Introduction: Navigating the Global Market for flask bottle for alcohol

In the dynamic landscape of global commerce, sourcing high-quality flask bottles for alcohol presents unique challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a plethora of options available, businesses must navigate issues related to quality, compliance, and supplier reliability to ensure they meet both consumer expectations and regulatory requirements. This comprehensive guide delves into the diverse types of flask bottles, their various applications, and key factors to consider when evaluating suppliers.

By exploring different materials, capacities, and innovative designs—from classic stainless steel to modern ceramic options—this resource equips international buyers with the insights needed to make informed decisions. Moreover, we will address critical aspects of cost analysis and supplier vetting to help mitigate risks associated with purchasing. The guide aims to empower businesses to not only select the right products but also to establish fruitful partnerships with suppliers that align with their operational goals.

Whether you are a retailer looking to enhance your product range or a distributor aiming to meet the growing demand for portable drinkware, understanding the intricacies of the flask bottle market is essential. By leveraging the information within this guide, you can confidently navigate the complexities of sourcing and ultimately enhance your competitive edge in the marketplace.

Artikel navigatie

- Top 7 Flask Bottle For Alcohol Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for flask bottle for alcohol

- Understanding flask bottle for alcohol Types and Variations

- Key Industrial Applications of flask bottle for alcohol

- 3 Common User Pain Points for ‘flask bottle for alcohol’ & Their Solutions

- Strategic Material Selection Guide for flask bottle for alcohol

- In-depth Look: Manufacturing Processes and Quality Assurance for flask bottle for alcohol

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘flask bottle for alcohol’

- Comprehensive Cost and Pricing Analysis for flask bottle for alcohol Sourcing

- Alternatives Analysis: Comparing flask bottle for alcohol With Other Solutions

- Essential Technical Properties and Trade Terminology for flask bottle for alcohol

- Navigating Market Dynamics and Sourcing Trends in the flask bottle for alcohol Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of flask bottle for alcohol

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for flask bottle for alcohol

Understanding flask bottle for alcohol Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Stainless Steel Flask | Durable, rust-resistant, and often insulated | Gifting, promotional items, retail sales | Voordelen: Long-lasting, easy to clean. Minpunten: Can retain flavors. |

| Ceramic Flask | Unique aesthetic, flavor-neutral, often handcrafted | Specialty liquor stores, gift shops | Voordelen: Preserves taste, visually appealing. Minpunten: Breekbaar, zwaarder. |

| Hybrid Flask (e.g., FreePour) | Combines mixing capabilities with traditional flask design | Outdoor events, sports marketing | Voordelen: Multi-functional, convenient. Minpunten: More complex design may deter some users. |

| Plastic Flask | Lightweight, shatter-resistant, often clear | Budget markets, outdoor activities | Voordelen: Affordable, portable. Minpunten: Less premium feel, potential for leakage. |

| Leather-Wrapped Flask | Enhanced grip and aesthetics, often with personalized options | Corporate gifts, luxury markets | Voordelen: Elegant, customizable. Minpunten: Requires careful maintenance to avoid damage. |

What Are the Characteristics of Stainless Steel Flasks?

Stainless steel flasks are renowned for their durability and rust resistance, making them ideal for long-term use. Many models feature an insulated design to keep beverages at the desired temperature, which appeals to outdoor enthusiasts and event planners. When considering B2B purchases, companies should focus on the quality of the stainless steel and the ease of cleaning, as these factors can influence customer satisfaction and repeat purchases.

Why Choose Ceramic Flasks for Specialty Markets?

Ceramic flasks offer a unique aesthetic that can attract customers looking for something different. Their flavor-neutral properties make them suitable for storing various spirits without imparting any unwanted tastes. B2B buyers should evaluate the craftsmanship and design of ceramic flasks, as these elements can significantly impact their market appeal, especially in upscale retail environments.

What Are the Benefits of Hybrid Flasks Like FreePour?

Hybrid flasks, such as those incorporating mixing capabilities, provide a versatile solution for consumers who enjoy cocktails on the go. These innovative designs are particularly appealing for outdoor events, sports marketing, and promotional campaigns. B2B buyers should consider the functionality and ease of use, as well as the potential for branding opportunities, when selecting these products for their inventory.

How Do Plastic Flasks Fit into Budget Markets?

Plastic flasks are lightweight and shatter-resistant, making them an excellent choice for budget-conscious consumers and outdoor activities. Their clear design allows users to monitor liquid levels easily. Buyers should weigh the cost-effectiveness against the perceived value, as these flasks may lack the premium feel of metal or ceramic options, which could affect customer preferences.

Why Opt for Leather-Wrapped Flasks in Luxury Markets?

Leather-wrapped flasks are often seen as elegant and customizable, making them ideal for corporate gifts and luxury markets. They provide an enhanced grip and a sophisticated look that appeals to high-end consumers. B2B buyers should consider the maintenance requirements and the potential for personalization, as these factors can enhance the product’s attractiveness and value proposition in competitive markets.

Key Industrial Applications of flask bottle for alcohol

| Industrie/sector | Specific Application of flask bottle for alcohol | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Gastvrijheid | Portable drink service at events and gatherings | Enhances guest experience; promotes brand loyalty | Quality materials, customization options, compliance with health regulations |

| Buitenrecreatie | Flasks for camping, hiking, and sports activities | Convenience for consumers; increases product sales | Durability, insulation properties, and lightweight design |

| Relatiegeschenken | Gifting personalized flasks for employees or clients | Strengthens business relationships; unique branding | Customization capabilities, bulk pricing, and lead times |

| Detailhandel & E-commerce | Selling stylish flasks as lifestyle products | Expands product range; attracts diverse customer base | Trend alignment, packaging, and supply chain efficiency |

| Event Management | Customized flasks as promotional items | Increased brand visibility; memorable giveaways | Minimum order quantities, design flexibility, and delivery timelines |

How Are Flask Bottles for Alcohol Used in the Hospitality Industry?

In the hospitality sector, flask bottles are often utilized for portable drink service during events, weddings, and corporate gatherings. They allow bartenders and servers to offer a wide range of spirits without the need for traditional glassware, enhancing the guest experience while promoting brand loyalty. Buyers in this industry should prioritize sourcing flasks made from high-quality materials that comply with health regulations and offer customization options to align with their branding.

What Role Do Flask Bottles Play in Outdoor Recreation?

Flask bottles serve as essential accessories for outdoor enthusiasts engaged in activities like camping, hiking, and sports. Their portability and discreet design make it easy for users to carry their favorite spirits without the bulk of traditional bottles. For international buyers, particularly from regions with diverse climates, sourcing durable and insulated flasks that can withstand rugged conditions is crucial to meet consumer expectations.

Why Are Flask Bottles Effective Corporate Gifts?

In corporate settings, personalized flask bottles are often used as gifts for employees or clients, serving as unique branding tools. They help strengthen business relationships by offering a thoughtful and memorable item that recipients are likely to use and appreciate. When sourcing for this application, businesses should consider customization capabilities, bulk pricing, and lead times to ensure timely delivery for events or holidays.

How Can Retailers Benefit from Selling Flask Bottles?

Retailers can expand their product range by including stylish and functional flask bottles as lifestyle products. These items appeal to a diverse customer base, from casual drinkers to outdoor enthusiasts. Sourcing considerations should include aligning with current trends, ensuring attractive packaging, and maintaining supply chain efficiency to meet consumer demand promptly.

What Advantages Do Flask Bottles Provide for Event Management?

In event management, customized flask bottles are increasingly used as promotional items or giveaways, enhancing brand visibility and creating memorable experiences for attendees. These items can be branded with logos or event themes, making them attractive souvenirs. Buyers should focus on minimum order quantities, design flexibility, and reliable delivery timelines to ensure successful event execution and customer satisfaction.

3 Common User Pain Points for ‘flask bottle for alcohol’ & Their Solutions

Scenario 1: Inconsistent Quality Control in Flask Production

Het probleem: B2B buyers often face challenges with the quality consistency of flask bottles for alcohol. Variability in materials, manufacturing processes, and design can lead to products that do not meet customer expectations or regulatory standards. For instance, a buyer might order a batch of stainless steel flasks only to discover that some are prone to leaking or that the finish is inconsistent. This not only affects the buyer’s reputation but also can lead to costly returns and dissatisfied customers.

De oplossing: To mitigate this issue, buyers should establish clear quality control protocols with their suppliers. This includes setting specific material standards, conducting regular audits, and requiring samples before placing large orders. Utilizing third-party quality assurance services can also help in verifying that the products meet international standards. Additionally, investing in technology for tracking production quality can provide insights into potential issues before they escalate, ensuring a consistent product that aligns with customer expectations.

Scenario 2: Difficulties in Customization for Diverse Markets

Het probleem: Many B2B buyers targeting international markets struggle with the challenge of customizing flask bottles to suit regional preferences and regulations. For example, a buyer in the Middle East may need to consider cultural norms and legal restrictions regarding alcohol consumption, while a buyer in Europe might focus on sustainability and eco-friendly materials. This complexity can lead to delays in product launches and missed opportunities in key markets.

De oplossing: To effectively navigate this challenge, buyers should engage in comprehensive market research to understand the specific needs and preferences of their target regions. Collaborating with local distributors or consultants can provide valuable insights into cultural and regulatory nuances. Furthermore, establishing flexible design specifications that allow for easy customization can streamline the process. Buyers should also consider modular designs or limited editions that cater to local tastes while maintaining a cohesive brand identity, ensuring that the product resonates with diverse customer bases.

Scenario 3: Inefficient Supply Chain Management for Flask Distribution

Het probleem: Managing the supply chain for flask bottles can be complex, particularly when dealing with international logistics. B2B buyers may encounter delays due to customs regulations, shipping complications, or inadequate inventory management. These delays not only impact customer satisfaction but also can lead to lost sales opportunities, especially during peak seasons or promotional events.

De oplossing: Implementing a robust supply chain management system can significantly enhance efficiency. Buyers should consider leveraging technology such as inventory management software that integrates with their existing systems to provide real-time tracking of shipments and inventory levels. Establishing strong relationships with reliable shipping partners and understanding the customs regulations for each target market can also minimize delays. Additionally, maintaining a safety stock or using just-in-time inventory strategies can help ensure that supply meets demand, allowing for timely fulfillment of customer orders while reducing excess inventory costs.

Strategic Material Selection Guide for flask bottle for alcohol

What Are the Key Properties of Common Materials Used in Flask Bottles for Alcohol?

When selecting materials for flask bottles designed for alcohol, several factors must be considered, including durability, temperature resistance, and compatibility with various spirits. The most common materials used in the production of these flasks are stainless steel, glass, ceramic, and plastic. Each material offers distinct advantages and disadvantages that can influence the final product’s performance and marketability.

How Does Stainless Steel Perform in Flask Bottle Applications?

Stainless steel is the most popular choice for alcohol flasks due to its excellent corrosion resistance and durability. It can withstand a wide range of temperatures, making it suitable for both hot and cold beverages. The key properties of stainless steel include a high tensile strength and a low thermal conductivity, which helps maintain the temperature of the contents.

Voordelen: Stainless steel flasks are highly durable, resistant to rust and corrosion, and easy to clean. They are also relatively lightweight, which is beneficial for portability.

Minpunten: The manufacturing process can be complex and may involve higher costs compared to other materials. Additionally, stainless steel can impart a metallic taste to certain spirits if not properly treated.

Invloed op de toepassing: Stainless steel is compatible with a wide range of alcoholic beverages, including spirits and cocktails. Its resistance to corrosion makes it ideal for outdoor use.

Overwegingen voor internationale kopers: Buyers from regions like Africa and the Middle East should ensure that the stainless steel used complies with international standards such as ASTM or DIN to guarantee quality and safety.

What Are the Advantages and Limitations of Glass Flasks?

Glass flasks offer a unique aesthetic appeal and are often used for premium products. They do not react chemically with alcohol, preserving the beverage’s original flavor.

Voordelen: Glass is non-reactive, easy to clean, and provides a high-end look. It can also be manufactured in various designs and colors, appealing to diverse consumer preferences.

Minpunten: Glass is fragile and can break easily, making it less suitable for rugged environments. The production process can be energy-intensive, leading to higher costs.

Invloed op de toepassing: Glass flasks are best suited for high-end spirits and are often used in gift sets or premium packaging.

Overwegingen voor internationale kopers: Buyers should be aware of shipping regulations regarding glass products, as they are more prone to damage during transit. Compliance with local safety standards is also crucial.

How Do Ceramic Flasks Compare in Terms of Performance?

Ceramic flasks are gaining popularity due to their unique aesthetic and ability to maintain the flavor profile of the alcohol. They typically feature a glaze that provides a protective layer, enhancing durability.

Voordelen: Ceramic flasks are visually appealing and can be designed with intricate patterns. They also do not impart any flavors to the contents.

Minpunten: The fragility of ceramics can be a significant drawback, and they may not withstand extreme temperatures. Manufacturing can be labor-intensive, increasing costs.

Invloed op de toepassing: Ceramic is suitable for spirits that require a neutral environment to maintain flavor integrity, such as whiskey or rum.

Overwegingen voor internationale kopers: Buyers should ensure that ceramic products meet safety standards, particularly regarding lead content in glazes.

What Role Does Plastic Play in Flask Bottle Manufacturing?

Plastic flasks, often made from materials like Tritan or polyethylene, are lightweight and shatter-resistant, making them ideal for outdoor activities.

Voordelen: They are highly durable, resistant to breaking, and often less expensive than metal or glass options.

Minpunten: Plastic can retain odors and flavors, which may not be ideal for all types of alcohol. Additionally, some plastics may not be suitable for hot liquids.

Invloed op de toepassing: Plastic flasks are commonly used for casual drinking scenarios, such as picnics or outdoor events, where durability is more critical than aesthetics.

Overwegingen voor internationale kopers: Buyers should verify that the plastic used is BPA-free and complies with local health regulations.

Summary Table of Material Selection for Flask Bottles

| Materiaal | Typical Use Case for flask bottle for alcohol | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Roestvrij staal | Everyday use, outdoor activities | Highly durable and corrosion-resistant | Can impart metallic taste if untreated | Medium |

| Glas | Premium spirits, gift sets | Non-reactive and aesthetically pleasing | Fragile and prone to breakage | Hoog |

| Ceramic | High-end spirits, decorative purposes | Maintains flavor integrity and visually appealing | Fragile and labor-intensive to manufacture | Medium |

| Kunststof | Casual use, outdoor events | Lichtgewicht en breukvast | Can retain odors and flavors | Laag |

This strategic material selection guide provides B2B buyers with actionable insights into the properties and considerations of various materials used in flask bottles for alcohol, facilitating informed purchasing decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for flask bottle for alcohol

What Are the Key Stages in Manufacturing Flask Bottles for Alcohol?

The manufacturing of flask bottles for alcohol involves several critical stages, each contributing to the final product’s quality, durability, and aesthetic appeal. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Commonly Used?

The choice of materials is fundamental in flask bottle production. Stainless steel is the most common material due to its strength, resistance to corrosion, and non-reactivity with alcohol. Other materials like glass and ceramic are also used, often for aesthetic reasons or specific use cases. The preparation stage involves sourcing high-quality raw materials, which may include:

- Roestvrij staal: Typically 304 or 316 grade, known for excellent corrosion resistance.

- Glass: Often used in decorative or luxury flasks, requiring careful handling to avoid breakage.

- Ceramics: Provides a unique look but may be more fragile.

Once sourced, materials undergo quality checks to ensure they meet industry standards before moving on to the forming stage.

How Are Flask Bottles Formed?

The forming stage is where the raw materials are transformed into the desired flask shape. This typically involves several techniques:

- Stamping and Punching: Used for stainless steel flasks, where sheets are stamped into the desired shape using dies.

- Molding: Commonly used for glass and ceramic flasks, where molten material is poured into molds and allowed to cool and harden.

- Welding and Soldering: Essential for joining parts of stainless steel flasks, ensuring a leak-proof design.

Each technique requires skilled labor and precise machinery to maintain consistency and quality.

What Happens During Assembly?

Assembly is where individual components come together to form the final product. This stage may include:

- Attaching Caps and Lids: Ensuring a secure fit that prevents leakage.

- Adding Insulation: For insulated flasks, a vacuum seal may be created between two layers of stainless steel.

- Quality Checks: Before final assembly, components are often tested for fit and function.

Attention to detail during assembly is crucial, as even minor defects can lead to product failure.

What Finishing Techniques Are Applied?

The finishing stage enhances the flask’s appearance and functionality. Common techniques include:

- Polishing: To achieve a smooth and shiny surface on stainless steel.

- Coating: Using powder coating or paint to provide a protective layer and aesthetic appeal.

- Printing and Etching: For branding purposes, logos or designs may be printed or etched onto the flask.

These finishing touches not only improve the product’s look but also increase its resistance to wear and tear.

How Is Quality Assurance Managed in Flask Bottle Production?

Quality assurance (QA) is vital in ensuring that flasks meet specific standards before reaching the market. B2B buyers should be aware of various international and industry-specific standards that guide quality control processes.

What International Standards Should Buyers Consider?

International standards like ISO 9001 are crucial for manufacturers looking to ensure consistent quality in their production processes. This standard provides a framework for quality management systems, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) may also apply.

How Are Quality Control Checkpoints Established?

Quality control checkpoints are integrated throughout the manufacturing process. Common checkpoints include:

- Inkomende kwaliteitscontrole (IQC): Inspects raw materials upon arrival to ensure they meet specified criteria.

- Kwaliteitscontrole tijdens het proces (IPQC): Monitors the production process at various stages to catch defects early.

- Final Quality Control (FQC): Conducts a thorough inspection of finished products before they are packaged and shipped.

By implementing these checkpoints, manufacturers can significantly reduce the risk of defective products reaching the market.

What Testing Methods Are Commonly Used?

To ensure compliance with quality standards, various testing methods are employed:

- Lektests: Ensures that flasks do not leak under pressure or during normal use.

- Drop Testing: Assesses the durability of the flask under impact.

- Temperature Testing: For insulated flasks, tests confirm that they maintain temperature effectively.

These tests help to validate that the flask bottles will perform as expected in real-world conditions.

Hoe kunnen B2B-inkopers de kwaliteitscontroleprocessen van leveranciers controleren?

B2B buyers must be proactive in verifying the quality control processes of their suppliers. Here are several strategies:

- Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insight into the supplier’s quality management practices.

- Requesting Quality Reports: Suppliers should provide documentation of their quality assurance processes, including test results and compliance certifications.

- Inspecties door derden: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate additional complexities in quality control. These may include:

- Naleving van regelgeving: Understanding local regulations regarding materials and manufacturing practices can be critical.

- Cultural Differences: Variations in quality expectations and manufacturing standards can exist between regions. Buyers must communicate their requirements clearly.

- Transparantie van de toeleveringsketen: Ensuring that all stages of the supply chain adhere to quality standards is essential, especially when sourcing from multiple countries.

By being aware of these nuances, B2B buyers can better manage their relationships with suppliers and ensure that they receive high-quality flask bottles for alcohol.

Conclusion: Why Quality Assurance Matters in Flask Bottle Manufacturing

In the competitive market of flask bottles for alcohol, understanding the manufacturing processes and the importance of quality assurance is essential for B2B buyers. By focusing on these elements, buyers can make informed choices that align with their quality expectations and market demands, ultimately leading to successful partnerships and satisfied end consumers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flask bottle for alcohol’

Inleiding

This guide serves as a practical checklist for B2B buyers seeking to procure high-quality flask bottles for alcohol. By following these steps, you can ensure that your sourcing process is efficient, effective, and aligned with your business needs. The market for flask bottles varies significantly across regions, and understanding key factors will help you make informed purchasing decisions.

Stap 1: Je technische specificaties definiëren

Before initiating your search, clarify the specifications of the flask bottles you need. Consider aspects such as material (stainless steel, ceramic, or glass), capacity (ranging from 6 to 11 ounces), and design features (e.g., leak-proof, insulated). These specifications will guide your supplier discussions and help avoid miscommunication.

- Material Considerations: Choose materials that align with your brand’s values and the intended use of the flasks. Stainless steel is durable and resistant to corrosion, while ceramic offers a unique aesthetic.

- Capacity Needs: Determine the capacity based on typical usage scenarios. For instance, flasks designed for outdoor events may require larger capacities.

Stap 2: Onderzoek potentiële leveranciers

Conduct thorough research to identify suppliers that specialize in flask bottles. Utilize online platforms, trade shows, and industry directories to compile a list of candidates. Pay attention to suppliers with a proven track record in your target market regions, such as Africa or Europe.

- Market Presence: Look for suppliers with a strong presence in your desired geographic areas, as they may better understand local regulations and consumer preferences.

- Product Range: Ensure the suppliers offer a variety of designs and materials to meet your specifications.

Stap 3: Leverancierscertificeringen evalueren

Before proceeding with any supplier, verify their certifications and compliance with industry standards. This step is crucial for ensuring product safety and quality.

- Quality Certifications: Check for certifications like ISO 9001, which indicates quality management systems, or FDA approval for food-grade materials.

- Sustainability Practices: Inquire about their environmental practices if sustainability is important to your brand.

Stap 4: Monsters aanvragen

Once you have narrowed down your list of potential suppliers, request product samples. Testing samples allows you to assess the quality, design, and functionality of the flask bottles firsthand.

- Quality Assessment: Look for any defects, the ease of use, and how well the flask holds liquids without leaking.

- Brand Alignment: Ensure the design aligns with your brand image and resonates with your target audience.

Stap 5: Onderhandelen over prijzen en voorwaarden

Engage in negotiations with your selected suppliers to secure favorable pricing and terms. Be prepared to discuss volume discounts, payment terms, and delivery timelines.

- Volume Discounts: Inquire about pricing tiers based on order quantity to optimize your budget.

- Payment Flexibility: Ensure the payment terms align with your cash flow needs and consider options like net 30 or net 60 terms.

Stap 6: Confirm Logistics and Shipping Arrangements

Once terms are agreed upon, confirm logistics and shipping arrangements. This step is essential for timely delivery and managing costs effectively.

- Shipping Options: Discuss various shipping methods and their associated costs, including express options if you need rapid delivery.

- Customs and Duties: If sourcing internationally, be aware of customs regulations and duties that may apply to your order.

Stap 7: Establish a Long-term Relationship

After the initial order, focus on building a long-term relationship with your supplier. A strong partnership can lead to better pricing, priority service, and collaborative opportunities for product development.

- Regular Communication: Maintain open lines of communication to address any concerns and discuss future needs.

- Feedback Loop: Provide feedback on product performance and service to foster mutual improvement and innovation.

Comprehensive Cost and Pricing Analysis for flask bottle for alcohol Sourcing

What Are the Key Cost Components in Flask Bottle Manufacturing?

Understanding the cost structure of flask bottle manufacturing is essential for B2B buyers looking to source these products efficiently. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include stainless steel, glass, ceramic, and plastic. Premium materials like high-grade stainless steel and ceramic can increase costs but offer benefits like durability and aesthetic appeal.

-

Labor: Labor costs vary depending on the region and the complexity of the production process. Regions with lower wage rates may offer more competitive pricing, but this can also correlate with variations in quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and salaries of non-production staff. These costs can vary widely based on the operational efficiency of the manufacturing facility.

-

Tooling: The initial investment in molds and equipment necessary for production can be substantial. The complexity of the flask design will determine the tooling costs, which can be amortized over higher production volumes.

-

Quality Control (QC): Implementing stringent quality control processes ensures product reliability, particularly important for items designed to hold consumables. QC costs can vary based on the certification requirements, especially for international markets.

-

Logistics: Shipping and transportation costs must be factored in, particularly for international buyers. These costs include freight, customs duties, and insurance, which can significantly impact the total cost.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the margin expectations of suppliers can aid in negotiation and securing favorable pricing.

How Do Price Influencers Affect the Cost of Flask Bottles?

Several factors can influence pricing for flask bottles, making it crucial for buyers to understand them:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their purchasing capacity to maximize cost efficiency.

-

Specifications and Customization: Custom designs, logos, or specific materials can increase costs. Buyers should balance the need for customization with budget constraints.

-

Quality and Certifications: Premium products that meet specific certifications (e.g., food-safe materials) may command higher prices. Buyers should assess whether the added cost justifies the benefits in their target markets.

-

Supplier Factors: The reputation, reliability, and geographical location of suppliers can affect pricing. Suppliers with established quality and service records may charge more but provide better assurance of product consistency.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties, impacting total costs.

What Buyer Tips Can Help Secure Competitive Pricing for Flask Bottles?

B2B buyers can leverage several strategies to optimize their sourcing of flask bottles:

-

Negotiation Skills: Effective negotiation can lead to better pricing terms. Buyers should be prepared with market research and a clear understanding of their requirements to negotiate effectively.

-

Cost-Efficiency Considerations: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, logistics, and potential returns. This broader perspective can guide better purchasing decisions.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, import tariffs, and local taxes that can affect the final cost. Establishing relationships with local suppliers can also mitigate some of these issues.

-

Engage Multiple Suppliers: Requesting quotes from multiple suppliers can provide insights into market pricing and enable better comparison to secure the most favorable terms.

-

Long-Term Partnerships: Building long-term relationships with suppliers can lead to loyalty discounts and improved service, enhancing overall procurement efficiency.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and strategic buyer tips can empower B2B buyers in their sourcing of flask bottles for alcohol. By carefully considering these factors, buyers can make informed decisions that align with their business objectives while optimizing costs.

Alternatives Analysis: Comparing flask bottle for alcohol With Other Solutions

Exploring Alternatives to Flask Bottles for Alcohol

When considering the various solutions available for carrying and consuming alcoholic beverages, it’s essential to evaluate alternatives to traditional flask bottles. While flasks are popular for their convenience and portability, other innovative options can serve similar purposes. This analysis will compare the classic flask bottle with two notable alternatives: the FreePour System and insulated beverage containers.

Vergelijkende tabel

| Vergelijkingsaspect | Flask Bottle For Alcohol | FreePour System | Insulated Beverage Container |

|---|---|---|---|

| Prestaties | High, portable, discreet | High, mixes drinks easily | High, maintains temperature |

| Kosten | $19.99 – $59.99 | $29.99 – $49.99 | $30.00 – $70.00 |

| Gemak van implementatie | Simple to fill/use | Requires some setup | Easy to fill, use is intuitive |

| Onderhoud | Moderate, easy to clean | Moderate, parts may need replacement | Low, durable materials |

| Beste gebruikscasus | Discreet drinking on-the-go | Mixing drinks on-the-go | Keeping beverages cold/hot |

In-Depth Analysis of Alternatives

What Are the Advantages of the FreePour System?

The FreePour System offers a unique solution by combining a beverage container with a built-in liquor well. This innovative design allows users to discreetly carry and mix drinks as they sip, making it ideal for social events or outings. Its leakproof feature ensures no spillage, and it is compatible with various drinkware brands. However, the system requires some initial setup and understanding of how to operate the mixing mechanism, which might deter some users who prefer straightforward options like traditional flasks.

How Do Insulated Beverage Containers Compare?

Insulated beverage containers, such as those made by brands like YETI or S’well, are designed to maintain the temperature of drinks for extended periods. They can hold both hot and cold beverages, offering versatility that flasks do not. These containers are typically made from durable materials that resist wear and tear, making them low-maintenance. However, they may lack the discreetness of flasks, as their bulkier design can be less portable. Therefore, they are better suited for picnics or extended outings rather than discreet consumption in social settings.

Making the Right Choice: What Should B2B Buyers Consider?

For B2B buyers looking to invest in drinkware solutions, the choice between a flask bottle for alcohol and its alternatives should be guided by the intended use case. If the primary goal is to provide customers with a discreet way to carry spirits, then traditional flasks or the FreePour System would be ideal. Conversely, if the emphasis is on maintaining beverage temperature for longer periods, insulated containers would be more suitable. Considerations such as cost, ease of use, and maintenance will further influence the decision, ensuring that the chosen product aligns with customer needs and enhances their overall experience.

Essential Technical Properties and Trade Terminology for flask bottle for alcohol

What are the Key Technical Properties of Flask Bottles for Alcohol?

Understanding the technical properties of flask bottles is crucial for B2B buyers looking to source high-quality products. Here are some essential specifications to consider:

1. Material Grade

The most common materials used for flasks include stainless steel, glass, and ceramic. Stainless steel is favored for its durability and resistance to corrosion, making it ideal for outdoor use. Glass provides a premium feel but is more fragile, while ceramic offers unique aesthetics but can be prone to breakage. Selecting the right material can impact product longevity and customer satisfaction, particularly in markets where rugged use is expected.

2. Capacity

Flask capacity typically ranges from 6 ounces to 11 ounces, with some innovative designs featuring built-in compartments for additional storage. Understanding capacity is essential for meeting customer preferences and regulatory standards in various regions. For instance, smaller flasks may appeal to discreet consumers, while larger options may cater to those wanting to carry more liquid.

3. Leak Resistance

Leakproof designs are critical for ensuring that flasks do not spill their contents during transport. This property often relies on the quality of the cap and sealing mechanisms. A flask that is not leakproof can lead to customer complaints and returns, affecting brand reputation. Buyers should inquire about testing methods and warranty guarantees related to leak resistance.

4. Insulation Properties

Insulated flasks are designed to maintain the temperature of their contents, whether hot or cold. This is achieved through double-wall construction, often using vacuum insulation. Insulation is particularly important for consumers who wish to keep beverages at a desired temperature for extended periods. B2B buyers should assess insulation effectiveness to ensure it meets consumer expectations.

5. Finish and Aesthetics

The finish of the flask—be it matte, polished, or textured—can significantly influence market appeal. Aesthetic considerations are essential in markets where design and branding play crucial roles. Custom finishes can also serve as a differentiating factor in competitive markets, allowing for unique branding opportunities.

What are Common Trade Terms in the Flask Bottle Industry?

Familiarity with industry jargon is vital for smooth transactions and negotiations. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the flask industry, OEM partnerships can allow businesses to leverage existing designs or technologies to create unique flasks without starting from scratch.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs based on their sales forecasts and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to submit price offers for specific products or services. In the context of flask procurement, an RFQ can help buyers compare costs and identify the best suppliers based on pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They are crucial for defining the responsibilities of buyers and sellers in international shipping. Understanding Incoterms can help buyers mitigate risks related to shipping costs, insurance, and liability.

5. Customization Options

Customization refers to the ability to modify products to meet specific buyer requirements, such as branding, size, or design features. Customization is particularly relevant in the flask market, where unique branding can significantly enhance product appeal.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their business strategies and customer expectations, ultimately leading to successful procurement and sales outcomes.

Navigating Market Dynamics and Sourcing Trends in the flask bottle for alcohol Sector

What Are the Key Trends Influencing the Flask Bottle for Alcohol Market?

The flask bottle for alcohol sector is experiencing dynamic shifts driven by evolving consumer preferences and technological advancements. Globally, the demand for portable drinking solutions is on the rise, fueled by lifestyle changes that favor convenience. Particularly in markets like Africa and the Middle East, outdoor activities such as tailgating, picnicking, and camping are becoming increasingly popular, creating a robust demand for stylish yet functional flasks. In contrast, European and South American markets are witnessing a growing trend towards personalization and premiumization, where consumers seek unique designs and high-quality materials that reflect their individual tastes.

Emerging technologies are also reshaping sourcing strategies for international B2B buyers. Digital platforms for sourcing are gaining traction, allowing companies to streamline procurement processes and reduce lead times. Additionally, innovations such as integrated mixing systems, as seen in products like the FreePour collection, are attracting attention for their dual functionality, catering to consumers who value both convenience and versatility. These trends underscore the importance of staying attuned to consumer preferences and leveraging technology for efficient sourcing.

How Are Sustainability and Ethical Sourcing Impacting the Flask Bottle for Alcohol Industry?

As environmental concerns gain prominence, sustainability is becoming a critical focus in the flask bottle for alcohol sector. Buyers are increasingly prioritizing products made from eco-friendly materials, such as stainless steel, glass, and biodegradable plastics, which minimize environmental impact. This shift is not merely a trend; it reflects a growing demand for transparency in supply chains. B2B buyers must assess suppliers based on their commitment to ethical sourcing practices and the sustainability of their materials.

Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems are becoming essential indicators of a supplier’s commitment to sustainability. These certifications not only enhance a brand’s credibility but also appeal to a consumer base that values ethical consumption. B2B buyers should prioritize partnerships with manufacturers who demonstrate a commitment to sustainability, thereby aligning their business practices with the increasing demand for eco-conscious products.

What Is the Historical Context of Flask Bottles for Alcohol?

The history of flask bottles dates back centuries, originating as functional vessels for transporting spirits discreetly. Initially crafted from materials like leather and pewter, these flasks served practical purposes for travelers and soldiers. Over time, the design evolved, with stainless steel emerging as a popular material due to its durability and resistance to corrosion.

In the late 20th century, flasks transitioned from purely utilitarian items to fashionable accessories, with manufacturers introducing a variety of styles, colors, and personalization options. This evolution has made flasks not only a practical choice for consumers but also a statement piece that reflects personal style. For B2B buyers, understanding this historical context can provide valuable insights into consumer behavior and preferences, informing product selection and marketing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of flask bottle for alcohol

-

How do I choose the right flask bottle for alcohol for my business needs?

When selecting a flask bottle for alcohol, consider factors such as material, capacity, and design. Stainless steel options are durable and resistant to rust, while ceramic flasks can preserve taste but are more fragile. Evaluate the intended use—whether for gifting, promotional events, or retail—and ensure the design aligns with your brand image. Additionally, assess the capacity that meets your customer needs; popular sizes range from 6 to 11 ounces. Lastly, check for customization options to enhance branding and appeal. -

What is the best material for a flask bottle for alcohol?

The best material for a flask bottle largely depends on the intended use and target market. Stainless steel is widely preferred for its durability, resistance to corrosion, and ease of cleaning. Ceramic flasks offer a unique aesthetic and preserve the flavor of spirits but can be more fragile. For brands targeting outdoor activities, insulated flasks that maintain temperature are ideal. Consider your audience’s preferences and the environments in which the flasks will be used to determine the best material. -

What customization options are available for flask bottles?

Customization options for flask bottles often include engraving, printing, and color choices. Many suppliers offer the ability to add logos, brand names, or unique designs, enhancing promotional appeal. Some manufacturers allow for tailored shapes and sizes to fit specific marketing strategies. When sourcing, inquire about minimum order quantities (MOQs) for customized items and the potential for bulk discounts. Personalization can significantly boost customer engagement, making it a worthwhile investment. -

What should I consider regarding minimum order quantities (MOQ) when sourcing flask bottles?

Minimum order quantities (MOQ) can vary significantly among suppliers, often depending on the type of flask and customization options. Generally, MOQs for standard designs may start as low as 50 units, while customized products might require higher quantities. It’s essential to align your order size with your sales projections to avoid overstock or shortage. Engaging with suppliers to negotiate MOQs can lead to favorable terms, especially for long-term partnerships. -

How can I ensure quality assurance (QA) when sourcing flask bottles internationally?

To ensure quality assurance when sourcing flask bottles, select reputable suppliers who provide detailed product specifications and certifications. Request samples to evaluate the materials, design, and functionality before placing a bulk order. Establish clear quality control standards and consider third-party inspections at various stages of production. Additionally, maintain open communication with your supplier to address any potential issues proactively, ensuring that the final products meet your expectations. -

What payment terms should I expect when purchasing flask bottles from international suppliers?

Payment terms can vary widely depending on the supplier and the relationship established. Common arrangements include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipping. Some suppliers may offer net 30 or net 60 terms for established businesses. It’s advisable to discuss payment methods (such as wire transfers, letters of credit, or escrow services) to protect your investment. Always review terms in detail to ensure they align with your financial processes and risk management strategies. -

What logistics considerations should I keep in mind when importing flask bottles?

Logistics for importing flask bottles involve several key considerations, including shipping methods, customs regulations, and lead times. Determine whether air or sea freight is more suitable based on your timeline and budget. Be aware of import duties and taxes applicable in your region, as these can significantly affect total costs. Collaborating with a freight forwarder can streamline the process, ensuring compliance with international shipping laws and efficient delivery to your location. -

How do I vet suppliers when sourcing flask bottles for alcohol?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching potential suppliers through trade directories, industry associations, and online reviews. Evaluate their production capabilities, certifications, and past client testimonials. Request references and conduct background checks to assess their reputation. Additionally, consider visiting their manufacturing facility if possible, or engage in video calls to discuss your specific requirements. Establishing a strong relationship with a trustworthy supplier can lead to long-term benefits and smoother transactions.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 7 Flask Bottle For Alcohol Manufacturers & Suppliers List

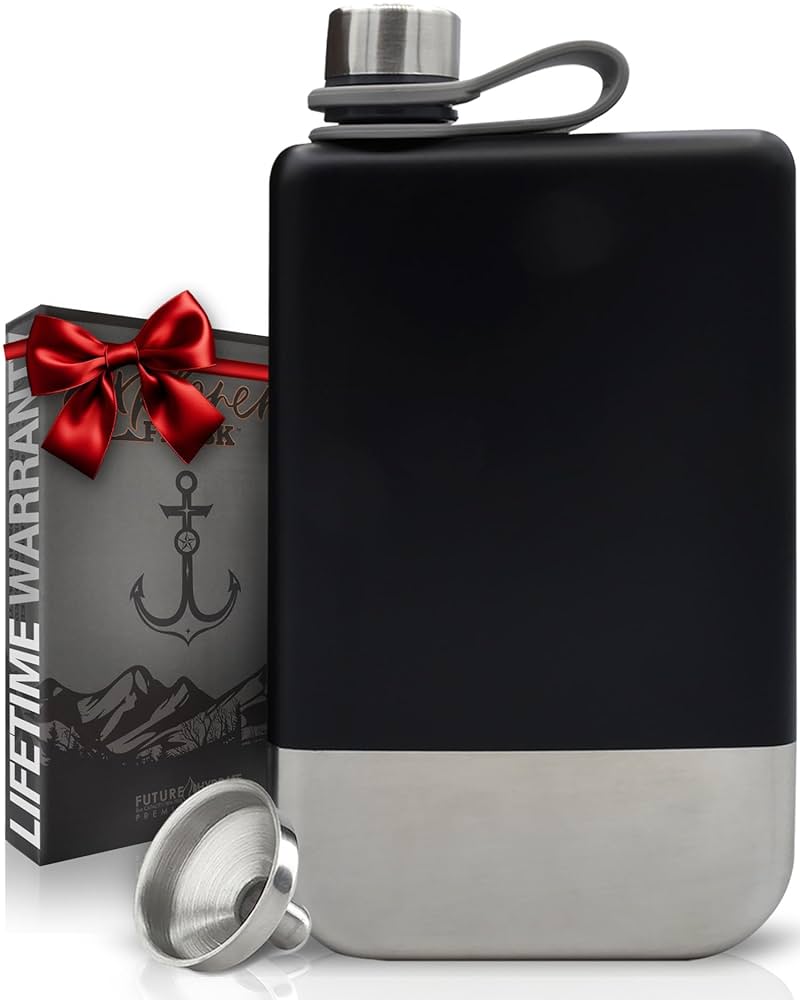

1. Viski – Warren Flask

Domein: viski.com

Geregistreerd: 2003 (22 jaar)

Inleiding: Viski offers a selection of stylish flasks designed for convenience and sophistication, perfect for carrying spirits on the go. Key products include: 1. Warren Flask – Price: $57.99, Rating: 4.8 (10 reviews) 2. Harrison Flask – Price: $42.99, Rating: 5.0 (3 reviews) 3. Belmont Flask – Price: $59.99, Rating: 4.9 (17 reviews) 4. Stainless Steel Slim Flask – Regular Price: $32.99, Sale Price: $19.79,…

2. True Rogue – Discreet 6oz Plastic Flask Set

Domein: doelwit.nl

Geregistreerd: 1997 (28 jaar)

Inleiding: This company, True Rogue – Discreet 6oz Plastic Flask Set, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Flaskap – FreePour Collection

Domein: flaskap.com

Geregistreerd: 2017 (8 jaar)

Inleiding: The FreePour Collection includes a 26-ounce tumbler and flask water bottle. It features a built-in 6-ounce liquor well that allows users to discreetly store liquor inside the bottle. The product is leakproof and includes the Freepour Kap, a removable liquor well, and a stainless steel bottle. The collection is available in various colors including Black, Blazin Green, Bright White, Camp Fire Orang…

4. Nutcase Shop – Designer Hip Flasks

Domein: nutcaseshop.com

Geregistreerd: 2014 (11 jaar)

Inleiding: This company, Nutcase Shop – Designer Hip Flasks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Prestige – Premium Liquor Flasks

Domein: prestigehaus.com

Registered: 2016 (9 years)

Inleiding: Prestige Premium Liquor Flasks; Types: Hip Flasks; Price: $35.00 each; Materials: Engraved Wooden and Genuine Top-Grain Leather; Features: Various city maps and patriotic designs; Available Products: American Flag Engraved Wooden Flask, South Carolina Flag Leather Flask, Texas State Leather Flask, Charlotte City Map Engraved Wooden Flask, Houston Engraved Wooden Flask, Chicago Engraved Wooden Flas…

6. Stanley – Classic Flask

Domein: thespruceeats.com

Geregistreerd: 2018 (7 jaar)

Inleiding: Best Overall: Stanley Classic Flask – Price: $26, Material: Stainless steel, Capacity: 6.4 ounces, Dimensions: 7.5 x 2.88 x 1.25 inches, Features: Wide mouth, solid construction, easy to clean, rustproof, cap mounted to a hinge, does not leak.

Best Budget: Rabbit Discreet Flask – Price: $13, Material: Tritan and silicone, Capacity: 6 ounces, Dimensions: 3.25 x 1.2 x 6 inches, Features: Removable…

7. WaterBottle – Wholesale Stainless Steel Hip Flask 8oz Matte Red

Domein: waterfles.tech

Geregistreerd: 2018 (7 jaar)

Inleiding: Product Name: Wholesale Stainless Steel Hip Flask 8oz Matte Red Drinking Liquor Metal Alcohol Whiskey Wine

Model Number / SKU: S310800

Capacity / Size: 8oz (240ml), (6oz, 4oz, 2oz, 10oz optional)

Mouth Diameter: 9 mm

Flask Material: 18/8 food grade stainless steel (SUS 304 stainless steel)

Lid Material: 18/8 food grade stainless steel

Surface Decoration Technical: powder coating

Insulation Perform…

Strategic Sourcing Conclusion and Outlook for flask bottle for alcohol

What Are the Key Takeaways for B2B Buyers in Sourcing Alcohol Flasks?

In summary, the strategic sourcing of alcohol flasks presents a unique opportunity for international B2B buyers to capitalize on a growing market segment. The rising consumer preference for portable and stylish drinkware, coupled with the increasing demand for customized and functional designs, underscores the importance of selecting suppliers who offer high-quality, innovative products. Key factors to consider include material durability, ease of use, and the ability to meet regional compliance standards.

Why Is Strategic Sourcing Essential in This Market?

Effective strategic sourcing not only enhances product offerings but also strengthens supplier relationships, ensuring consistent quality and competitive pricing. By leveraging insights from market trends and consumer preferences, businesses can position themselves as leaders in the alcohol flask market. This approach enables companies to respond swiftly to evolving consumer demands and capitalize on seasonal sales opportunities.

How Can International Buyers Prepare for Future Trends in Flask Bottles?

As we look ahead, international buyers—especially those from Africa, South America, the Middle East, and Europe—should remain vigilant in monitoring emerging trends, such as sustainability and customization. Engaging with manufacturers that prioritize eco-friendly materials and innovative designs will be crucial. Take proactive steps to explore partnerships with reliable suppliers who can support your growth in this dynamic market. By doing so, you will not only enhance your product portfolio but also meet the expectations of a discerning customer base.