuring that all printed materials adhere correctly and that packaging is robust enough to protect the bottles during transport.

What Quality Assurance Standards Are Relevant for Microwave-Safe Water Bottles?

Quality assurance (QA) in the manufacturing of microwave-safe water bottles is critical to ensure safety and compliance with international standards. The following standards are commonly referenced:

Which International Standards Should Buyers Be Aware Of?

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers who comply with ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE-markering: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is especially relevant for B2B buyers in Europe, including Germany, who require assurance of product safety.

- API Standards: For products used in specific industries, such as food and beverage, adherence to American Petroleum Institute (API) standards may also be necessary, ensuring that materials are safe for food contact.

What Are the Key QC Checkpoints in Manufacturing?

Quality control in the manufacturing process typically involves several checkpoints:

- Inkomende kwaliteitscontrole (IQC): This initial stage checks raw materials for compliance with specifications before production begins.

- Kwaliteitscontrole tijdens het proces (IPQC): During manufacturing, ongoing inspections are performed to monitor the production process and identify any deviations from quality standards.

- Final Quality Control (FQC): Before products are shipped, final inspections ensure that the bottles meet all required specifications, including safety tests for microwave use.

What Common Testing Methods Are Used to Ensure Safety?

Several testing methods are employed to validate the safety of microwave-safe water bottles:

- Thermal Stability Testing: This involves exposing bottles to varying temperatures to ensure they do not warp or leach harmful chemicals.

- Chemical Migration Testing: This test assesses whether any harmful substances migrate from the bottle into the water when heated.

- Pressure Testing: For sealed bottles, this test ensures that they can withstand pressure changes without bursting.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are several methods to ensure compliance:

What Steps Can Buyers Take to Audit Suppliers?

- Supplier Audits: Conducting regular audits of suppliers can help ensure that they adhere to required quality standards and processes. This should include both announced and unannounced visits to evaluate production practices.

- Requesting Quality Reports: Buyers should request documentation of quality control measures and testing results. This transparency can help establish trust and confidence in the supplier’s processes.

- Inspecties door derden: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes and adherence to standards.

What Are the Quality Control Nuances for International Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding local regulations and quality standards is crucial. Each region may have specific requirements that manufacturers must comply with, and failing to meet these can result in costly penalties or product recalls.

Buyers should familiarize themselves with the regulatory landscape in their target markets, including any additional certifications or testing that may be required. Engaging with local experts or regulatory bodies can provide valuable insights into these nuances.

In conclusion, understanding the manufacturing processes and quality assurance measures for microwave-safe water bottles is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and stringent quality controls, businesses can ensure they are sourcing safe and reliable products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you put water bottles in the microwave’

Inleiding

This guide provides a practical checklist for B2B buyers interested in sourcing water bottles that can be safely microwaved. Understanding the properties of different materials and ensuring compliance with safety standards is crucial for making informed purchasing decisions. This checklist will help you navigate the complexities of sourcing microwave-safe water bottles, ensuring quality and safety for your customers.

Stap 1: Identify Material Specifications

Start by defining the materials suitable for microwave use. The most common microwave-safe materials include polyethylene terephthalate (PET) and certain types of glass. Avoid materials like polycarbonate and stainless steel, as they can leach harmful chemicals or pose fire hazards when heated.

- Look for recycling codes: PET bottles typically have a recycling symbol #1.

- Consider user experience: Ensure that the materials are not only safe but also user-friendly, minimizing the risk of spills or burns.

Stap 2: Verify Product Certifications

Ensure that the water bottles meet relevant safety and health certifications. Look for certifications from recognized bodies like the U.S. Food and Drug Administration (FDA) or European Food Safety Authority (EFSA). These certifications indicate that the product has been tested for safety in food contact applications.

- Request documentation: Suppliers should provide clear evidence of compliance.

- Investigate regional standards: Different regions may have specific regulations; ensure that your supplier adheres to these.

Stap 3: Evaluate Supplier Reputation

Assess the credibility and reliability of potential suppliers. A reputable supplier will have a proven track record of delivering quality products. Check for customer reviews, industry ratings, and any past compliance issues.

- Ask for references: Request case studies or testimonials from businesses in similar markets.

- Conduct background checks: Look into the supplier’s history and any legal issues that could affect their reliability.

Stap 4: Conduct Material Testing

Before finalizing your purchase, perform thorough testing of the water bottles. This can include microwave safety tests to ensure that they do not warp or release harmful substances when heated.

- Engage third-party testing labs: They can provide unbiased assessments of material safety and performance.

- Check for durability: Ensure that the bottles can withstand multiple uses without degrading.

Stap 5: Assess Design and Usability

Evaluate the design aspects of the water bottles to ensure they are user-friendly. Look for features such as ergonomic shapes, easy-to-open lids, and clear measurement markings. These factors can enhance the user experience and reduce the risk of accidents.

- Consider user feedback: Conduct surveys or focus groups to gather insights on design preferences.

- Examine packaging: Ensure that the packaging protects the bottles during shipping and is also microwave-safe.

Stap 6: Onderhandelen over prijzen en voorwaarden

Once you have identified suitable suppliers and products, engage in negotiations regarding pricing and delivery terms. It’s essential to balance cost with quality to ensure a good return on investment.

- Compare quotes: Gather multiple bids to find competitive pricing.

- Discuss bulk discounts: Many suppliers offer reduced rates for large orders; leverage this for better pricing.

Stap 7: Establish After-Sales Support

Ensure that your supplier provides adequate after-sales support. This includes warranties, return policies, and customer service assistance. A reliable support system can mitigate risks associated with product defects or safety concerns.

- Evaluate response times: Quick responses to inquiries can be a good indicator of a supplier’s reliability.

- Clarify warranty terms: Understand the duration and conditions of any warranties offered.

By following this checklist, B2B buyers can make informed decisions when sourcing water bottles that are safe for microwave use, ultimately protecting their customers and enhancing their brand reputation.

Comprehensive Cost and Pricing Analysis for can you put water bottles in the microwave Sourcing

What Are the Key Cost Components for Sourcing Water Bottles Suitable for Microwaving?

When sourcing water bottles that are microwave-safe, it’s essential to understand the various cost components involved. The primary factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Materialen: The choice of materials significantly impacts costs. For microwave-safe bottles, polyethylene terephthalate (PET) or BPA-free plastics are commonly used. The prices for these materials can vary based on market conditions and availability. Stainless steel, while not microwave-safe, is often used in premium products and carries a higher material cost.

-

Arbeid: Labor costs will depend on the region of production. For instance, manufacturing in Vietnam might offer lower labor costs compared to Germany. Additionally, skilled labor may be required for quality assurance processes, impacting overall expenses.

-

Productie Overhead: This includes utilities, rent, and other indirect costs associated with production. Overhead can vary significantly between regions, influenced by local economic conditions and factory efficiency.

-

Gereedschap: Initial tooling costs for molds and machinery can be substantial, especially for custom designs. These costs are amortized over production runs, affecting the unit price.

-

Kwaliteitscontrole (QC): Ensuring that bottles meet safety standards for microwaving is crucial. Implementing rigorous QC processes can add to costs but is essential for maintaining product integrity and compliance with regulations.

-

Logistiek: Shipping costs can vary widely based on the Incoterms used. For international buyers, understanding freight costs, customs duties, and potential tariffs is critical for calculating total expenses.

-

Marge: Finally, suppliers will factor in their profit margin, which can vary based on market competition and perceived product value.

How Do Price Influencers Impact the Cost of Microwave-Safe Water Bottles?

Several price influencers play a pivotal role in determining the final cost of microwave-safe water bottles:

-

Volume/MOQ: Bulk purchasing often leads to discounts. Buyers should consider minimum order quantities (MOQ) that can significantly affect unit pricing. Higher volumes typically reduce costs per unit.

-

Specificaties/Aanpassing: Custom designs or specifications can increase costs due to the need for specialized tooling and additional labor. Buyers should weigh the benefits of customization against potential price increases.

-

Materialen: The type of plastic used (e.g., PET vs. polycarbonate) and certifications for safety can impact pricing. Higher-quality materials may result in higher costs but can enhance the product’s marketability.

-

Quality/Certifications: Products with certifications (like FDA approval for food safety) may have higher production costs but can justify a premium price point in the market.

-

Factoren van leveranciers: Supplier reliability, reputation, and production capabilities can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is essential for managing logistics costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly affect pricing structures.

What Buyer Tips Can Enhance Cost-Efficiency for International B2B Purchases?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, certain strategies can enhance cost-efficiency:

-

Onderhandeling: Engage suppliers in discussions to negotiate better terms, especially for larger orders. Leverage your purchasing power to secure discounts.

-

Totale eigendomskosten (TCO): Evaluate the TCO, which includes not just the purchase price but also shipping, handling, and potential warranty costs. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances: Be aware of currency fluctuations and their impact on pricing. Additionally, consider the implications of tariffs and trade agreements that may affect costs.

-

Supplier Diversification: Consider sourcing from multiple suppliers to mitigate risks and ensure competitive pricing.

-

Quality Over Price: While it may be tempting to choose the lowest-cost option, prioritize quality and safety certifications, especially for products intended for consumer use.

Disclaimer over indicatieve prijzen

Prices for microwave-safe water bottles can fluctuate based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making well-informed purchasing decisions.

Alternatives Analysis: Comparing can you put water bottles in the microwave With Other Solutions

Introduction to Alternatives for Heating Water

When considering methods for quickly heating water, businesses must weigh the benefits and drawbacks of various solutions. While the idea of microwaving water bottles may seem convenient, safety concerns and potential damage to both the water bottle and microwave can lead companies to explore alternative approaches. This analysis compares the traditional method of using a microwave with other viable heating solutions: electric kettles and stovetop heating.

Vergelijkende tabel

| Vergelijkingsaspect | Can You Put Water Bottles In The Microwave | Electric Kettle | Stovetop Heating |

|---|---|---|---|

| Prestaties | Can heat water but risks explosion | Quickly boils water efficiently | Slower, requires monitoring |

| Kosten | Low (if no damage occurs) | Moderate (typically $20-$100) | Low (if using existing cookware) |

| Gemak van implementatie | Simple but risky | User-friendly, plug and play | Requires more steps, manual oversight |

| Onderhoud | Risk of damage to microwave and bottles | Weinig onderhoud, gemakkelijk schoon te maken | Moderate, depends on cookware |

| Beste gebruikscasus | Quick, but not recommended | Ideal for quick boiling | Good for larger quantities or cooking |

Gedetailleerd overzicht van alternatieven

Electric Kettles

Electric kettles are a popular choice for quickly boiling water. They are designed for efficiency, often equipped with automatic shut-off features to prevent overheating. Their performance is superior for heating water compared to microwaving, as they can bring water to a boil faster and more safely. On the downside, electric kettles have a moderate cost and require electrical outlets, which may not be available in all settings, particularly in remote locations. Maintenance is minimal, mostly involving regular cleaning to prevent mineral buildup.

Stovetop Heating

Heating water on a stovetop is a traditional method that can be effective for larger quantities. This method allows for precise control over heat levels, making it suitable for recipes requiring specific temperatures. However, stovetop heating is generally slower than using an electric kettle or microwave, and it necessitates constant monitoring to avoid boiling over or burning. The initial investment is low if a business already has pots and pans, but it can be cumbersome in high-demand situations. Maintenance involves cleaning cookware, which can be more labor-intensive depending on the material used.

Conclusie: De juiste oplossing voor uw behoeften kiezen

In selecting the most appropriate method for heating water, B2B buyers should consider the specific demands of their operations. For rapid heating in a controlled environment, electric kettles provide a safe and efficient alternative to microwaving water bottles. Conversely, stovetop heating may be more suitable for larger quantities or when precise temperature control is necessary. Ultimately, understanding the pros and cons of each option will enable businesses to make informed decisions that align with their operational requirements and safety standards.

Essential Technical Properties and Trade Terminology for can you put water bottles in the microwave

What Are the Key Technical Properties of Water Bottles for Microwaving?

When considering the safety and functionality of water bottles in a microwave, several technical properties are essential for B2B buyers. Understanding these specifications can guide purchasing decisions and ensure compliance with safety standards.

1. Material Grade

The material used in water bottles is crucial. Common materials include polyethylene terephthalate (PET), polypropylene (PP), and stainless steel. PET (recycling symbol #1) is generally microwave-safe, while polypropylene (symbol #5) can also be suitable if specified. Stainless steel, however, should never be microwaved due to its reflective properties that can cause sparks and damage to the appliance. Understanding material grades helps buyers select products that meet safety regulations and customer preferences.

2. Temperature Tolerance

Temperature tolerance refers to the maximum temperature a material can withstand without deforming or releasing harmful substances. For instance, PET bottles can typically withstand temperatures up to 70°C (158°F) before beginning to warp. This property is vital as it determines how effectively a water bottle can be used in a microwave setting without compromising safety or functionality.

3. Pressure Resistance

Water expands when heated, which can create pressure within a sealed container. Bottles designed for microwave use must account for this by allowing for some pressure relief, either through a vented lid or sufficient headspace. Understanding pressure resistance is important to prevent dangerous situations, such as explosions or leaks, which can lead to product liability issues.

4. Chemical Composition

The chemical composition of the materials used in water bottles directly affects their safety when heated. For example, certain plastics can leach harmful chemicals when subjected to high temperatures. B2B buyers should prioritize bottles made from BPA-free plastics and those that have been tested for safety when heated. This knowledge is crucial for maintaining product integrity and safeguarding consumer health.

5. Microwave Compatibility Certification

Water bottles that are certified microwave-safe undergo rigorous testing to ensure they can withstand microwave energy without compromising structural integrity. Certifications such as FDA approval or similar international standards indicate a product’s reliability. For B2B buyers, sourcing certified products can enhance brand reputation and consumer trust.

What Are Common Trade Terms Related to Water Bottles?

Navigating the complexities of B2B transactions requires familiarity with industry jargon. Here are several common terms that are particularly relevant when dealing with water bottles and their microwave safety.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are marketed under another company’s brand. In the context of water bottles, an OEM might manufacture bottles that are labeled and sold by a different brand. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better terms.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For water bottles, MOQs can vary significantly based on material, design, and supplier. Knowing the MOQ is essential for buyers to manage inventory costs and ensure they meet demand without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific quantities of products. When sourcing water bottles, submitting an RFQ can facilitate competitive pricing and help buyers compare multiple suppliers efficiently.

4. Incoterms

Incoterms (International Commercial Terms) are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, costs, and risks associated with the transportation of water bottles.

5. Compliance Standards

Compliance standards refer to the regulations that products must meet to be deemed safe for consumer use. For water bottles, this includes safety certifications for microwave use. Familiarity with relevant compliance standards helps businesses avoid legal issues and ensure product safety.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing water bottles intended for microwave use, ultimately enhancing product safety and consumer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the can you put water bottles in the microwave Sector

What Are the Key Market Drivers for Water Bottle Microwaving Trends?

The market for water bottles, particularly those labeled as microwave-safe, is influenced by several global drivers. First, the increasing demand for convenience in food and beverage consumption is propelling growth. Consumers are looking for multifunctional products that can easily transition from storage to heating without the need for additional containers. This trend is particularly pronounced in regions such as Africa and South America, where urbanization is leading to busier lifestyles and a preference for quick meal solutions.

Additionally, advancements in materials science have introduced new types of plastics and composites that can withstand microwave heating without releasing harmful chemicals. This innovation is particularly relevant for B2B buyers in Europe and the Middle East, where safety regulations are stringent and consumer awareness around product safety is high. The rise of e-commerce platforms is also making it easier for international buyers to access a variety of products, fostering competition and pushing manufacturers to innovate.

Emerging technologies, such as smart kitchen appliances that can monitor heating times and temperatures, are further shaping the market dynamics. These tech advancements appeal to modern consumers who prioritize efficiency and safety in their cooking practices.

How Are Sustainability and Ethical Sourcing Affecting the Water Bottle Market?

Sustainability has become a cornerstone of modern B2B sourcing strategies, especially in the water bottle sector. The environmental impact of plastic waste has led to an increased focus on ethical supply chains and sustainable materials. For B2B buyers, it is crucial to ensure that the products they source not only meet safety standards for microwaving but are also environmentally friendly.

Materials such as recycled plastics and bioplastics are gaining traction, with certifications such as the Global Recycle Standard (GRS) and FSC (Forest Stewardship Council) becoming important benchmarks. These certifications provide assurance that the materials are sourced responsibly, thus reducing the carbon footprint associated with production and disposal.

Furthermore, the shift toward sustainability is encouraging manufacturers to adopt circular economy principles, where products are designed for reuse and recycling. This trend is particularly relevant for international buyers from regions like Europe, where regulatory frameworks around sustainability are increasingly strict. By prioritizing ethically sourced and environmentally friendly products, businesses can not only meet consumer demand but also enhance their brand reputation and long-term viability.

What Has Been the Evolution of Water Bottle Safety Standards?

The evolution of safety standards for water bottles, particularly concerning their use in microwaves, reflects broader societal changes in consumer safety awareness. Initially, most plastic bottles were not designed with microwave use in mind, leading to widespread misconceptions about their safety. Over the past two decades, however, regulatory bodies like the U.S. Food and Drug Administration (FDA) have established clearer guidelines regarding which materials are deemed microwave-safe.

Today, materials such as polyethylene terephthalate (PET) and polypropylene are commonly recognized as safe for microwave use, provided they are not overheated. In contrast, other materials like polycarbonate and stainless steel have been shown to pose risks, such as chemical leaching or fire hazards, when subjected to microwave radiation.

As a result, manufacturers are increasingly investing in research and development to create water bottles that can withstand microwave heating while ensuring consumer safety. This focus on compliance with safety standards not only protects consumers but also positions companies as responsible players in a competitive market, appealing to B2B buyers who prioritize safety and quality in their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of can you put water bottles in the microwave

-

How do I determine if a water bottle is microwave-safe?

To ascertain if a water bottle is microwave-safe, check for the recycling symbol on the bottom of the bottle. Look for polyethylene terephthalate (PET) marked with #1, which is generally considered microwave-safe. Avoid bottles made from polycarbonate (recycling symbol #7) as they can release harmful chemicals when heated. Additionally, ensure that the bottle is not sealed; the cap should be removed to prevent pressure buildup during microwaving. -

What materials are safe for microwaving water bottles?

Microwave-safe materials typically include certain plastics, ceramics, and glass. For water bottles, polyethylene (PET) and polypropylene (PP) are generally safe options. Avoid metals like stainless steel or aluminum, as they reflect microwaves and can cause sparking or damage to the microwave. When sourcing products for international markets, consider local regulations regarding materials to ensure compliance and safety. -

What are the risks of microwaving a plastic water bottle?

Microwaving plastic water bottles can pose risks such as chemical leaching if the bottle is made from non-microwave-safe materials. High temperatures can also cause the plastic to warp or degrade. To mitigate these risks, always use bottles made from approved materials like PET and ensure they are labeled microwave-safe. Educating your customers about these risks can enhance your brand’s reputation for safety. -

How can I customize water bottles for my business?

Customization options for water bottles can include branding, colors, sizes, and materials. Many suppliers offer services like screen printing or engraving for logos. When sourcing, inquire about minimum order quantities (MOQ) for custom designs, as these can vary significantly. Establish clear communication with suppliers regarding your customization needs to ensure timely delivery and quality standards. -

What are the best payment terms for sourcing water bottles internationally?

Best practices for payment terms in international sourcing include negotiating terms that protect both parties, such as a letter of credit or escrow services for large orders. Common terms may include 30% upfront and 70% upon delivery. Evaluate the supplier’s reliability and consider using secure payment methods to minimize risk. Understanding local banking practices in your target market is also essential for smooth transactions. -

How do I vet suppliers for water bottles?

When vetting suppliers for water bottles, consider their certifications, production capacity, and customer reviews. Request samples to assess product quality and ensure compliance with international safety standards. It’s beneficial to visit the manufacturing facility if possible or use third-party auditing services. Establishing a strong relationship with your supplier can lead to better communication and reliability in the long term. -

What logistics considerations should I be aware of when importing water bottles?

Logistics for importing water bottles involve understanding shipping methods, customs regulations, and potential tariffs. Consider the lead time for production and shipping, as well as the reliability of your logistics partners. Ensure you have the proper documentation for customs clearance, and factor in potential delays that can occur during transit. Collaborating with a logistics expert can help streamline the process and avoid costly mistakes. -

How can I ensure quality assurance (QA) for my water bottle orders?

Implementing a robust QA process is crucial for maintaining product standards. Establish clear specifications and quality benchmarks with your suppliers before production begins. Conduct pre-shipment inspections to verify compliance with these standards, and consider third-party QA services for added assurance. Regularly communicating with suppliers about quality expectations can help prevent issues and ensure consistent product delivery.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 9 Can You Put Water Bottles In The Microwave Manufacturers & Suppliers List

1. Reddit – Microwaving Disposable Plastic Bottles

Domein: reddit.nl

Geregistreerd: 2005 (20 jaar)

Inleiding: Disposable plastic water bottles are not suitable for microwaving beverages. Heating them can cause the plastic to leach harmful chemicals into the drink.

2. Buzio – Microwave-Safe Water Bottles

Domein: buziolife.com

Geregistreerd: 2017 (8 jaar)

Inleiding: Buzio water bottles are made of polyethylene terephthalate (PET), indicated by recycling symbol #1, which is microwave-safe. It is advised to remove the cap before microwaving to prevent pressure buildup. Users should not overfill the bottle and should place it in the center of the microwave for even heating. Heating should not exceed two minutes to avoid scalding.

3. Haers – Versatile Water Bottles

Domein: haers.com

Geregistreerd: 2002 (23 jaar)

Inleiding: Haers offers a variety of water bottles made from different materials including stainless steel, titanium, Tritan, and glass. The products are available in various types such as tumblers, flasks, jugs, cups, kettles, and food jars. Capacities range from less than 14oz (414ml) to over 1 gallon (3784ml). Customization options include choosing product models, lids, colors, patterns, and adding logos …

4. Bearaby – Hot Water Bottles

Domein: bearaby.com

Geregistreerd: 2018 (7 jaar)

Inleiding: Hot water bottles are versatile for warmth and pain relief. Whether you can microwave a hot water bottle depends on its specific design and manufacturer’s guidelines. Microwavable bottles have specific heating instructions to avoid damage and safety hazards. Inspect materials, design, and labels to determine if a bottle is microwavable.

5. Samply – Hot Water Bottles UZhen 1.7L & 1.2L

Domein: samply.com

Geregistreerd: 2006 (19 jaar)

Inleiding: Hot Water Bottle UZhen CAPACITY:1.7L, UZhen CAPACITY:1.2L

6. Facebook – Microwave Mug Tips

Domein: facebook.com

Geregistreerd: 1997 (28 jaar)

Inleiding: This company, Facebook – Microwave Mug Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Water Bottle – Safety Guidelines

Domein: waterfles.tech

Geregistreerd: 2018 (7 jaar)

Inleiding: Hydro Flasks and Yeti Cups are not microwave safe due to their stainless steel construction, which can cause sparks and potential fire hazards when microwaved. The plastic components, such as caps and handles, may also melt or deform. It is recommended to transfer liquids to microwave-safe containers for heating. Proper usage includes washing before first use, preheating or precooling for effectiv…

8. Parenting – Microwaving Baby Bottles

Domein: parenting.stackexchange.com

Geregistreerd: 2009 (16 jaar)

Inleiding: This company, Parenting – Microwaving Baby Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. Hotties – Microwave Hot Water Bottles

Domein: thenakedscientists.com

Geregistreerd: 2001 (24 jaar)

Inleiding: Hotties range of microwave hot water bottles have been sold safely in the UK and Europe for ten years with no significant injuries reported. They are designed with safety as a priority, featuring fail-safe mechanisms to prevent dangerous temperatures and pressures. Hotties are engineered to fail safely if overheated, avoiding explosive failures. They hold heat for around 45 minutes to 1 hour and a…

Strategic Sourcing Conclusion and Outlook for can you put water bottles in the microwave

What Are the Key Insights for B2B Buyers Regarding Microwave Use with Water Bottles?

In summary, while certain water bottles can technically be microwaved, numerous safety concerns must be addressed. For businesses, understanding the material composition of water bottles—whether plastic, stainless steel, or aluminum—is crucial in guiding customers toward safe usage. This knowledge not only helps prevent product misuse but also enhances customer satisfaction and brand loyalty.

Strategic sourcing plays a pivotal role in ensuring that products meet safety standards and consumer expectations. By prioritizing suppliers that offer high-quality, microwave-safe bottles, companies can mitigate risks associated with product failures and enhance their market reputation.

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is an increasing demand for safe, user-friendly products. B2B buyers should seize this opportunity to invest in water bottles that adhere to safety regulations while offering convenience. By doing so, businesses not only safeguard their customers but also position themselves as leaders in the competitive landscape. Engage with reliable suppliers today to ensure your offerings align with consumer safety needs and preferences.