Introduction: Navigating the Global Market for coke bottle caps

The global market for coke bottle caps presents a unique challenge for B2B buyers seeking to source reliable, sustainable, and innovative packaging solutions. With increasing emphasis on environmental responsibility, the demand for attached caps that facilitate recycling and reduce litter is on the rise. This guide delves into the various types of coke bottle caps available in the market, their applications across different beverage sectors, and the latest innovations that enhance functionality and sustainability.

In this comprehensive resource, international buyers will find valuable insights into effective supplier vetting processes, key cost considerations, and industry trends that influence purchasing decisions. For stakeholders in regions such as Africa, South America, the Middle East, and Europe—including major markets like Brazil and Germany—this guide serves as an essential tool to navigate the complexities of sourcing coke bottle caps. By providing actionable strategies and expert knowledge, it empowers decision-makers to make informed choices that align with their business goals and sustainability initiatives.

As the beverage industry evolves, understanding the nuances of coke bottle caps—from material composition to design innovations—will be pivotal in ensuring compliance with local regulations and meeting consumer expectations. This guide not only addresses the current challenges but also highlights emerging opportunities in the dynamic landscape of packaging solutions.

Artikel navigatie

- Top 9 Coke Bottle Caps Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for coke bottle caps

- Understanding coke bottle caps Types and Variations

- Key Industrial Applications of coke bottle caps

- 3 Common User Pain Points for ‘coke bottle caps’ & Their Solutions

- Strategic Material Selection Guide for coke bottle caps

- In-depth Look: Manufacturing Processes and Quality Assurance for coke bottle caps

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘coke bottle caps’

- Comprehensive Cost and Pricing Analysis for coke bottle caps Sourcing

- Alternatives Analysis: Comparing coke bottle caps With Other Solutions

- Essential Technical Properties and Trade Terminology for coke bottle caps

- Navigating Market Dynamics and Sourcing Trends in the coke bottle caps Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of coke bottle caps

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for coke bottle caps

Understanding coke bottle caps Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Standard Twist Cap | Classic design, easy to open, typically made of plastic | Beverage packaging, mass production | Voordelen: Cost-effective, widely accepted. Minpunten: Environmental concerns due to plastic waste. |

| Attached Cap | Cap remains attached post-opening, promotes recycling | Sustainability-focused brands | Voordelen: Reduces litter, enhances recycling. Minpunten: May increase production costs. |

| Yellow Kosher Cap | Specifically designed for Kosher for Passover, uses cane sugar | Niche markets, religious observances | Voordelen: Appeals to specific consumer demographics. Minpunten: Limited production runs may affect availability. |

| Vintage Collector Cap | Unique designs, often made of metal or commemorative materials | Collectibles, promotional items | Voordelen: High resale value, unique branding. Minpunten: Higher initial investment, niche market. |

| Recycled Material Cap | Made from post-consumer recycled materials | Eco-conscious brands, CSR initiatives | Voordelen: Supports sustainability goals. Minpunten: May have a higher cost compared to standard caps. |

What Are the Characteristics of Standard Twist Caps?

Standard twist caps are the most recognizable type of bottle cap, predominantly used in beverage packaging. Made primarily from plastic, they feature a simple screw-top design that ensures a secure seal while allowing for easy opening. These caps are ideal for high-volume production runs, making them a staple for manufacturers aiming for cost efficiency. However, B2B buyers should consider the environmental implications of plastic waste, as sustainability becomes increasingly important in consumer preferences.

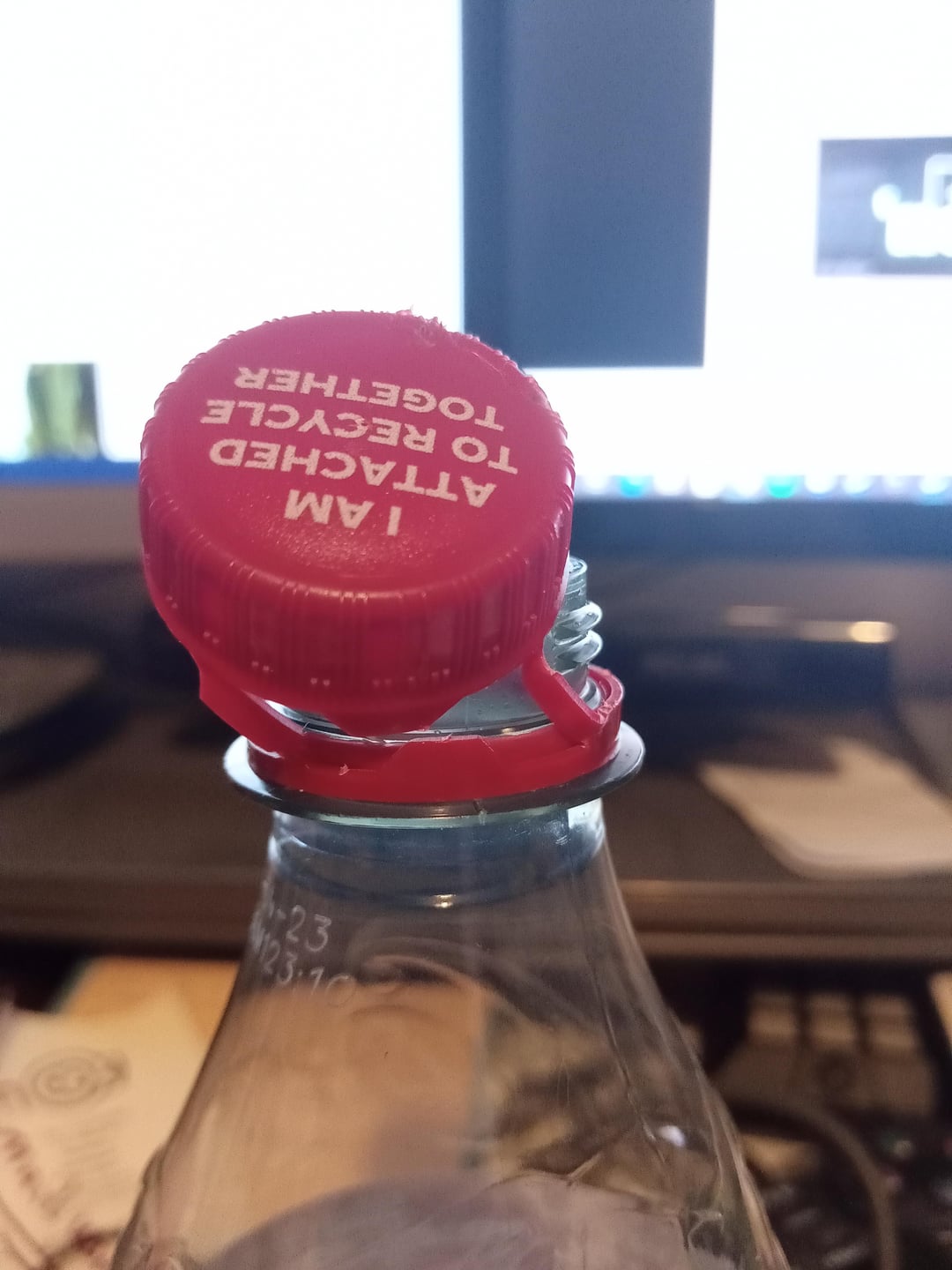

How Do Attached Caps Enhance Recycling Efforts?

Attached caps are an innovative solution that keeps the cap connected to the bottle after opening. This design not only minimizes the risk of littering but also improves the likelihood of both components being recycled together. Companies focused on enhancing their sustainability profile may find attached caps particularly appealing. While they may incur slightly higher production costs, the potential for improved brand image and compliance with environmental regulations can outweigh these expenses.

What Are the Benefits of Yellow Kosher Caps?

Yellow kosher caps signify that the beverage inside meets specific dietary requirements for Passover, using cane sugar instead of high-fructose corn syrup. This type of cap caters to a niche market, particularly among consumers who observe kosher dietary laws. B2B buyers targeting this demographic can capitalize on seasonal demand, but they should be aware of the limited production runs that may affect availability. The appeal of these caps lies in their ability to attract a loyal customer base during specific times of the year.

What Makes Vintage Collector Caps a Unique Investment?

Vintage collector caps often feature unique designs and are made from materials like metal, appealing to collectors and promotional markets. These caps can serve as effective branding tools, creating a memorable connection with consumers. While they can command a higher price point, the potential for resale value makes them an attractive option for B2B buyers in niche markets. However, companies should be prepared for a more specialized sales approach, as the audience for these products may be limited.

Why Are Recycled Material Caps Important for Eco-Conscious Brands?

Recycled material caps are made from post-consumer recycled plastics, aligning with the growing demand for sustainable packaging solutions. Brands that prioritize corporate social responsibility (CSR) may find these caps essential in meeting consumer expectations for environmentally friendly products. Although they may come at a premium compared to standard caps, the investment can enhance brand loyalty and attract environmentally conscious consumers, positioning companies favorably in a competitive market.

Key Industrial Applications of coke bottle caps

| Industrie/sector | Specific Application of coke bottle caps | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Beverage Manufacturing | Sealing carbonated soft drink bottles | Ensures product freshness and prevents leakage | Quality control, compatibility with production lines |

| Recycling & Waste Management | Promoting recycling initiatives with attached caps | Enhances recycling rates and reduces environmental impact | Compliance with local regulations, material recyclability |

| Food & Beverage Retail | Seasonal packaging variations (e.g., Kosher for Passover) | Meets cultural dietary requirements, broadening market appeal | Certification processes, sourcing from compliant suppliers |

| Custom Merchandise | Creating promotional items or collectibles | Increases brand visibility and customer engagement | Material quality, design specifications, and production time |

| Packaging Innovation | Development of eco-friendly cap designs | Supports sustainability goals and improves brand reputation | Material sourcing, sustainability certifications, innovation focus |

How Are Coke Bottle Caps Used in Beverage Manufacturing?

In the beverage manufacturing sector, coke bottle caps serve a critical function in sealing carbonated soft drink bottles. They prevent leakage and maintain carbonation, ensuring the product remains fresh until it reaches consumers. For international buyers, particularly in regions like Africa and South America, sourcing caps that align with local production capabilities and quality standards is essential. Manufacturers must consider compatibility with their bottling processes and the potential for varying bottle sizes and designs.

What Role Do Coke Bottle Caps Play in Recycling and Waste Management?

Coke bottle caps, especially those designed to remain attached to bottles, significantly enhance recycling efforts. This innovation reduces the likelihood of caps being littered and discarded separately, which can complicate recycling processes. For businesses in waste management, particularly in Europe, focusing on sourcing caps that meet environmental regulations and promote higher recycling rates can lead to improved sustainability outcomes and reduced operational costs.

How Are Coke Bottle Caps Adapted for Seasonal Packaging in the Food & Beverage Retail Sector?

In the food and beverage retail sector, seasonal packaging variations, such as yellow-capped Coca-Cola bottles for Passover, cater to specific cultural dietary requirements. This adaptation allows brands to tap into niche markets and enhance consumer loyalty. International B2B buyers, especially from the Middle East, must ensure that they source caps that meet certification processes for dietary compliance, which can involve working with suppliers who understand local regulations and consumer preferences.

In What Ways Can Coke Bottle Caps Be Used for Custom Merchandise?

Coke bottle caps can also be leveraged to create custom merchandise or collectibles, increasing brand visibility and customer engagement. This application is particularly relevant for promotional campaigns and limited-edition releases. Businesses interested in this avenue should prioritize sourcing high-quality materials and ensuring that the designs align with brand identity. For buyers in Europe and South America, understanding the market demand for such items can drive successful promotional strategies.

How Are Coke Bottle Caps Contributing to Packaging Innovation?

Coke bottle caps are at the forefront of packaging innovation, particularly with the shift towards eco-friendly designs. These caps not only enhance the sustainability of packaging but also improve brand reputation among environmentally conscious consumers. For businesses focusing on sustainable practices, sourcing caps made from recyclable materials and obtaining relevant sustainability certifications is critical. This focus is especially pertinent for buyers in regions like Africa and the Middle East, where environmental concerns are increasingly influencing consumer choices.

3 Common User Pain Points for ‘coke bottle caps’ & Their Solutions

Scenario 1: Difficulties in Recycling and Sustainability Compliance

Het probleem: B2B buyers in the beverage packaging sector often grapple with sustainability regulations and consumer demands for eco-friendly practices. Traditional bottle caps are frequently discarded and become litter, leading to environmental concerns and potential fines for companies that fail to meet recycling standards. Buyers may find themselves at a crossroads, needing to balance cost-efficiency with compliance to the increasing pressure for sustainable packaging solutions.

De oplossing: Adopting attached caps can significantly enhance recycling rates while addressing sustainability challenges. These caps remain connected to the bottle after opening, reducing the likelihood of littering and facilitating easier recycling. When sourcing coke bottle caps, buyers should prioritize suppliers that offer attached caps and demonstrate their commitment to sustainable practices, such as using recycled materials. Additionally, integrating education programs for consumers about proper recycling methods can foster a culture of sustainability and compliance, ultimately benefiting the brand’s reputation and reducing potential liabilities.

Scenario 2: Inconsistent Product Quality Across Suppliers

Het probleem: For international B2B buyers, sourcing coke bottle caps can be fraught with challenges related to quality consistency. Different suppliers may provide caps that vary in material, durability, and design, leading to product integrity issues. This inconsistency can affect branding, customer satisfaction, and even the safety of the beverage itself, as poorly fitting caps may lead to leaks or spoilage.

De oplossing: Establishing rigorous quality control standards and conducting supplier audits can help mitigate these risks. Buyers should develop a clear set of specifications for coke bottle caps, including material composition, size, and production standards. Engaging in long-term partnerships with reputable suppliers who can guarantee consistent quality is essential. Additionally, implementing a trial phase where new suppliers provide samples for testing can help ensure that the caps meet the required standards before committing to larger orders.

Scenario 3: Navigating Regional Variations in Packaging Regulations

Het probleem: B2B buyers operating across multiple regions face the challenge of varying packaging regulations, which can complicate the sourcing of coke bottle caps. For instance, certain countries may have specific requirements regarding materials, labeling, and recycling symbols that differ from others, leading to potential compliance issues and costly penalties if not adhered to.

De oplossing: Buyers should invest in comprehensive market research to understand the packaging regulations in each target region. Collaborating with local experts or legal advisors can provide valuable insights into compliance requirements. Furthermore, choosing suppliers who have experience with international shipping and regional regulations can streamline the sourcing process. Buyers should also consider customizable caps that can be adapted to meet local regulations while maintaining brand identity, thus ensuring compliance without sacrificing marketability.

Strategic Material Selection Guide for coke bottle caps

What Materials Are Commonly Used for Coke Bottle Caps?

When selecting materials for coke bottle caps, it’s essential to consider various factors, including performance properties, manufacturing complexity, and compliance with international standards. Here, we analyze four common materials used in coke bottle caps: polypropylene (PP), polyethylene (PE), aluminum, and bioplastics.

How Does Polypropylene (PP) Perform for Coke Bottle Caps?

Polypropylene is a widely used thermoplastic polymer known for its excellent chemical resistance, lightweight nature, and versatility. It has a temperature rating of up to 100°C, making it suitable for a range of beverage applications.

Voordelen: Polypropylene is durable and resistant to moisture, which helps maintain the integrity of the beverage. It is also cost-effective and easy to manufacture, allowing for high-volume production.

Minpunten: While it offers good resistance to many chemicals, polypropylene may not be suitable for products requiring high-temperature sterilization. Additionally, it has a lower barrier property compared to other materials, which could impact the shelf life of carbonated beverages.

Invloed op de toepassing: Polypropylene caps are generally compatible with soft drinks and can withstand the pressure of carbonated beverages. However, buyers should consider the specific beverage formulation to ensure compatibility.

Internationale overwegingen: For buyers in regions like Europe and South America, compliance with EU regulations on food safety and recycling standards is crucial. Polypropylene is often favored due to its recyclability, aligning with sustainability initiatives in these markets.

What Are the Benefits of Using Polyethylene (PE) for Coke Bottle Caps?

Polyethylene, particularly high-density polyethylene (HDPE), is another common choice for bottle caps. It boasts excellent impact resistance and is chemically inert, making it safe for various food and beverage applications.

Voordelen: HDPE caps are lightweight and provide a good seal, which is essential for maintaining carbonation in soft drinks. They are also cost-effective and can be produced in various colors, enhancing branding opportunities.

Minpunten: While HDPE has decent chemical resistance, it may not perform well under high temperatures, limiting its application in hot-fill processes. Additionally, its lower rigidity compared to other materials may lead to deformation under stress.

Invloed op de toepassing: PE caps are suitable for carbonated beverages and can effectively contain liquids without leakage. However, their performance should be evaluated based on the specific product requirements.

Internationale overwegingen: Buyers in Africa and the Middle East should ensure that the PE caps meet local food safety standards. Additionally, adherence to recycling regulations is increasingly important in these markets.

Why Choose Aluminum for Coke Bottle Caps?

Aluminum caps are less common but are gaining popularity due to their excellent sealing properties and aesthetic appeal. They are often used in premium products and specialty beverages.

Voordelen: Aluminum offers superior barrier properties against oxygen and light, which can enhance the shelf life of the beverage. It is also recyclable, aligning with global sustainability goals.

Minpunten: The manufacturing process for aluminum caps can be more complex and costly compared to plastic alternatives. Additionally, they may not be suitable for all types of beverages, particularly those that require a flexible sealing solution.

Invloed op de toepassing: Aluminum caps are ideal for beverages that require extended shelf life and protection from external factors. However, they may not be compatible with all bottling lines, requiring specialized equipment.

Internationale overwegingen: Compliance with international standards such as ASTM and DIN is critical for aluminum caps. Buyers in Europe, particularly Germany, should be aware of stringent recycling regulations that favor recyclable materials.

How Do Bioplastics Compare for Coke Bottle Caps?

Bioplastics, made from renewable resources, are emerging as a sustainable alternative for traditional materials. They can offer similar performance to conventional plastics while reducing environmental impact.

Voordelen: Bioplastics can be designed to be biodegradable or compostable, appealing to environmentally conscious consumers. They can also provide good barrier properties and sealing capabilities.

Minpunten: The cost of bioplastics can be higher than conventional materials, and their availability may be limited in some regions. Additionally, the performance of bioplastics can vary based on the specific formulation.

Invloed op de toepassing: Bioplastics are suitable for various beverages, including carbonated drinks, but buyers should evaluate their performance under specific conditions.

Internationale overwegingen: As sustainability becomes a priority, buyers in Africa and South America may find increasing demand for bioplastics. Compliance with local environmental regulations will also be necessary.

Summary Table of Material Selection for Coke Bottle Caps

| Materiaal | Typical Use Case for coke bottle caps | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Polypropylene | Standard soft drink caps | Kosteneffectief en duurzaam | Lower barrier properties | Laag |

| Polyethylene | Carbonated beverage caps | Good sealing and impact resistance | Limited high-temperature performance | Laag |

| Aluminium | Premium beverage caps | Superior barrier properties | Higher manufacturing complexity | Hoog |

| Bioplastics | Eco-friendly beverage caps | Sustainable and biodegradable options | Higher cost and variable performance | Med |

This strategic material selection guide provides insights into the properties, advantages, and considerations for various materials used in coke bottle caps, aiding international B2B buyers in making informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for coke bottle caps

What Are the Key Stages in the Manufacturing Process of Coke Bottle Caps?

The manufacturing of coke bottle caps is a precise and technical process that involves several stages, ensuring both functionality and quality.

Materiaalvoorbereiding: Welke materialen worden gebruikt?

The primary material used in the production of coke bottle caps is high-density polyethylene (HDPE) or polypropylene (PP), both of which offer excellent durability and resistance to environmental stress. During the material preparation stage, the raw plastic is sourced and tested for quality. This includes checking for impurities and ensuring that the material meets international quality standards. Additionally, recycled plastics are increasingly being integrated into the production process to enhance sustainability efforts.

How Are Coke Bottle Caps Formed?

Once the material is prepared, the forming process begins. This typically involves injection molding, where heated plastic is injected into a mold that shapes it into the desired cap form. The temperature and pressure during this process are carefully controlled to ensure the cap’s structural integrity and functionality.

In some cases, advanced techniques such as blow molding may be used, especially for caps that require a specific design or feature, such as attached caps. This innovation not only helps in reducing waste but also ensures that the cap remains with the bottle after opening, aiding in recycling efforts.

What Does the Assembly Process Entail?

After forming, the caps may undergo an assembly process if they include additional features such as tamper-evident rings or integrated seals. Automated assembly lines are often utilized to attach these components efficiently. Quality checks are performed at this stage to ensure that each cap meets design specifications and functional requirements.

What Finishing Techniques Are Applied to Coke Bottle Caps?

The final stage in the manufacturing process is finishing, which includes processes such as printing, labeling, and surface treatment. Caps may be printed with branding or information using techniques like pad printing or screen printing. These processes must ensure that the ink adheres properly and is resistant to wear and tear, as caps are subject to handling and exposure to various elements.

What Quality Assurance Measures Are Implemented in the Production of Coke Bottle Caps?

Quality assurance (QA) is crucial in the manufacturing of coke bottle caps to ensure that they meet international standards and are safe for consumer use.

Which International Standards Govern Quality Assurance?

For manufacturers, adhering to international standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system and ensures that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, region-specific certifications like CE marking in Europe or FDA approval in the United States may be required, depending on the market.

Wat zijn de belangrijkste controlepunten voor kwaliteitscontrole?

Quality control (QC) checkpoints are implemented throughout the manufacturing process. These typically include:

- Inkomende kwaliteitscontrole (IQC): This step involves testing the raw materials for defects before they enter the production line.

- Kwaliteitscontrole tijdens het proces (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from the standard are caught early.

- Final Quality Control (FQC): Once the caps are produced, they undergo final inspections to verify that they meet all specifications and standards before being packaged and shipped.

What Testing Methods Are Commonly Used?

Common testing methods for coke bottle caps include:

- Mechanical Testing: Assessing the tensile strength and impact resistance of the caps.

- Chemical Testing: Ensuring that the materials used do not leach harmful substances into the beverage.

- Dimensional Testing: Verifying that the caps fit correctly on the bottles.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial for ensuring product consistency and compliance.

What Are the Best Practices for Auditing Suppliers?

One effective way to verify quality is through supplier audits. B2B buyers should conduct regular audits to assess the supplier’s manufacturing processes, QC measures, and compliance with international standards. This can be done through on-site visits or by requesting detailed reports that outline the supplier’s QA practices.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can further validate the supplier’s quality claims. These independent entities can provide objective assessments of the manufacturing process and product quality, ensuring that the caps meet required specifications and standards.

What Should Buyers Look for in Quality Reports?

When reviewing quality reports, buyers should pay attention to:

- Compliance with International Standards: Ensure that the supplier adheres to ISO 9001 and other relevant certifications.

- Historical Quality Metrics: Look for data on defect rates, return rates, and any corrective actions taken in response to past issues.

- Traceability: Ensure that the supplier can trace materials and processes for accountability.

What Are the Key Considerations for International Buyers?

For international buyers, particularly those operating in regions with varying regulations, understanding the nuances of QC and certifications is vital.

Are There Regional Variations in Quality Standards?

Different regions may have specific quality standards or certifications that must be met. For example, buyers in Europe may need to ensure compliance with CE marking, while those in the Middle East may have different regulatory requirements. Understanding these nuances can prevent costly compliance issues.

How Can Buyers Ensure Consistent Quality Across Different Markets?

To ensure consistent quality, buyers should establish clear specifications and expectations with their suppliers. This includes detailed documentation of quality standards, testing methods, and compliance requirements. Regular communication and collaboration with suppliers can also help in addressing any potential quality issues proactively.

By understanding the manufacturing processes and quality assurance measures for coke bottle caps, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring that they receive high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coke bottle caps’

In the competitive landscape of beverage packaging, sourcing the right coke bottle caps is essential for ensuring product quality, sustainability, and regulatory compliance. This guide provides a practical checklist for B2B buyers looking to procure coke bottle caps, with a focus on international markets including Africa, South America, the Middle East, and Europe.

Stap 1: Je technische specificaties definiëren

Clearly outline the specific requirements for the coke bottle caps you need. This includes material type (e.g., plastic or metal), size, and any unique features like attached caps for enhanced recycling. Understanding these specifications will help streamline your search and ensure that suppliers can meet your exact needs.

Stap 2: Research Regulatory Compliance

Verify that potential suppliers comply with local and international regulations regarding packaging materials. This includes checking for certifications such as FDA approval or compliance with the European Union’s Packaging and Packaging Waste Directive. Understanding these regulations will help you avoid legal complications and ensure your product meets market standards.

Stap 3: Potentiële leveranciers evalueren

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have experience with large-scale production and can demonstrate a commitment to quality and sustainability practices, especially if you’re interested in eco-friendly options like attached caps.

Stap 4: Assess Sustainability Practices

With growing consumer demand for sustainable practices, it’s vital to assess suppliers’ sustainability initiatives. Inquire about their use of recycled materials, waste management processes, and any innovations they have implemented to reduce environmental impact. Suppliers who are proactive in sustainability can enhance your brand’s image and meet the expectations of eco-conscious consumers.

Stap 5: Request Samples for Quality Assurance

Always request samples of the coke bottle caps before making a bulk order. This allows you to assess the quality, fit, and functionality of the caps firsthand. Pay attention to details such as sealing effectiveness, ease of use, and overall durability, as these factors will significantly impact the consumer experience.

Stap 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, discuss pricing, lead times, and payment terms. Ensure that all details are clearly defined in a contract to avoid misunderstandings later. Consider negotiating for bulk discounts or flexible payment options to maximize your budget.

Stap 7: Establish a Communication Plan

Effective communication is critical for a successful sourcing partnership. Set clear expectations regarding updates on production, shipment schedules, and any potential issues that may arise. Regular communication will help build a strong relationship with your supplier and facilitate smoother transactions.

By following this checklist, B2B buyers can navigate the complexities of sourcing coke bottle caps more effectively, ensuring they choose the right suppliers while aligning with industry standards and consumer expectations.

Comprehensive Cost and Pricing Analysis for coke bottle caps Sourcing

What Are the Key Cost Components in Sourcing Coke Bottle Caps?

When sourcing coke bottle caps, understanding the cost structure is vital for B2B buyers. The cost components typically include:

-

Materialen: The primary material for coke bottle caps is high-density polyethylene (HDPE) or polypropylene, both of which vary in price based on market fluctuations. The choice of material can significantly impact overall costs, especially if sustainability certifications or recycled materials are desired.

-

Arbeid: Labor costs encompass wages for workers involved in manufacturing, assembling, and quality checking the caps. These costs can vary significantly by region, with countries in Africa or South America often having lower labor costs compared to Europe.

-

Productie Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient production processes can help minimize overhead, thereby reducing total costs.

-

Gereedschap: Initial tooling costs for creating molds and machinery setup can be substantial but are amortized over the production run. Custom designs or unique specifications can increase these costs, so it’s essential to evaluate the scale of production.

-

Kwaliteitscontrole (QC): Implementing robust QC processes ensures that the caps meet safety and quality standards, which is particularly crucial for international markets. While QC adds to the cost, it can prevent costly recalls or brand damage due to defective products.

-

Logistiek: Transportation and shipping costs can vary based on the distance from the manufacturing site to the buyer’s location. Incoterms (International Commercial Terms) play a crucial role in determining who bears these costs and risks.

-

Marge: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market demand, competition, and the supplier’s reputation.

How Do Pricing Influencers Affect Coke Bottle Cap Costs?

Several factors influence the pricing of coke bottle caps in the B2B market:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their consumption patterns to optimize pricing.

-

Specificaties en aanpassingen: Unique designs or specific requirements (such as attached caps for recycling purposes) can increase costs. Buyers should be clear about their needs upfront to get accurate quotes.

-

Materials Quality and Certifications: Caps made from certified, sustainable materials may carry a premium price. Buyers should assess the value of these certifications against their brand’s sustainability goals.

-

Factoren van leveranciers: The reputation and reliability of suppliers can affect pricing. Established suppliers might charge more due to their proven track record, while newer suppliers may offer competitive rates to gain market share.

-

Incoterms: Understanding the shipping terms is crucial. Different Incoterms can shift costs and responsibilities between buyers and sellers, impacting the total cost of ownership.

What Are Essential Tips for B2B Buyers Negotiating Coke Bottle Cap Prices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

-

Onderhandelen over voorwaarden: Don’t hesitate to negotiate pricing, especially for larger orders. Seek discounts for bulk purchases or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate all costs associated with sourcing caps, including shipping, handling, and potential tariffs. A lower upfront price may not always result in the best value.

-

Nuances in prijsstelling begrijpen: Be aware that prices can fluctuate based on raw material costs and market demand. Staying informed about market trends can provide leverage during negotiations.

-

Relaties opbouwen met leveranciers: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Trust and reliability are significant factors in long-term partnerships.

-

Evaluate Local vs. International Suppliers: While international suppliers may offer competitive pricing, local suppliers can reduce shipping costs and lead times. Assess the trade-offs based on your business needs.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier evaluations before finalizing any agreements.

Alternatives Analysis: Comparing coke bottle caps With Other Solutions

Exploring Alternatives to Coke Bottle Caps

In the beverage industry, the choice of packaging solutions, such as bottle caps, significantly impacts sustainability, customer experience, and operational efficiency. As companies aim to enhance their environmental footprint while maintaining product integrity, exploring alternative solutions becomes essential. This section presents a comparative analysis of Coke bottle caps against two viable alternatives: attached caps and biodegradable caps.

| Vergelijkingsaspect | Coke Bottle Caps | Attached Caps | Biodegradable Caps |

|---|---|---|---|

| Prestaties | Reliable sealing, easy to use | Retains cap post-opening | Varies based on material |

| Kosten | Low cost per unit | Slightly higher than standard | Potentially higher due to materials |

| Gemak van implementatie | Widely adopted, easy to source | Requires redesign of bottles | Needs supplier education and sourcing |

| Onderhoud | Minimal maintenance required | No maintenance required | Varies based on composting conditions |

| Beste gebruikscasus | General soft drink packaging | Eco-conscious brands | Brands targeting eco-aware consumers |

What are the Benefits and Drawbacks of Attached Caps?

Attached caps, a recent innovation by Coca-Cola, are designed to remain connected to the bottle after opening. This feature significantly reduces littering and enhances recycling rates, as consumers are less likely to discard the cap separately. While the initial cost of implementing attached caps might be slightly higher, the long-term benefits in sustainability and consumer perception can outweigh the costs. However, businesses must consider redesigning their bottles, which may involve additional investment in production processes.

How Do Biodegradable Caps Compare to Traditional Options?

Biodegradable caps represent a forward-thinking approach to packaging that aligns with growing consumer demand for sustainable products. These caps decompose over time, reducing environmental impact. However, they can have variable performance characteristics, depending on the materials used, and may not provide the same reliable seal as traditional caps. Cost can also be a concern, as biodegradable materials tend to be more expensive, which could affect pricing strategies for businesses. Additionally, the successful composting of these caps relies heavily on proper disposal methods, which could complicate logistics for some companies.

How Should B2B Buyers Choose the Right Cap Solution?

When selecting the appropriate cap solution, B2B buyers should assess their specific operational needs, target market preferences, and sustainability goals. Companies focused on enhancing their environmental credentials may gravitate towards attached or biodegradable caps, whereas those prioritizing cost and reliability might prefer traditional Coke bottle caps. Conducting a comprehensive analysis that incorporates cost considerations, consumer expectations, and long-term sustainability objectives will empower businesses to make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for coke bottle caps

What Are the Key Technical Properties of Coke Bottle Caps?

When sourcing coke bottle caps for production or distribution, several technical properties are critical to ensure quality, functionality, and compliance with industry standards. Understanding these specifications can aid in making informed purchasing decisions.

1. Material Grade

Coke bottle caps are typically made from high-density polyethylene (HDPE) or polypropylene (PP). These materials are chosen for their strength, durability, and resistance to chemicals. In a B2B context, selecting the right material grade is crucial for ensuring the caps can withstand transportation and storage conditions while maintaining product integrity.

2. Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension of the cap, such as height or diameter. For example, a cap may have a tolerance of ±0.5mm on its diameter. Adhering to strict tolerance levels is vital for ensuring that caps fit securely on bottles, preventing leaks and product spoilage. Inconsistent tolerances can lead to increased production costs and customer dissatisfaction.

3. Closure Type

Coke bottle caps can be categorized into different closure types, including twist-off and attached caps. Attached caps are designed to remain connected to the bottle after opening, promoting sustainability by reducing litter. Understanding the closure type is essential for manufacturers and suppliers to meet consumer preferences and regulatory requirements, particularly in markets prioritizing environmental responsibility.

4. Seal Integrity

The seal integrity of a bottle cap is measured by its ability to create an airtight seal once applied. This property is vital for preserving carbonation and preventing contamination. In B2B transactions, evaluating seal integrity is important for ensuring product quality and compliance with food safety standards, which vary across different regions.

5. Color and Customization Options

Color can serve both functional and marketing purposes. For instance, Coca-Cola uses distinct colors, like yellow for Passover, to signify special product variations. Customization options for cap colors and designs can enhance brand visibility and consumer appeal. B2B buyers should consider these options to strengthen their brand identity in competitive markets.

What Common Trade Terms Should You Know When Buying Coke Bottle Caps?

Understanding industry jargon can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some essential terms frequently encountered in the trade of coke bottle caps.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of coke bottle caps, OEM suppliers provide caps that meet the specific requirements of beverage manufacturers. This relationship is important for ensuring product compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers who need to understand the minimum purchase requirements to avoid excess inventory costs. Knowing the MOQ helps businesses plan their budgets and inventory management more effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For buyers of coke bottle caps, issuing an RFQ can streamline the procurement process, allowing for comparison of pricing, lead times, and other terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears the risk and cost at various points during shipping. Understanding Incoterms is vital for B2B buyers involved in international transactions, as they impact overall costs and liabilities.

5. Sustainability Certifications

Sustainability certifications indicate that products meet specific environmental standards. For coke bottle caps, certifications such as those from the UK Plastics Pact can enhance a brand’s reputation and appeal to environmentally conscious consumers. B2B buyers should consider these certifications when selecting suppliers to align with their sustainability goals.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing coke bottle caps more effectively, ensuring that they meet both their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the coke bottle caps Sector

What Are the Key Trends Shaping the Coke Bottle Caps Market?

The global coke bottle caps market is experiencing significant transformation driven by sustainability demands, technological innovations, and evolving consumer preferences. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their supply chains, understanding these dynamics becomes crucial. One of the most notable trends is the shift towards attached caps, pioneered by Coca-Cola in Great Britain. This innovation not only enhances user experience by keeping the cap connected to the bottle but also addresses environmental concerns by reducing litter and improving recycling rates. The move aligns with the global push for circular economy practices, which emphasize the reuse and recycling of materials.

Moreover, digital sourcing platforms and B2B e-commerce solutions are emerging as vital tools for buyers to access a diverse range of suppliers and streamline procurement processes. These technologies facilitate real-time data sharing, allowing buyers to make informed decisions based on market trends, pricing fluctuations, and supplier reliability. Additionally, the trend of customization is gaining traction, as brands look to differentiate their products through unique cap designs and functionalities, catering to specific regional preferences, such as the Kosher for Passover variations seen in some markets.

How Is Sustainability Influencing Sourcing Decisions for Coke Bottle Caps?

Sustainability is no longer just a buzzword; it is a fundamental aspect of sourcing strategies in the coke bottle caps sector. Environmental impact considerations have led to a heightened focus on ethical supply chains and responsible sourcing practices. For B2B buyers, understanding the sustainability credentials of their suppliers is essential in aligning with global sustainability goals and meeting the expectations of increasingly eco-conscious consumers.

Coca-Cola’s initiative to use 100% recycled materials in its packaging exemplifies the industry’s shift towards sustainable practices. Buyers are now prioritizing suppliers who can provide eco-friendly certifications and materials, such as recycled plastics or biodegradable alternatives. Additionally, the demand for transparency in the supply chain is rising; buyers want to ensure that their suppliers adhere to ethical labor practices and environmental regulations. Certifications like ISO 14001 for environmental management and the Global Recycled Standard can serve as benchmarks for evaluating supplier sustainability.

What Historical Developments Have Influenced the Coke Bottle Caps Market?

The evolution of coke bottle caps reflects broader trends in packaging technology and consumer behavior. Initially, caps served a simple functional purpose—sealing bottles to maintain carbonation. However, as consumer expectations evolved, so did the design and functionality of bottle caps. The introduction of twist-off caps in the mid-20th century marked a significant advancement, allowing for easier access and enhanced convenience.

In recent decades, the focus has shifted towards sustainability and innovation. The development of attached caps, which remain connected to the bottle after opening, is a direct response to environmental concerns about litter and recycling. This evolution highlights the industry’s ability to adapt to changing market demands while maintaining functionality and consumer appeal. As international B2B buyers navigate these developments, understanding the historical context can provide valuable insights into future trends and opportunities within the coke bottle caps market.

Frequently Asked Questions (FAQs) for B2B Buyers of coke bottle caps

-

How do I select the right supplier for coke bottle caps?

When selecting a supplier for coke bottle caps, consider their production capacity, quality certifications, and experience in international trade. Request samples to evaluate the material quality and design, and check for compliance with global standards such as ISO and food safety regulations. Additionally, investigate their reputation through reviews and testimonials from other B2B clients. Establish clear communication channels and ensure they can handle your specific logistics needs, especially if you’re sourcing from regions like Africa or South America. -

What are the minimum order quantities (MOQ) for coke bottle caps?

Minimum order quantities for coke bottle caps can vary significantly depending on the supplier and the specific type of caps required. Typically, MOQs can range from a few thousand to tens of thousands of units. It’s essential to communicate your needs upfront and inquire if the supplier offers flexibility for smaller orders, especially for new businesses or those testing a market. Understanding the MOQ will help you plan your inventory and manage costs effectively. -

What customization options are available for coke bottle caps?

Many suppliers offer customization options for coke bottle caps, including color, size, and branding elements like logos or unique designs. Depending on the supplier’s capabilities, you can choose from standard designs or request bespoke solutions that cater to your brand’s identity. Be sure to discuss your specific requirements early in the negotiation process to ensure the supplier can meet your needs, and request prototypes to verify the design before mass production. -

What payment terms should I expect when purchasing coke bottle caps?

Payment terms for coke bottle caps can vary by supplier and region. Common terms include a deposit upfront (often 30-50%) with the balance due before shipment or upon delivery. It’s crucial to clarify payment methods accepted, whether bank transfers, letters of credit, or other means. Ensure that the terms are mutually agreeable and consider factors such as currency exchange rates and transaction fees, especially when dealing with international suppliers. -

How do I ensure quality assurance for coke bottle caps?

To ensure quality assurance for coke bottle caps, verify that the supplier adheres to recognized quality management systems like ISO 9001. Request documentation of their quality control processes, including testing methods and certifications. It may also be beneficial to conduct factory audits or third-party inspections before shipment. Establishing clear quality expectations and communication with the supplier will help mitigate risks and ensure that the caps meet your specifications. -

What are the logistics considerations for importing coke bottle caps?

When importing coke bottle caps, consider logistics factors such as shipping methods, lead times, and customs regulations in your region. Discuss with your supplier the best shipping options, whether air freight for speed or sea freight for cost-effectiveness. Familiarize yourself with import tariffs and duties that may apply, and ensure all documentation is in order to facilitate smooth customs clearance. Collaborating with a logistics partner experienced in international trade can streamline the process. -

How can I stay updated on market trends for coke bottle caps?

To stay updated on market trends for coke bottle caps, subscribe to industry publications, attend trade shows, and participate in relevant online forums or associations. Networking with other B2B buyers and suppliers can also provide insights into emerging trends and innovations in packaging. Additionally, keeping an eye on sustainability initiatives and regulatory changes in packaging can help you anticipate market shifts and adapt your sourcing strategies accordingly. -

What environmental considerations should I be aware of when sourcing coke bottle caps?

Environmental considerations are increasingly important in sourcing coke bottle caps. Look for suppliers that prioritize sustainable practices, such as using recyclable materials or implementing eco-friendly production processes. Inquire about their commitment to reducing plastic waste and whether they offer options like attached caps, which enhance recycling efficiency. Understanding the supplier’s sustainability initiatives can align your business with global eco-conscious trends and appeal to environmentally aware consumers.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 9 Coke Bottle Caps Manufacturers & Suppliers List

1. Coca-Cola – Bottle Caps

Domein: ebay.com

Geregistreerd: 1995 (30 jaar)

Inleiding: Coca-Cola Bottle Caps for sale on eBay. Color options include multi-color, red, silver, brown, orange, green, yellow, blue, black, and gray. Categories include vintage, pre-owned, and brand new items. Prices range from $1.59 to $200.00 with various shipping costs. Notable listings include vintage FIFA World Cup album caps, 1960s “Tour the World” caps, and modern style caps for arts and crafts. Add…

2. Coca-Cola – Attached Caps Initiative

Domein: coca-cola.com

Geregistreerd: 1994 (31 jaar)

Inleiding: Coca-Cola has introduced attached caps across its entire portfolio in Great Britain. This innovation keeps the cap connected to the bottle after opening, making it easier to collect and recycle all parts of the packaging. The attached caps are designed to reduce littering and enhance the recycling process. Coca-Cola is the first major soft drinks company to implement this change across its entire …

3. Coca-Cola – Kosher for Passover

Domein: eten-en-wijn.com

Geregistreerd: 1998 (27 jaar)

Inleiding: Coca-Cola bottles with yellow caps are certified Kosher for Passover, indicating that the soda is acceptable for consumption during the Jewish holiday. These bottles are produced annually in limited quantities, typically available before Passover, which begins on April 22 this year. The recipe for these bottles substitutes high-fructose corn syrup with cane sugar, making it similar to Mexican Coke…

4. Pinterest – Bottle Cap Crafts

Domein: pinterest.com

Geregistreerd: 2009 (16 jaar)

Inleiding: Coke bottle caps crafts, DIY projects, upcycling ideas, home decor, bottle cap art, beer bottle caps, Coca-Cola themed decor, creative bottle cap crafts, eco-friendly crafts, bottle cap jewelry, wind chimes, coasters, ornaments, wall art, and various recycling projects.

5. Coca-Cola – Sustainable Bottle Caps

Domein: wsj.com

Geregistreerd: 1994 (31 jaar)

Inleiding: Coca-Cola’s new sustainable bottle caps are attached to the bottles to comply with EU regulations on plastic recycling. This design was first tested in Germany and Spain in 2021 and has since expanded to other European markets. The attached caps aim to ensure that more caps are recycled with their bottles rather than discarded. The bottle top features the message, ‘I am attached to recycle togethe…

6. Coca-Cola – Premium Silver Bottle Caps

Domein: reddit.nl

Geregistreerd: 2005 (20 jaar)

Inleiding: Coca-Cola 6 gram bottle caps, premium silver, priced around $29.99 to $31, with resale values noted at approximately $50. They are considered collectibles appealing to both silver and Coca-Cola product collectors. Some users express concerns about high premiums and low resale value, while others appreciate them for novelty and personal enjoyment.

7. Department 56 – Coca-Cola Bottle Caps

Domein: speachfamilycandy.com

Registered: 2007 (18 years)

Inleiding: {“product_name”: “Coca-Cola Bottle Caps”, “product_id”: “4056665”, “department”: “Department 56”, “description”: “At the North Pole, this very unique factory specializes in producing Coca-Cola bottle caps. Crafted with actual bottle caps, this brightly lit animated building features a spinning conveyor belt, turning as if to drop finished caps into the cart below.”, “introduction_date”: “January 2…

8. Facebook – Craft Supplies

Domein: facebook.com

Geregistreerd: 1997 (28 jaar)

Inleiding: Coke bottle cap, craft supplies, best out of waste, crafts

9. Coca-Cola – Product Caps

Domein: disboards.com

Geregistreerd: 2000 (25 jaar)

Inleiding: Coca-Cola product caps contain codes for rewards, which are being phased out. As of June 30, 2023, the redemption of these codes has ended. Users can still collect and donate their codes to charities until that date. The caps are not recyclable and can cause issues in recycling machines. Users are encouraged to minimize single-use plastics and consider alternative packaging options.

Strategic Sourcing Conclusion and Outlook for coke bottle caps

How Can Strategic Sourcing Enhance Your Supply Chain for Coke Bottle Caps?

In conclusion, strategic sourcing of coke bottle caps presents a unique opportunity for international B2B buyers to optimize their supply chains while aligning with sustainability goals. The shift towards attached caps, as demonstrated by Coca-Cola’s recent initiatives, underscores the importance of innovative design that promotes recycling and reduces waste. By partnering with suppliers who prioritize sustainable materials and practices, businesses can enhance their brand reputation and meet the growing consumer demand for eco-friendly products.

Moreover, understanding regional variations, such as the introduction of specialty caps for Kosher markets, allows buyers to cater to diverse consumer needs while expanding their market reach.

As you look ahead, consider the potential for collaboration with manufacturers focused on sustainable practices and innovative solutions. By taking proactive steps to source responsibly, you not only secure a competitive edge but also contribute to a more sustainable future. Engage with suppliers that share your vision for sustainability and quality, and explore opportunities for growth in emerging markets across Africa, South America, the Middle East, and Europe. Your strategic sourcing decisions today will shape the packaging landscape of tomorrow.