Introduction: Navigating the Global Market for best hot bottle

In the fast-paced global market, sourcing the best hot bottle can be a daunting task for B2B buyers, especially when quality and performance vary widely across suppliers. As businesses seek to offer their customers reliable and efficient solutions for beverage storage, understanding the nuances of hot bottles—ranging from thermoses to insulated flasks—becomes crucial. This comprehensive guide aims to demystify the landscape of hot bottles by exploring various types, their applications, and how to effectively vet suppliers to ensure product excellence.

From analyzing the latest insulation technologies to comparing price points and materials, our guide equips international buyers, particularly from regions like Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—with the insights needed to make informed purchasing decisions. We delve into critical factors such as heat retention capabilities, durability, and user safety, which are essential in catering to diverse market demands.

Moreover, we provide a framework for evaluating suppliers, ensuring that you can confidently navigate the complexities of global sourcing. By the end of this guide, you will be empowered to select the best hot bottle solutions that not only meet your operational needs but also enhance your competitive edge in the marketplace.

Artikel navigatie

- Top 9 Best Hot Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best hot bottle

- Understanding best hot bottle Types and Variations

- Key Industrial Applications of best hot bottle

- 3 Common User Pain Points for ‘best hot bottle’ & Their Solutions

- Strategic Material Selection Guide for best hot bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for best hot bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best hot bottle’

- Comprehensive Cost and Pricing Analysis for best hot bottle Sourcing

- Alternatives Analysis: Comparing best hot bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for best hot bottle

- Navigating Market Dynamics and Sourcing Trends in the best hot bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best hot bottle

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for best hot bottle

Understanding best hot bottle Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Vacuum Insulated Bottles | Double-wall vacuum insulation for heat retention | Food service, catering, outdoor activities | Voordelen: Excellent heat retention; durable. Minpunten: Hogere initiële kosten. |

| Traditional Thermos | Classic design with screw-on, leak-proof cap | Corporate gifts, promotional items | Voordelen: Reliable heat retention; large capacity. Minpunten: Bulkier than modern options. |

| Travel Mugs | Compact design, often fits in car cup holders | Employee gifts, daily office use | Voordelen: Portable; easy to clean. Minpunten: Limited volume; may not retain heat as long. |

| Specialty Beverage Bottles | Designed for specific beverages (e.g., tea, coffee) | Cafés, restaurants, specialty shops | Voordelen: Tailored features for specific drinks; attractive designs. Minpunten: Niche market; can be expensive. |

| Stainless Steel Bottles | Durable, rust-resistant materials | Outdoor gear suppliers, fitness industry | Voordelen: Long-lasting; eco-friendly. Minpunten: Zwaarder dan plastic opties. |

What are the Characteristics of Vacuum Insulated Bottles?

Vacuum insulated bottles are designed with double-wall construction that creates a vacuum layer between the walls, significantly reducing heat transfer. This type of bottle is ideal for businesses in the food service and catering industries, where maintaining beverage temperature is crucial. When sourcing these bottles, buyers should consider the insulation efficiency, material quality, and branding options for customization.

Why Choose Traditional Thermoses for B2B Purchases?

Traditional thermoses feature a classic design with a screw-on cap that ensures leak-proof storage. They are particularly useful for corporate gifting and promotional items, offering a practical solution for clients and employees alike. Buyers should assess the thermos size, heat retention capabilities, and potential for branding when making purchasing decisions.

How Do Travel Mugs Benefit Businesses?

Travel mugs are compact and designed to fit in car cup holders, making them a practical choice for daily office use and employee gifts. Their portability and ease of cleaning make them appealing for businesses looking to promote a culture of sustainability. Buyers should focus on the material, heat retention duration, and ergonomic design when selecting travel mugs for their workforce.

What Makes Specialty Beverage Bottles Unique?

Specialty beverage bottles are tailored for specific drinks, such as tea or coffee, and often feature unique designs or functionalities. Businesses like cafés and specialty shops can benefit from offering these bottles to enhance customer experience. When purchasing, buyers should consider the target market, product aesthetics, and pricing strategies to ensure alignment with their brand.

Why Are Stainless Steel Bottles a Sustainable Choice?

Stainless steel bottles are known for their durability and rust resistance, making them a long-lasting option for outdoor gear suppliers and fitness industries. They are eco-friendly alternatives to plastic bottles, appealing to consumers who prioritize sustainability. Buyers should evaluate the weight, capacity, and insulation properties of stainless steel bottles to meet their specific needs.

Key Industrial Applications of best hot bottle

| Industrie/sector | Specific Application of best hot bottle | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Gastvrijheid | Serving hot beverages in cafes and restaurants | Enhances customer experience with quality service | Durable materials, insulation performance, design |

| Gezondheidszorg | Providing hot water for patient care | Improves patient comfort and satisfaction | Safety standards, ease of cleaning, thermal efficiency |

| Buitenrecreatie | Keeping drinks hot during hiking and camping | Supports outdoor activities with reliable hydration | Lightweight, portability, insulation capabilities |

| Food Service | Transporting hot meals for catering | Maintains food quality during transport | Size options, thermal retention, leak-proof design |

| Corporate Gifting | Promotional items for businesses | Strengthens brand presence and customer loyalty | Customization options, branding capabilities, bulk pricing |

How is ‘best hot bottle’ utilized in the hospitality industry?

In the hospitality sector, the best hot bottles are essential for serving hot beverages like coffee and tea in cafes and restaurants. They help maintain optimal temperatures, ensuring that guests enjoy their drinks at the right heat level. With a focus on customer experience, businesses can enhance service quality by using high-performance hot bottles that reflect their brand’s commitment to excellence. Buyers should prioritize durability, insulation performance, and aesthetic design to meet varying customer preferences.

What role does the best hot bottle play in healthcare settings?

In healthcare, the best hot bottles are utilized to provide hot water for patient care, such as in the preparation of hot compresses or for making tea. This contributes to patient comfort and satisfaction, making it a vital component of healthcare services. Buyers in this sector must consider safety standards, ease of cleaning, and thermal efficiency to ensure that the bottles are suitable for frequent use in sensitive environments like hospitals and clinics.

How are hot bottles beneficial for outdoor recreation?

For outdoor enthusiasts, the best hot bottles serve as indispensable tools during hiking and camping trips. They keep drinks hot for extended periods, allowing adventurers to enjoy warm beverages in remote locations. This reliability enhances the overall outdoor experience, making it crucial for businesses catering to this market to source lightweight, portable options with excellent insulation capabilities. Buyers should also consider the durability of materials to withstand harsh outdoor conditions.

In what ways do best hot bottles support food service applications?

In the food service industry, hot bottles are used for transporting hot meals, ensuring that food quality is maintained from kitchen to event. This is particularly vital for catering services that require reliable thermal retention to prevent food from cooling too quickly. Buyers need to look for size options that fit their specific needs, strong thermal retention capabilities, and leak-proof designs to avoid any spills during transport, which could impact the service quality.

How can businesses leverage hot bottles for corporate gifting?

The best hot bottles are increasingly used as promotional items in corporate gifting, helping businesses strengthen their brand presence and customer loyalty. Customized bottles with company logos serve as practical gifts that resonate with clients and employees alike. When sourcing these items, businesses should prioritize customization options, branding capabilities, and bulk pricing to maximize their marketing impact while ensuring that the products remain functional and appealing.

3 Common User Pain Points for ‘best hot bottle’ & Their Solutions

Scenario 1: Ineffective Temperature Retention for Long Trips

Het probleem: B2B buyers, particularly those in the hospitality or catering sectors, often face challenges with hot bottles that fail to retain heat over extended periods. This issue is critical when transporting beverages like coffee, tea, or soups to remote locations or during events. If a bottle does not maintain the desired temperature for several hours, it can lead to dissatisfied customers and a tarnished reputation. For example, a catering service may find that their coffee arrives lukewarm, compromising the quality of their service.

De oplossing: To address this problem, buyers should prioritize sourcing hot bottles with proven insulation capabilities. Conduct thorough research on products that have been independently tested for temperature retention, such as those highlighted in industry reviews. Look for bottles made from double-wall vacuum-insulated stainless steel, which is known for its superior heat retention. Additionally, consider investing in products with a larger capacity, which can often retain temperature better than smaller bottles. Implementing a testing phase before bulk purchasing can help ensure the selected hot bottles meet specific temperature retention needs for long trips.

Scenario 2: Complications with Leaks and Spills

Het probleem: Another significant concern for B2B buyers is the risk of leaks and spills when using hot bottles, especially in environments like food delivery or outdoor events. A leak can not only create messes but also lead to safety hazards and loss of product. For instance, a corporate catering company may encounter issues where hot soups spill during transport, resulting in wasted product and increased cleanup costs.

De oplossing: To mitigate this risk, buyers should focus on sourcing hot bottles that feature robust, leak-proof designs. Look for products with screw-on lids or silicone seals that ensure a secure closure. Conduct quality checks and request samples to assess the sealing mechanism before making bulk orders. Additionally, consider training staff on the correct handling and storage practices for hot bottles to further minimize the risk of spills during transport. Establishing a quality assurance protocol can help identify potential issues early in the procurement process.

Scenario 3: Difficulty in Maintaining Hygiene and Cleanliness

Het probleem: For B2B buyers in the food service industry, maintaining hygiene is paramount. However, many hot bottles can be challenging to clean, leading to concerns about residual flavors and bacteria growth. This is particularly problematic for businesses that frequently switch between different beverages. For example, a coffee shop using the same hot bottle for both coffee and herbal teas may struggle to maintain flavor integrity and hygiene.

De oplossing: Buyers should seek hot bottles designed with easy-to-clean features, such as wide openings that allow for thorough washing and materials that resist staining and odors. Stainless steel bottles often offer superior cleaning properties compared to plastic. Additionally, consider products that are dishwasher safe or come with cleaning accessories. Implementing a standard operating procedure (SOP) for cleaning and sanitizing hot bottles after each use can further enhance hygiene practices. Educating staff on the importance of proper cleaning techniques will ensure that the bottles maintain their integrity and prevent cross-contamination.

Strategic Material Selection Guide for best hot bottle

When selecting materials for hot bottles, understanding the properties, advantages, and limitations of each material is crucial for international B2B buyers. The choice of material can significantly affect performance, compliance with regional standards, and overall product suitability.

What are the Key Properties of Stainless Steel for Hot Bottles?

Stainless steel is a popular choice for hot bottles due to its excellent temperature retention and durability. It typically has a high temperature rating, allowing it to withstand boiling liquids without degrading. Stainless steel also exhibits good corrosion resistance, making it suitable for various environments, including humid conditions often found in tropical regions like Nigeria and Brazil.

Pros: Stainless steel is highly durable, resistant to rust and staining, and can be easily cleaned. Its robust nature allows for a longer product life, which is a significant advantage for B2B buyers looking for cost-effective solutions.

Cons: The manufacturing process for stainless steel can be complex and costly, which may increase the final product price. Additionally, while it is generally safe, some grades of stainless steel may not be suitable for acidic beverages over long periods.

Invloed op toepassing: Stainless steel is compatible with a wide range of liquids, including hot water, tea, and coffee. However, buyers should ensure the specific grade used is suitable for their intended applications.

How Does Glass Perform as a Material for Hot Bottles?

Glass is another material often considered for hot bottles. It offers excellent thermal resistance and does not leach chemicals into beverages, making it a safe choice for consumers.

Pros: Glass provides a clean taste and is easy to clean, maintaining the integrity of the beverage. It is also recyclable, appealing to environmentally conscious buyers.

Cons: The fragility of glass is a significant drawback; it can break easily if dropped, leading to potential safety hazards. Additionally, glass is heavier than other materials, which may not be ideal for portable hot bottles.

Invloed op toepassing: Glass is suitable for hot liquids but may not be the best choice for outdoor or rugged applications due to its breakability. Buyers in regions with high outdoor activity levels should consider this limitation.

What Advantages Does BPA-Free Plastic Offer for Hot Bottles?

BPA-free plastic is increasingly popular for hot bottles due to its lightweight nature and versatility. It typically has a lower temperature rating compared to metal and glass but can still perform well with hot liquids if designed correctly.

Pros: The lightweight nature of BPA-free plastic makes it ideal for portable applications. It is also generally less expensive than stainless steel or glass, making it an attractive option for budget-conscious buyers.

Cons: While BPA-free plastics are safer than traditional plastics, they may still have limitations in terms of heat resistance and longevity. Over time, exposure to high temperatures can lead to warping or degradation.

Invloed op toepassing: BPA-free plastic is suitable for hot beverages but may not be ideal for prolonged exposure to high temperatures. Buyers should ensure they choose high-quality plastics that can withstand the intended use.

Why is Aluminum a Viable Option for Hot Bottles?

Aluminum is lightweight and has good thermal conductivity, making it a viable option for hot bottles. It is often coated to enhance its resistance to corrosion and to provide insulation.

Pros: Aluminum is lightweight and can be produced at a lower cost than stainless steel, making it an attractive option for mass production. It also has a modern aesthetic appeal.

Cons: Aluminum can react with acidic or alkaline liquids, which may affect the taste and safety of the beverage. Additionally, the coatings used to prevent corrosion can wear off over time.

Invloed op toepassing: Aluminum is suitable for hot beverages if properly coated, but buyers should be cautious about its compatibility with certain liquids. Compliance with safety standards is crucial, especially in regions with strict regulations.

Summary Table of Material Selection for Hot Bottles

| Materiaal | Typical Use Case for best hot bottle | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Roestvrij staal | Hot beverages, travel mugs | High durability and excellent insulation | Higher manufacturing cost, potential leaching | Hoog |

| Glas | Home use, premium products | Clean taste, recyclable | Breekbaar, zwaarder dan alternatieven | Med |

| BPA-vrij plastic | Lightweight, budget-friendly options | Lichtgewicht en kosteneffectief | Lower heat resistance, potential degradation | Laag |

| Aluminium | Outdoor use, lightweight applications | Lightweight and modern aesthetic | Reactivity with certain liquids, coating wear | Med |

This strategic material selection guide provides B2B buyers with essential insights into the materials used for hot bottles, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for best hot bottle

What Are the Main Stages in the Manufacturing Process of the Best Hot Bottles?

The manufacturing process of high-quality hot bottles involves several critical stages that ensure the final product meets performance and safety standards. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: What Materials Are Typically Used?

The first step in manufacturing hot bottles is material selection. Common materials include stainless steel, which provides durability and excellent thermal insulation, and BPA-free plastics for lightweight options. The materials undergo rigorous quality checks to ensure they meet international safety standards. For instance, stainless steel is often sourced with certifications confirming its resistance to corrosion and ability to retain heat.

Once the materials are selected, they are prepared through processes such as cutting and shaping. Stainless steel sheets may be cut into specific dimensions, while plastic components are molded into the desired shapes. This preparation phase is crucial because the quality of raw materials directly impacts the performance of the finished product.

How Are Hot Bottles Formed and Assembled?

After preparation, the forming stage begins, typically involving techniques such as deep drawing for stainless steel or injection molding for plastic components. During this stage, the material is shaped into the bottle’s body, ensuring it meets both aesthetic and functional requirements.

Following forming, assembly takes place. This involves attaching various components such as lids, seals, and insulation layers. High-quality hot bottles often feature double-wall vacuum insulation, which requires precise assembly to eliminate air gaps that could compromise thermal retention. Automated machinery and skilled labor are both employed to ensure that each bottle is assembled correctly and consistently.

What Quality Assurance Measures Are Implemented in Hot Bottle Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final products meet both customer expectations and international standards. The following are key QA practices typically implemented in hot bottle production.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are crucial in assessing a manufacturer’s quality management system. This standard emphasizes continuous improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) are important for products sold in Europe, indicating compliance with health, safety, and environmental protection standards.

For hot bottles, industry-specific certifications may also apply, such as those from the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), which provide guidelines for thermal performance and safety.

Wat zijn de belangrijkste controlepunten voor kwaliteitscontrole bij productie?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure each bottle meets quality standards:

-

Inkomende kwaliteitscontrole (IQC): This initial checkpoint assesses raw materials upon receipt. Suppliers are evaluated based on their material certifications and quality reports.

-

Kwaliteitscontrole tijdens het proces (IPQC): During manufacturing, periodic checks are performed at various stages, including material preparation, forming, and assembly. These checks ensure that any deviations from specifications are identified and corrected immediately.

-

Final Quality Control (FQC): Once the bottles are assembled, a final inspection takes place. This may involve pressure testing, thermal retention tests, and visual inspections to detect defects.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control can be challenging but essential. Here are some actionable steps:

Wat zijn de beste werkwijzen voor het uitvoeren van leveranciersaudits?

Conducting on-site audits is one of the most effective ways to evaluate a supplier’s quality control processes. During an audit, buyers can assess the manufacturer’s adherence to international standards, review their QC documentation, and observe production practices firsthand. It is advisable to prepare a checklist based on relevant standards to ensure a comprehensive evaluation.

How Can Buyers Use Reports and Third-Party Inspections?

Buyers should request detailed quality assurance reports from suppliers, including IQC, IPQC, and FQC results. Additionally, third-party inspections can be beneficial, especially for international shipments. Engaging a reputable inspection agency can provide an unbiased assessment of the product quality before it reaches the buyer.

What Testing Methods Are Commonly Used for Hot Bottles?

Quality assurance in hot bottle manufacturing also involves various testing methods to ensure performance and safety. Some commonly used methods include:

-

Thermal Retention Tests: These tests measure how long a bottle can keep liquids hot or cold. Manufacturers typically conduct these tests under controlled conditions to provide accurate results.

-

Leak Tests: Bottles undergo pressure testing to ensure they are leak-proof. This is crucial for maintaining the integrity of the product during use.

-

Material Testing: Various tests, including tensile strength and corrosion resistance, are performed on the materials used in manufacturing to ensure they meet necessary standards.

What Are the Unique QC Considerations for International B2B Buyers?

When sourcing hot bottles internationally, buyers should be aware of several nuances in quality control:

-

Cultural Differences in Quality Standards: Different regions may have varying expectations and standards for quality. Buyers should familiarize themselves with local regulations and ensure suppliers comply.

-

Communication Barriers: Language differences can lead to misunderstandings about quality expectations. Establishing clear communication channels and documentation can help mitigate this risk.

-

Logistics and Supply Chain Considerations: Buyers should consider how shipping and handling might affect product quality. Ensuring that suppliers adhere to proper packaging and transportation methods is vital to maintaining the integrity of the bottles.

By understanding the manufacturing processes and quality assurance measures involved in producing hot bottles, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only aids in ensuring product quality but also fosters long-term partnerships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best hot bottle’

To assist international B2B buyers in sourcing the best hot bottles, this guide provides a structured checklist that outlines the key steps necessary for effective procurement. By following these steps, you can ensure that you select high-quality products that meet your specific needs while fostering reliable supplier relationships.

Stap 1: Je technische specificaties definiëren

Before you begin your search, it’s essential to clarify your technical requirements for the hot bottles. Consider factors such as capacity, insulation efficiency, material (e.g., stainless steel, plastic), and design features (e.g., leak-proof, ergonomic).

– Key Considerations: Determine the intended use (e.g., for beverages, food) and the temperature retention duration you require.

Stap 2: Research Market Trends and Demands

Understanding current market trends can provide insights into consumer preferences and competitive pricing. Analyze reports and studies relevant to the regions you are targeting, such as Africa or South America, to identify popular features and styles.

– Actionable Insights: Look for emerging brands or innovations in insulation technology that could enhance your offerings.

Stap 3: Potentiële leveranciers evalueren

Before making a commitment, it’s crucial to vet potential suppliers thoroughly. Request company profiles, product samples, and case studies to assess their reliability and quality.

– Verification Process: Ask for references from other businesses in similar industries or regions to gauge their performance and customer satisfaction levels.

Stap 4: Productkwaliteit en naleving beoordelen

Ensure that the products meet international standards for safety and quality, particularly if you plan to distribute them in multiple countries. Check for certifications such as ISO, BPA-free, or FDA approval.

– Quality Assurance: Request documentation that verifies compliance with local regulations in your target markets to avoid future legal issues.

Stap 5: Onderhandelen over prijzen en voorwaarden

Once you have shortlisted suppliers, initiate negotiations to establish favorable pricing and terms. Consider bulk purchasing discounts, payment terms, and shipping costs.

– Strategic Negotiation: Don’t hesitate to explore alternative options if a supplier is unwilling to meet your budget or terms, as this can help you secure a better deal.

Stap 6: Conduct a Trial Order

Before placing a large order, conduct a trial with a smaller quantity. This allows you to evaluate product performance, quality, and supplier responsiveness without significant financial risk.

– Feedback Loop: Collect feedback from your team or customers to assess satisfaction and identify any necessary adjustments before a full-scale launch.

Stap 7: Establish a Long-Term Relationship

Building a strong, long-term relationship with your chosen supplier can lead to better pricing, improved communication, and collaborative product development.

– Continuous Engagement: Maintain regular contact and consider periodic reviews of performance and product offerings to adapt to changing market needs.

By following this structured checklist, B2B buyers can confidently navigate the complexities of sourcing the best hot bottles, ensuring quality products that meet market demands while fostering productive supplier partnerships.

Comprehensive Cost and Pricing Analysis for best hot bottle Sourcing

What Are the Key Cost Components in Sourcing the Best Hot Bottles?

When sourcing hot bottles for B2B markets, it’s essential to understand the breakdown of costs involved. The primary cost components include:

-

Materialen: The choice of materials greatly impacts the final product price. High-quality stainless steel or insulated plastics are preferred for their durability and thermal retention capabilities. Additionally, eco-friendly materials may attract a premium but can enhance brand value.

-

Arbeid: Labor costs vary significantly by region. In developing countries, labor may be less expensive, but ensure that the quality is not compromised. Skilled labor is often necessary for quality assurance and intricate manufacturing processes.

-

Productie Overhead: This includes utilities, facility costs, and equipment maintenance. Efficient production processes can help reduce overhead costs, ultimately affecting pricing.

-

Gereedschap: Custom molds or tools may be required for unique designs or branding. The initial investment can be substantial, but it becomes more cost-effective with higher production volumes.

-

Kwaliteitscontrole (QC): Implementing stringent QC measures ensures product reliability, which can prevent costly recalls or customer dissatisfaction. This aspect should be factored into the overall cost structure.

-

Logistiek: Shipping costs, including freight, customs duties, and insurance, play a critical role in total expenses. Understanding Incoterms can help in negotiating better shipping terms.

-

Marge: Finally, suppliers will include a markup to cover their costs and ensure profitability. The margin can vary based on market competition and perceived product value.

How Do Price Influencers Affect the Cost of Hot Bottles?

Several factors can influence the pricing of hot bottles in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Negotiating favorable terms based on expected order volumes can be beneficial.

-

Specificaties en aanpassingen: Custom designs or specifications can increase costs. Buyers should evaluate whether the added expense aligns with their branding and market needs.

-

Kwaliteit en certificeringen: Products that meet specific quality standards or certifications (e.g., FDA approval) may command higher prices. However, these certifications can enhance marketability and customer trust.

-

Factoren van leveranciers: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding shipping terms is crucial for budgeting. Different Incoterms can shift costs and responsibilities between buyer and seller, impacting the overall price.

What Tips Can Help Buyers Optimize Their Sourcing Strategy for Hot Bottles?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Onderhandeling: Engage in open discussions with suppliers about pricing, volume discounts, and payment terms. Building a good relationship can lead to better deals over time.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the initial purchase price. Consider factors like durability, warranty, and maintenance when evaluating overall costs.

-

Prijsnuances voor internationale kopers: Be aware of currency fluctuations, import tariffs, and local regulations that can affect pricing. It’s advisable to work with suppliers familiar with your market to mitigate risks.

-

Marktonderzoek: Conduct thorough research to understand market trends, competitor pricing, and customer preferences. This knowledge can provide leverage in negotiations and help you select the best products.

Disclaimer over indicatieve prijzen

Prices for hot bottles can vary significantly based on the factors mentioned above. It’s crucial for buyers to conduct their due diligence and obtain quotes from multiple suppliers to ensure competitive pricing and quality assurance.

Alternatives Analysis: Comparing best hot bottle With Other Solutions

In the quest for effective beverage insulation, the ‘best hot bottle’ presents a popular solution for businesses seeking to maintain temperature control for hot liquids. However, it is essential for B2B buyers to consider various alternatives that may suit different operational needs and environments. This analysis will compare the best hot bottle against two viable alternatives: insulated travel mugs and traditional thermoses.

Vergelijkende tabel

| Vergelijkingsaspect | Best Hot Bottle | Insulated Travel Mug | Traditional Thermos |

|---|---|---|---|

| Prestaties | Excellent heat retention; keeps beverages hot for up to 12 hours. | Good heat retention; typically holds heat for 4-8 hours. | Superior insulation; retains heat for 12+ hours. |

| Kosten | Moderate; usually ranges from $30-$50. | Affordable; typically ranges from $15-$35. | Variable; can range from $20-$60 depending on brand and capacity. |

| Gemak van implementatie | Simple to use; requires no special setup. | User-friendly; often fits in cup holders for easy transport. | Slightly bulkier; requires careful handling to avoid spills. |

| Onderhoud | Low; easy to clean and typically dishwasher safe. | Low; often dishwasher safe, but check manufacturer guidelines. | Low; requires periodic cleaning, but generally easy to maintain. |

| Beste gebruikscasus | Ideal for long-duration events or outdoor activities. | Best for daily commuting or short trips. | Perfect for group outings or extended trips where multiple servings are needed. |

Gedetailleerd overzicht van alternatieven

Insulated Travel Mug

Insulated travel mugs are designed for convenience and portability, making them an excellent choice for daily commuters and short trips. They typically feature a lid with a sipping port, which minimizes spills and allows for easy drinking on the go. However, their heat retention capacity may not match that of the best hot bottles, often keeping beverages hot for only 4 to 8 hours. This can be a drawback for businesses needing longer-lasting heat retention. Additionally, their lower cost makes them an attractive option for bulk purchases, but their limited capacity might not meet the needs of larger groups.

Traditional Thermos

Traditional thermoses offer superior insulation and are designed for maximum heat retention, often keeping liquids hot for over 12 hours. This makes them ideal for scenarios where beverages need to be maintained at a specific temperature for extended periods, such as during outdoor events or long travel. However, their bulkier size can pose challenges in terms of portability and storage. Moreover, while they are generally affordable, the price can vary significantly based on brand and capacity. Businesses that require high-capacity solutions for group settings may find thermoses to be the best fit despite their size.

Conclusie: Hoe u de juiste oplossing voor uw behoeften kiest

When selecting the right solution for maintaining beverage temperature, B2B buyers should consider their specific operational requirements. The best hot bottle excels in heat retention and is suitable for long-duration use, making it ideal for outdoor activities or events. Insulated travel mugs provide a cost-effective, portable option for daily use but may lack the longevity needed for extended events. Traditional thermoses are perfect for group settings where multiple servings are needed, though their bulk can be a limitation. Ultimately, the choice will depend on factors such as budget, intended use case, and the importance of heat retention in your specific business context.

Essential Technical Properties and Trade Terminology for best hot bottle

What Are the Key Technical Properties to Consider for the Best Hot Bottle?

When selecting the best hot bottle for your business needs, understanding critical technical properties is essential. Here are some key specifications to consider:

1. Materiaalklasse

The most common materials for hot bottles are stainless steel, glass, and BPA-free plastic. Stainless steel, particularly food-grade 304 or 316, offers excellent durability and corrosion resistance, making it ideal for long-term use. Glass provides a non-reactive surface, ensuring that the taste of beverages remains untainted, while BPA-free plastic is lightweight and often more affordable. Choosing the right material impacts product longevity and user safety.

2. Type isolatie

Hot bottles typically employ double-wall vacuum insulation, which minimizes heat transfer and maximizes temperature retention. This technology is crucial for maintaining hot beverages for extended periods, making it a key selling point in B2B transactions. Understanding insulation efficiency helps buyers make informed decisions about product performance and customer satisfaction.

3. Capacity and Size

Hot bottles come in various capacities, typically ranging from 500 ml to 2 liters. The size affects the volume of liquid a bottle can hold, which is vital for businesses targeting specific consumer needs, such as outdoor activities or daily commuting. Consideration of capacity ensures that the product meets market demands and customer expectations.

4. Leak Resistance

The design of the cap and seal significantly influences a bottle’s leak resistance. A reliable, screw-on cap with a silicone or rubber seal can prevent spills and maintain temperature. This feature is particularly important for B2B buyers focused on quality, as it reflects product reliability and user satisfaction.

5. Durability and Impact Resistance

Durability is often measured by a product’s ability to withstand drops or impacts. Materials and construction techniques play a significant role in this property. For instance, bottles made from high-grade stainless steel or reinforced glass are more durable than standard plastic. This aspect is vital for businesses selling to active consumers or industries where the bottles may experience rough handling.

What Trade Terminology Should B2B Buyers Know When Sourcing Hot Bottles?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some common terms relevant to sourcing hot bottles:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are sold under another brand’s name. In the hot bottle industry, businesses may partner with OEMs to create customized products that meet specific design or performance criteria. This relationship allows companies to leverage existing manufacturing capabilities while focusing on branding and distribution.

2. MOQ (minimale bestelhoeveelheid)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to ensure they can meet inventory needs without overcommitting financially. This metric can influence pricing and shipping costs, impacting overall profitability.

3. RFQ (Offerteaanvraag)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific product. This process allows businesses to compare offers and negotiate better deals. Using an RFQ can streamline procurement and ensure that buyers receive competitive pricing for hot bottles.

4. Incoterms (internationale handelsvoorwaarden)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps businesses navigate international transactions more effectively, ensuring that both parties understand their obligations and rights.

5. Doorlooptijd

Lead time refers to the time it takes from placing an order to receiving the product. In the hot bottle market, lead times can vary significantly based on manufacturing processes and supply chain logistics. Understanding lead times is crucial for inventory management and meeting customer demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their business objectives and customer needs.

Navigating Market Dynamics and Sourcing Trends in the best hot bottle Sector

What Are the Key Market Trends Influencing the Best Hot Bottle Sector?

The global hot bottle market is witnessing dynamic shifts driven by a growing emphasis on health, wellness, and sustainable living. As consumers increasingly prioritize hydration and the consumption of hot beverages, B2B buyers are presented with opportunities to source high-quality insulated bottles that meet these demands. Key trends include the integration of advanced insulation technologies, such as double-wall vacuum insulation, which enhances heat retention for extended periods. This technology not only ensures that beverages stay hot for longer but also caters to the rising preference for reusable products that reduce single-use plastic consumption.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are observing a surge in demand for customized and branded hot bottles. This trend is particularly prominent in corporate gifting and promotional merchandise, where businesses seek to align with eco-conscious values. Additionally, the influence of e-commerce is reshaping sourcing strategies, allowing buyers to access a broader range of suppliers and products globally. This shift is particularly significant in markets like Brazil and Nigeria, where digital platforms facilitate direct sourcing and better pricing options.

How Is Sustainability Reshaping the Sourcing of Best Hot Bottles?

Sustainability and ethical sourcing have become paramount in the hot bottle sector, as both consumers and businesses are increasingly aware of their environmental impact. B2B buyers are now prioritizing suppliers that adhere to sustainable practices, including the use of recycled materials and eco-friendly production processes. Certifications such as B Corp, Fair Trade, and ISO 14001 are becoming essential in supplier evaluations, as they demonstrate a commitment to environmental stewardship and social responsibility.

Moreover, the demand for ‘green’ materials, such as stainless steel and BPA-free plastics, is on the rise. These materials not only enhance the durability and usability of hot bottles but also align with the values of environmentally conscious consumers. International buyers must remain vigilant about the sustainability claims made by suppliers, ensuring transparency in the sourcing and manufacturing processes. This focus on ethical supply chains not only mitigates reputational risks but also opens up new markets, as consumers increasingly favor brands that demonstrate a commitment to sustainability.

What Is the Historical Context of the Hot Bottle Market?

The evolution of hot bottles can be traced back to the early 20th century, when the first vacuum-insulated bottles were introduced, primarily for medical and industrial use. Over the decades, these products transitioned into mainstream consumer markets, with brands like Thermos leading the way. The late 20th century saw an explosion of designs and materials, catering to diverse consumer preferences and lifestyles.

In recent years, the hot bottle sector has experienced a renaissance, fueled by a surge in outdoor activities and health-conscious living. As consumers seek more sustainable alternatives to disposable containers, the demand for high-quality, reusable hot bottles has surged. This historical context underscores the importance of innovation and adaptability in the sector, as suppliers strive to meet evolving consumer demands while maintaining a focus on sustainability.

By understanding these market dynamics and trends, B2B buyers can make informed sourcing decisions that not only meet current demands but also anticipate future shifts in the hot bottle landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of best hot bottle

1. How do I choose the best hot bottle for my business needs?

Selecting the right hot bottle involves assessing your specific requirements, such as insulation performance, capacity, and material. Look for bottles that offer dual-wall vacuum insulation for superior heat retention. Consider the target market—different regions may prefer varying designs, sizes, and materials, such as stainless steel or BPA-free plastics. Request samples from suppliers to evaluate quality firsthand, and review customer feedback to gauge performance under real-world conditions. Lastly, consider customization options to enhance branding and appeal to local preferences.

2. What is the best hot bottle for keeping beverages hot for extended periods?

The best hot bottles are those that utilize high-quality vacuum insulation technology. Brands like Stanley and Zojirushi have proven to excel in heat retention, often keeping liquids hot for over 12 hours. When sourcing, check for specifications that indicate performance in hot beverage retention tests. Additionally, consider the bottle’s design and ease of use, such as a wide mouth for filling and cleaning, which can enhance user experience.

3. What are the minimum order quantities (MOQs) for hot bottles when sourcing internationally?

Minimum order quantities (MOQs) can vary significantly by supplier and product type. Generally, MOQs for hot bottles range from 500 to 1,000 units, depending on material and customization requirements. It’s crucial to communicate your needs clearly and negotiate with suppliers to reach a mutually beneficial agreement. Some manufacturers may offer lower MOQs for specific designs or colors, so exploring multiple options is advisable to find the best deal for your business.

4. How can I ensure the quality of hot bottles before purchasing?

To ensure quality, conduct thorough supplier vetting, including checking certifications (like ISO 9001) and factory audits. Request product samples to evaluate insulation effectiveness and overall build quality. Additionally, consider asking for quality assurance reports and previous customer testimonials. Engaging a third-party inspection service can also provide an unbiased assessment before shipment, particularly important for large orders.

5. What payment terms should I negotiate with suppliers for hot bottles?

When negotiating payment terms, aim for conditions that balance security and cash flow. Common arrangements include a 30% deposit upfront with the remaining 70% due upon delivery or after inspection. Consider using secure payment methods such as letters of credit for larger orders, which protect both parties. It’s also wise to discuss penalties for late payments or early shipment discounts to foster a positive relationship with your supplier.

6. What logistics considerations should I keep in mind when importing hot bottles?

Logistics are crucial in ensuring timely delivery and minimizing costs. Factor in shipping methods (air vs. sea), customs clearance, and potential tariffs that may apply to hot bottles. Establish a reliable freight forwarder experienced in handling such products to navigate international shipping complexities. Additionally, consider the lead time for production and shipping to align with your inventory needs and avoid stock shortages.

7. Can I customize hot bottles with my brand logo?

Yes, most manufacturers offer customization options, including printing or engraving your brand logo on hot bottles. The extent of customization may depend on the supplier’s capabilities and the order volume. Discuss design options, colors, and placement with your supplier to ensure your branding aligns with your marketing strategy. Additionally, inquire about any associated costs and lead times for custom orders.

8. How do I address issues with defective hot bottles upon receipt?

If you receive defective hot bottles, act quickly to resolve the issue. Document the defects with photographs and detailed descriptions, then communicate with your supplier immediately. Most reputable suppliers will have policies in place for defective goods, often offering replacements or refunds. Understanding the warranty and return policy beforehand can help streamline this process and ensure you maintain a positive relationship with your supplier.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 9 Best Hot Bottle Manufacturers & Suppliers List

1. BottlePro – Top Insulated Bottles

Domein: bottlepro.net

Geregistreerd: 2014 (11 jaar)

Inleiding: Hot Test, Best 3: 1) S’well (Original 25oz) 2) Stanley Thermos (1L) 3) RevoMax (20oz) Hot Test, Worst 3: 30) Stanley Quencher (40oz) 31) Hydro Flask Tumbler (40oz) 32) Brumate Era Tumbler (40oz) Cold Test, Best 3: 1) Stanley Thermos (1L) 2) Camelbak Chute Mag (32oz) 3) S’well (Original 25oz) Cold Test, Worst 3: 30) Hydro Flask Tumbler (40oz) 31) Stanley Quencher (40oz) 32) Zulu Ace (24oz) Best Col…

2. Thermos – Beverage Bottles

Domein: thermos.nl

Geregistreerd: 1997 (28 jaar)

Inleiding: Beverage Bottles from Thermos Brand include various sizes (12oz, 16oz, 24oz, 32oz, 40oz) and colors (Beige, Black, Blue, Brown, Green, Pink, Red, Stainless Steel). Lid types include Push Button with Spout and Push Button with Spout – Locking Lid. Temperature preferences are available for Cold or Hot/Cold. Customizable options are available. Notable products include: 32oz ICON™ Dual Temp Beverage B…

3. Hydroflask – Wide Mouth, Simple Modern – Tumblers, S’well – Bottles

Domein: reddit.nl

Geregistreerd: 2005 (20 jaar)

Inleiding: 1. Hydroflask Wide Mouth – Insulated, keeps water warm for hours, prone to dents, higher price tag.

2. Simple Modern Tumblers – Comparable insulation and durability to Hydroflask, better price point, leak-proof lid, available in 24oz and larger sizes.

3. S’well Bottles – Excellent heat retention (up to 12 hours), sleek design, available in 24oz and larger sizes, no straw issues.

4. Taylor Swift…

4. Yeti – Rambler Water Bottle

Domein: allrecipes.com

Geregistreerd: 1998 (27 jaar)

Inleiding: Top Picks: My Top Pick: Yeti Rambler Water Bottle at Amazon $32 – Durable; leakproof; color doesn’t fade or chip; Heavy. Best Budget: Contigo AutoSeal Chill 2.0 Water Bottle, 24-Ounce at Amazon $29 $24 – Great temperature retention; sliding lock lid; slim profile; May not fit car cup holder; body is hand-wash only. Best Lightweight: S’well 17-Ounce Stainless Steel Water Bottle at Amazon $39. Best …

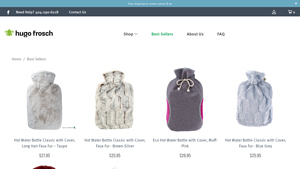

5. Hugo Frosch – Hot Water Bottles

Domein: hugofroschusa.com

Geregistreerd: 2019 (6 jaar)

Inleiding: [{‘name’: ‘Hot Water Bottle Classic with Cover, Long Hair Faux Fur’, ‘color’: ‘Taupe’, ‘price’: ‘$27.95’}, {‘name’: ‘Hot Water Bottle Classic with Cover, Faux Fur’, ‘color’: ‘Brown-Silver’, ‘price’: ‘$25.95’}, {‘name’: ‘Eco Hot Water Bottle with Cover, Muff’, ‘color’: ‘Pink’, ‘price’: ‘$26.95’}, {‘name’: ‘Hot Water Bottle Classic with Cover, Faux Fur’, ‘color’: ‘Blue Grey’, ‘price’: ‘$25.95’}, {‘n…

6. Zojirushi – Stainless Insulated Bottle SJ-JS10

Domein: seriouseats.nl

Geregistreerd: 2006 (19 jaar)

Inleiding: Top Picks: 1. Zojirushi Stainless Insulated Bottle SJ-JS10 – Price: $35, Best Overall for heat retention and size. 2. Stanley Legendary Classic Bottle – Price: $30, Traditional thermos option. 3. Zojirushi Stainless Bottle SJ-TG08/10 – Price: $38, Best for commuters. 4. MiiR Water Bottle – Price: $40, Best wide mouth thermos. Heat Retention Test Results: Stanley Legendary Classic Bottle – Initial …

7. Silicone Mania – Travel Drink Bottle

Domein: siliconemania.com

Geregistreerd: 2024 (1 jaar)

Inleiding: Best Travel Drink Bottle for Hot & Cold Beverages

– Purpose: Keeps drinks at the right temperature while commuting, hiking, or road trips.

– Benefits: Saves money, reduces plastic waste, environmentally friendly.

– Insulation: Double-wall vacuum technology for maintaining temperature.

– Material Options: Glass (taste preservation, heavy), Stainless Steel (durable, long-lasting cold), Plastic (ligh…

8. YUYU – Stylish Hot Water Bottles

Domein: mumsnet.com

Geregistreerd: 2000 (25 jaar)

Inleiding: Recommendations for high-quality hot water bottles include YUYU water bottles, which are noted for their lovely design, and The White Company hot water bottle, which features a long faux fur cover, priced around £45. Users express a desire for bottles that last longer than a couple of years and have decent covers, as well as concerns about the heat retention of long and narrow designs like YUYU.

9. Sänger – Hot Water Bottle

Domein: bostongeneralstore.com

Geregistreerd: 2013 (12 jaar)

Inleiding: {“name”: “Sänger Hot Water Bottle”, “price”: “$24.00”, “colors”: [“Red”, “White”, “Orange”, “Yellow”, “Blue”, “Green”, “Purple”], “description”: “One of our perennial best-sellers, this classic rubber hot water bottle is made in Germany by Sänger. Great for reducing muscle pain and stiffness or staying warm during the long, cold winter months. Crafted from a single piece of rubber with no seams fo…

Strategic Sourcing Conclusion and Outlook for best hot bottle

In the competitive landscape of beverage containers, strategic sourcing of high-quality hot bottles is essential for B2B buyers. The comprehensive analysis highlights that leading brands like S’well, Stanley, and RevoMax excel in heat retention, ensuring beverages stay hot for extended periods. This capability is not just a selling point; it represents reliability and customer satisfaction, crucial for businesses catering to diverse markets across Africa, South America, the Middle East, and Europe.

When sourcing hot bottles, consider not only insulation performance but also material quality, design, and brand reputation. Sustainable sourcing practices can enhance your brand’s image and appeal to eco-conscious consumers. Establishing relationships with reputable suppliers will provide you with competitive pricing and exclusive access to innovative products that can meet evolving consumer demands.

Looking ahead, the demand for premium hot bottles will continue to rise as consumers prioritize quality and functionality. By leveraging strategic sourcing, international B2B buyers can position themselves to seize market opportunities, ensuring they meet consumer expectations while driving profitability. Embrace this journey and explore partnerships that align with your business goals to stay ahead in the dynamic beverage market.