Introduction: Navigating the Global Market for different size water bottles

Choosing the right size water bottles for your business needs can be a daunting task, especially in a diverse global market where options are plentiful. As an international B2B buyer, you may find yourself grappling with the challenge of sourcing water bottles that not only meet quality standards but also cater to varying consumer preferences across regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Vietnam. This comprehensive guide addresses these challenges head-on by exploring the myriad types of water bottles available, their specific applications, and how to effectively vet suppliers to ensure you make the best purchasing decisions.

In this guide, we will delve into the different sizes of water bottles—from compact 8 oz options ideal for children or short outings to larger 64 oz bottles that cater to athletes and outdoor enthusiasts. We will also discuss the materials used, the environmental impact of reusable versus single-use bottles, and the cost implications of various options. By providing actionable insights and expert recommendations, this guide empowers B2B buyers to navigate the complexities of the water bottle market with confidence. Whether your focus is on bulk purchasing for retail, promotional giveaways, or corporate branding, our goal is to equip you with the knowledge necessary to make informed, strategic choices that align with your business objectives and consumer demands.

Artikel navigatie

- Top 6 Different Size Water Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for different size water bottles

- Understanding different size water bottles Types and Variations

- Key Industrial Applications of different size water bottles

- 3 Common User Pain Points for ‘different size water bottles’ & Their Solutions

- Strategic Material Selection Guide for different size water bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for different size water bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘different size water bottles’

- Comprehensive Cost and Pricing Analysis for different size water bottles Sourcing

- Alternatives Analysis: Comparing different size water bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for different size water bottles

- Navigating Market Dynamics and Sourcing Trends in the different size water bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of different size water bottles

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for different size water bottles

Understanding different size water bottles Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Small Water Bottles | Ranges from 8 oz to 16 oz, portable, lightweight | Kid’s products, promotional giveaways | Voordelen: Easy to carry, cost-effective. Minpunten: Frequent refills needed. |

| Medium Water Bottles | Typically 20 oz to 32 oz, versatile for daily use | Office hydration, fitness centers | Voordelen: Good balance of capacity and portability. Minpunten: May still require refills during long use. |

| Large Water Bottles | Sizes from 40 oz to 64 oz, ideal for outdoor use | Sports events, camping, outdoor activities | Voordelen: Fewer refills, suitable for high hydration needs. Minpunten: Bulky, may require special carrying solutions. |

| Gallon Water Bottles | 1 gallon (128 oz), designed for bulk hydration | Catering, large events, construction sites | Voordelen: Meets high-volume hydration needs. Minpunten: Heavy and less portable. |

| Customizable Bottles | Available in various sizes, with branding options | Corporate gifts, promotional items | Voordelen: Enhances brand visibility, tailored to client needs. Minpunten: Hogere aanloopkosten voor maatwerk. |

What Are the Characteristics of Small Water Bottles?

Small water bottles, typically ranging from 8 oz to 16 oz, are designed for quick hydration needs. Their lightweight and compact design makes them ideal for children, promotional giveaways, or short outings. B2B buyers should consider these bottles for events where convenience and low cost are priorities. However, frequent refilling can be a drawback, especially for prolonged use.

How Do Medium Water Bottles Fit into Daily Hydration Needs?

Medium water bottles, generally between 20 oz and 32 oz, strike a balance between capacity and portability. They are suitable for daily office use or gym activities, allowing users to stay hydrated without constant refills. B2B applications include supplying fitness centers and corporate offices with durable options that cater to a wide audience. Buyers should note that while they are versatile, they may still require refills during extended periods.

Why Choose Large Water Bottles for Outdoor Activities?

Large water bottles, ranging from 40 oz to 64 oz, are designed for users with high hydration demands, such as athletes or outdoor enthusiasts. These bottles minimize the need for frequent refills, making them ideal for sports events and camping trips. B2B buyers should consider the practicality of these bottles for outdoor activities, although they may require special carrying solutions due to their bulkiness.

What Are the Benefits of Gallon Water Bottles?

Gallon water bottles, holding 128 oz, cater to bulk hydration needs and are commonly used in catering, large events, or construction sites. Their size makes them ideal for situations where multiple users require access to water. While they effectively meet high-volume hydration demands, their weight and reduced portability can be a disadvantage for buyers focusing on ease of transport.

How Can Customizable Bottles Enhance Brand Visibility?

Customizable bottles are available in various sizes and can feature branding, making them an excellent choice for corporate gifts and promotional items. They serve as a unique marketing tool that enhances brand visibility while providing practical hydration solutions. B2B buyers should weigh the benefits of customization against the higher upfront costs, as these bottles can create lasting impressions in target markets.

Key Industrial Applications of different size water bottles

| Industrie/sector | Specific Application of different size water bottles | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Gastvrijheid | Providing guests with complimentary water bottles in rooms. | Enhances guest experience and promotes brand loyalty. | Quality of materials, customization options, and eco-friendliness. |

| Sport en fitness | Hydration stations with various bottle sizes for athletes. | Supports performance and recovery, reduces waste. | Durability, ease of use, and branding opportunities. |

| Onderwijs | Reusable water bottles for students in schools and universities. | Encourages hydration, reduces plastic waste, and promotes sustainability. | Safety standards, variety of sizes, and affordability. |

| Bedrijf Wellness | Employee hydration programs using personalized water bottles. | Improves employee health and productivity. | Custom branding, BPA-free materials, and bulk purchasing options. |

| Outdoor & Adventure | Water bottles for hiking and camping gear packages. | Attracts outdoor enthusiasts and enhances product offerings. | Lightweight materials, insulation options, and capacity range. |

How Are Different Size Water Bottles Used in the Hospitality Industry?

In the hospitality sector, different size water bottles serve a crucial role in enhancing guest experiences. Hotels often provide complimentary water bottles in rooms, ranging from small 8 oz bottles for quick refreshment to larger 32 oz bottles for extended stays. This not only improves guest satisfaction but also fosters brand loyalty as guests associate positive experiences with the brand. Buyers in this sector should prioritize eco-friendly materials and customization options to align with sustainability goals.

What Are the Applications of Water Bottles in Sports & Fitness?

In sports and fitness, hydration is essential for performance and recovery. Gyms and sports facilities typically implement hydration stations equipped with various bottle sizes, from 20 oz for quick workouts to 64 oz for endurance training. This approach minimizes single-use plastic waste and encourages athletes to stay hydrated. When sourcing, businesses should consider the durability of the bottles and the potential for branding, as well as the ease of use during workouts.

How Do Educational Institutions Utilize Different Size Water Bottles?

Educational institutions, from primary schools to universities, utilize reusable water bottles to promote hydration among students. Typically, bottles ranging from 16 oz to 32 oz are ideal, encouraging students to drink more water while reducing reliance on single-use plastics. This initiative not only supports health but also aligns with sustainability efforts. Buyers should ensure that the bottles meet safety standards and are affordable for bulk purchasing, considering the budget constraints of many educational institutions.

How Can Corporations Benefit from Employee Hydration Programs?

Corporate wellness programs increasingly include personalized water bottles to promote employee hydration. These bottles, often in the 20 oz to 32 oz range, help employees meet daily hydration goals, which can lead to improved health and productivity. Businesses should look for options that allow for custom branding, ensuring that the bottles reflect the corporate identity. Additionally, sourcing BPA-free materials is critical to ensure employee safety and well-being.

What Role Do Water Bottles Play in Outdoor & Adventure Markets?

In the outdoor and adventure markets, water bottles are essential components of hiking and camping gear packages. Offering a range of sizes, from compact 12 oz bottles for day hikes to larger 64 oz bottles for extended trips, can attract outdoor enthusiasts. Buyers in this sector should focus on lightweight materials, insulation options, and a variety of capacities to meet diverse consumer needs, enhancing their product offerings and appealing to adventure seekers.

3 Common User Pain Points for ‘different size water bottles’ & Their Solutions

Scenario 1: Finding the Right Size for Diverse Customer Needs

Het probleem: B2B buyers often struggle with selecting the appropriate water bottle sizes to meet the varied preferences of their customers. For instance, a retailer may cater to both fitness enthusiasts who prefer larger bottles (32 oz or more) and families looking for smaller, portable options (8 oz to 16 oz) for children. This diversity can lead to overstocking some sizes while understocking others, resulting in lost sales and wasted inventory. Additionally, different markets may have specific preferences that complicate inventory decisions further.

De oplossing: Conduct thorough market research to understand the specific needs of your target demographic. Utilize surveys or feedback forms from your existing customers to gauge their preferences for water bottle sizes. This insight will help you tailor your inventory to meet demand. Furthermore, consider partnering with manufacturers who offer a range of customizable sizes and materials, allowing you to quickly adapt your offerings based on customer trends. Implementing a just-in-time inventory system can help maintain flexibility, ensuring you can meet demand without incurring unnecessary costs.

Scenario 2: Managing Bulk Orders for Large Water Bottles

Het probleem: B2B buyers, particularly in sectors like hospitality or events management, often face challenges when ordering large quantities of water bottles (40 oz and above). These buyers may need these bottles for outdoor events, sports teams, or corporate wellness programs. However, bulk ordering can lead to logistical headaches, including storage issues, transportation costs, and the risk of ordering too many or too few based on fluctuating demand.

De oplossing: Establish a relationship with suppliers who specialize in bulk orders and can provide flexible shipping and storage options. Negotiate terms that allow for staggered deliveries based on your projected needs. Utilize data analytics to forecast demand accurately, considering factors such as seasonality and regional events that might influence sales. Additionally, consider offering a bottle exchange program where customers can return unused bottles for discounts on future purchases, thus reducing excess inventory and ensuring you maintain a steady flow of supplies.

Scenario 3: Ensuring Quality and Compliance in Water Bottles Sourcing

Het probleem: Another significant concern for B2B buyers is ensuring that the water bottles they source are compliant with health and safety regulations, particularly regarding materials used, such as BPA-free plastics or food-grade stainless steel. The consequences of non-compliance can include product recalls, legal liabilities, and damage to brand reputation. Buyers may find it challenging to vet suppliers and verify the quality and safety of their products.

De oplossing: Prioritize working with suppliers who provide transparent information about their products, including certifications and compliance documents. Create a checklist of essential quality markers, such as FDA approval, BPA-free certification, and durability tests, to evaluate potential suppliers. Regularly conduct audits or request samples to assess product quality before committing to larger orders. Additionally, consider forming partnerships with third-party testing organizations that can provide independent verification of product safety and compliance, giving you confidence in the quality of your offerings.

Strategic Material Selection Guide for different size water bottles

What Are the Key Properties of Common Materials for Water Bottles?

When selecting materials for water bottles, it is crucial to consider their properties, advantages, and limitations. Here, we analyze four common materials used in the production of different-sized water bottles: BPA-free plastic, stainless steel, glass, and aluminum. Each material has unique characteristics that can influence the final product’s performance, cost, and suitability for various applications.

BPA-Free Plastic: A Versatile Choice for Water Bottles

BPA-free plastic is widely used in the production of water bottles due to its lightweight nature and cost-effectiveness. Key properties include high impact resistance, a temperature rating suitable for cold liquids, and good chemical resistance. However, it has limitations regarding heat exposure, which can lead to leaching of chemicals if not properly formulated.

Pros: BPA-free plastic bottles are generally more affordable and lighter than alternatives, making them ideal for everyday use and travel. They are also available in various sizes, from small 8 oz to large 64 oz bottles.

Cons: The durability of plastic is lower than that of metal or glass, and they may scratch or degrade over time, especially under UV exposure. Additionally, they are less environmentally friendly compared to other materials.

For international buyers, compliance with regulations such as FDA and EU standards is essential. In regions like Africa and South America, where regulations may vary, ensuring that products meet local safety standards is crucial.

Stainless Steel: Durability and Insulation Benefits

Stainless steel is known for its durability and excellent insulation properties, making it a popular choice for larger water bottles. Key properties include high corrosion resistance, the ability to withstand high temperatures, and a robust structure that prevents breakage.

Pros: Stainless steel bottles are reusable, environmentally friendly, and can keep beverages hot or cold for extended periods. They are ideal for outdoor activities and heavy usage.

Cons: The manufacturing process for stainless steel bottles can be more complex and costly than plastic options, which may affect the final price point. They are also heavier than plastic, which may deter some consumers.

International buyers should consider compliance with standards such as ASTM and DIN, especially in Europe, where environmental regulations are stringent. In regions like the Middle East, the demand for durable products is high, making stainless steel an attractive option.

Glass: A Premium Option for Health-Conscious Consumers

Glass water bottles are increasingly popular due to their non-reactive nature and aesthetic appeal. Key properties include high chemical resistance and the ability to maintain the purity of the beverage. However, glass is more fragile and can break easily.

Pros: Glass bottles do not leach chemicals, making them a safer choice for health-conscious consumers. They are also recyclable, appealing to environmentally aware buyers.

Cons: The weight and fragility of glass make it less suitable for outdoor activities or travel. Additionally, the cost of glass bottles is generally higher than that of plastic.

For B2B buyers, understanding local preferences is vital. In Europe, there is a growing trend toward sustainable products, which can make glass bottles an appealing option. However, in regions like Africa, where transportation and breakage can be concerns, the practicality of glass may be questioned.

Aluminum: Lightweight and Recyclable

Aluminum water bottles are lightweight and offer good durability. They are often coated internally to prevent reactions with beverages. Key properties include corrosion resistance and a relatively low weight, making them easy to carry.

Pros: Aluminum bottles are recyclable and can be produced with a wide variety of designs and colors, appealing to a broad market. They are also more durable than plastic.

Cons: The internal coating can wear off over time, potentially leading to leaching. Additionally, aluminum may not provide the same level of insulation as stainless steel.

International buyers should be aware of the recycling capabilities in their region. In South America, for example, aluminum recycling is well-established, making it a favorable option. However, buyers in regions with less recycling infrastructure may face challenges.

Overzichtstabel materiaalselectie voor waterflessen

| Materiaal | Typical Use Case for different size water bottles | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| BPA-vrij plastic | Everyday use, travel, sports | Lichtgewicht en kosteneffectief | Less durable, potential leaching | Laag |

| Roestvrij staal | Outdoor activities, heavy usage | Durable and excellent insulation | Hogere kosten, zwaarder gewicht | Hoog |

| Glas | Health-conscious consumers, premium markets | Non-reactive, recyclable | Fragile and heavier | Hoog |

| Aluminium | Lightweight travel, design-focused markets | Lightweight and recyclable | Internal coating wear, less insulation | Medium |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions regarding the optimal materials for different-sized water bottles, considering performance, cost, and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for different size water bottles

What Are the Main Stages in the Manufacturing Process of Water Bottles?

The manufacturing process of water bottles, regardless of size, involves several critical stages that ensure the final product meets quality and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Materiaalvoorbereiding: This initial stage involves selecting the right material for the water bottles. Common materials include BPA-free plastics, stainless steel, and glass. The material is sourced from reputable suppliers and undergoes rigorous testing to ensure it meets quality specifications. For instance, plastic materials are checked for purity and safety to comply with international standards.

-

Het vormen van: Once the materials are prepared, the next step is forming. This process varies by material type:

– Plastic Bottles: Typically manufactured using blow molding techniques, where pre-formed plastic is heated and inflated into bottle shapes. This method is efficient for producing bottles in various sizes, from small 8 oz bottles to large 5-gallon containers.

– Glazen flessen: These are often produced through glass blowing or molding processes. The glass is heated to a molten state and then shaped into bottles, followed by annealing to relieve internal stresses.

– Stainless Steel Bottles: The process involves stamping and welding sheets of stainless steel into the desired bottle shape. This ensures durability and insulation, particularly for larger bottles. -

Montage: After forming, the bottles undergo assembly. This includes adding components such as caps, straws, and handles. For reusable bottles, assembly may also involve incorporating insulation layers or filters. Automated assembly lines are commonly used to enhance efficiency and precision.

-

Afwerking: The final stage involves surface treatment and quality checks. Bottles may undergo polishing, coating, or printing of branding elements. This stage ensures that the product not only looks appealing but also meets functional requirements like durability and ease of use.

What Quality Assurance Standards Are Relevant for Water Bottle Manufacturing?

Quality assurance (QA) is paramount in the water bottle manufacturing process to ensure safety, durability, and compliance with international regulations. Here are some relevant standards and practices:

-

International Standards: ISO 9001 is a widely recognized quality management standard that outlines requirements for a quality management system (QMS). Manufacturers aiming for ISO certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements. This is crucial for B2B buyers who prioritize reliability in their supply chains.

-

Industry-Specific Standards: Certifications such as CE (Conformité Européenne) mark for European markets and API (American Petroleum Institute) standards for specific applications ensure that products meet safety and performance criteria. For water bottles, compliance with food safety regulations is vital, particularly for materials in contact with consumables.

-

Kwaliteitscontrolepunten:

– Inkomende kwaliteitscontrole (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility to ensure they meet specified standards.

– Kwaliteitscontrole tijdens het proces (IPQC): During production, various checkpoints are established to monitor processes and outputs. This may include dimensional checks, weight verification, and visual inspections.

– Finale kwaliteitscontrole (FQC): This stage involves a comprehensive inspection of the finished products. Bottles are tested for leak-proofing, durability, and compliance with size specifications.

What Common Testing Methods Are Used in Water Bottle Quality Control?

To ensure product safety and quality, several testing methods are employed throughout the manufacturing process:

-

Material Testing: Tests such as tensile strength, impact resistance, and thermal stability are conducted on raw materials to assess their suitability for water bottle production.

-

Lektests: Finished bottles undergo leak tests to ensure that they can withstand pressure and do not leak during use. This is particularly important for insulated and larger bottles.

-

Chemische analyse: Testing for harmful substances, such as BPA and phthalates in plastics, is conducted to ensure compliance with health regulations. This is crucial for maintaining consumer trust and meeting international safety standards.

-

Durability Testing: Bottles are subjected to drop tests and cyclic loading to assess their durability under normal usage conditions. This helps in identifying potential weaknesses in the design or material.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those sourcing from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some actionable strategies:

-

Leveranciersaudits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures firsthand. This includes reviewing the production line, quality control checkpoints, and documentation practices.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can provide insights into their testing methods, results, and compliance with relevant standards. These reports should include information on IQC, IPQC, and FQC processes.

-

Inspecties door derden: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. These inspections typically cover material quality, manufacturing processes, and final product assessments.

-

Certification Verification: Confirming the validity of certifications such as ISO 9001, CE, or API can provide additional assurance of the supplier’s commitment to quality. Buyers should request copies of certificates and check their status with the issuing bodies.

Wat zijn de nuances op het gebied van kwaliteitscontrole voor internationale B2B-kopers?

International buyers face unique challenges when sourcing water bottles. Key considerations include:

-

Inzicht in plaatselijke voorschriften: Different regions have varying regulations concerning materials and safety standards. Buyers must be aware of these differences to ensure compliance when importing products.

-

Cultural Differences in Quality Perception: Quality expectations can vary significantly across cultures. What is considered acceptable in one region may not meet the standards in another. Understanding these nuances can aid in effective communication with suppliers.

-

Logistical Considerations: Ensuring that quality control measures are maintained throughout the supply chain is vital. Buyers should consider the transportation and storage conditions of products, as these can impact quality.

-

Langetermijnrelaties opbouwen: Establishing a strong relationship with suppliers can facilitate better communication regarding quality control practices and expectations. This partnership approach can lead to improved product quality and reliability over time.

By understanding the intricacies of the manufacturing processes and quality assurance practices associated with different sizes of water bottles, B2B buyers can make informed decisions, ensuring that they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different size water bottles’

In the competitive landscape of B2B procurement, selecting the right size and type of water bottles is crucial for meeting diverse customer needs and ensuring brand satisfaction. This guide provides a comprehensive checklist for international buyers looking to source different sizes of water bottles, tailored to specific markets such as Africa, South America, the Middle East, and Europe.

Stap 1: Identify Your Target Market Requirements

Understanding the preferences and requirements of your target market is essential. Different regions may have varying needs based on cultural practices, environmental concerns, and hydration habits. Research local preferences regarding bottle sizes, materials, and designs to ensure your selection aligns with customer expectations.

Stap 2: Je technische specificaties definiëren

Clearly outline the technical specifications for the water bottles you wish to procure. Consider factors such as:

– Size Range: Common sizes include 8 oz, 16 oz, 32 oz, and larger options like 1 gallon.

– Materials: Decide between BPA-free plastic, stainless steel, or glass based on durability and customer preferences.

Having well-defined specifications helps streamline the sourcing process and ensures you receive products that meet your quality standards.

Stap 3: Potentiële leveranciers evalueren

Thoroughly vet potential suppliers to ensure reliability and quality. Look for:

– Certifications: Verify compliance with international standards (ISO, FDA) and regional regulations.

– Experience: Assess their track record in the industry and seek testimonials from other B2B buyers.

This step is critical to mitigate risks associated with product quality and delivery timelines.

Stap 4: Request Samples for Quality Assurance

Before placing a bulk order, always request product samples. Testing samples allows you to evaluate:

– Material Quality: Ensure the bottles meet your durability and safety standards.

– Design and Functionality: Confirm that the sizes and features align with your specifications and market needs.

Receiving samples helps you make informed decisions and reduces the likelihood of returns or dissatisfaction.

Stap 5: Assess Pricing and Payment Terms

Compare pricing structures among different suppliers to find a balance between cost and quality. Consider:

– Bulk Discounts: Many suppliers offer reduced rates for larger orders, which can significantly lower your overall costs.

– Payment Flexibility: Evaluate payment terms, including deposits, credit options, and any potential discounts for early payments.

Understanding pricing and payment terms is vital for maintaining healthy cash flow while maximizing profitability.

Stap 6: Establish a Clear Communication Plan

Effective communication is crucial throughout the sourcing process. Establish a plan that includes:

– Regular Updates: Set expectations for updates on order status and any potential delays.

– Point of Contact: Designate a representative from both your team and the supplier’s to streamline communication.

A clear communication strategy fosters a strong relationship with suppliers and helps resolve issues promptly.

Stap 7: Plan voor logistiek en distributie

Finally, consider the logistics involved in transporting and distributing the water bottles. Factors to evaluate include:

– Shipping Options: Assess various shipping methods based on cost and delivery speed.

– Storage Requirements: Ensure you have adequate storage facilities for the different sizes of water bottles.

Planning logistics effectively minimizes delays and helps maintain your supply chain efficiency.

By following this checklist, B2B buyers can strategically source various sizes of water bottles that cater to their market’s unique needs, ensuring successful procurement and customer satisfaction.

Comprehensive Cost and Pricing Analysis for different size water bottles Sourcing

What Are the Key Cost Components in Sourcing Different Size Water Bottles?

When sourcing water bottles, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margins.

-

Materials: The choice of material significantly influences the cost. Common options include BPA-free plastic, stainless steel, and glass, each with varying price points. For instance, stainless steel is generally more expensive than plastic but offers better durability and insulation properties.

-

Labor: Labor costs fluctuate based on the region of production. Countries with lower labor costs may offer competitive pricing, but this can be offset by potential quality issues.

-

Manufacturing Overhead: This encompasses costs associated with running production facilities, including utilities, equipment maintenance, and administrative expenses. Efficient production processes can minimize overhead and enhance pricing competitiveness.

-

Tooling: Initial tooling costs for custom molds or unique designs can be significant. These costs are typically amortized over larger production runs, which underscores the importance of minimum order quantities (MOQs).

-

Quality Control (QC): Implementing stringent QC measures can increase upfront costs but is vital for ensuring product reliability and compliance with international standards, particularly for buyers in Europe or the Middle East.

-

Logistics: Shipping costs can vary dramatically based on the size and weight of the bottles, as well as the distance from the supplier. International buyers should consider the full logistical costs, including customs duties and tariffs.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. Understanding typical margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect Sourcing Costs for Water Bottles?

Several factors can influence the pricing of water bottles, particularly for international B2B buyers.

-

Volume/MOQ: Higher order volumes usually lead to reduced per-unit costs. Suppliers often provide tiered pricing, where the price per bottle decreases as the order size increases.

-

Specifications/Customization: Custom designs or specific features (e.g., insulation, built-in straws) can increase costs. Buyers should assess whether the added features justify the higher price.

-

Materials and Quality Certifications: Bottles made from premium materials or those that come with certifications (e.g., BPA-free, FDA-approved) can command higher prices. Buyers should evaluate whether these certifications align with their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge a premium due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can significantly impact the final price. Buyers should understand the implications of different terms (e.g., FOB, CIF) on shipping responsibilities and costs.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Water Bottles?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, achieving cost-efficiency is critical. Here are some actionable tips:

-

Negotiate Terms: Leverage your purchasing power by negotiating not only the price but also payment terms, delivery schedules, and warranty conditions. Long-term relationships with suppliers can lead to better pricing over time.

-

Overweeg de totale gebruikskosten: Look beyond the initial purchase price. Factor in shipping, customs duties, storage, and potential returns or defects to understand the total cost of ownership.

-

Be Aware of Pricing Nuances: Different regions may have varying price expectations based on local market conditions, currency fluctuations, and economic stability. Staying informed about these factors can help in negotiations.

-

Conduct Supplier Audits: Regularly assess your suppliers to ensure they meet quality and cost expectations. This can help mitigate risks associated with poor-quality products that may lead to increased long-term costs.

Disclaimer over indicatieve prijzen

Pricing for water bottles can vary widely based on the factors discussed above. Buyers should seek specific quotes from suppliers to ensure accurate budgeting and cost planning.

Alternatives Analysis: Comparing different size water bottles With Other Solutions

Exploring Alternatives to Different Size Water Bottles

In the quest for effective hydration solutions, various options exist beyond traditional water bottles. This analysis compares different sizes of water bottles with alternative methods, such as water filtration systems and hydration packs. Understanding these alternatives can help B2B buyers make informed decisions based on their unique needs, whether for corporate wellness programs, outdoor adventures, or retail offerings.

| Vergelijkingsaspect | Different Size Water Bottles | Waterfiltersystemen | Hydratatie Pakken |

|---|---|---|---|

| Prestaties | Varies by size; effective for portable hydration | Provides clean water on demand; no need for bottles | Offers hands-free hydration; ideal for active use |

| Kosten | Moderate to high; one-time purchase with varying material costs | Initial investment can be high; long-term savings on bottled water | Moderate cost; reusable and durable |

| Gemak van implementatie | Simple to distribute and use; requires no setup | Installation required; maintenance needed for filters | Easy to wear and use; may require adjustment for comfort |

| Onderhoud | Minimal; occasional cleaning required | Regular filter replacements; depends on water source quality | Requires cleaning after use; can be cumbersome to manage |

| Beste gebruikscasus | Daily hydration at work, gym, or travel | Environments where bottled water is scarce or expensive | Outdoor activities, sports events, or long hikes |

Gedetailleerd overzicht van alternatieven

Waterfiltersystemen

Water filtration systems are designed to purify water from municipal supplies or natural sources, making it safe for consumption. These systems can range from simple pitcher filters to complex under-sink setups. The primary advantage is the cost-effectiveness over time, as they eliminate the need for purchasing bottled water. However, the initial setup cost can be substantial, and ongoing maintenance is necessary to ensure optimal performance. For businesses operating in areas with limited access to clean water or where bottled water is prohibitively expensive, filtration systems represent a sustainable solution.

Hydratatie Pakken

Hydration packs, which are worn like backpacks and come with built-in reservoirs and tubes for drinking, are particularly popular among outdoor enthusiasts and athletes. They provide hands-free hydration, allowing users to drink while on the move. This convenience makes hydration packs ideal for sports events, hiking, and cycling. While they generally have a moderate upfront cost, their reusable nature can lead to savings over time. However, they may require more maintenance than traditional water bottles, as cleaning the reservoir and tubes can be cumbersome.

Conclusie: De juiste oplossing kiezen voor uw behoeften

When considering hydration solutions, B2B buyers should evaluate their specific requirements, such as budget constraints, usage contexts, and maintenance capabilities. Different size water bottles offer flexibility and immediate access to hydration, making them suitable for various settings. Conversely, water filtration systems can provide long-term savings and sustainability, while hydration packs cater to active lifestyles. By assessing the performance, cost, ease of implementation, maintenance needs, and ideal use cases, businesses can select the most effective hydration solution that aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for different size water bottles

What Are the Key Technical Properties of Different Size Water Bottles?

When sourcing water bottles for B2B purposes, understanding the technical specifications is crucial for ensuring product quality and compliance with industry standards. Here are some essential properties to consider:

-

Materiaalklasse

– Water bottles are typically made from materials such as BPA-free plastic, stainless steel, aluminum, and glass. Each material has unique properties affecting durability, insulation, and safety. For example, BPA-free plastics are essential for health-conscious markets, while stainless steel is preferred for its durability and insulation capabilities. -

Capacity and Size Specifications

– Water bottles come in various sizes, ranging from 8 oz to 5 gallons. Understanding the specific capacities helps in meeting customer needs and ensuring that the bottles are suitable for their intended use, whether for personal hydration, outdoor activities, or bulk distribution. -

Neck Size

– The neck size of a bottle is crucial for compatibility with caps and dispensers. Common neck sizes include 24-400, 28-400, and 38-400. Proper neck sizing ensures that the bottle can be sealed tightly, which is vital for preventing leaks and maintaining product integrity. -

Tolerance Levels

– Tolerance refers to the acceptable range of variation in manufacturing dimensions. In water bottles, this can affect the fit of caps, the bottle’s ability to withstand pressure, and overall quality. High tolerance levels are vital for maintaining consistency across large production runs, which is particularly important for OEM partnerships. -

Insulation Properties

– For bottles designed to keep beverages hot or cold, insulation properties are paramount. Double-walled stainless steel bottles, for example, are known for their excellent thermal retention. Understanding insulation technology can influence product selection based on market demands for performance. -

Gewicht en draagbaarheid

– The weight of water bottles can significantly affect their usability, especially for travel and outdoor activities. Lightweight materials are preferred for portable options, while heavier materials may be acceptable for stationary use. Evaluating weight ensures that the product meets the end-user’s needs, enhancing customer satisfaction.

What Are Common Trade Terms in the Water Bottle Industry?

Navigating the B2B water bottle market requires familiarity with specific trade terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the water bottle industry, businesses often partner with OEMs for custom designs or bulk production, allowing them to offer unique products without significant upfront investment. -

MOQ (minimale bestelhoeveelheid)

– MOQ indicates the smallest quantity of product that a supplier is willing to sell. Understanding MOQ is critical for budget-conscious buyers, as it affects inventory management and pricing strategies. It is essential to negotiate MOQs that align with demand forecasts. -

RFQ (Offerteaanvraag)

– An RFQ is a document sent to suppliers asking for pricing and terms for a specific quantity of goods. This process is vital for B2B transactions, allowing companies to compare offers and negotiate favorable terms before making purchasing decisions. -

Incoterms (internationale handelsvoorwaarden)

– These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping responsibilities, insurance, and risk management, which are crucial for smooth cross-border trade. -

Doorlooptijd

– This term refers to the time taken from placing an order to receiving the goods. Understanding lead times helps businesses plan their inventory and manage customer expectations. It is particularly important when sourcing from international suppliers, where shipping times can vary significantly. -

Sustainability Standards

– With increasing awareness of environmental issues, sustainability standards refer to the guidelines and certifications that ensure products are eco-friendly. Buyers should be aware of these standards to align with consumer preferences and regulatory requirements, particularly in regions where sustainability is a significant concern.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing water bottles, ensuring they meet market demands and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the different size water bottles Sector

What Are the Key Market Dynamics Influencing the Different Size Water Bottles Sector?

The global water bottle market is experiencing significant growth, driven by increasing health awareness and a shift toward sustainable living. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for both reusable and disposable water bottles. The market is projected to expand as more consumers prioritize hydration, sustainability, and convenience. Emerging trends include the customization of bottle sizes and shapes to cater to specific consumer needs, such as gym-goers preferring 20 oz bottles, while outdoor enthusiasts lean towards larger 32 oz or 64 oz options.

Technological advancements are shaping sourcing practices, with digital platforms facilitating the procurement process. B2B buyers can now leverage online marketplaces to compare products, assess supplier reliability, and evaluate pricing. Furthermore, the advent of smart water bottles, equipped with hydration tracking features, is gaining traction, offering opportunities for innovative suppliers to differentiate themselves in the market.

How Does Sustainability Impact Sourcing Trends in the Water Bottles Sector?

Sustainability is increasingly becoming a focal point for B2B buyers in the water bottle sector. The environmental impact of plastic waste has prompted a shift towards eco-friendly materials, such as BPA-free plastics, stainless steel, and glass. As a result, suppliers are increasingly emphasizing ethical sourcing practices and transparency in their supply chains. Buyers are now more inclined to partner with manufacturers that prioritize sustainability, offering products made from recycled materials or those with certifications like FSC (Forest Stewardship Council) or ISO 14001.

Ethical sourcing not only aligns with corporate social responsibility goals but also meets the growing consumer demand for sustainable products. B2B buyers should evaluate potential suppliers based on their commitment to sustainability and ethical practices, as these factors can significantly influence brand reputation and customer loyalty. Additionally, investing in ‘green’ certifications can enhance marketability and provide a competitive edge in regions where environmental consciousness is paramount.

What Is the Historical Evolution of Water Bottles and Its Relevance to B2B Buyers?

The evolution of water bottles traces back to the early 20th century, primarily with the introduction of glass bottles. Over the decades, the advent of plastic revolutionized the industry, leading to the mass production of lightweight, disposable bottles. However, growing environmental concerns over single-use plastics have spurred a resurgence in the popularity of reusable bottles, particularly those made from sustainable materials.

For B2B buyers, understanding this historical context is crucial, as it underscores the shifting consumer preferences towards sustainability and ethical sourcing. This evolution also highlights the opportunities for suppliers to innovate and adapt their product offerings in line with market demands. By recognizing these trends, B2B buyers can make informed sourcing decisions that align with both their business objectives and the values of their target market.

Frequently Asked Questions (FAQs) for B2B Buyers of different size water bottles

-

How do I choose the right size water bottle for my business needs?

Selecting the appropriate size of water bottles for your business hinges on understanding your target market and usage scenarios. For everyday office use, a medium bottle (20 oz to 32 oz) is often ideal, as it provides ample hydration without being cumbersome. If your business caters to outdoor events or athletic activities, larger bottles (40 oz to 64 oz) may be more suitable, ensuring users have enough water for extended periods. Always consider factors such as portability, refill frequency, and the audience’s hydration habits to make an informed choice. -

What is the most common size for a water bottle in the B2B market?

The most prevalent size for water bottles in the B2B market is typically 16.9 oz (500 ml), which aligns with standard disposable bottles. However, reusable options like 20 oz to 32 oz bottles are increasingly popular for their balance between capacity and convenience. These sizes cater to various needs, including office use, events, and fitness activities, making them versatile options for bulk purchases. Understanding market trends can help you choose sizes that resonate with your clientele. -

How can I ensure the quality of the water bottles I am sourcing?

To ensure the quality of sourced water bottles, it’s essential to vet suppliers rigorously. Request samples to assess material durability, insulation properties, and design quality. Look for certifications such as BPA-free and compliance with international standards. Additionally, inquire about their manufacturing processes and quality assurance protocols. Establishing a strong relationship with suppliers who have a proven track record of quality can significantly mitigate risks associated with sourcing inferior products. -

What are the typical minimum order quantities (MOQs) for bulk water bottles?

Minimum order quantities for bulk water bottles can vary widely depending on the supplier and bottle specifications. Generally, MOQs can range from as low as 100 units for smaller suppliers to several thousand units for larger manufacturers. It’s crucial to discuss your requirements directly with potential suppliers to negotiate terms that align with your business needs. Understanding their production capabilities can also help in managing inventory effectively. -

What customization options are available for water bottles?

Many suppliers offer a range of customization options for water bottles, including size, color, material, and branding features. Common choices include screen printing or embossing your company logo and choosing specific lid styles or additional features like straws or handles. When considering customization, clarify the costs, lead times, and minimum order requirements. Personalized bottles can enhance brand visibility and create a unique product that resonates with your audience. -

What payment terms should I expect when sourcing water bottles internationally?

Payment terms for international sourcing can vary, but common practices include a deposit upfront (typically 30-50%) and the balance upon delivery or before shipping. Some suppliers may offer flexible terms based on your relationship and order size. It’s essential to discuss payment methods (e.g., wire transfer, letters of credit) and ensure they align with your financial capabilities. Understanding these terms upfront can help avoid cash flow issues during the transaction. -

How should I handle logistics and shipping for international orders of water bottles?

When managing logistics for international orders, consider partnering with a reliable freight forwarder who can navigate customs regulations and shipping routes efficiently. Determine whether you prefer air or sea freight based on budget and urgency. It’s also wise to discuss shipping insurance and incoterms with your supplier to clarify responsibilities. Establishing a clear logistics plan can prevent delays and ensure timely delivery of your products. -

What are the environmental considerations when sourcing water bottles?

In today’s market, sustainability is a key consideration for B2B buyers. Look for suppliers who offer eco-friendly materials, such as BPA-free plastics or stainless steel, and those that have sustainable manufacturing practices. Certifications like ISO 14001 can indicate a commitment to environmental management. Additionally, consider how the bottles are packaged and shipped, as minimizing waste and opting for recyclable materials can align with your company’s sustainability goals and appeal to environmentally conscious consumers.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 6 Different Size Water Bottles Manufacturers & Suppliers List

1. The Water Bottle Store – Reusable Water Bottles

Domein: thewaterbottlestore.com

Geregistreerd: 2005 (20 jaar)

Inleiding: Reusable water bottles available in various sizes including 1 Liter/32 oz, 13 oz, and 20 oz. Brands include Asobu, Aquaovo, EarthLust, EcoVessel, KOR, Nalgene, and New Wave Enviro. Materials include BPA-free plastic, stainless steel, glass, and silicone. Types of bottles include insulated, collapsible, filtered, freezable, infuser, and kids’ water bottles. Sizes range from <8oz to 5 Gallon. Replac…

2. My Own Water – Versatile Water Bottles

Domein: myownwater.com

Geregistreerd: 2000 (25 jaar)

Inleiding: We offer several water bottle sizes ranging from 8 oz up to 1 gallon. Our bottles come in a variety of styles and materials, including:

1. **Value Bottles** (Ribbed style, made from BPA free PET plastic):

– 8 oz

– 10 oz

– 12 oz

– 16.9 oz

– 23.7 oz

– 33.8 oz

2. **Modern Bottles** (Sleek design, no ribs):

– 12 oz

– 16.9 oz

– 23.7 oz

– 33.8 oz

– 50 oz

3. **Aluminum…

3. HydraPeak – Water Bottles

Domein: hydrapeak.com

Geregistreerd: 2017 (8 jaar)

Inleiding: {“product_types”:[{“name”:”Water Bottle”,”count”:7}],”sizes”:[{“size”:”14 oz”,”count”:1},{“size”:”20 oz”,”count”:1},{“size”:”26 oz”,”count”:3},{“size”:”32 oz”,”count”:2}],”features”:[{“type”:”Straw”,”count”:4},{“type”:”Chug”,”count”:2}],”colors”:[{“name”:”Alpine”,”count”:3},{“name”:”Belize”,”count”:1},{“name”:”Black”,”count”:4},{“name”:”Bubble Gum”,”count”:4},{“name”:”Citrus”,”count”:2},{“name”:”C…

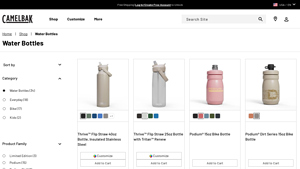

4. CamelBak – Key Products

Domein: camelbak.nl

Geregistreerd: 1996 (29 jaar)

Inleiding: CamelBak offers a variety of adventure-ready water bottles, including the following key products: 1. Thrive™ Flip Straw 40oz Bottle, Insulated Stainless Steel – Price: $27.99 (reduced from $37.99) 2. Thrive™ Flip Straw 25oz Bottle with Tritan™ Renew – Price: $12.99 (reduced from $17.99) 3. Podium® 15oz Bike Bottle – Price: $8.99 (reduced from $12.00) 4. Podium® Dirt Series 15oz Bike Bottle – Price…

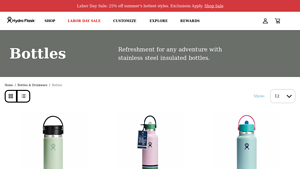

5. Hydro Flask – 16 oz Coffee with Flex Sip™ Lid

Domein: hydroflask.com

Geregistreerd: 2009 (16 jaar)

Inleiding: Insulated & Stainless Steel Water Bottles | Hydro Flask

Labor Day Sale: 25% off summer’s hottest styles. Exclusions Apply.

Free shipping on orders $39+

Key Products:

– 16 oz Coffee with Flex Sip™ Lid – $32.95 (Sale Price: $24.71)

– 21 oz Standard Mouth with Flex Straw Cap – $34.95

– Remix 32 oz Wide Mouth with Flex Straw Cap – Polar Plunge – Sale Price: $22.48 (Original Price: $44.95)

– Remix 24…

6. Hydro Flask – 24 oz Wide Mouth with Flex Chug Cap

Domein: nytimes.com

Geregistreerd: 1994 (31 jaar)

Inleiding: Dit bedrijf, Hydro Flask - 24 oz Wide Mouth with Flex Chug Cap, is een opmerkelijke entiteit op de markt. Voor specifieke productdetails kun je het beste direct naar hun website gaan.

Strategic Sourcing Conclusion and Outlook for different size water bottles

In conclusion, the strategic sourcing of different sizes of water bottles is a crucial consideration for international B2B buyers seeking to enhance their product offerings and meet diverse consumer needs. With sizes ranging from compact 8 oz bottles for children to robust 64 oz options for outdoor enthusiasts, understanding the market demand allows businesses to tailor their inventory effectively.

Investing in quality materials, such as BPA-free plastics and stainless steel, not only ensures durability but also aligns with growing consumer preferences for sustainability. Buyers should prioritize suppliers who offer a variety of styles and sizes, enabling them to cater to various segments, including fitness enthusiasts, office workers, and travelers.

As we look to the future, it is essential for B2B buyers in Africa, South America, the Middle East, and Europe to leverage strategic sourcing to adapt to evolving market trends. Embrace innovation and sustainability in your product selections, and consider forming partnerships with manufacturers who can provide customized solutions. The right choices today will position your business for success in the competitive landscape of water bottle distribution.