Introduction: Navigating the Global Market for custom engraved stainless water bottle

In today’s global marketplace, sourcing custom engraved stainless water bottles presents both opportunities and challenges for B2B buyers. With increasing consumer demand for sustainable and personalized products, businesses must navigate a plethora of options to find the right suppliers who can deliver high-quality, customized solutions that align with their branding and functional needs. This guide offers a comprehensive overview of the various types of custom engraved stainless water bottles available, their diverse applications across different industries, and essential considerations for supplier vetting.

From understanding the manufacturing process and exploring the latest design trends to assessing costs and negotiating contracts, this guide empowers international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil—to make informed purchasing decisions. By highlighting best practices in sourcing and showcasing innovative examples, we aim to equip buyers with the knowledge necessary to enhance their product offerings and strengthen customer loyalty through customized solutions. Whether you are a distributor, retailer, or corporate buyer, our insights will help you navigate the complexities of the market and secure the best custom engraved stainless water bottles for your needs.

Artikel navigatie

- Top 10 Custom Engraved Stainless Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom engraved stainless water bottle

- Understanding custom engraved stainless water bottle Types and Variations

- Key Industrial Applications of custom engraved stainless water bottle

- 3 Common User Pain Points for ‘custom engraved stainless water bottle’ & Their Solutions

- Strategic Material Selection Guide for custom engraved stainless water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for custom engraved stainless water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom engraved stainless water bottle’

- Comprehensive Cost and Pricing Analysis for custom engraved stainless water bottle Sourcing

- Alternatives Analysis: Comparing custom engraved stainless water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for custom engraved stainless water bottle

- Navigating Market Dynamics and Sourcing Trends in the custom engraved stainless water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom engraved stainless water bottle

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for custom engraved stainless water bottle

Understanding custom engraved stainless water bottle Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Laser Engraved Bottles | Precision engraving, high durability, customizable designs | Corporate gifts, promotional items | Voordelen: Long-lasting branding; Minpunten: Hogere initiële kosten. |

| Color Printed Bottles | Vibrant graphics, multi-color options, suitable for complex designs | Marketing campaigns, events | Voordelen: Eye-catching; Minpunten: May fade over time. |

| Insulated Stainless Bottles | Double-walled, vacuum insulation, keeps beverages hot or cold | Outdoor events, sports sponsorships | Voordelen: Functional; Minpunten: Slightly heavier. |

| Flip-top or Straw Bottles | Convenient drinking mechanisms, often with built-in straws | Fitness promotions, giveaways | Voordelen: User-friendly; Minpunten: More parts to clean. |

| Custom Shaped Bottles | Unique designs tailored to brand identity, various shapes available | Niche marketing, brand differentiation | Voordelen: Stand out from competitors; Minpunten: Limited production options. |

What Are the Characteristics of Laser Engraved Bottles?

Laser engraved bottles are renowned for their precision and durability. The engraving process creates a permanent mark that can withstand wear and tear, making it an ideal choice for corporate gifts or promotional items. Businesses looking to establish a strong brand presence can benefit from this type of bottle, as it offers a sophisticated look that appeals to a professional audience. When considering this option, buyers should weigh the initial investment against the longevity of the branding.

How Do Color Printed Bottles Enhance Marketing Efforts?

Color printed bottles are designed to captivate attention with vibrant graphics and multi-color options. This versatility allows brands to incorporate complex designs, logos, or slogans, making them suitable for marketing campaigns and events. However, while they offer an eye-catching solution, it’s important for buyers to consider the potential for fading over time, which may affect the longevity of their promotional message.

Why Choose Insulated Stainless Bottles for Events?

Insulated stainless bottles are double-walled and vacuum-sealed, ensuring beverages maintain their temperature for extended periods. This feature makes them particularly appealing for outdoor events or sports sponsorships, where functionality is paramount. Businesses can leverage these bottles as practical gifts that enhance the user experience. Buyers should consider the slight increase in weight compared to standard bottles, which could influence shipping and handling costs.

What Are the Benefits of Flip-top or Straw Bottles?

Flip-top or straw bottles provide a convenient drinking mechanism that appeals to fitness enthusiasts and active individuals. Their user-friendly design is perfect for fitness promotions or giveaways, ensuring that users can hydrate easily on the go. While they offer significant convenience, buyers should be aware that the additional parts may require more maintenance and cleaning, which could affect usability.

How Do Custom Shaped Bottles Differentiate Brands?

Custom shaped bottles are tailored to reflect a brand’s unique identity, allowing companies to stand out in a crowded market. These bottles can be designed in various shapes, aligning with specific marketing themes or product lines. While they offer a distinct advantage in branding, buyers should consider the potential limitations in production options and costs associated with creating molds for unique designs.

Key Industrial Applications of custom engraved stainless water bottle

| Industrie/sector | Specific Application of custom engraved stainless water bottle | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Relatiegeschenken | Custom engraved water bottles for employee gifts and incentives | Enhances employee satisfaction and brand loyalty | Consider bulk ordering options, customization capabilities, and lead times. |

| Hospitality & Events | Branded water bottles for events, conferences, and promotions | Increases brand visibility and provides a practical takeaway for attendees | Evaluate quality, design options, and sustainable materials. |

| Health & Wellness | Personalized bottles for fitness centers and wellness programs | Promotes healthy hydration habits among clients | Look for durable designs, insulation properties, and the ability to withstand rigorous use. |

| Educational Institutions | Engraved bottles as student gifts or merchandise | Fosters school spirit and provides a reusable alternative to plastic | Assess customization options, pricing for bulk orders, and shipping logistics. |

| Outdoor & Adventure | Custom bottles for outdoor brands or adventure companies | Aligns with eco-friendly initiatives and promotes brand identity | Ensure product durability, insulation, and suitability for various climates. |

How Are Custom Engraved Stainless Water Bottles Used in Corporate Gifts?

In the corporate sector, custom engraved stainless water bottles serve as thoughtful gifts for employees, enhancing morale and fostering a sense of belonging. Companies can personalize these bottles with logos or motivational quotes, reinforcing brand loyalty. For international buyers, ensuring that the bottles are produced sustainably can also align with corporate social responsibility goals, making them an attractive option for employee incentives across diverse markets, including Africa and Europe.

What Role Do Custom Engraved Water Bottles Play in Hospitality and Events?

In the hospitality and events sector, custom engraved stainless water bottles are popular for branding at conferences, trade shows, and corporate events. They offer a practical and eco-friendly alternative to single-use plastics, enhancing the attendee experience while promoting the brand. For B2B buyers in South America and the Middle East, considerations around design and local market preferences are crucial to ensure the product resonates with the audience.

How Do Custom Engraved Bottles Promote Health and Wellness?

Fitness centers and wellness programs utilize custom engraved stainless water bottles to encourage healthy hydration habits among their clients. These bottles can be personalized with gym logos or motivational messages, creating a connection between the brand and its members. Buyers from Europe and Africa should focus on sourcing bottles that are durable, easy to clean, and insulated to maintain beverage temperatures, catering to the active lifestyles of their clientele.

Why Are Custom Engraved Bottles Valuable for Educational Institutions?

Educational institutions often use custom engraved water bottles as merchandise or gifts for students, promoting school spirit and providing a sustainable alternative to disposable plastic bottles. These items can be customized with school logos or mottos, enhancing their appeal. For international buyers in regions like Brazil, understanding local educational trends and pricing for bulk orders can facilitate effective procurement strategies.

How Are Custom Engraved Bottles Beneficial for Outdoor and Adventure Brands?

Outdoor and adventure brands leverage custom engraved stainless water bottles as part of their marketing strategy, aligning with eco-friendly initiatives and enhancing brand identity. These bottles are not only practical for outdoor activities but also serve as a reminder of the brand’s commitment to sustainability. Buyers in the Middle East and Africa should prioritize sourcing products that are durable and capable of withstanding diverse environmental conditions, ensuring they meet the needs of adventure enthusiasts.

3 Common User Pain Points for ‘custom engraved stainless water bottle’ & Their Solutions

Scenario 1: Difficulty in Meeting Customization Requirements

Het probleem: Many B2B buyers face challenges when attempting to customize stainless steel water bottles to meet their branding or promotional needs. This includes selecting the right engraving method, color options, and ensuring that the design aligns with their brand image. Additionally, different suppliers may offer varying capabilities regarding customization, leading to confusion and potential mismatches in expectations. Buyers often worry about whether the final product will accurately reflect their desired specifications, which can lead to frustration and wasted resources.

De oplossing: To overcome this issue, B2B buyers should start by conducting thorough research on potential suppliers who specialize in custom engraved stainless steel water bottles. It is essential to request samples of previous work to evaluate engraving quality and design capabilities. Buyers should also prepare a detailed design brief that includes specific requirements such as preferred engraving methods (e.g., laser engraving vs. color printing), color preferences, and branding elements. This level of detail will help suppliers understand expectations clearly and minimize the risk of miscommunication. Moreover, engaging in open dialogue with suppliers during the design process can facilitate adjustments and improvements before final production, ensuring the final product aligns with the buyer’s vision.

Scenario 2: Concerns Over Quality and Durability

Het probleem: Quality and durability are paramount concerns for B2B buyers investing in custom engraved stainless water bottles, particularly when the bottles are intended for corporate gifts or promotional giveaways. Buyers often question whether the materials used will withstand daily use, and whether the engraving will remain intact over time. There is a fear that poor-quality products could reflect badly on their brand, especially if the items are given to clients or employees as tokens of appreciation.

De oplossing: To address these quality concerns, B2B buyers should prioritize suppliers who offer high-grade stainless steel and provide clear information on their manufacturing processes. Buyers can request certifications or details about the materials used to ensure they meet industry standards. Additionally, it’s beneficial to ask about warranty policies and customer reviews to gauge the longevity of the products. Engaging in conversations about the durability of the engraving process—such as whether the design will chip or fade—can also provide buyers with greater assurance. By choosing suppliers known for their quality craftsmanship and durability, buyers can confidently select products that will uphold their brand’s reputation.

Scenario 3: Navigating Minimum Order Quantities and Pricing

Het probleem: B2B buyers often struggle with minimum order quantities (MOQs) and pricing structures when sourcing custom engraved stainless water bottles. Suppliers may impose high MOQs that exceed the buyer’s needs, leading to financial strain or surplus inventory. Furthermore, without a clear understanding of pricing tiers, buyers can feel overwhelmed by the prospect of budgeting for their orders, especially when factoring in customization costs.

De oplossing: To effectively navigate this challenge, B2B buyers should seek suppliers who are flexible with MOQs or offer tiered pricing based on order size. Initiating conversations with potential suppliers about their willingness to accommodate smaller orders can open doors to tailored solutions. Buyers should also consider leveraging group purchasing with other businesses to meet MOQ requirements while sharing costs. Additionally, requesting a detailed breakdown of pricing—including base costs, customization fees, and shipping—can help buyers make informed decisions and budget accordingly. Establishing strong relationships with suppliers who understand the buyer’s needs can lead to more favorable terms and a better overall purchasing experience.

Strategic Material Selection Guide for custom engraved stainless water bottle

When selecting materials for custom engraved stainless water bottles, B2B buyers must consider various factors that influence product performance, durability, and compliance with regional standards. Below is a detailed analysis of common materials used in the manufacturing of these bottles, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

What Are the Key Properties of Stainless Steel for Water Bottles?

Stainless Steel (304 and 316 Grades)

Stainless steel is the most commonly used material for custom engraved water bottles. The 304 grade is known for its excellent corrosion resistance and is suitable for a wide range of temperatures. The 316 grade offers even better corrosion resistance, particularly against chlorides, making it ideal for marine environments.

- Voordelen: Stainless steel is highly durable, resistant to rust and corrosion, and can withstand high temperatures. It is also easy to clean and maintain, making it suitable for repeated use.

- Minpunten: The initial cost of stainless steel can be higher compared to other materials. Additionally, it can be heavier, which may not appeal to all consumers.

- Invloed op de toepassing: Stainless steel bottles are compatible with various beverages, including acidic drinks, without leaching harmful substances. They maintain the temperature of liquids effectively, making them suitable for both hot and cold beverages.

- Overwegingen voor internationale kopers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should ensure that the stainless steel used is food-grade and meets local regulations, particularly in regions with stringent health and safety standards.

How Do Plastic and Aluminum Compare in Terms of Performance?

Plastic (BPA-Free Polypropylene)

BPA-free plastics are lightweight and cost-effective alternatives to stainless steel. They are often used for promotional items and are available in various colors and designs.

- Voordelen: Plastic bottles are lightweight, affordable, and can be produced in bulk with various customization options.

- Minpunten: They are less durable than stainless steel and can warp or degrade over time, especially with exposure to heat. Additionally, they may retain odors and flavors from previous contents.

- Invloed op de toepassing: While suitable for cold beverages, plastic bottles may not be ideal for hot liquids. They are often used in promotional settings where cost is a primary concern.

- Overwegingen voor internationale kopers: Ensure compliance with local regulations regarding food safety and material safety standards. In regions like Europe, strict regulations on plastic use may limit options.

Aluminium

Aluminum bottles are lightweight and offer a sleek appearance. They are often coated to prevent reactions with acidic beverages.

- Voordelen: Aluminum is lightweight and can be produced in various colors and finishes. It also provides good thermal insulation.

- Minpunten: Aluminum is prone to denting and may not be as durable as stainless steel. It can also react with certain beverages unless properly coated.

- Invloed op de toepassing: Aluminum bottles are suitable for cold beverages but may not be ideal for hot liquids without a protective lining. They are often used in outdoor and sports settings.

- Overwegingen voor internationale kopers: Buyers should be aware of the coatings used, ensuring they comply with safety standards. In markets with high temperatures, the thermal properties of aluminum may be a concern.

What Are the Emerging Trends in Material Selection for Custom Engraved Bottles?

Recycled Materials (Recycled Stainless Steel or Plastic)

Sustainability is becoming increasingly important in product selection. Bottles made from recycled materials appeal to environmentally conscious consumers.

- Voordelen: Using recycled materials reduces environmental impact and can lower production costs. They also align with corporate social responsibility goals.

- Minpunten: The availability of high-quality recycled materials can vary, potentially affecting product consistency and performance.

- Invloed op de toepassing: These bottles can be used for various beverages, but quality assurance is critical to ensure they meet safety standards.

- Overwegingen voor internationale kopers: Buyers should verify the source and quality of recycled materials to ensure compliance with local regulations and standards.

Summary Table of Material Properties for Custom Engraved Stainless Water Bottles

| Materiaal | Typical Use Case for custom engraved stainless water bottle | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Stainless Steel (304/316) | Hot and cold beverages, outdoor use | Excellent durability and corrosion resistance | Hogere initiële kosten | Hoog |

| Plastic (BPA-Free) | Promotional items, cold beverages | Lichtgewicht en kosteneffectief | Less durable, can retain odors | Laag |

| Aluminium | Sports and outdoor activities | Lightweight and customizable | Prone to denting, may react with beverages | Medium |

| Recycled Materials | Eco-friendly promotional items | Sustainable and reduces environmental impact | Variable quality and performance | Medium |

This analysis provides B2B buyers with a comprehensive understanding of material options for custom engraved stainless water bottles, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for custom engraved stainless water bottle

What Are the Key Stages in the Manufacturing Process of Custom Engraved Stainless Water Bottles?

The manufacturing of custom engraved stainless water bottles involves several critical stages that ensure the final product meets both aesthetic and functional requirements. The main stages include material preparation, forming, assembly, and finishing.

-

Materiaalvoorbereiding: The process begins with sourcing high-quality stainless steel, typically grade 304 or 316, known for its corrosion resistance and durability. The raw materials are inspected and tested for compliance with relevant standards. This stage may also involve cutting the stainless steel sheets into appropriate sizes for the bottle components.

-

Het vormen van: The cut stainless steel is then shaped into the desired bottle form using techniques such as deep drawing or spinning. In deep drawing, the steel is pressed into a mold to create the bottle’s shape. This process must be closely monitored to avoid defects such as thinning or cracking.

-

Montage: After forming, the different parts of the water bottle—such as the body, cap, and any insulation layers—are assembled. This stage may involve welding or the use of food-grade adhesives. Proper alignment and fitting are crucial to ensure the bottle is leak-proof and functions as intended.

-

Afwerking: The final stage involves polishing, coating, and engraving. Polishing improves the bottle’s aesthetic appeal and surface smoothness, while protective coatings may be applied to enhance durability. For custom engraving, laser engraving techniques are often used for precision and detail. This method allows for intricate designs and personalization without compromising the material integrity.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is vital in ensuring that the final product adheres to industry standards and customer expectations. Various international and industry-specific standards guide the quality assurance process.

-

Relevant International Standards: Compliance with ISO 9001 is essential for manufacturers, as it outlines the requirements for a quality management system. This certification ensures that the manufacturing process is efficient and that products consistently meet customer and regulatory requirements. Other standards, such as CE marking for products sold in the European Economic Area, may also apply, particularly regarding safety and health.

-

Kwaliteitscontrolepunten: Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and rectify defects early. Common checkpoints include:

– Inkomende kwaliteitscontrole (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

– Kwaliteitscontrole tijdens het proces (IPQC): This ongoing inspection occurs during various stages of manufacturing to monitor processes and identify any deviations from quality standards.

– Finale kwaliteitscontrole (FQC): After finishing, a comprehensive inspection is conducted to ensure that the final product meets all design specifications and quality standards before shipping. -

Gangbare testmethoden: Various testing methods are employed to verify the quality of the stainless steel water bottles. These may include:

– Pressure Testing: To ensure that the bottles can withstand internal pressure without leaking.

– Drop Testing: To assess durability and the ability to withstand impacts.

– Thermal Testing: To evaluate insulation performance for bottles designed to keep beverages hot or cold.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

-

Audits and Reports: Buyers should request regular quality audit reports from suppliers. These reports should detail the outcomes of internal audits, including any corrective actions taken. An on-site audit may also be beneficial for assessing the manufacturing environment and quality control processes firsthand.

-

Inspecties door derden: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of production, ensuring compliance with international standards and providing an additional layer of assurance.

-

Certification Verification: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001, CE, and any other applicable industry-specific certifications. This verification can usually be done through the certifying bodies.

Wat zijn de nuances op het gebied van kwaliteitscontrole voor internationale B2B-kopers?

Understanding the nuances of quality control is critical for international B2B buyers, as different regions may have varying standards and expectations.

-

Regionale normen: Different countries may have specific regulations regarding product safety and quality. For instance, EU regulations may be stricter compared to those in other regions. Buyers should be aware of these differences and ensure that suppliers comply with the necessary regulations for their target markets.

-

Culturele overwegingen: Communication styles and business practices can differ significantly across regions. Establishing clear expectations regarding quality standards and compliance is essential. Buyers should engage in open discussions with suppliers to ensure mutual understanding.

-

Supply Chain Transparency: Buyers should prioritize suppliers who demonstrate transparency in their manufacturing processes. This includes clear documentation of materials used, production methods, and quality assurance practices. Transparency builds trust and facilitates smoother transactions.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing custom engraved stainless water bottles, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom engraved stainless water bottle’

Inleiding

This guide serves as a comprehensive checklist for B2B buyers looking to source custom engraved stainless steel water bottles. With the rising demand for personalized and sustainable products, ensuring you follow a structured approach will help you make informed decisions and secure high-quality products that meet your business needs.

Stap 1: Identify Your Target Market

Understanding your audience is essential for choosing the right product specifications. Consider factors such as age, lifestyle, and environmental awareness, as these will influence your design and branding choices. Tailoring your product to fit your market can enhance customer satisfaction and boost sales.

Stap 2: Je technische specificaties definiëren

Clearly outline the specifications for the stainless steel water bottles you wish to procure. This includes:

– Capacity Options: Determine if you need various sizes (e.g., 12oz, 20oz, 36oz) to cater to different consumer preferences.

– Material Quality: Ensure the bottles are made from high-grade stainless steel for durability and safety.

– Customization Features: Decide on engraving methods (laser engraving vs. color printing) and design elements (logos, monograms).

Stap 3: Potentiële leveranciers evalueren

Before committing to any supplier, conduct thorough evaluations. Request detailed company profiles, production capabilities, and case studies. Additionally:

– Check References: Reach out to other businesses that have sourced similar products.

– Assess Local vs. International Suppliers: Consider logistics, import duties, and delivery times, especially if you’re sourcing from different continents.

Stap 4: Monsters aanvragen

Always request samples before making a bulk purchase. This step is crucial to verify the product quality and engraving accuracy. When reviewing samples, focus on:

– Finish and Texture: Ensure the bottles have a premium feel and look.

– Engraving Quality: Confirm that the logo or design is clear and meets your branding standards.

Stap 5: Certificeringen en naleving controleren

Ensure that your suppliers comply with relevant health and safety regulations, especially for products intended for food and beverage use. Look for:

– ISO Certifications: Such as ISO 9001 for quality management systems.

– Sustainability Practices: Certifications like FDA approval for food safety and adherence to environmental standards.

Stap 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in discussions to negotiate pricing, payment terms, and delivery timelines. Pay attention to:

– Minimum Order Quantities (MOQs): Ensure they align with your purchasing power.

– Warranty and Return Policies: Understand the terms in case of defects or unsatisfactory products.

Stap 7: Plan voor logistiek en distributie

Finally, establish a clear logistics plan for transporting your products. Consider:

– Shipping Methods: Choose between air or sea freight based on cost and urgency.

– Customs Regulations: Be aware of import duties and regulations in your target markets to avoid delays.

By following these steps, you can ensure a smooth sourcing process for custom engraved stainless steel water bottles, ultimately leading to successful product launches and satisfied customers.

Comprehensive Cost and Pricing Analysis for custom engraved stainless water bottle Sourcing

What Are the Key Cost Components in Custom Engraved Stainless Water Bottles?

When sourcing custom engraved stainless water bottles, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materialen: The choice of stainless steel grade significantly impacts the cost. Higher-quality stainless steel (e.g., 304 grade) offers better corrosion resistance and durability but comes at a premium. Additionally, customization options such as color coatings or unique finishes can elevate material costs.

-

Arbeid: Labor costs encompass the workforce involved in manufacturing and engraving. Skilled labor is required for precise engraving, which can increase costs, especially if manual processes are involved. Automation in production can mitigate some labor costs but may require a larger upfront investment.

-

Productie Overhead: This includes utilities, facility costs, and equipment maintenance. Overhead can vary by region; for instance, manufacturers in Europe may have higher operational costs compared to those in Africa or South America.

-

Gereedschap: Custom molds and engraving tools represent a significant initial investment. The cost of tooling can be amortized over larger production runs, making it crucial to consider minimum order quantities (MOQs) when negotiating prices.

-

Kwaliteitscontrole (QC): Ensuring product quality is vital, particularly for branded items. Implementing rigorous QC processes can add to costs but is necessary to maintain brand reputation and customer satisfaction.

-

Logistiek: Shipping costs can vary widely based on the supplier’s location and the buyer’s destination. Factors such as freight costs, insurance, and customs duties should be factored into the total cost.

-

Marge: Suppliers typically apply a markup to cover their costs and profit margins. Understanding the typical margins in your industry can help you gauge whether a quoted price is fair.

How Do Price Influencers Affect the Cost of Custom Engraved Water Bottles?

Several factors influence the pricing of custom engraved stainless water bottles, including:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous to negotiate based on anticipated demand.

-

Specificaties en aanpassingen: The complexity of the design and the degree of customization will directly impact the price. Simple engravings will be less expensive than intricate designs or multi-color prints.

-

Materialen en kwaliteitscertificaten: Bottles that meet specific industry certifications (e.g., BPA-free, food safety standards) tend to be priced higher. Buyers should assess the importance of these certifications based on their target market.

-

Factoren van leveranciers: The supplier’s reputation, reliability, and production capabilities can significantly influence pricing. Established suppliers may command higher prices due to their proven quality and service.

-

Incoterms: International shipping terms can affect the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating total expenses.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Custom Engraved Bottles?

To optimize costs when sourcing custom engraved stainless water bottles, consider the following tips:

-

Conduct Market Research: Familiarize yourself with industry pricing standards and competitor offerings to strengthen your negotiating position.

-

Volumekortingen benutten: If your business can commit to larger orders, use this as leverage in negotiations to secure better pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial pricing. Consider factors such as durability, maintenance, and logistics when assessing overall costs.

-

Onderhandelen over voorwaarden: Don’t hesitate to negotiate payment terms, delivery schedules, and return policies. Flexible terms can enhance your cash flow and reduce risk.

-

Cultural Awareness: When dealing with suppliers from different regions, understanding cultural nuances in negotiation can improve communication and outcomes.

-

Build Long-Term Relationships: Establishing a solid partnership with suppliers can lead to better pricing and terms over time as trust develops.

Conclusie

Understanding the cost components and price influencers in sourcing custom engraved stainless water bottles is vital for B2B buyers. By leveraging negotiation strategies and considering the total cost of ownership, businesses can make informed purchasing decisions that align with their budget and quality requirements. Keep in mind that prices are indicative and may vary based on market conditions and supplier capabilities.

Alternatives Analysis: Comparing custom engraved stainless water bottle With Other Solutions

Exploring Alternatives to Custom Engraved Stainless Water Bottles

In the competitive landscape of promotional products, businesses often seek alternatives to custom engraved stainless water bottles that provide similar functionality, aesthetic appeal, and brand visibility. Understanding the various options available can help B2B buyers make informed decisions that align with their marketing strategies and budget constraints.

| Vergelijkingsaspect | Custom Engraved Stainless Water Bottle | Alternative 1: Plastic Water Bottles | Alternative 2: Glass Water Bottles |

|---|---|---|---|

| Prestaties | High durability and insulation | Lightweight but less durable | Breakable but stylish and eco-friendly |

| Kosten | Moderate to high cost | Low cost | Moderate cost |

| Gemak van implementatie | Requires specialized engraving | Simple printing or labeling | Requires careful handling in production |

| Onderhoud | Easy to clean, dishwasher safe | Generally low maintenance | Requires careful cleaning to avoid breakage |

| Beste gebruikscasus | Corporate gifts and events | Mass giveaways and promotional events | Eco-conscious branding initiatives |

What Are the Pros and Cons of Plastic Water Bottles?

Plastic water bottles offer a cost-effective alternative for businesses focused on large-scale distribution. Their lightweight nature makes them ideal for events where portability is essential. However, they lack the durability of stainless steel and may not provide insulation for hot or cold beverages. Additionally, while they can be printed with logos, the branding impact may not be as premium as engraved options, which can affect perceived value.

Why Consider Glass Water Bottles as an Alternative?

Glass water bottles present a stylish and eco-friendly option, appealing to environmentally conscious consumers. They can be customized with labels or etching, enhancing brand visibility. However, their fragility poses a risk during transportation and use, which can lead to higher replacement costs. Moreover, the production process may require more careful handling, impacting lead times. Glass bottles are best suited for brands that prioritize sustainability and aesthetics.

How to Choose the Right Solution for Your Needs?

When selecting the appropriate product for your promotional strategy, consider factors such as your target audience, budget, and intended use. Custom engraved stainless water bottles are ideal for creating lasting impressions through high-quality gifts. In contrast, plastic bottles may be better suited for mass giveaways where cost-effectiveness is paramount. Glass bottles can elevate brand perception but require careful management due to their fragility.

In conclusion, evaluating the performance, cost, implementation ease, maintenance, and best use case of each option will empower B2B buyers to make strategic choices. By aligning the selected solution with brand values and customer expectations, businesses can enhance their promotional efforts and foster stronger connections with their audience.

Essential Technical Properties and Trade Terminology for custom engraved stainless water bottle

What Are the Key Technical Properties of Custom Engraved Stainless Water Bottles?

When considering custom engraved stainless water bottles, several technical properties play a crucial role in determining their quality, functionality, and suitability for various applications. Understanding these properties can help B2B buyers make informed decisions.

1. Material Grade: What Type of Stainless Steel Is Used?

Stainless steel water bottles are typically made from grades such as 304 or 316. Grade 304 is the most common due to its excellent corrosion resistance and formability, making it suitable for everyday use. Grade 316, often referred to as marine grade, offers superior resistance to saltwater and is ideal for more demanding environments. For B2B buyers, selecting the right material grade ensures durability and longevity, reducing replacement costs.

2. Capacity: What Sizes Are Available?

Custom engraved stainless water bottles come in various capacities, commonly ranging from 12oz to 40oz. The choice of size depends on the intended use—whether for sports, daily hydration, or corporate gifting. Understanding the capacity options allows buyers to cater to specific market needs and consumer preferences, enhancing customer satisfaction.

3. Insulation Technology: How Does It Affect Performance?

Many stainless water bottles feature double-wall vacuum insulation, which keeps beverages hot or cold for extended periods. This technology is critical for consumers who prioritize temperature retention, such as athletes or outdoor enthusiasts. B2B buyers should consider insulation performance as a selling point, especially in regions with extreme temperatures.

4. Finish and Coating: What Aesthetic Options Are There?

The finish of the water bottle can vary from matte to glossy, and coatings can include powder coating or electroplating. These finishes not only enhance aesthetics but also provide additional protection against scratches and corrosion. For businesses, offering diverse finishes can appeal to various customer segments, allowing for more personalized branding opportunities.

5. Weight: How Does It Impact Portability?

The weight of the water bottle can significantly affect its portability. Lightweight options are favored for travel and outdoor activities, while heavier models may be perceived as more durable. Buyers should assess the balance between weight and sturdiness to meet the expectations of their target market.

6. Customization Options: How Can Brands Stand Out?

Customization options, including laser engraving, color printing, and monograms, allow businesses to create unique branding opportunities. This personalization can enhance brand recognition and customer loyalty. B2B buyers should evaluate the available customization methods to maximize their branding potential.

What Common Trade Terms Should B2B Buyers Know When Sourcing Custom Engraved Stainless Water Bottles?

Navigating the procurement process for custom engraved stainless water bottles involves familiarizing oneself with industry-specific terminology. Here are some essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer): What Does It Mean for Custom Products?

OEM refers to companies that produce goods based on specifications provided by another company. In the context of custom water bottles, this means that manufacturers can create products tailored to specific branding requirements. Understanding OEM relationships can lead to more effective sourcing strategies.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ indicates the smallest number of units a supplier is willing to produce for a given order. This term is vital for B2B buyers as it affects inventory management and cost efficiency. Buyers should negotiate MOQs that align with their sales forecasts to optimize cash flow.

3. RFQ (Request for Quotation): How to Get Accurate Pricing?

An RFQ is a document issued by buyers to solicit price quotes from suppliers. Including detailed specifications in an RFQ helps ensure that responses are accurate and comparable. This process is essential for budgeting and financial planning in procurement.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. Understanding these terms can clarify shipping costs, risks, and delivery responsibilities, which is crucial for B2B transactions across different countries.

5. Lead Time: What Is Its Significance in Production?

Lead time refers to the period between placing an order and receiving the product. Knowing the lead time helps businesses plan their inventory and marketing strategies effectively. Buyers should always inquire about lead times to ensure timely delivery.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing custom engraved stainless water bottles more effectively, ensuring a successful procurement process that meets their business needs.

Navigating Market Dynamics and Sourcing Trends in the custom engraved stainless water bottle Sector

What are the Key Market Trends Influencing the Custom Engraved Stainless Water Bottle Sector?

The custom engraved stainless water bottle market is experiencing robust growth driven by several global trends. As consumers increasingly prioritize health and wellness, there is a rising demand for eco-friendly and reusable products. This shift is particularly evident in regions like Africa, South America, the Middle East, and Europe, where sustainability is becoming a crucial buying criterion. Emerging B2B technologies, such as advanced laser engraving techniques and digital printing, are enhancing customization capabilities, allowing businesses to offer unique designs that resonate with consumers’ identities.

Moreover, the rise of e-commerce platforms has transformed sourcing dynamics, enabling international buyers to access a wider range of suppliers and products. The ability to compare prices, quality, and delivery times across different vendors empowers businesses to make informed purchasing decisions. In Europe, particularly in Germany, there is a significant trend toward personalized corporate gifts, which has led to increased interest in custom engraved products. Similarly, in Brazil, local brands are leveraging cultural motifs in their designs to appeal to regional consumers.

How is Sustainability Shaping the Sourcing of Custom Engraved Stainless Water Bottles?

Sustainability is a central theme influencing sourcing practices in the custom engraved stainless water bottle sector. Businesses are increasingly aware of the environmental impact of their supply chains, leading to a preference for suppliers that prioritize ethical practices. This includes using stainless steel that is either recycled or sourced from sustainable manufacturers. Buyers are also looking for certifications that demonstrate a commitment to environmental responsibility, such as the Forest Stewardship Council (FSC) certification and other eco-labels.

Incorporating eco-friendly materials and processes not only meets regulatory requirements but also enhances brand reputation. Companies that adopt sustainable practices often find that they can differentiate themselves in a competitive marketplace. For instance, using biodegradable packaging and promoting the recyclability of products can appeal to environmentally conscious consumers. This trend is particularly pronounced in the Middle East, where sustainability initiatives are gaining traction among both consumers and businesses.

What is the Historical Context of Custom Engraved Stainless Water Bottles in B2B?

The evolution of custom engraved stainless water bottles has its roots in the broader trends of personalization and sustainability that have gained momentum over the past two decades. Initially, stainless steel bottles were primarily marketed as durable alternatives to plastic. However, as awareness of environmental issues grew, the focus shifted toward customization, allowing businesses to promote their brands while catering to individual consumer preferences.

Technological advancements in engraving and printing have further revolutionized the sector, making it easier for companies to offer unique, personalized products. This evolution has positioned stainless steel bottles not just as functional items but also as lifestyle accessories, appealing to a diverse range of consumers across various markets. The confluence of these trends has solidified the custom engraved stainless water bottle as a staple in promotional merchandise, particularly in B2B contexts where brand visibility and sustainability are paramount.

Frequently Asked Questions (FAQs) for B2B Buyers of custom engraved stainless water bottle

-

How do I choose the right supplier for custom engraved stainless water bottles?

When selecting a supplier, consider their experience in the industry, customer reviews, and their production capabilities. Request samples to assess the quality of their products and engraving. Ensure they can meet your customization requirements, including design specifications and volume needs. Additionally, verify their compliance with international trade regulations, especially if you are importing from different continents, to avoid future complications. -

What are the typical minimum order quantities (MOQs) for custom engraved stainless water bottles?

MOQs can vary significantly based on the supplier and the complexity of customization. Generally, you might find MOQs ranging from 50 to 500 units. It’s advisable to discuss your specific needs with potential suppliers to see if they can accommodate smaller orders or provide bulk pricing for larger quantities. This flexibility can be crucial for businesses just starting or those testing new products in different markets. -

What customization options are available for engraved stainless water bottles?

Most suppliers offer various customization options, including laser engraving, color printing, and monogramming. You can often choose from different bottle sizes, colors, and materials. It’s essential to communicate your specific branding needs to the supplier, including logo placement and design intricacies, to ensure your product reflects your brand identity effectively. -

What payment terms should I expect when ordering custom products internationally?

Payment terms can differ widely among suppliers, but common practices include a deposit upfront (usually 30-50%) and the balance upon completion or before shipment. Some suppliers may offer net terms for established customers. Always clarify payment methods accepted (e.g., credit card, bank transfer) and ensure that you have a written agreement to avoid misunderstandings. -

How can I ensure quality assurance (QA) for my custom engraved water bottles?

To ensure quality, request a detailed quality assurance plan from your supplier, which should outline their inspection processes. Consider conducting a factory audit if possible, or request pre-shipment samples to check engraving quality and overall product standards. Additionally, inquire about warranties or return policies for defective items to safeguard your investment. -

What logistics considerations should I keep in mind for international shipping?

When shipping internationally, consider factors like customs duties, import regulations, and shipping costs. Choose a reliable logistics partner experienced in handling international shipments. Discuss delivery timelines and track your shipment to ensure timely arrival. It’s also wise to understand the implications of Incoterms (International Commercial Terms) to clarify responsibilities between you and the supplier. -

How do I handle potential delays in production and shipping?

Communicate regularly with your supplier to stay updated on production schedules and any potential delays. Establish clear timelines during the order process and ask about their contingency plans for unforeseen circumstances. If delays occur, evaluate alternative suppliers or consider adjusting your order schedule to minimize disruption to your business operations. -

What are the key benefits of using custom engraved stainless water bottles for my brand?

Custom engraved stainless water bottles serve as excellent promotional items that enhance brand visibility and customer loyalty. They are durable, reusable, and environmentally friendly, appealing to eco-conscious consumers. By incorporating your logo and branding, you create a product that customers will use regularly, thereby keeping your brand top of mind. This can lead to increased recognition and potential referrals, driving further business growth.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 10 Custom Engraved Stainless Water Bottle Manufacturers & Suppliers List

1. S’well – Customized Water Bottles

Domein: swell.com

Geregistreerd: 1998 (27 jaar)

Inleiding: Customized Water Bottles, S’well Custom Studio, Color Printing, Laser Engraving, Various Colors and Patterns, Multiple Capacities (9oz to 184oz), Product Types: Bento Box, Explorers, Ice Bucket, Lunch Tote, Original Bottles, S’well Eats, Salad Bowls, Travelers, Tumblers, Wine Chiller, Wine Tumbler, Free Shipping on Orders Over $30, 20% Off First Order, Club S’well Rewards, Corporate Gifts and Bulk…

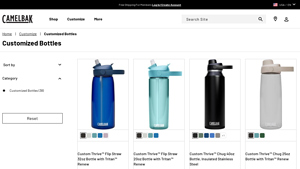

2. CamelBak – Custom Thrive™ Flip Straw 32oz Bottle

Domein: camelbak.nl

Geregistreerd: 1996 (29 jaar)

Inleiding: Customized Bottles: 38 items available. Price range: $0.00 – $24.99 (4 items), $25.00 – $49.99 (32 items), $50.00 – $74.99 (2 items). Examples include: Custom Thrive™ Flip Straw 32oz Bottle with Tritan™ Renew ($28.99), Custom Thrive™ Chug 40oz Bottle, Insulated Stainless Steel ($47.99), Custom Podium® Steel 22oz Bike Bottle ($54.00). Features include high-flow caps, insulated options, and customiz…

3. Swig Life – Personalized Stainless Steel Water Bottles

Domein: swiglife.com

Geregistreerd: 2018 (7 jaar)

Inleiding: Personalized Stainless Steel Water Bottles available in various shapes and sizes (12oz – 26oz). Options for monograms or custom designs. Large variety of colors and prints. Insulated for hot and cold drinks. Free shipping on orders over $75. Pay later option available with Klarna.

4. Crystal Imagery – Custom Laser Engraved Water Bottles

Domein: crystalimagery.com

Geregistreerd: 2000 (25 jaar)

Inleiding: Custom Laser Engraved Water Bottles, Insulated Water Bottles

5. 4imprint – Custom Stainless Steel Water Bottles

Domein: 4imprint.com

Geregistreerd: 1998 (27 jaar)

Inleiding: Custom Stainless Steel Water Bottles, 418 products available, various colors including Black, Blue, Gray, Green, Red, White, and more. Options for imprint colors and locations. Production times range from 24 hours to 3 days or less. Suitable for promotional gifts.

6. Survival Gear – Custom Metal Water Bottle

Domein: reddit.nl

Geregistreerd: 2005 (20 jaar)

Inleiding: Custom metal water bottle, similar to Hydro Flask, intended for survival kit use, with potential for engraving helpful information.

7. Totally Promotional – Custom Metal Water Bottles

Domein: totallypromotional.com

Geregistreerd: 2008 (17 jaar)

Inleiding: Custom Metal Water Bottles, Custom Stainless Steel Water Bottles, Free Delivery, USA-Made, On Sale, 24-Hour Rush

8. Lazer Designs – Engraved 40oz Polar Camel Water Bottle

Domein: lazerdesigns.com

Geregistreerd: 2002 (23 jaar)

Inleiding: This company, Lazer Designs – Engraved 40oz Polar Camel Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

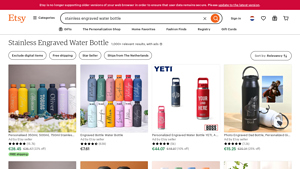

9. Etsy – Custom Engraved Stainless Water Bottles

Domein: etsy.com

Geregistreerd: 2004 (21 jaar)

Inleiding: Stainless Engraved Water Bottle, Custom Laser Engraved, Insulated Stainless Steel, Various Sizes (20/32/40oz), Personalized Options, Gifts for Him/Her, Prices range from $7.16 to $43.95, Free shipping available, Discounts up to 40% off on select items.

10. BannerBuzz – Personalized Magnum Stainless Steel Water Bottle

Domein: bannerbuzz.com

Geregistreerd: 2009 (16 jaar)

Inleiding: {“Product Name”: “Personalized Magnum Stainless Steel Water Bottle”, “SKU”: “NALTSB06”, “Price”: “$16.27 (Originally $27.12, Save 40%)”, “Material”: “Stainless Steel”, “Capacity”: “750 ml”, “Weight”: “170g”, “Dimensions”: “7 x 7 x 24 cm”, “Key Features”: [“Durable Construction: Corrosion-resistant and designed for daily use”, “Reliable Leak Prevention: Ensures no spills during transport”, “Sleek T…

Strategic Sourcing Conclusion and Outlook for custom engraved stainless water bottle

In summary, the strategic sourcing of custom engraved stainless water bottles presents a valuable opportunity for international B2B buyers. By leveraging customization options such as color printing and laser engraving, businesses can enhance brand visibility and create lasting impressions on their customers. As the demand for eco-friendly and reusable products continues to rise, investing in high-quality stainless steel bottles not only aligns with sustainability goals but also caters to health-conscious consumers.

The key takeaway is that a well-executed sourcing strategy can significantly elevate your brand’s presence in competitive markets across Africa, South America, the Middle East, and Europe. Establishing strong partnerships with reliable suppliers will ensure consistent quality, timely delivery, and the ability to meet diverse customer preferences.

Looking ahead, now is the time to explore the innovative designs and customization capabilities available in the market. Embrace the potential of custom engraved stainless water bottles as a unique promotional tool that resonates with your target audience. Take action today—evaluate your sourcing options, connect with suppliers, and position your brand for success in the evolving landscape of promotional products.