Introduction: Navigating the Global Market for gallon bottles

In today’s competitive global market, sourcing high-quality gallon bottles can present unique challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia. With varying regional regulations, quality standards, and supplier capabilities, it is essential to navigate these complexities effectively. This comprehensive guide aims to equip international buyers with the critical insights needed to successfully procure gallon bottles that meet their specific needs.

Throughout this guide, we will delve into various types of gallon bottles available on the market, from durable plastic jugs to specialized containers designed for specific applications, such as food and beverage storage or industrial use. We will also explore the importance of supplier vetting, highlighting key considerations for evaluating potential partners, including quality assurance, compliance with international standards, and pricing structures.

Additionally, we will address cost factors and bulk purchasing strategies that can significantly impact the bottom line. By leveraging the knowledge and strategies outlined in this guide, B2B buyers will be empowered to make informed purchasing decisions, ensuring they secure the right gallon bottles for their operations while optimizing value and efficiency.

Artikel navigatie

- Top 7 Gallon Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for gallon bottles

- Understanding gallon bottles Types and Variations

- Key Industrial Applications of gallon bottles

- 3 Common User Pain Points for ‘gallon bottles’ & Their Solutions

- Strategic Material Selection Guide for gallon bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for gallon bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘gallon bottles’

- Comprehensive Cost and Pricing Analysis for gallon bottles Sourcing

- Alternatives Analysis: Comparing gallon bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for gallon bottles

- Navigating Market Dynamics and Sourcing Trends in the gallon bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gallon bottles

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for gallon bottles

Understanding gallon bottles Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| HDPE Plastic Jugs | High-density polyethylene, lightweight, recyclable | Food and beverage storage, chemicals | Voordelen: Durable, cost-effective, customizable. Minpunten: Limited temperature resistance. |

| Glass Gallon Jars | Glass material, often with airtight seals | Specialty foods, high-end beverages | Voordelen: Non-reactive, preserves flavor. Minpunten: Heavy, fragile. |

| Stainless Steel Water Bottles | Insulated, durable, and often BPA-free | Outdoor activities, hydration solutions | Voordelen: Excellent insulation, long-lasting. Minpunten: Higher initial cost, heavier than plastic. |

| F-style Gallon Containers | Rectangular shape, built-in handle, often HDPE | Industrial cleaners, automotive fluids | Voordelen: Easy to handle, stackable. Minpunten: Limited aesthetic appeal. |

| Tamper-Evident Gallon Bottles | Special closures that indicate tampering | Pharmaceuticals, food safety | Voordelen: Enhances product safety, compliance. Minpunten: May increase costs. |

What are the Characteristics of HDPE Plastic Jugs?

HDPE (High-Density Polyethylene) plastic jugs are widely recognized for their versatility in various industries. These jugs are lightweight yet durable, making them ideal for bulk storage of liquids such as food products, cleaning supplies, and chemicals. Their recyclable nature adds to their appeal, especially for environmentally conscious businesses. When purchasing, consider factors such as neck size for compatibility with closures and potential customization options for branding.

Why Choose Glass Gallon Jars for Specialty Products?

Glass gallon jars are favored in the specialty food and beverage sectors due to their non-reactive properties, which help preserve the integrity of contents like oils, sauces, and high-end beverages. Their airtight seals prevent contamination and extend shelf life. However, buyers should weigh the benefits against the fragility and weight of glass, which may impact shipping and handling costs.

How Do Stainless Steel Water Bottles Stand Out?

Stainless steel water bottles are designed for durability and insulation, making them perfect for outdoor activities and hydration solutions. They maintain the temperature of liquids for extended periods, catering to customers who prioritize quality and functionality. While they tend to be more expensive than plastic options, their longevity and effectiveness can justify the investment, especially for businesses targeting a premium market.

What are the Advantages of F-style Gallon Containers?

F-style gallon containers feature a rectangular shape with a built-in handle, making them user-friendly for industrial applications. Commonly made from HDPE, they are ideal for storing automotive fluids, industrial cleaners, and other liquids. Their stackable design facilitates efficient storage and transportation. However, their aesthetic appeal may be limited compared to other options, which could be a consideration for brands focusing on presentation.

Why are Tamper-Evident Gallon Bottles Important for Compliance?

Tamper-evident gallon bottles are essential in industries where product safety and compliance are paramount, such as pharmaceuticals and food production. These bottles feature closures that show visible signs of tampering, enhancing consumer confidence and regulatory compliance. While they may come at a higher cost, the added safety and assurance they provide can be invaluable, especially in markets where trust is critical.

Key Industrial Applications of gallon bottles

| Industrie/sector | Specific Application of gallon bottles | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Eten en drinken | Storage of cooking oils, sauces, and dressings | Ensures product integrity and minimizes waste | Compliance with food safety regulations; material certifications |

| Chemical Manufacturing | Containment of industrial chemicals and cleaning agents | Durable and leak-proof storage solutions | Chemical compatibility; availability of bulk orders |

| Agriculture | Transport of fertilizers and pesticides | Facilitates efficient application and reduces spillage | UV protection; strength against environmental factors |

| Water and Beverage Distribution | Delivery of drinking water and beverages | Cost-effective and environmentally friendly packaging | Recyclability; closure options for safety and convenience |

| Personal Care Products | Packaging for lotions, shampoos, and cleaning products | Enhances brand visibility and consumer convenience | Customization options; design flexibility for branding |

How Are Gallon Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, gallon bottles are commonly used for storing cooking oils, sauces, and dressings. These containers help maintain product integrity by preventing contamination and minimizing waste during storage and transport. For international buyers, it’s essential to ensure that the materials used comply with food safety regulations and that they have the necessary certifications, especially when importing to regions with stringent standards.

What Role Do Gallon Bottles Play in Chemical Manufacturing?

Gallon bottles serve as reliable containment solutions for industrial chemicals and cleaning agents. Their robust design ensures that they are leak-proof, providing a safe method for transporting and storing hazardous substances. Buyers in this sector must consider chemical compatibility when sourcing bottles to avoid reactions that could compromise safety. Additionally, the ability to order in bulk can lead to significant cost savings.

How Are Gallon Bottles Utilized in Agriculture?

In agriculture, gallon bottles are frequently employed for transporting fertilizers and pesticides. These containers facilitate efficient application while minimizing spillage, which is crucial for maintaining environmental safety. Buyers should look for bottles that offer UV protection and are designed to withstand various environmental factors, ensuring that the contents remain effective throughout their shelf life.

Why Are Gallon Bottles Important for Water and Beverage Distribution?

Gallon bottles are a staple in the delivery of drinking water and various beverages, providing a cost-effective and eco-friendly packaging option. Their lightweight nature makes them easy to transport, while the availability of different closure options enhances safety and convenience during use. International buyers should prioritize recyclability and ensure that the bottles meet local regulations regarding water quality and packaging.

How Do Gallon Bottles Benefit the Personal Care Products Sector?

In the personal care industry, gallon bottles are often used for packaging lotions, shampoos, and cleaning products. These containers not only enhance brand visibility but also offer convenience for consumers who prefer bulk purchases. Buyers should seek customization options to align the packaging with their branding strategies, while also considering design flexibility that accommodates various product types.

3 Common User Pain Points for ‘gallon bottles’ & Their Solutions

Scenario 1: Choosing the Right Gallon Bottle for Specific Liquids

Het probleem: B2B buyers often struggle to select the appropriate gallon bottle for their specific liquid products, such as oils, cleaning agents, or chemicals. Each liquid requires a different type of container that can withstand various conditions, including temperature changes, chemical interactions, and pressure. For instance, using a bottle not designed for a particular chemical may result in leakage or degradation of the bottle material, leading to product loss and safety hazards. This challenge is compounded by the vast array of bottle shapes, sizes, and materials available in the market.

De oplossing: To overcome this challenge, it is crucial to conduct thorough research on the chemical compatibility of materials used in gallon bottles. High-density polyethylene (HDPE) is often recommended for many liquids due to its resistance to impact and moisture, but not all HDPE bottles are the same. Buyers should engage with suppliers to discuss their product specifications and potential environmental factors affecting the container, such as temperature and exposure to sunlight. It’s also wise to request samples of different bottle types to test compatibility before placing a bulk order. Establishing a strong relationship with packaging experts can provide insights into customized solutions tailored to specific liquid requirements, ensuring safety and product integrity.

Scenario 2: Navigating Bulk Order Discounts and Pricing Strategies

Het probleem: Many B2B buyers are unaware of how to leverage bulk order discounts effectively when purchasing gallon bottles. This lack of knowledge can lead to overspending or missed opportunities for cost savings. For example, a buyer may need 1,000 bottles but only orders 500 due to uncertainty about pricing tiers, resulting in unnecessary expenditure. Additionally, without understanding the terms of bulk pricing, buyers may overlook additional costs, such as shipping or storage, that can erode their savings.

De oplossing: To maximize cost efficiency, buyers should engage directly with suppliers to understand their pricing structure and minimum order quantities. It is advisable to request a detailed quote that outlines costs associated with different order sizes, including potential shipping costs and discounts. Buyers should also consider consolidating orders with other products to meet minimum quantity requirements. Establishing a strategic partnership with suppliers can yield better pricing and more favorable terms over time. Furthermore, buyers can explore group purchasing options with other businesses in their industry to gain bulk discounts collectively, thereby reducing individual costs.

Scenario 3: Ensuring Proper Handling and Storage of Gallon Bottles

Het probleem: Once purchased, the handling and storage of gallon bottles can present significant challenges, particularly in warehouses or distribution centers. Improper handling can lead to damage, such as cracks or leaks, while inadequate storage solutions can waste space and increase operational inefficiencies. Buyers may also struggle with ensuring that bottles are stored in conditions that maintain their integrity, especially for sensitive liquids that require specific temperature or humidity controls.

De oplossing: Implementing a robust training program for warehouse staff is essential for proper handling techniques to minimize the risk of damage. This training should cover best practices for lifting, stacking, and moving gallon bottles, as well as the importance of using appropriate storage equipment, such as shelving designed to accommodate the weight and shape of gallon bottles. Additionally, buyers should consider investing in climate-controlled storage solutions for products that are sensitive to environmental conditions. Regular audits of inventory and storage practices can further ensure compliance with safety standards and operational efficiency. By adopting these strategies, businesses can enhance their supply chain management, reduce losses, and ensure that products remain in optimal condition.

Strategic Material Selection Guide for gallon bottles

What Are the Key Properties of Common Materials Used for Gallon Bottles?

In the realm of gallon bottle manufacturing, the choice of material is crucial for ensuring product performance, safety, and compliance with international standards. Here, we analyze four common materials used for gallon bottles: High-Density Polyethylene (HDPE), Polypropylene (PP), Glass, and Stainless Steel.

Hoge dichtheid polyethyleen (HDPE)

HDPE is a widely used plastic for gallon bottles due to its excellent strength-to-density ratio. It has a temperature rating of up to 120°C (248°F) and offers good resistance to impact and chemicals, making it suitable for storing a variety of liquids, including cleaning products and food items.

Voordelen:

– Cost-effective and lightweight, reducing shipping expenses.

– Excellent chemical resistance, particularly against acids and bases.

– Recyclable, aligning with growing environmental concerns.

Minpunten:

– Limited temperature resistance compared to glass or stainless steel.

– Can degrade under UV exposure unless treated.

– Less durable than glass or metal options, potentially leading to leaks.

Invloed op de toepassing:

HDPE is compatible with a wide range of media, making it ideal for industries such as food and beverage, chemicals, and cleaning products. However, its limitations in high-temperature applications should be considered.

Overwegingen voor internationale kopers:

Buyers from regions like Africa and South America should ensure compliance with local regulations regarding food safety and environmental standards. Common standards include ASTM and ISO certifications, which are essential for ensuring product quality.

Polypropyleen (PP)

Polypropylene is another plastic option frequently used for gallon bottles. It has a higher melting point than HDPE, around 160°C (320°F), and offers good resistance to fatigue and stress.

Voordelen:

– Higher temperature resistance makes it suitable for hot-fill applications.

– Good chemical resistance, particularly to solvents.

– Lightweight and cost-effective.

Minpunten:

– Less impact-resistant than HDPE, which may lead to cracking under stress.

– Not as widely recyclable as HDPE.

– Can be more expensive than HDPE in some markets.

Invloed op de toepassing:

PP is particularly useful for applications requiring sterilization or exposure to high temperatures, such as in the pharmaceutical industry. Its compatibility with various chemicals enhances its utility.

Overwegingen voor internationale kopers:

Buyers should check for compliance with international safety standards, especially in sectors like pharmaceuticals, where stringent regulations apply.

Glas

Glass bottles offer a premium option for gallon containers, known for their excellent barrier properties and aesthetic appeal. They are inert, meaning they do not interact with the contents, making them ideal for beverages and sensitive chemicals.

Voordelen:

– Superior chemical resistance and non-reactivity.

– Excellent barrier properties against gases and moisture.

– Recyclable and environmentally friendly.

Minpunten:

– Heavier and more fragile than plastic options, increasing shipping costs and risk of breakage.

– Higher manufacturing costs due to complexity in production.

– Limited design flexibility compared to plastics.

Invloed op de toepassing:

Glass is particularly suited for high-value products such as premium beverages and specialty chemicals. Its inert nature ensures the integrity of sensitive products.

Overwegingen voor internationale kopers:

Buyers must consider local regulations regarding glass packaging, including safety standards and recycling practices. Compliance with DIN and JIS standards may also be relevant, particularly in Europe and Asia.

Roestvrij staal

Stainless steel is a durable and corrosion-resistant option for gallon bottles, often used in food and beverage applications. It can withstand high temperatures and is highly resistant to rust and corrosion.

Voordelen:

– Extremely durable and long-lasting, reducing replacement costs.

– Excellent temperature resistance and insulation properties.

– Non-reactive, making it safe for food and beverages.

Minpunten:

– Higher initial cost compared to plastic options.

– Heavier, which can increase shipping costs.

– Requires more complex manufacturing processes.

Invloed op de toepassing:

Stainless steel is ideal for applications requiring durability and temperature control, such as in the food and beverage industry. Its robustness makes it suitable for both hot and cold liquids.

Overwegingen voor internationale kopers:

Buyers should ensure compliance with food safety standards, such as FDA regulations in the U.S. and EFSA guidelines in Europe. Additionally, understanding local preferences for material sustainability can influence purchasing decisions.

Summary Table of Material Selection for Gallon Bottles

| Materiaal | Typical Use Case for gallon bottles | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Hoge dichtheid polyethyleen (HDPE) | Food and beverage, cleaning products | Cost-effective, lightweight | Beperkte temperatuurbestendigheid | Laag |

| Polypropyleen (PP) | Pharmaceutical, hot-fill applications | Higher temperature resistance | Less impact-resistant | Medium |

| Glas | Premium beverages, specialty chemicals | Superior chemical resistance | Heavier and more fragile | Hoog |

| Roestvrij staal | Food and beverage, durable applications | Extremely durable and long-lasting | Hogere initiële kosten | Hoog |

This strategic material selection guide provides a comprehensive overview for B2B buyers, aiding in informed decision-making based on application needs, cost considerations, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for gallon bottles

What Are the Key Stages of the Manufacturing Process for Gallon Bottles?

The manufacturing of gallon bottles involves several critical stages, each designed to ensure the final product meets industry standards for quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

-

Materiaalvoorbereiding: The process begins with the selection and preparation of raw materials, typically high-density polyethylene (HDPE) or polypropylene. The materials are sourced from certified suppliers to ensure they meet safety and environmental regulations. The pellets are then dried and processed to remove any moisture, which is crucial for achieving optimal molding results.

-

Het vormen van: The next step is forming, which can involve different techniques such as injection molding or blow molding. In injection molding, the melted plastic is injected into a mold to create the desired shape. Blow molding, on the other hand, involves inflating a heated plastic tube within a mold to form the bottle. Both methods can be tailored to produce various bottle designs and sizes, ensuring flexibility for manufacturers to meet specific client needs.

-

Montage: After forming, the bottles may require additional components such as caps or handles. This assembly stage often involves automated systems to ensure efficiency and consistency. The integration of these components is critical, particularly for bottles used for hazardous materials or food products, where secure closures are paramount.

-

Afwerking: The final stage includes finishing processes such as labeling, printing, and quality checks. Labels may be applied either through direct printing or adhesive methods, depending on the design requirements. Finishing also includes inspecting the bottles for any defects, ensuring they meet the aesthetic and functional standards set by clients.

How Is Quality Assurance Implemented in Gallon Bottle Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the products not only meet but exceed client expectations. This involves adherence to international and industry-specific standards.

-

International Standards: Many manufacturers comply with ISO 9001, which outlines a framework for quality management systems. This certification demonstrates a commitment to consistent quality and continuous improvement. Compliance with CE marking may also be necessary, especially for products sold in Europe, indicating conformity with health, safety, and environmental protection standards.

-

Industry-Specific Standards: Depending on the application of the gallon bottles, additional certifications may be required. For instance, bottles intended for food products may need to meet standards set by the FDA in the United States or similar regulatory bodies in other regions. API (American Petroleum Institute) certifications may be relevant for bottles used in the oil and gas industry.

What Are the Key Quality Control Checkpoints in Gallon Bottle Production?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any potential issues before products are completed. Common checkpoints include:

-

Inkomende kwaliteitscontrole (IQC): This involves inspecting raw materials upon arrival to ensure they meet the specified standards. Any non-conforming materials are rejected and returned to the supplier.

-

Kwaliteitscontrole tijdens het proces (IPQC): During the manufacturing process, periodic checks are conducted to monitor critical parameters such as temperature, pressure, and material viscosity. This helps in identifying issues early, reducing waste and rework.

-

Finale kwaliteitscontrole (FQC): After the bottles are completed, they undergo a comprehensive final inspection. This includes visual checks for defects, dimensional checks to ensure they meet specifications, and functionality tests for closures and seals.

What Testing Methods Are Commonly Used for Gallon Bottles?

Testing methods play a crucial role in ensuring the durability and safety of gallon bottles. Common testing techniques include:

- Valproeven: Assessing the bottle’s ability to withstand impact by dropping it from a specified height.

- Burst Tests: Evaluating the strength of the bottle by applying pressure until it fails.

- Lektests: Ensuring that closures are secure and that the bottles do not leak under normal usage conditions.

- Temperature Resistance Tests: Checking how the bottles perform under extreme temperature variations, which is particularly important for containers used in industrial applications.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability. Here are several strategies to achieve this:

-

Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers can assess compliance with international standards and evaluate the effectiveness of the supplier’s QA practices.

-

Kwaliteitsrapporten: Requesting detailed quality reports from suppliers can help buyers understand the QC measures in place and any issues that have been identified during production.

-

Inspecties door derden: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly beneficial for buyers who may not have the resources to conduct their own inspections.

Wat zijn de nuances van kwaliteitscontrole voor internationale B2B-kopers?

International B2B buyers need to be aware of several nuances when it comes to quality control:

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers should familiarize themselves with the specific requirements of their target markets to ensure compliance.

-

Culturele overwegingen: Understanding the cultural context of suppliers can aid in establishing effective communication and expectations regarding quality. This is particularly relevant when dealing with suppliers in regions with different business practices.

-

Supply Chain Risks: International supply chains can introduce risks related to quality control. Buyers should evaluate the entire supply chain, from raw material sourcing to final product delivery, to mitigate these risks effectively.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing gallon bottles, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gallon bottles’

In this guide, we present a comprehensive checklist for B2B buyers aiming to procure gallon bottles. This step-by-step process will help ensure that you make informed decisions, optimizing both your sourcing strategy and procurement outcomes.

Stap 1: Je technische specificaties definiëren

Establishing clear technical specifications is the first step in the sourcing process. Consider the intended use of the gallon bottles—whether for liquids such as water, chemicals, or food products—as this will dictate the material and design requirements. Key specifications to define include:

– Material Type: High-density polyethylene (HDPE) is common for its durability and recyclability.

– Size and Shape: Determine if you need standard round, square, or customized shapes based on your storage needs.

Stap 2: Identify Regulatory Compliance Requirements

Compliance with local and international regulations is critical when sourcing gallon bottles. Depending on your market, you may need to adhere to specific standards such as FDA approval for food-grade materials or environmental regulations regarding recyclability. Verify:

– Certifications: Check for relevant certifications like ISO or FDA compliance.

– Labeling Requirements: Ensure that the bottles can accommodate necessary product labeling and safety information.

Stap 3: Potentiële leveranciers evalueren

Before making a purchase commitment, it is crucial to thoroughly vet potential suppliers. This step helps mitigate risks associated with quality and reliability. Look for:

– Company Profiles: Assess the supplier’s history, industry experience, and product range.

– References and Reviews: Seek testimonials from other buyers in your region or industry to gauge supplier performance.

Stap 4: Request Samples and Test Quality

Once you have identified potential suppliers, request samples of the gallon bottles. Testing the samples for quality and suitability will help ensure they meet your specifications. Focus on:

– Duurzaamheidstests: Evaluate the bottles for structural integrity under various conditions.

– Compatibility Testing: If applicable, check how the bottles interact with the liquids they will contain, ensuring no chemical leaching occurs.

Stap 5: Onderhandelen over prijzen en voorwaarden

Negotiating pricing and contract terms is essential for maximizing value. When discussing with suppliers, consider:

– Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

– Payment Terms: Clarify payment options, lead times, and return policies to avoid future complications.

Stap 6: Plan voor logistiek en distributie

Effective logistics planning is vital to ensure timely delivery and storage of your gallon bottles. Discuss with your supplier:

– Shipping Options: Understand the shipping methods available and their associated costs.

– Storage Requirements: Confirm how the bottles should be stored to maintain their integrity during transit and after delivery.

Stap 7: Establish a Quality Control Process

Finally, implement a quality control process for the bottles received. This ensures consistency and reliability in your supply chain. Consider:

– Inspection Procedures: Set up a checklist for inspecting the quality upon receipt.

– Feedback Loop: Create a system for providing feedback to suppliers regarding product performance and any issues encountered.

By following this checklist, B2B buyers can streamline the sourcing process for gallon bottles, ensuring they find reliable suppliers and high-quality products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for gallon bottles Sourcing

What Are the Key Cost Components for Sourcing Gallon Bottles?

When evaluating the cost structure for sourcing gallon bottles, several critical components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

- Materials: The choice of materials, such as high-density polyethylene (HDPE) or glass, significantly impacts costs. HDPE is typically less expensive, offering a balance of durability and recyclability, which is appealing for many manufacturers.

- Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs, such as parts of South America or Africa, may offer more competitive pricing, though this should be weighed against quality and reliability.

- Manufacturing Overhead: This includes utilities, rent, and other operational costs associated with production. Efficient manufacturing processes can lower these costs, impacting the overall pricing of gallon bottles.

- Tooling: Custom tooling for specific bottle designs can be a significant upfront cost. However, once established, it allows for greater efficiency in production.

- Quality Control: Ensuring that products meet safety and quality standards adds to the cost but is essential for maintaining brand reputation and compliance with international regulations.

- Logistics: Transportation costs depend on the distance from the supplier and the chosen shipping method. International shipping can involve additional fees, particularly with customs duties.

- Margin: Suppliers typically build in a profit margin, which can vary based on competition and market demand.

How Do Price Influencers Affect the Cost of Gallon Bottles?

Several factors influence the pricing of gallon bottles, which can vary widely based on buyer specifications and market conditions.

- Volume/MOQ: Suppliers often provide discounts for bulk orders. Understanding minimum order quantities (MOQs) is crucial for buyers looking to optimize costs.

- Specifications and Customization: Custom designs, colors, or sizes may incur additional costs. Buyers should be clear about their requirements to avoid unexpected expenses.

- Materials and Quality Certifications: Bottles made from premium materials or those with certifications (like food-grade or eco-friendly) may cost more but can enhance product value and consumer trust.

- Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer higher quality but at a premium, while newer entrants might provide lower prices but with variable quality.

- Incoterms: Understanding shipping terms (Incoterms) is vital for managing costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the overall price by determining who bears the shipping and insurance costs.

What Are Effective Buyer Tips for Sourcing Gallon Bottles?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic purchasing can lead to significant cost savings.

- Negotiation: Engage in negotiations with suppliers to secure better pricing, especially when placing large orders. Leveraging relationships can lead to more favorable terms.

- Cost-Efficiency Analysis: Assess the total cost of ownership (TCO), which includes purchase price, shipping, handling, and potential tariffs. A lower initial price may not always result in overall savings.

- Pricing Nuances for International Buyers: Be aware of the local market conditions and currency fluctuations that may affect pricing. Conducting thorough market research can provide insights into fair pricing.

- Vraag monsters aan: Before committing to a large order, request samples to evaluate quality. This can prevent costly returns and dissatisfaction with the product.

- Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times, making it a viable option.

Disclaimer over indicatieve prijzen

Prices for gallon bottles can fluctuate based on market conditions, supplier changes, and material costs. The figures provided are indicative and should be verified with suppliers for current pricing. Always conduct due diligence to ensure that you are making informed purchasing decisions.

Alternatives Analysis: Comparing gallon bottles With Other Solutions

Exploring Alternatives to Gallon Bottles in Liquid Storage Solutions

When evaluating liquid storage solutions for B2B applications, it’s essential to consider various alternatives to gallon bottles. Each option presents unique advantages and challenges, influencing the decision based on performance, cost, and specific use cases. Below is a comparative analysis of gallon bottles against two viable alternatives: bulk plastic containers and metal drums.

| Vergelijkingsaspect | Gallon Bottles | Bulk Plastic Containers | Metal Drums |

|---|---|---|---|

| Prestaties | Good for individual consumer use; limited in bulk storage | Excellent for large quantities; versatile sizes available | Durable; ideal for hazardous or high-pressure liquids |

| Kosten | Moderate initial cost; bulk discounts available | Generally lower cost per unit when purchased in bulk | Higher upfront cost; long lifespan offsets price |

| Gemak van implementatie | Easy to handle and transport; requires minimal setup | Requires more space; heavier when full | Requires specialized equipment for handling |

| Onderhoud | Low maintenance; easy to clean and reuse | Moderate; can be prone to wear over time | High; regular inspections required for integrity |

| Beste gebruikscasus | Ideal for beverages, cleaning products, and small-scale applications | Suitable for chemical storage, large-scale food products | Best for industrial applications and hazardous materials |

Understanding Bulk Plastic Containers as an Alternative

Bulk plastic containers are designed for larger storage needs and are available in various sizes, often exceeding the capacity of gallon bottles. These containers are made from high-density polyethylene (HDPE) or polypropylene, offering excellent durability and resistance to chemicals. The primary advantage of bulk containers is their cost-effectiveness, especially when purchased in large quantities. However, they require more handling equipment and space, which may not be suitable for all businesses. Additionally, while they can be reused, they may require more maintenance to ensure they remain clean and functional.

Evaluating Metal Drums for Liquid Storage

Metal drums, typically made from steel or aluminum, are another alternative to gallon bottles. They are highly durable and can withstand extreme conditions, making them ideal for storing hazardous materials or liquids under pressure. The strength and longevity of metal drums are significant advantages; however, their higher initial cost may be a deterrent for some companies. Moreover, they require specialized equipment for transport and handling, which can complicate logistics. Regular inspections are crucial to maintain their integrity and safety, adding to the maintenance burden.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting a liquid storage solution, B2B buyers must carefully assess their specific requirements, including volume, type of liquid, budget constraints, and logistical capabilities. Gallon bottles offer a practical solution for smaller, consumer-oriented applications, while bulk plastic containers provide a more economical option for larger quantities. Metal drums, on the other hand, are best suited for industrial applications requiring robust, durable storage. By understanding the strengths and weaknesses of each alternative, businesses can make informed decisions that align with their operational needs and goals.

Essential Technical Properties and Trade Terminology for gallon bottles

What Are the Key Technical Properties of Gallon Bottles?

When sourcing gallon bottles for your business, understanding their technical properties is crucial for ensuring product compatibility and performance. Here are some of the most significant specifications to consider:

1. Materiaalklasse

Gallon bottles are commonly made from materials such as High-Density Polyethylene (HDPE), Polypropylene (PP), or glass. HDPE is favored for its strength, resistance to impact, and chemical stability, making it suitable for various liquids, including food and chemicals. Understanding the material grade helps businesses select the right bottle for their specific application, ensuring safety and compliance with regulations.

2. Neck Finish and Size

The neck finish refers to the design and dimensions of the bottle’s opening, which is essential for compatibility with closures and dispensing systems. Common sizes include 38-400 and 33-400 neck finishes. Proper neck sizing ensures a secure seal, preventing leaks and contamination during storage and transportation, which is critical for maintaining product integrity.

3. Volume Capaciteit

While gallon bottles typically hold 128 ounces (or 3.78 liters), variations exist. Businesses should consider their specific volume requirements based on usage, shipping constraints, and customer preferences. Understanding volume capacity helps optimize logistics and inventory management.

4. Wall Thickness

Wall thickness affects the durability and weight of the bottle. Thicker walls provide enhanced strength and resistance to crushing or puncturing, which is vital for transporting heavy liquids. Conversely, thinner walls may reduce material costs but can compromise the bottle’s integrity. Evaluating wall thickness allows businesses to balance cost with performance.

5. Tamper-Evident Features

For products requiring consumer safety, tamper-evident features are essential. These mechanisms, such as breakable seals or unique cap designs, reassure end-users that the product is secure and untampered. Understanding these features helps businesses comply with safety regulations and build consumer trust.

6. Recyclebaarheid en milieueffecten

As sustainability becomes increasingly important, knowing whether the gallon bottles are recyclable can influence purchasing decisions. Many manufacturers now provide eco-friendly options, such as recyclable HDPE. This knowledge not only supports corporate responsibility goals but also aligns with consumer preferences for sustainable products.

What Are Common Trade Terms Related to Gallon Bottles?

Navigating the B2B landscape involves understanding specific terminology that can impact procurement and sales processes. Here are some essential trade terms related to gallon bottles:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of gallon bottles, businesses may source bottles from OEMs who specialize in specific designs or materials, ensuring quality and brand consistency.

2. MOQ (minimale bestelhoeveelheid)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ for gallon bottles is crucial for inventory planning and cost management, as larger orders may offer better pricing but require upfront capital.

3. RFQ (Offerteaanvraag)

An RFQ is a formal request to suppliers for pricing and terms for specific products. When sourcing gallon bottles, issuing an RFQ can help businesses compare offers and negotiate better deals, ensuring they receive competitive pricing for their needs.

4. Incoterms (internationale handelsvoorwaarden)

Incoterms are predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding these terms is vital for managing shipping costs, risk, and delivery timelines when importing gallon bottles from international suppliers.

5. Doorlooptijd

Lead time refers to the time taken from placing an order to receiving the product. Knowing the lead time for gallon bottles helps businesses plan their inventory and production schedules effectively, minimizing disruptions in supply.

6. Customs Duties and Tariffs

These are taxes imposed on imported goods. Being aware of customs duties related to gallon bottles can significantly impact total landed costs, influencing pricing strategies and profitability for businesses involved in international trade.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing gallon bottles, ensuring they meet their operational needs while optimizing costs and compliance.

Navigating Market Dynamics and Sourcing Trends in the gallon bottles Sector

What Are the Current Market Dynamics and Key Trends Affecting the Gallon Bottles Sector?

The global market for gallon bottles is being driven by several key factors. The increasing demand for bulk storage solutions, particularly in sectors such as food and beverage, chemicals, and cleaning products, has led to a significant rise in the consumption of plastic jugs. Emerging markets in Africa and South America are particularly notable for their growing industrial sectors, which require reliable and cost-effective packaging solutions. Furthermore, the trend toward convenience and sustainability is influencing B2B purchasing decisions, with buyers increasingly looking for eco-friendly materials and designs.

Technological advancements in manufacturing and sourcing are also shaping the gallon bottle market. Automation and the use of advanced materials are streamlining production processes, reducing costs, and improving product quality. Additionally, e-commerce platforms are facilitating easier access to a diverse range of suppliers, enabling international buyers to compare products and prices effectively. For instance, platforms that offer bulk discounts and customizable options are becoming more popular among B2B buyers in regions like the Middle East and Europe.

Another emerging trend is the focus on product differentiation through unique designs and closures. Manufacturers are responding to market demands for more specialized applications by offering a variety of shapes, sizes, and neck designs. This adaptability is crucial for companies looking to establish a competitive edge in their respective markets.

How Is Sustainability Influencing B2B Sourcing for Gallon Bottles?

Sustainability is rapidly becoming a cornerstone of B2B sourcing strategies in the gallon bottles sector. The environmental impact of plastic waste has prompted international buyers to prioritize suppliers who adhere to ethical sourcing practices and sustainability certifications. Many companies are now seeking products made from recyclable materials, such as high-density polyethylene (HDPE), which is both durable and environmentally friendly.

The importance of ethical supply chains cannot be overstated. B2B buyers are increasingly aware of the social and environmental implications of their purchases. By partnering with manufacturers that prioritize sustainable practices, companies can enhance their brand reputation and appeal to environmentally conscious consumers. Certifications such as ISO 14001 (Environmental Management Systems) and the use of recycled materials are becoming essential criteria in the supplier selection process.

Moreover, innovation in packaging design is also contributing to sustainability efforts. Many manufacturers are investing in research and development to create lighter, more efficient designs that reduce material usage without compromising quality. This not only minimizes environmental impact but also lowers shipping costs, providing additional savings for B2B buyers.

What Is the Historical Context Behind the Evolution of Gallon Bottles?

The evolution of gallon bottles can be traced back to the early 20th century when the need for efficient liquid storage solutions became paramount. Initially made from glass, these containers were heavy and prone to breakage, making them impractical for widespread use. The introduction of plastic in the mid-20th century revolutionized the industry, leading to the development of lightweight, durable, and cost-effective options.

Over the decades, advancements in polymer technology allowed manufacturers to produce a variety of plastic jugs that cater to specific needs, such as food safety and chemical resistance. As global trade expanded, so did the demand for standardized container sizes, with the gallon bottle becoming a preferred choice for bulk packaging across various industries.

In recent years, the focus has shifted towards sustainability and environmental responsibility, prompting manufacturers to innovate further. Today, B2B buyers benefit from a wider range of options that not only meet their functional requirements but also align with their sustainability goals. This ongoing evolution illustrates how the gallon bottles sector is adapting to meet changing market demands and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of gallon bottles

-

How do I ensure the quality of gallon bottles when sourcing from international suppliers?

To ensure quality, start by conducting thorough research on potential suppliers. Request samples to assess the material, durability, and design of the gallon bottles. Verify their certifications, such as ISO or food safety compliance, to ensure they meet international standards. Additionally, consider visiting the supplier’s manufacturing facility if possible or hiring a third-party inspection service to evaluate the production process and quality control measures before placing a large order. -

What is the best material for gallon bottles used in chemical storage?

High-density polyethylene (HDPE) is often regarded as the best material for gallon bottles intended for chemical storage. HDPE is resistant to many chemicals, making it suitable for storing substances like cleaning agents or industrial liquids. It is also lightweight, durable, and recyclable, which can be beneficial for companies focused on sustainability. Ensure that the specific HDPE used is compatible with the chemicals being stored by consulting with your supplier. -

What customization options are available for gallon bottles?

Many manufacturers offer customization options for gallon bottles, including color, shape, size, and closure types. You can also request custom labeling to enhance branding and product identification. Some suppliers provide options for tamper-evident seals and child-resistant caps, which are essential for certain products. When inquiring about customization, discuss your specific requirements with the supplier to ensure they can accommodate your needs. -

What are the typical minimum order quantities (MOQs) for gallon bottles?

Minimum order quantities for gallon bottles can vary significantly based on the supplier and the type of bottle. Generally, MOQs range from 500 to 10,000 units, depending on the customization and material. It’s advisable to negotiate with suppliers, especially if you’re looking to place a smaller initial order. Some manufacturers may offer lower MOQs for standard products, so be clear about your needs when reaching out. -

What payment terms should I expect when sourcing gallon bottles internationally?

Payment terms can vary widely among international suppliers, typically ranging from 30% upfront payment and 70% upon delivery to net 30 or net 60 terms. Always clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal. Be aware of any foreign transaction fees and consider using escrow services for larger orders to protect both parties. Building a trustworthy relationship with your supplier can also lead to more favorable payment terms over time. -

How can I manage logistics and shipping for gallon bottles from international suppliers?

To manage logistics effectively, partner with a reliable freight forwarder who understands the complexities of international shipping. Ensure they are familiar with customs regulations in your country and can handle necessary documentation. Discuss shipping options, such as air freight for faster delivery or sea freight for cost savings. Always factor in lead times, potential tariffs, and insurance options to mitigate risks during transportation. -

What are the key factors to consider when vetting suppliers for gallon bottles?

When vetting suppliers, prioritize their experience and reputation in the industry. Look for reviews and testimonials from previous clients. Assess their production capacity and whether they can meet your demand consistently. Additionally, inquire about their quality assurance processes and certifications to ensure compliance with international standards. Establishing clear communication and a trial order can also help you gauge their reliability and service quality. -

Are there specific regulations I need to comply with when importing gallon bottles into my country?

Yes, each country has specific regulations governing the import of packaging materials, including gallon bottles. Familiarize yourself with local standards, such as safety regulations for food-grade containers or chemical storage requirements. Check for any import duties, taxes, or labeling requirements that may apply. Engaging with a customs broker can provide guidance on regulatory compliance and help streamline the import process, ensuring that your shipments meet all necessary criteria.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 7 Gallon Bottles Manufacturers & Suppliers List

1. Bottlestore – Plastic Jugs for Bulk Liquid Storage

Domein: bottlestore.com

Geregistreerd: 1998 (27 jaar)

Inleiding: Plastic jugs are ideal for bulk liquid storage and come in a variety of shapes and sizes. Bottlestore.com carries the most popular and common plastic jugs available online today. When purchasing plastic jugs, consider the final application, as some designs are custom tailored for specific use. Bottlestore.com offers a bulk quantity discount on large orders of plastic jugs, which means better prici…

2. Jarstore – 1 Gallon Round Plastic Bottle

Domein: jarstore.com

Geregistreerd: 2004 (21 jaar)

Inleiding: {“Product Name”: “1 Gallon Round Plastic Bottle”, “SKU”: “RGB128N-PC”, “Volume”: “128 oz”, “Material”: “HDPE”, “Neck Size”: “38-400”, “Features”: “Certified for Food Use”, “Ideal For”: [“Bulk food items like sauces, condiments, cooking oils, vinegars, extracts”, “Storing and pouring lotions, detergents, soaps”], “Lid Options”: “Available”, “Current Stock”: 7784}

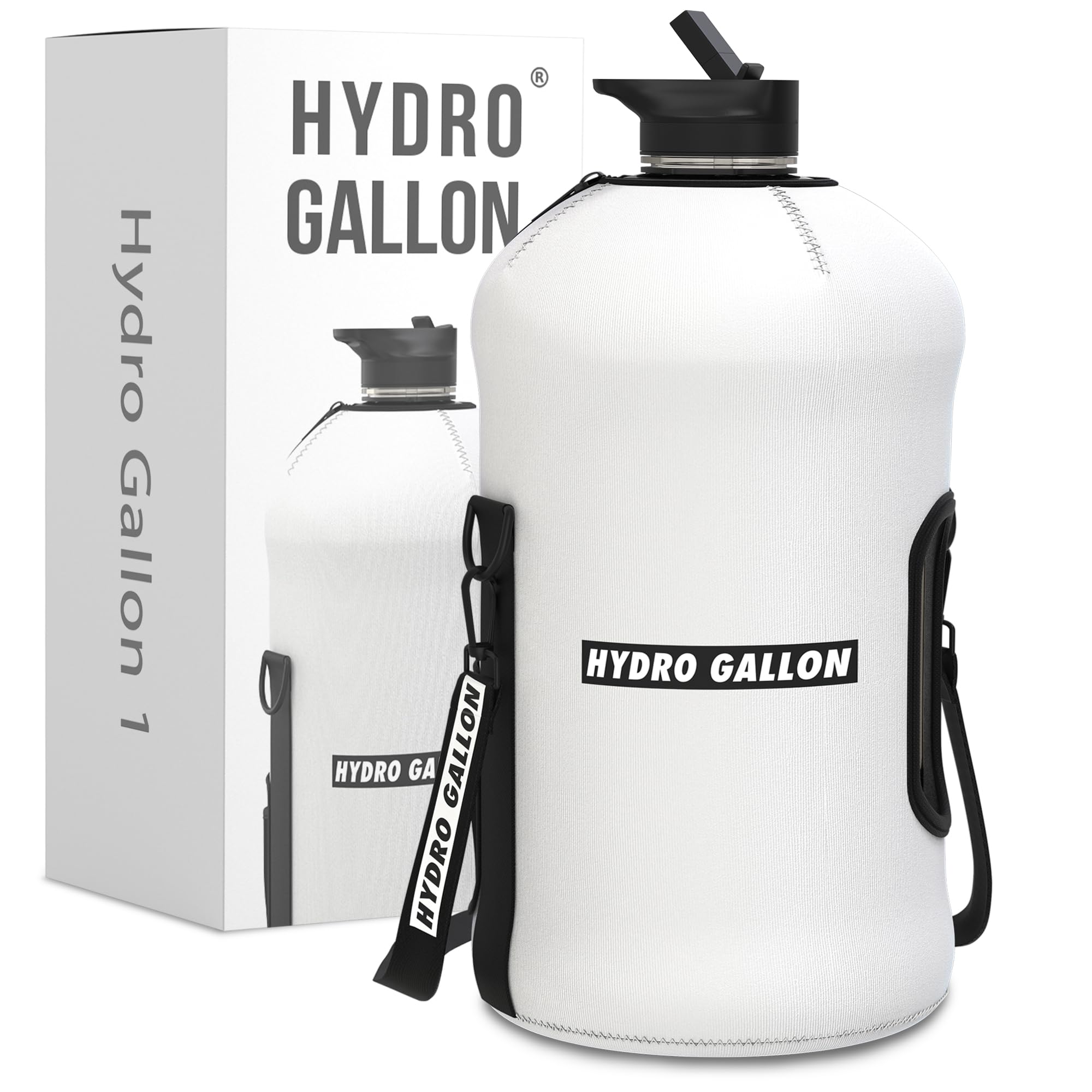

3. Hydro Gallon® – Gallon Water Bottles

Domein: hydrogallon.com

Geregistreerd: 2020 (5 jaar)

Inleiding: Hydro Gallon® offers a range of gallon water bottles designed for all-day hydration. Key products include: 1 Gallon Hydro Gallon, Hydro Gallon 1 Pro, Hydro Gallon Tactical, and a new Half Gallon Hydro Gallon Nomad. Features include 24-hour cold retention, durability, and a backpack mode for easy transport. The bottles come with sleeves and replacement parts are available. Customers can also purcha…

4. Yeti – One Gallon Water Bottle

Domein: reddit.nl

Geregistreerd: 2005 (20 jaar)

Inleiding: Looking for a good one gallon water bottle for work. Considering Yeti but skeptical due to insulation performance in tests. Preference for durability and ability to withstand drops. Concerns about weight for carrying. Mention of lid issues with Yeti, but overall satisfaction with insulation performance in hot climates. Comparison with Hydroflask regarding denting and durability.

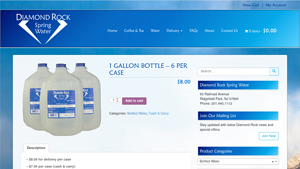

5. Diamond Rock – 1 Gallon Natural Spring Water

Domein: diamondrock.com

Geregistreerd: 1997 (28 jaar)

Inleiding: {“product_name”: “1 Gallon Bottle – 6 Per Case”, “price_delivery”: “$8.00”, “price_cash_and_carry”: “$7.00”, “quantity_per_case”: “6”, “water_type”: “100% Natural Spring Water”, “certifications”: “Government tested, FDA approved”, “security_deposit”: “$0.00”, “category”: “Bottled Water”}

6. ReadyRefresh – 5 Gallon Water Delivery

Domein: readyrefresh.com

Geregistreerd: 2014 (11 jaar)

Inleiding: Big Bottles from ReadyRefresh offer 3 and 5 gallon bottles of purified or spring water for delivery to homes or offices. Available brands include:

1. Pure Life® Distilled Water – 5 Gallon Bottle – $10.49

2. Primo® Purified Water – 5 Gallon Bottle – $7.99

3. Crystal Springs® Crystal Fresh Purified Water – 5 Gallon Bottle – $29.99

4. Crystal Springs® Spring Water – 5 Gallon Bottle – $8.99

5. Crysta…

7. Water.com – Bottled Water Delivery & Filtration Solutions

Domein: water.com

Geregistreerd: 1994 (31 jaar)

Inleiding: Water Delivery: Convenient bottled water delivery for home and business. Water Refill: Refill 1-, 3-, or 5-gallon bottles at retail locations. Water Exchange: Exchange empty bottles for purified Primo Water. Water Filtration: Direct tap water filtration systems with installation and maintenance. Commercial Services: Variety of products for organizational needs. Water Types: Purified, spring, disti…

Strategic Sourcing Conclusion and Outlook for gallon bottles

In the evolving landscape of gallon bottle sourcing, international B2B buyers must prioritize strategic sourcing practices to maximize efficiency and cost-effectiveness. Key considerations include selecting high-quality materials, such as HDPE, which offer durability and recyclability, crucial for businesses aiming to maintain sustainability in their operations. Understanding the diverse range of designs and closure options available can significantly enhance product safety and appeal, ensuring that your liquid products are stored effectively.

As you explore suppliers, leveraging bulk purchasing options can lead to substantial savings, making it imperative to negotiate favorable terms and explore potential discounts for larger orders. Engaging with packaging experts can provide insights tailored to your specific needs, optimizing your selection process.

Looking ahead, the demand for innovative, eco-friendly gallon bottle solutions is poised to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing strategic partnerships and remaining adaptable to market trends, B2B buyers can not only meet current demands but also anticipate future opportunities. Take the next step in your sourcing strategy today to ensure your business is well-positioned for success in a competitive marketplace.