Introduction: Navigating the Global Market for 330ml bottle

In today’s competitive global market, sourcing the right 330ml bottle can be a pivotal challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a diverse array of options—ranging from glass to PET, and from long necks to squeeze bottles—understanding the intricacies of each type is essential for making informed purchasing decisions. This guide offers a comprehensive exploration of the 330ml bottle market, detailing various types, applications, supplier vetting processes, and cost considerations.

By delving into the specifics of different 330ml bottle formats, including their suitability for carbonated beverages, natural spring water, and even customizable options for branding, this resource empowers buyers to align their choices with their product requirements. Additionally, the guide highlights the importance of sustainability in packaging, showcasing options made from recycled materials, which resonate with eco-conscious consumers and brands alike.

In essence, this guide serves as an essential tool for B2B buyers seeking to navigate the complexities of the 330ml bottle market, ensuring that they can make strategic, informed decisions that enhance their product offerings and support their business goals. With actionable insights tailored to the unique needs of international buyers, it lays the foundation for successful sourcing and supplier partnerships.

Artikel navigatie

- Top 8 330Ml Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 330ml bottle

- Understanding 330ml bottle Types and Variations

- Key Industrial Applications of 330ml bottle

- 3 Common User Pain Points for ‘330ml bottle’ & Their Solutions

- Strategic Material Selection Guide for 330ml bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 330ml bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘330ml bottle’

- Comprehensive Cost and Pricing Analysis for 330ml bottle Sourcing

- Alternatives Analysis: Comparing 330ml bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 330ml bottle

- Navigating Market Dynamics and Sourcing Trends in the 330ml bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 330ml bottle

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategic Sourcing Conclusion and Outlook for 330ml bottle

Understanding 330ml bottle Types and Variations

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Long Neck Glass Bottle | Flint glass, 26mm crown pry-off closure, pressure rated | Craft beverages, soft drinks, water | Voordelen: Excellent product visibility, reusable. Minpunten: Fragile, higher shipping costs. |

| Amber Glass Bottle | Amber color, crown seal, customizable options | Beer, cider, carbonated beverages | Voordelen: Protects contents from UV light, customizable. Minpunten: Heavier than plastic, limited visibility. |

| PET Plastic Bottle | Made from recycled materials, fully recyclable | Water, soft drinks, juices | Voordelen: Lightweight, cost-effective, recyclable. Minpunten: Less premium perception, potential environmental concerns. |

| Sleek Aluminum Can | Premium finish, customizable design, lightweight | Craft beers, soft drinks | Voordelen: Quick chilling, infinitely recyclable. Minpunten: Limited to carbonated beverages, can dent easily. |

| Squeeze Plastic Bottle | Flexible design, easy dispensing, lightweight | Sauces, condiments, water | Voordelen: Convenient for consumers, versatile. Minpunten: Limited branding opportunities, less durable. |

What Are the Key Features of Long Neck Glass Bottles?

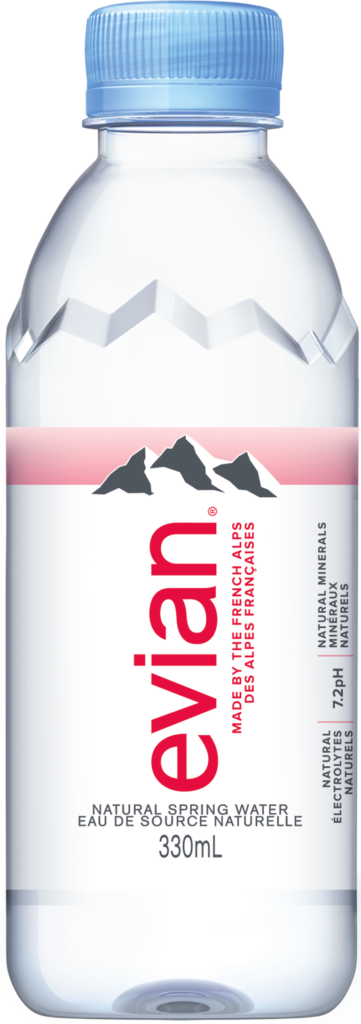

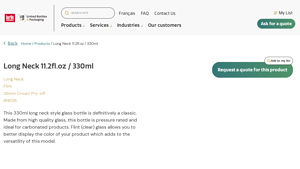

Long neck glass bottles, typically made from flint glass, are a staple for beverages that require a premium presentation. Their 330ml capacity and 26mm crown pry-off closure make them ideal for craft beers, soft drinks, and bottled water. B2B buyers appreciate their ability to showcase product color, enhancing marketability. However, their fragile nature can lead to higher shipping costs and breakage during transport, making careful handling essential.

How Do Amber Glass Bottles Benefit Beverage Producers?

Amber glass bottles are specifically designed to protect contents from UV light, making them an excellent choice for beers and ciders. With customizable options available, they allow brands to create unique presentations that stand out in the market. The weight of these bottles can increase shipping costs, but their recyclability and durability often justify the investment for producers focused on sustainability and quality.

Why Choose PET Plastic Bottles for Beverage Packaging?

PET plastic bottles offer a lightweight and cost-effective solution for packaging water and soft drinks. Made from recycled materials, they appeal to environmentally conscious consumers and brands alike. While they are fully recyclable, some buyers may find that PET bottles lack the premium feel of glass, which can affect brand perception. Nonetheless, their practicality in terms of shipping and handling makes them a popular choice among beverage manufacturers.

What Advantages Do Sleek Aluminum Cans Provide?

Sleek aluminum cans are increasingly favored for their premium appearance and lightweight nature, making them suitable for craft beers and soft drinks. Their ability to chill quickly and be infinitely recycled adds to their appeal. However, B2B buyers should consider that while they offer excellent branding opportunities, they are limited to carbonated beverages and may dent easily during transport, which could affect product presentation.

What Are the Uses of Squeeze Plastic Bottles in the Market?

Squeeze plastic bottles are designed for convenience and ease of use, making them suitable for sauces, condiments, and water. Their flexible design allows for easy dispensing, appealing to consumers looking for practicality. However, they may not provide the same level of branding opportunities as rigid bottles, and their durability can be a concern for some buyers. Nevertheless, their versatility makes them an attractive option for various food and beverage applications.

Key Industrial Applications of 330ml bottle

| Industrie/sector | Specific Application of 330ml bottle | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Beverage Industry | Packaging for beer, cider, and carbonated drinks | Enhances brand visibility and consumer appeal | Material quality, customization options, and recyclability |

| Food Service | Single-serving sauces and dressings | Convenience for consumers; reduces waste | Compatibility with food safety standards and distribution logistics |

| Persoonlijke verzorging en cosmetica | Bottling of lotions and serums | Offers a premium presentation; enhances product value | Tamper-proof closures and compliance with cosmetic regulations |

| Water & Beverage Distribution | Portable bottled water for events and travel | Easy to transport; meets consumer demand for hydration | Sourcing from eco-friendly suppliers; availability of recycled materials |

| Health & Wellness | Nutritional supplements and health drinks | Convenient dosing; appeals to health-conscious consumers | Quality assurance and certifications for health products |

How is the 330ml Bottle Used in the Beverage Industry?

In the beverage industry, the 330ml bottle serves as an ideal packaging solution for beer, cider, and carbonated soft drinks. Its compact size meets consumer preferences for single servings, while the glass or PET material enhances the product’s visual appeal on shelves. This format also addresses challenges related to carbonization and preservation, ensuring the beverage remains fresh and flavorful. International buyers should consider sourcing options that emphasize sustainability, such as bottles made from recycled materials and those with customizable labeling to strengthen brand identity.

What Role Does the 330ml Bottle Play in Food Service?

The 330ml bottle is increasingly utilized in the food service sector for packaging single-serving sauces and dressings. This application offers convenience for both restaurants and consumers, as it allows for precise portion control and reduces food waste. Buyers in this sector must ensure that the bottles comply with food safety regulations and can withstand various storage conditions. Additionally, sourcing from suppliers that offer bulk purchasing options can lead to cost savings, making it a practical choice for food service operations.

How is the 330ml Bottle Beneficial in Personal Care & Cosmetics?

In the personal care and cosmetics industry, the 330ml bottle is commonly used for lotions, serums, and other liquid products. Its sleek design not only enhances the aesthetic appeal but also conveys a sense of premium quality to consumers. The ability to customize the bottle with unique closures and labeling options further boosts brand recognition. Buyers should prioritize sourcing bottles that are tamper-proof and compliant with cosmetic regulations to ensure product integrity and consumer safety.

What Advantages Does the 330ml Bottle Offer for Water & Beverage Distribution?

For water and beverage distribution, the 330ml bottle is an excellent choice for portable bottled water, particularly for events and travel. Its lightweight and compact design make it easy to transport, catering to the growing consumer demand for hydration on-the-go. When sourcing these bottles, buyers should focus on eco-friendly options, such as those made from recycled plastics, to appeal to environmentally conscious consumers. Additionally, ensuring a reliable supply chain is crucial for maintaining consistent availability.

How is the 330ml Bottle Used in Health & Wellness Applications?

In the health and wellness sector, the 330ml bottle is frequently employed for nutritional supplements and health drinks. Its size is ideal for convenient dosing, making it appealing to health-conscious consumers who prioritize convenience in their busy lifestyles. Buyers should look for suppliers that can guarantee product quality and certifications, ensuring that the bottles meet industry standards for health products. Furthermore, customization options can help brands stand out in a competitive marketplace, enhancing their overall appeal.

3 Common User Pain Points for ‘330ml bottle’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality 330ml Bottles

Het probleem: B2B buyers often struggle to find reliable suppliers of high-quality 330ml bottles that meet their specific needs. For businesses in the beverage industry, sourcing bottles that can withstand pressure, especially for carbonated drinks, is crucial. The challenge lies in navigating through numerous suppliers, each offering varying quality standards, prices, and lead times. This can lead to production delays, increased costs, and ultimately, dissatisfied customers if the bottles fail to perform.

De oplossing: To effectively source high-quality 330ml bottles, B2B buyers should begin by establishing clear specifications based on their product requirements. They should prioritize suppliers that provide detailed product descriptions, including material quality, pressure ratings, and compatibility with their beverages. Engaging with manufacturers that offer samples can also help assess quality firsthand. Additionally, leveraging platforms that specialize in B2B transactions can streamline the process by providing access to verified suppliers and user reviews, ensuring that buyers are making informed decisions. Regular communication with suppliers regarding lead times and inventory levels can further mitigate delays.

Scenario 2: Environmental Concerns Regarding Packaging

Het probleem: As sustainability becomes a priority for consumers, B2B buyers face the challenge of selecting 330ml bottles that align with eco-friendly practices. Many buyers are concerned about the environmental impact of their packaging choices, particularly in regions like Europe and South America where regulations and consumer preferences are increasingly favoring sustainable options. This concern can complicate purchasing decisions, as buyers must balance cost-effectiveness with sustainability.

De oplossing: B2B buyers can address environmental concerns by opting for suppliers that offer bottles made from recycled materials or those that are fully recyclable. For instance, choosing 330ml PET bottles that incorporate recycled plastic can significantly reduce environmental footprints. Buyers should also look for certifications such as B Corp or Carbon Neutral labels, which indicate a company’s commitment to sustainability. Collaborating with suppliers to develop custom bottles that utilize less material while maintaining functionality can also contribute to sustainability goals. Educating customers about the sustainability of their packaging can enhance brand reputation and consumer loyalty.

Scenario 3: Inflexibility in Order Quantities and Customization

Het probleem: Many B2B buyers encounter inflexible minimum order quantities when purchasing 330ml bottles, making it challenging for smaller businesses or startups to manage their inventory effectively. Additionally, the lack of customization options can hinder brands from differentiating their products in a competitive market. This inflexibility can lead to excess inventory, increased storage costs, and a limited ability to respond to market demands.

De oplossing: To overcome these challenges, buyers should seek suppliers who offer flexible order quantities and customization options for their 330ml bottles. Establishing partnerships with manufacturers that understand the needs of smaller businesses can lead to more accommodating terms. Buyers can request quotes for smaller batch orders and inquire about the possibility of customized designs, such as unique colors, shapes, or labels that reflect their brand identity. Utilizing digital printing technologies allows for cost-effective short runs, enabling brands to adapt quickly to consumer trends without incurring significant costs. By prioritizing suppliers that support flexibility, buyers can optimize inventory management and enhance their market presence.

Strategic Material Selection Guide for 330ml bottle

What Are the Key Properties of Glass Bottles for 330ml Applications?

Glass is a traditional choice for beverage packaging, particularly for carbonated drinks. The key properties of glass include excellent chemical resistance, high clarity, and the ability to maintain the integrity of the product. Glass bottles can withstand high pressure, making them suitable for carbonated beverages, with a typical pressure rating of around 10 bar. Furthermore, glass does not react with the contents, ensuring that the taste and quality remain unaltered.

Pros & Cons of Glass Bottles

The advantages of glass bottles include their durability and the premium perception they provide to consumers. They are also fully recyclable, aligning with sustainability goals. However, the disadvantages include higher manufacturing costs and weight, which can increase shipping expenses. Additionally, glass bottles are more fragile than other materials, posing a risk during transportation.

Invloed op toepassing

Glass bottles are particularly well-suited for beverages like beer, cider, and soft drinks. They are compatible with a wide range of media, ensuring that the product remains stable and retains its flavor. For international buyers, compliance with standards such as ASTM and DIN is crucial, especially in regions like Europe and South America, where regulations around food and beverage safety are stringent.

How Do Plastic Bottles Compare for 330ml Applications?

Plastic, particularly PET (Polyethylene Terephthalate), is increasingly popular for beverage packaging due to its lightweight and shatter-resistant properties. PET bottles can handle moderate pressure, making them suitable for still and lightly carbonated beverages. They are also fully recyclable, with many manufacturers opting for bottles made from recycled materials.

Pros & Cons of Plastic Bottles

The primary advantages of plastic bottles include lower production costs and reduced weight, which can lead to significant savings in transportation. However, they may not provide the same level of protection against oxygen and light as glass, potentially affecting product quality over time. Additionally, the perception of plastic may be less favorable among consumers seeking premium products.

Invloed op toepassing

Plastic bottles are ideal for products like bottled water and juices, where weight and convenience are significant factors. For international buyers, understanding the recycling capabilities and regulations in their specific markets is essential, particularly in regions like Africa and the Middle East, where plastic waste management can be a concern.

What Are the Benefits of Aluminum Bottles for 330ml Beverages?

Aluminum bottles are gaining traction in the beverage industry due to their lightweight and durability. They provide excellent protection against light and oxygen, which helps preserve the quality of the beverage. Aluminum bottles can handle moderate pressure, making them suitable for carbonated drinks.

Pros & Cons of Aluminum Bottles

The advantages of aluminum bottles include their recyclability and the ability to be produced in various shapes and sizes, allowing for unique branding opportunities. However, they can be more expensive than plastic and may require additional coatings to prevent reactions with certain beverages.

Invloed op toepassing

Aluminum bottles are particularly well-suited for premium beverages and craft beers, appealing to a market that values aesthetics and sustainability. International buyers should consider compliance with local regulations regarding aluminum recycling and food safety standards, especially in Europe where such regulations are stringent.

What Are the Considerations for Selecting Squeeze Bottles for 330ml Applications?

Squeeze bottles, often made from flexible plastics, are designed for easy dispensing of liquids. They are typically used for sauces, condiments, or other semi-viscous products. These bottles can withstand low pressure but are not suitable for carbonated beverages.

Pros & Cons of Squeeze Bottles

The main advantage of squeeze bottles is their convenience and ease of use, making them ideal for products requiring controlled dispensing. However, they may not offer the same level of durability as glass or aluminum and are typically less suitable for long-term storage of sensitive products.

Invloed op toepassing

Squeeze bottles are best suited for sauces and condiments. For international buyers, understanding the material’s compliance with food safety standards is essential, particularly in regions with strict regulations like Germany and Brazil.

Summary Table of Material Selection for 330ml Bottles

| Materiaal | Typical Use Case for 330ml bottle | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Glas | Beer, cider, carbonated beverages | Uitstekende chemische weerstand | Higher weight and fragility | Hoog |

| Kunststof | Bottled water, juices | Lichtgewicht en kosteneffectief | Less protection against light/oxygen | Medium |

| Aluminium | Premium beverages, craft beers | Good protection and recyclability | Higher production costs | Medium to High |

| Squeeze | Sauces, condiments | Easy dispensing | Less durable, not for carbonated | Laag |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them navigate the complexities of choosing the right packaging material for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for 330ml bottle

What Are the Key Manufacturing Processes for 330ml Bottles?

The manufacturing of 330ml bottles, whether glass or plastic, is a multifaceted process involving several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess the quality and reliability of their suppliers.

How Is Material Prepared for 330ml Bottle Production?

The first step in the manufacturing process is material preparation. For glass bottles, raw materials such as silica sand, soda ash, and limestone are meticulously weighed and mixed to create glass. This mixture is then melted in a furnace at high temperatures, typically around 1,700 degrees Celsius. For plastic bottles, particularly PET (Polyethylene Terephthalate), resin pellets are dried and melted before being molded.

Buyers should inquire about the sourcing of these materials, as the quality can significantly impact the final product’s integrity. Recycled materials are increasingly being used, especially in PET bottles, which can enhance sustainability efforts. For instance, some manufacturers use up to 50% recycled plastic in their PET bottles.

What Techniques Are Used in the Forming of 330ml Bottles?

Once the materials are prepared, the next stage is forming. In glass bottle production, the molten glass is shaped using techniques such as blow molding or press molding. For instance, a glass parison is created and then blown into a mold that shapes it into the desired 330ml bottle form.

In the case of plastic bottles, injection or stretch blow molding is commonly employed. The PET resin is injected into a mold to form a preform, which is then heated and stretched to achieve the final bottle shape. The choice of technique can influence the bottle’s strength and aesthetic qualities, which are crucial factors for brand positioning.

How Is the Assembly of 330ml Bottles Conducted?

Assembly involves adding closures and labels to the formed bottles. For glass bottles, crown caps or twist-off caps are typically used. The assembly process must ensure that these closures fit snugly to prevent leakage, especially for carbonated beverages.

In plastic bottles, labeling is often done using adhesive labels or direct printing techniques. B2B buyers should consider the customization options available for branding, as this can significantly affect market appeal.

What Are the Finishing Steps in 330ml Bottle Manufacturing?

The final stage in the manufacturing process is finishing, which includes quality checks, cleaning, and packaging. Bottles are often subjected to washing to remove any residues from the manufacturing process.

After washing, the bottles undergo inspections to ensure they meet the specified quality standards. This is critical in maintaining brand reputation, especially in competitive markets.

What Quality Assurance Measures Are Relevant for 330ml Bottles?

Quality assurance is paramount in the manufacturing of 330ml bottles, particularly for B2B buyers who rely on consistent quality for their products. Several international and industry-specific standards guide this process.

Which International Standards Should Buyers Be Aware Of?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system. Manufacturers compliant with ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

Additionally, certifications such as CE (European Conformity) and API (American Petroleum Institute) may also be relevant, depending on the intended use of the bottles. For instance, food-grade certifications are crucial for bottles intended for beverages.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) in bottle manufacturing typically involves several checkpoints:

-

Inkomende kwaliteitscontrole (IQC): This phase assesses the quality of raw materials before production begins. Buyers should verify that suppliers conduct rigorous IQC to prevent defective materials from entering the production process.

-

Kwaliteitscontrole tijdens het proces (IPQC): During production, continuous monitoring is essential. This includes checking the temperature of the furnace for glass production or the pressure and temperature during plastic molding.

-

Finale kwaliteitscontrole (FQC): After production, bottles undergo final inspections to ensure they meet all specifications. This includes tests for strength, leakage, and aesthetic quality.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

For B2B buyers, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

-

Conduct Audits: Request to perform or review audits of the manufacturing facility. This provides insights into their operational standards and compliance with international norms.

-

Kwaliteitsrapporten aanvragen: Ask for detailed QC reports that outline testing methods and results. This information is vital in assessing the reliability of the supplier.

-

Engage Third-party Inspectors: Consider hiring third-party inspection services to evaluate the manufacturing processes and product quality. This adds an additional layer of assurance.

What Are the Specific Quality Control Nuances for International Buyers?

International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific quality nuances:

-

Cultural and Regulatory Differences: Different regions may have varying regulations regarding materials and safety standards. It’s essential to ensure that suppliers can meet these specific requirements.

-

Supply Chain Transparency: Establishing transparency in the supply chain can help mitigate risks. This includes understanding the sourcing of materials and production practices.

-

Duurzaamheidspraktijken: Increasingly, buyers are prioritizing sustainability. Suppliers that adhere to environmentally friendly practices, such as using recycled materials and reducing waste, can be more appealing.

In conclusion, understanding the manufacturing processes and quality assurance measures for 330ml bottles is vital for B2B buyers. By focusing on these elements, buyers can make informed decisions that align with their business needs and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘330ml bottle’

Inleiding

Sourcing the right 330ml bottle is a critical task for B2B buyers, especially when considering factors such as product compatibility, supplier reliability, and market demand. This guide provides a step-by-step checklist to streamline your procurement process, ensuring you select the best options that align with your business needs.

Stap 1: Je technische specificaties definiëren

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as the bottle material (glass vs. plastic), closure type (crown caps, twist-off), and pressure ratings, especially for carbonated beverages. This clarity helps avoid miscommunication with suppliers and ensures the final product meets your requirements.

Stap 2: Identify Your Target Market Requirements

Understanding the preferences and regulations of your target markets is essential. Different regions may have specific packaging requirements or consumer preferences, such as eco-friendly materials or particular bottle shapes. Researching these elements will help you choose a bottle that resonates with your audience while complying with local laws.

Stap 3: Potentiële leveranciers evalueren

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request detailed company profiles, product samples, and references from other businesses in similar markets. Look for suppliers with a proven track record of quality and reliability, as this will minimize risks in your supply chain.

- Controleer certificeringen: Ensure suppliers comply with relevant industry standards, such as ISO or food safety certifications. This is particularly important for businesses dealing with consumable products.

Stap 4: Assess Cost and Payment Terms

Cost is a significant factor in procurement, but it’s essential to evaluate the total cost of ownership rather than just the unit price. Consider additional expenses such as shipping, customs duties, and potential tariffs. Establish clear payment terms that suit both parties, allowing for flexibility while protecting your cash flow.

Stap 5: Request and Analyze Samples

Before making a bulk order, always request samples of the 330ml bottles. This step allows you to assess the quality, functionality, and aesthetics of the bottles firsthand. Pay attention to aspects such as weight, durability, and how well the bottles showcase your product.

Stap 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier and evaluated samples, initiate negotiations on pricing, lead times, and delivery schedules. Aim for a mutually beneficial agreement that includes clear terms on returns, quality control, and penalties for late delivery. This can protect your business from potential disruptions.

Stap 7: Plan for Quality Control and Compliance Checks

Establish a robust quality control process for incoming shipments. This includes checking for defects and ensuring compliance with your specifications and local regulations. Setting up a quality assurance protocol helps maintain product integrity and fosters a long-term relationship with your supplier.

By following this checklist, you can streamline your procurement process for 330ml bottles, ensuring that your choices align with both your operational needs and market expectations.

Comprehensive Cost and Pricing Analysis for 330ml bottle Sourcing

What Are the Key Cost Components in Sourcing 330ml Bottles?

When sourcing 330ml bottles, it is essential to understand the various cost components that contribute to the overall pricing. The primary elements include:

-

Materialen: The choice of material significantly impacts cost. Glass bottles, for example, can range from flint (clear) to colored glass, while PET plastic bottles often utilize recycled materials. The price of raw materials fluctuates based on market demand and availability.

-

Arbeid: Labor costs vary by region. Countries with lower labor costs can offer competitive pricing, but quality control may differ. Understanding the labor market in the supplier’s location is crucial for assessing potential costs.

-

Productie Overhead: This includes expenses related to the production process, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead and, consequently, the price per unit.

-

Gereedschap: Custom tooling for specific designs or bottle shapes can add to initial costs. This is particularly relevant for buyers looking for unique branding or customization options.

-

Kwaliteitscontrole (QC): Implementing stringent QC measures ensures product reliability but can increase costs. Certifications, such as ISO or BRC, can also add to the price but may be necessary for certain markets.

-

Logistiek: Transportation costs depend on the distance between the manufacturing facility and the buyer’s location. Factors like shipping method, packaging, and insurance also play a role in logistics expenses.

-

Marge: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins in your specific region can help in negotiations.

How Do Price Influencers Affect 330ml Bottle Sourcing?

Several factors influence the pricing structure for 330ml bottles, making it essential for buyers to consider these elements:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Negotiating for better pricing based on anticipated volume can lead to substantial savings.

-

Specificaties/Aanpassing: Customized bottles, such as those with specific shapes or branding, can incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materialen: The choice between glass and plastic, as well as the type of glass (e.g., amber for UV protection), affects pricing. Higher-quality materials typically command higher prices.

-

Kwaliteit en certificeringen: Bottles that meet specific quality standards or certifications may cost more but can lead to better consumer trust and marketability.

-

Factoren van leveranciers: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may charge more for their experience and service quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They define responsibilities for shipping costs, insurance, and risk, which can affect overall pricing.

What Are the Best Practices for Negotiating Costs and Ensuring Cost-Efficiency?

B2B buyers should adopt strategic approaches to ensure cost efficiency when sourcing 330ml bottles:

-

Leverage Total Cost of Ownership (TCO): Consider not just the initial purchase price but all associated costs, including shipping, handling, storage, and potential waste. A lower upfront cost might lead to higher TCO if quality issues arise.

-

Onderhandelen over voorwaarden: Establishing a good relationship with suppliers can facilitate better pricing and terms. Open discussions about volume discounts, payment terms, and long-term contracts can lead to favorable outcomes.

-

Assess Quality vs. Price: While it may be tempting to choose the lowest-cost option, prioritize quality to avoid issues down the line. A more expensive, high-quality bottle may provide better value in the long run.

-

Marktonderzoek: Conduct thorough research on pricing trends in your region. This knowledge can empower negotiations and help avoid overpaying.

Are There Any Pricing Nuances for International B2B Buyers in Specific Regions?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of regional pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly affect costs. Buyers should consider hedging strategies to manage currency risk.

-

Regulatory Compliance: Different regions have varying regulations regarding packaging materials, which can influence both cost and sourcing options. Ensure compliance to avoid fines and additional costs.

-

Supply Chain Dynamics: Local supply chain conditions, including transportation infrastructure and political stability, can affect pricing and lead times. Buyers should factor these into their sourcing strategy.

Conclusie

Understanding the cost structure and pricing dynamics for 330ml bottle sourcing is crucial for international B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic negotiation techniques, businesses can optimize their sourcing decisions and ensure better profitability. Always remember to consider the total cost of ownership and the unique nuances of your specific market when making purchasing decisions.

Alternatives Analysis: Comparing 330ml bottle With Other Solutions

Exploring Alternative Packaging Solutions to the 330ml Bottle

In today’s competitive market, businesses often seek alternatives to traditional packaging solutions like the 330ml bottle. Factors such as cost efficiency, environmental impact, and consumer preferences play pivotal roles in determining the best packaging option. This analysis compares the 330ml bottle against two viable alternatives: the 330ml PET plastic bottle and the 330ml aluminum can. Each option has its own set of advantages and drawbacks that can influence a B2B buyer’s decision-making process.

| Vergelijkingsaspect | 330ml Bottle | 330ml PET Plastic Bottle | 330ml Aluminum Can |

|---|---|---|---|

| Prestaties | High durability, suitable for carbonated beverages | Lightweight but less durable; suitable for various beverages | Excellent for preserving carbonation and flavor |

| Kosten | Moderate production cost | Generally lower production cost | Competitive cost, but varies by design |

| Gemak van implementatie | Requires more complex logistics for shipping | Simple logistics and handling | Efficient stacking and storage |

| Onderhoud | Reusable and recyclable | Single-use; recyclable but less eco-friendly | Fully recyclable, no maintenance needed |

| Beste gebruikscasus | Premium beverages, craft beers | On-the-go products, water, soft drinks | Beverages requiring airtight seals, like beers and sodas |

Understanding the Pros and Cons of Each Alternative

330ml PET Plastic Bottle

The 330ml PET plastic bottle is an increasingly popular alternative, particularly for on-the-go products. Its lightweight nature makes it easy to transport, reducing shipping costs. Additionally, PET bottles can be produced at a lower cost than glass, making them attractive for budget-conscious brands. However, while they are recyclable, the environmental impact of single-use plastics remains a concern, especially in regions where recycling infrastructure is limited.

330ml Aluminum Can

Aluminum cans are another viable alternative, particularly for carbonated beverages. They excel in preserving the freshness and carbonation of drinks, which is critical for consumer satisfaction. Cans are also infinitely recyclable, making them a more sustainable choice in many markets. However, the initial production cost can be higher than that of PET bottles, and branding options may be limited depending on the canning process. Despite this, their lightweight nature and efficiency in storage make them appealing for many manufacturers.

Conclusion: Making the Right Choice for Your Business

When evaluating packaging options, B2B buyers should consider their specific needs, including target market, product type, and environmental impact. The 330ml bottle remains a classic choice for premium products, while PET plastic bottles offer cost-effective solutions for high-volume sales. Aluminum cans stand out for their ability to maintain product quality and sustainability. Ultimately, understanding the unique strengths and weaknesses of each option will enable businesses to select the packaging solution that best aligns with their brand values and operational requirements.

Essential Technical Properties and Trade Terminology for 330ml bottle

What Are the Key Technical Properties of a 330ml Bottle?

When selecting a 330ml bottle, several critical specifications must be considered to ensure the product meets the specific needs of your business. Here are some of the essential technical properties:

-

Materiaalklasse

– Definition: The material grade refers to the type of material used in the bottle’s construction, such as glass (flint, amber) or plastic (PET).

– B2B Importance: Material choice impacts durability, recyclability, and the ability to preserve product quality. For instance, glass bottles are preferred for carbonated beverages due to their pressure resistance, while PET is lighter and often used for bottled water. -

Closure Type

– Definition: This refers to the mechanism used to seal the bottle, such as a crown cap, screw cap, or twist-off.

– B2B Importance: The closure type affects product freshness and ease of use. For carbonated drinks, a crown cap is crucial to maintain carbonation, while screw caps are often more user-friendly for non-carbonated beverages. -

Pressure Rating

– Definition: The pressure rating indicates the maximum internal pressure the bottle can withstand, typically measured in bar.

– B2B Importance: Understanding the pressure rating is essential for products like beer and soda, where carbonation creates significant internal pressure. A bottle rated for at least 10 bar is suitable for these beverages. -

Weight and Dimensions

– Definition: Weight (often in grams) and dimensions (height and diameter) of the bottle.

– B2B Importance: These factors influence shipping costs, handling, and storage. Lighter bottles can reduce transportation costs, while specific dimensions may be required for compatibility with existing packaging lines. -

Recycleerbaarheid

– Definition: This indicates whether the bottle can be recycled after use, and to what extent (e.g., made from recycled materials).

– B2B Importance: With increasing environmental regulations, offering recyclable products can enhance brand reputation and appeal to eco-conscious consumers. Bottles made from 100% recycled plastic, for example, can be a selling point. -

Minimum Order Quantity (MOQ)

– Definition: The minimum number of units that must be ordered at one time from a supplier.

– B2B Importance: Understanding MOQ is vital for inventory management and cost calculations. Suppliers often set MOQs to ensure production efficiency, which can influence order sizes and financial planning.

What Are Common Trade Terms Associated with 330ml Bottles?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to 330ml bottles:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Businesses often work with OEMs for custom bottle designs, ensuring that products meet specific branding requirements or functional needs. -

RFQ (Offerteaanvraag)

– Definition: A document issued by a buyer to solicit price offers from suppliers for specific products or services.

– Importance: RFQs help businesses compare prices and terms from different suppliers, facilitating informed purchasing decisions. -

Incoterms (internationale handelsvoorwaarden)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Importance: Understanding Incoterms is crucial for managing shipping risks and costs. For example, “FOB” (Free on Board) indicates that the seller covers shipping to the port, while the buyer assumes responsibility once the goods are on board. -

Doorlooptijd

– Definition: The amount of time from when an order is placed until it is fulfilled and shipped.

– Importance: Knowing lead times is essential for inventory planning and supply chain management. Longer lead times can affect production schedules and customer satisfaction. -

Pallet Configuration

– Definition: The arrangement of bottles on a pallet for storage or transportation.

– Importance: Efficient pallet configurations can maximize storage space and minimize shipping costs, making them a critical consideration for logistics.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 330ml bottles, ensuring that their product packaging aligns with operational and market needs.

Navigating Market Dynamics and Sourcing Trends in the 330ml bottle Sector

What are the Current Market Dynamics and Key Trends in the 330ml Bottle Sector?

The global 330ml bottle market is witnessing significant evolution, driven by various factors including consumer preference for convenience and the rising demand for sustainable packaging solutions. In regions such as Africa, South America, the Middle East, and Europe, B2B buyers are increasingly drawn to the versatility of 330ml bottles, which are commonly used for beverages ranging from water to craft beers. The trend toward smaller, portable packaging is gaining traction, especially in urban markets where consumers seek on-the-go hydration options.

Emerging technologies are reshaping sourcing practices, with an emphasis on automation and digital platforms that facilitate efficient supply chain management. International B2B buyers are leveraging e-commerce solutions to streamline procurement processes, allowing for more agile responses to market demands. Additionally, the integration of smart packaging technologies, such as QR codes and RFID, is enhancing product traceability and consumer engagement, providing valuable data for businesses to optimize their marketing strategies.

How is Sustainability Shaping Sourcing in the 330ml Bottle Market?

Sustainability is becoming a cornerstone of sourcing strategies in the 330ml bottle sector. With increasing awareness of environmental issues, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of recycled materials, such as PET bottles made from 50% recycled plastic, and glass bottles that are infinitely recyclable.

Ethical supply chains are critical in this context, as companies strive to minimize their carbon footprint and ensure responsible sourcing of materials. Certifications such as B Corp and Carbon Trust are becoming important indicators of a company’s sustainability credentials. Buyers in the international market are encouraged to assess potential partners based on their environmental impact and commitment to ethical practices. By selecting suppliers who prioritize sustainability, businesses can not only enhance their brand image but also meet the growing consumer demand for eco-friendly products.

What is the Brief Evolution of the 330ml Bottle?

The 330ml bottle has evolved significantly since its inception, adapting to changing consumer needs and industry innovations. Originally popularized in the beverage sector for its convenience, the format has become synonymous with quality and portability. Over the years, advancements in materials science have led to the development of lightweight, durable options, including glass and PET, which cater to various product requirements.

As health-conscious consumers increasingly favor smaller portion sizes, the 330ml bottle has solidified its position in the market. The rise of craft beverages and premium products has further fueled demand, as brands seek packaging that reflects their quality and uniqueness. This evolution illustrates how the 330ml bottle continues to meet the demands of an ever-changing marketplace, making it a vital choice for international B2B buyers looking to enhance their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of 330ml bottle

-

How do I choose the right type of 330ml bottle for my product?

When selecting a 330ml bottle, consider the product type you intend to package. For carbonated beverages, glass bottles with a pressure rating of at least 10 bar are ideal, such as flint or amber glass options. If you are packaging water or non-carbonated drinks, both PET and glass bottles are suitable. Additionally, think about the bottle’s aesthetic, closure type, and whether it aligns with your brand image. Conducting market research on consumer preferences in your target region can also provide valuable insights. -

What customization options are available for 330ml bottles?

Customization options for 330ml bottles can include color, shape, and labeling. Manufacturers often offer embossing and debossing to enhance brand visibility. You can also select different closure types, such as crown or twist-off caps, based on your product requirements. Additionally, consider the possibility of custom packaging solutions that cater to specific market needs, such as eco-friendly materials or unique designs that reflect your brand ethos. -

What are the minimum order quantities (MOQs) for 330ml bottles?

Minimum order quantities can vary significantly among suppliers. Typically, for bulk purchases, you may need to order at least one pallet, which can range from 1,500 to over 3,000 bottles depending on the manufacturer. It’s crucial to clarify MOQs during your initial discussions with suppliers, as this can impact your inventory and production planning. Some suppliers might offer flexibility for smaller orders, especially for new businesses or trial runs. -

What payment terms should I expect when sourcing 330ml bottles internationally?

Payment terms can vary based on the supplier’s policies and your negotiation skills. Common terms include a deposit (often 30-50%) upfront, with the balance due upon delivery or before shipping. Some suppliers may offer credit terms for established businesses. It is essential to discuss payment methods, such as bank transfers or letters of credit, and ensure that these terms are clearly outlined in your contract to avoid misunderstandings. -

How can I ensure the quality of 330ml bottles from international suppliers?

To ensure quality, start by vetting potential suppliers through references, reviews, and certifications. Request samples before placing a large order to assess the quality firsthand. Additionally, inquire about their quality assurance processes, including material sourcing, production standards, and testing protocols. Collaborating with third-party inspection services can also provide peace of mind by verifying product quality before shipment. -

What logistics considerations should I keep in mind when importing 330ml bottles?

Logistics are critical when importing bottles. Consider shipping methods (air vs. sea), as well as the associated costs and transit times. Ensure you are aware of customs regulations and duties in your destination country, as these can significantly impact overall costs. Working with a reliable freight forwarder can help streamline the process, ensuring timely and compliant delivery of your bottles. -

Are there any specific regulations for packaging beverages in 330ml bottles?

Yes, regulations vary by country and can include labeling requirements, safety standards, and environmental considerations. In Europe, for instance, there are strict guidelines regarding food safety and packaging materials. Ensure that your bottles comply with local regulations in your target markets, including any recycling or sustainability mandates. Consulting with legal experts or trade associations can provide clarity on compliance in specific regions. -

What are the benefits of using recyclable materials for 330ml bottles?

Utilizing recyclable materials for your 330ml bottles offers numerous benefits, including enhanced brand image and consumer appeal, particularly among environmentally conscious buyers. Many consumers prefer brands that demonstrate sustainability practices. Additionally, using recyclable materials can reduce production costs over time and may qualify your business for tax incentives or eco-certifications. This commitment to sustainability can also strengthen your market position, especially in regions with stringent environmental regulations.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 8 330Ml Bottle Manufacturers & Suppliers List

1. United Bottles – 11.2oz Flint Bottle

Domein: unitedbottles.com

Geregistreerd: 2003 (22 jaar)

Inleiding: {“Capacity”:”11.2fl.oz / 330ml”,”Color”:”Flint”,”Closure type”:”26mm Crown Pry-off”,”Weight”:”7.8oz / 220g”,”Height”:”8.9in / 226.5mm”,”Diameter”:”2.4in / 60.4mm”,”Pressure”:”10 bar”,”Reusable”:”Yes”,”Minimum order”:”1 pallet(s)”,”Pallet configuration”:{“In bulk”:”3249 bottles”,”In boxes”:”108 x 24 bottles (2592)”},”Availability”:”fast from stock”}

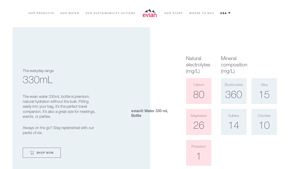

2. Evian – evian® Water 330 mL Bottle

Domein: evian.com

Geregistreerd: 1997 (28 jaar)

Inleiding: {“product_name”: “evian® Water 330 mL Bottle”, “size”: “330 mL”, “attributes”: {“natural_electrolytes”: {“calcium”: 80, “magnesium”: 26, “potassium”: 1}, “mineral_composition”: {“bicarbonates”: 360, “silica”: 15, “sulfates”: 14, “chlorides”: 10}, “pH”: 7.2}, “sustainability”: {“B_Corp_Certified”: true, “carbon_neutral”: true, “bottle_material”: “100% recycled plastic (excluding caps and labels)”},…

3. Petainer – 330ml Water Bottle

Domein: petainer.com

Geregistreerd: 2006 (19 jaar)

Inleiding: {‘name’: ‘330ml Water Bottle – 28mm PCO 1810’, ‘material’: ‘PET (up to 100% rPET)’, ‘colour’: ‘Clear’, ‘diameter’: ’59mm’, ‘height’: ‘171.4mm’, ‘weight’: ’20g’, ‘volume’: ‘330ml’, ‘neck_type’: ’28mm PCO 1810′, ‘compliance’: ‘FDA Compliant / EU Food Contact Compliant’, ‘manufacturing_process’: ‘Blow Molding’, ‘energy_source’: ‘100% Renewable’, ‘recyclable’: ‘Fully recyclable’, ‘UV_protection’: ‘Opt…

4. Orora – AG 118 CS3 Amber Bottle

Domein: ororabeverage.com

Geregistreerd: 2018 (7 jaar)

Inleiding: {“Product Name”: “AG 118 CS3 330mL Amber Bottle”, “Color”: “Amber”, “Capacity”: “330mL ± 3.6mL”, “Finish Name”: “Crown Seal”, “Label Size”: “Approx. 84mm”, “Finish Number”: “CS3”, “Weight”: “205g”, “Fill Point”: “52mm”, “Process”: “NNPB”, “Brimful Volume”: “351mL”, “Units per Pallet”: “2250”, “Height”: “222.9mm ± 1.2mm”, “Gas Volume”: “4 g/v”, “Diameter”: “60.9mm ± 1.2mm”, “Customizable”: “Yes”, “…

5. Sistema – 330ml Squeeze Bottle

Domein: sistemaplastics.com

Geregistreerd: 1998 (27 jaar)

Inleiding: Product Name: 330ml Squeeze Bottle

Brand: Sistema

Capacity: 330ml / 11.2 oz / 1.4 cups

Dimensions: L 61mm x H 162mm x W 64mm

Kenmerken:

– Durable and reusable drink bottle

– Leak proof design

– Twist ‘n’ Sip™ lid for hygienic drinking

– Sculptured easy grip shape

Key Uses: Ideal for school, sports, and on-the-go hydration

Care Instructions:

– Wash before use

– Safe for top rack of household dishw…

6. Reddit – Homebrewing Bottles

Domein: reddit.nl

Geregistreerd: 2005 (20 jaar)

Inleiding: 500 ml (17 oz) bottles and 330 ml (11 oz) bottles are used for homebrewing. Users have reported that IPAs and pale ales from 500 ml bottles taste better than those from 330 ml bottles. Factors influencing taste may include headspace, carbonation levels, and yeast suspension.

7. Pure Life – 330 mL Natural Spring Water

Domein: drinkpurelifewater.ca

Registered: 2022 (3 years)

Inleiding: {“product_name”: “Pure Life® 330 mL Bottle”, “product_type”: “Natural Spring Water”, “bottle_size”: “330 mL”, “pack_size”: “12 Pack”, “suitable_for”: “lunch boxes, backpacks, purses”, “nutrition_facts”: {“calories”: “0 mg”, “total_fat”: “0 mg”, “sodium”: “0 mg”, “protein”: “0 mg”}, “ingredients”: “Spring water”}

8. Stryda Brewing Co – 4.4% Bottles 330ml x24

Domein: strydabrewingco.com

Registered: 2023 (2 years)

Inleiding: {“product_name”: “4.4% bottles 330ml x24”, “price”: “$64.99”, “quantity”: “24 bottles”, “bottle_size”: “330ml”, “alcohol_content”: “4.4%”}

Strategic Sourcing Conclusion and Outlook for 330ml bottle

What Are the Key Takeaways for B2B Buyers in the 330ml Bottle Market?

As the demand for 330ml bottles continues to rise across diverse sectors, strategic sourcing emerges as a critical factor for international buyers. Prioritizing quality, sustainability, and versatility in bottle selection can significantly enhance product presentation and consumer appeal. For instance, glass bottles offer a premium look for beverages, while PET options provide lightweight convenience, especially for on-the-go consumption.

Moreover, consider the importance of supplier reliability and the ability to customize packaging to align with brand identity. Engaging with manufacturers who utilize recycled materials can not only meet consumer demands for eco-friendly products but also contribute to corporate sustainability goals.

How Can Buyers Position Themselves for Future Success?

Looking ahead, the 330ml bottle market is poised for innovation, driven by evolving consumer preferences and regulatory changes. B2B buyers should stay informed about emerging trends, such as the increasing shift towards sustainable packaging and the integration of smart technology in product offerings.

By leveraging strategic sourcing practices today, international buyers—particularly from Africa, South America, the Middle East, and Europe—can not only optimize their supply chains but also position their businesses for growth in a competitive landscape. Now is the time to explore partnerships that can drive value and enhance market presence.