Inleiding: Navigeren door de wereldwijde markt voor geïsoleerde fietsflessen

Terwijl de vraag naar geïsoleerde bidons van hoge kwaliteit wereldwijd toeneemt, staan B2B-inkopers voor de uitdaging om producten te vinden die niet alleen voldoen aan de prestatieverwachtingen, maar ook in lijn zijn met duurzaamheid en markttrends. Geïsoleerde bidons zijn essentieel voor het behoud van hydratatie in verschillende klimaten, waardoor ze een cruciaal onderdeel vormen voor retailers en distributeurs die zich richten op fietsliefhebbers. Deze gids biedt een diepgaande verkenning van de verschillende soorten geïsoleerde bidons die verkrijgbaar zijn, hun toepassingen in verschillende fietsdisciplines en de nieuwste innovaties op het gebied van ontwerp en materialen.

Daarnaast worden vitale aspecten van het doorlichten van leveranciers behandeld, waaronder naleving van internationale veiligheidsnormen, en wordt inzicht geboden in prijsstrategieën die inspelen op verschillende markten, met name in Afrika, Zuid-Amerika, het Midden-Oosten en Europa. Door internationale B2B-kopers uit te rusten met uitgebreide kennis over het inkopen van geïsoleerde bidons, zorgt deze gids voor weloverwogen inkoopbeslissingen die het productaanbod verbeteren en effectief voldoen aan de eisen van de consument.

Of u nu uw portfolio wilt uitbreiden met milieuvriendelijke opties of het concurrentielandschap wilt begrijpen, deze bron is een waardevol hulpmiddel bij het navigeren door de complexiteit van de wereldwijde markt voor geïsoleerde fietsflessen. Met bruikbare inzichten en strategische aanbevelingen kunt u uw bedrijf met vertrouwen positioneren voor succes in deze dynamische sector.

Artikel navigatie

- Top 7 geïsoleerde fietsfles fabrikanten en leveranciers lijst

- Inleiding: Navigeren door de wereldwijde markt voor geïsoleerde fietsflessen

- Inzicht in geïsoleerde bidonsoorten en -variaties

- Belangrijkste industriële toepassingen van geïsoleerde bidons

- 3 veelvoorkomende pijnpunten voor 'geïsoleerde bidon' en hun oplossingen

- Strategische materiaalselectiegids voor geïsoleerde fietsfles

- Diepgaande blik: Productieprocessen en kwaliteitsborging voor geïsoleerde bidons

- Praktische inkoopgids: Een stap-voor-stap checklist voor 'geïsoleerde bidon'.

- Uitgebreide kosten- en prijsanalyse voor geïsoleerde fietsflessen Sourcing

- Alternatieven Analyse: Geïsoleerde bidons vergelijken met andere oplossingen

- Essentiële technische eigenschappen en handelsterminologie voor geïsoleerde fietsflessen

- Navigeren door marktdynamiek en inkooptrends in de sector van geïsoleerde bidons

- Veelgestelde vragen (FAQ's) voor B2B-kopers van geïsoleerde fietsflessen

- Belangrijke disclaimer en gebruiksvoorwaarden

- Strategische Sourcing Conclusie en Vooruitzichten voor geïsoleerde fietsflessen

Inzicht in geïsoleerde bidonsoorten en -variaties

| Type Naam | Belangrijkste onderscheidende kenmerken | Primaire B2B-toepassingen | Korte voor- en nadelen voor kopers |

|---|---|---|---|

| Dubbelwandig vacuüm geïsoleerd | Superieure isolatietechnologie, lichtgewicht ontwerp, houdt drankjes meer dan 12 uur koud. | Sportwinkels, fietsenwinkels | Voordelen: Uitstekende thermische retentie; Minpunten: Hogere prijs vergeleken met standaard flessen. |

| Sportmondstuk met hoog debiet | Gepatenteerd mondstuk voor moeiteloos drinken zonder knijpen. | Sportteams, organisatoren van evenementen | Voordelen: Verbeterde hydratatie-ervaring; Minpunten: Heeft mogelijk meer onderhoud nodig om schoon te blijven. |

| Milieuvriendelijke materialen | Gemaakt van recyclebare materialen, BPA-vrij en ontworpen met het oog op duurzaamheid. | Eco-bewuste merken, outdoorwinkels | Voordelen: Aantrekkingskracht op milieubewuste consumenten; Minpunten: Beperkt verkrijgbaar in sommige markten. |

| Varianten met meerdere maten | Verkrijgbaar in verschillende capaciteiten (bijv. 17oz, 21oz, 25oz) om te voldoen aan verschillende behoeften. | Fitnesscentra, fietsevenementen | Voordelen: Veelzijdige opties voor verschillende gebruikers; Minpunten: Voorraadbeheer kan complex zijn. |

| Aanpasbare ontwerpen | Opties voor branding, kleuren en personalisaties om de verkoopbaarheid te vergroten. | Promotionele producten, relatiegeschenken | Voordelen: Verhoogde zichtbaarheid van het merk; Minpunten: Hogere aanloopkosten voor maatwerk. |

Wat zijn de belangrijkste kenmerken van dubbelwandige vacuümgeïsoleerde flessen?

Dubbelwandige vacuümgeïsoleerde bidons zijn ontworpen om dranken gedurende langere perioden op temperatuur te houden, vaak meer dan 12 uur voor koude dranken. Deze bidons maken meestal gebruik van geavanceerde lichtgewicht materialen, waardoor ze ideaal zijn voor fietsers die prestaties zonder extra gewicht belangrijk vinden. B2B inkopers in sportartikelen en fietsenwinkels zouden deze bidons moeten overwegen vanwege hun uitstekende thermische retentie en duurzaamheid, hoewel ze een hogere prijs hebben dan niet-geïsoleerde opties.

Hoe verbeteren sportsproeiers met hoog debiet de gebruikerservaring?

Sportdopjes met hoog debiet zijn ontworpen om moeiteloos te hydrateren zonder dat je erin hoeft te knijpen. Deze functie is vooral nuttig tijdens fietsen met hoge intensiteit, waarbij snelle slokjes essentieel zijn. B2B-toepassingen zijn onder andere sportteams en organisatoren van evenementen die atleten efficiënte hydratatieoplossingen moeten bieden. Hoewel deze sproeikoppen de drinkervaring verbeteren, moeten ze mogelijk vaker worden gereinigd om de hygiëne te handhaven.

Waarom kiezen voor milieuvriendelijke materialen voor fietsflessen?

Milieuvriendelijke bidons worden gemaakt van recyclebare materialen en zijn vaak BPA-vrij, waardoor ze een duurzame keuze zijn voor milieubewuste merken. Ze slaan goed aan bij consumenten die prioriteit geven aan duurzaamheid, wat steeds belangrijker wordt in de huidige markt. B2B-inkopers in milieubewuste sectoren, zoals detailhandelaren in buitensportartikelen, kunnen van deze trend profiteren. De beschikbaarheid van deze producten kan echter per regio verschillen, wat voor sommige distributeurs een uitdaging vormt.

Hoe voldoen varianten met meerdere maten aan de uiteenlopende behoeften van de klant?

Multi-size varianten van geïsoleerde bidons bieden flexibiliteit om tegemoet te komen aan verschillende voorkeuren van klanten, variërend van 17oz tot 25oz capaciteiten. Deze veelzijdigheid is vooral waardevol voor fitnesscentra en fietsevenementen waar deelnemers verschillende hydratatiebehoeften kunnen hebben. Hoewel het aanbieden van meerdere maten de klanttevredenheid kan vergroten, kan het het voorraadbeheer voor B2B inkopers bemoeilijken.

Wat zijn de voordelen van aanpasbare ontwerpen voor branding?

Met aanpasbare bidons kunnen bedrijven hun merkbekendheid vergroten met gepersonaliseerde kleuren, logo's en ontwerpen. Dit is vooral voordelig voor promotionele producten en relatiegeschenken, omdat het een blijvende indruk maakt. Hoewel het potentieel voor een grotere merkbekendheid aanzienlijk is, moeten B2B-kopers bij het plannen van hun aankopen ook rekening houden met de hogere aanloopkosten die met personalisering gepaard gaan.

Belangrijkste industriële toepassingen van geïsoleerde bidons

| Industrie/sector | Specifieke toepassing van geïsoleerde fietsfles | Waarde/Voordeel voor het bedrijf | Belangrijkste overwegingen bij de inkoop voor deze toepassing |

|---|---|---|---|

| Sport en recreatie | Gebruikt door wielerploegen en atleten voor hydratatie tijdens evenementen | Verbetert prestaties door koude hydratatie, verbetert uithoudingsvermogen | Duurzaamheid, gewicht en eenvoudige reiniging |

| Avontuurlijke outdoorkleding | Aangeboden als onderdeel van kampeer- en wandeluitrustingpakketten | Trekt milieubewuste consumenten aan die op zoek zijn naar duurzame opties | Materiaal duurzaamheid, isolatie-efficiëntie, capaciteit |

| Wellness-programma's voor bedrijven | Verspreid over welzijnsinitiatieven voor werknemers | Bevordert hydratatie en welzijn onder werknemers, waardoor de productiviteit toeneemt | Aangepaste merkopties, kortingen bij bulkaankopen |

| Reizen en toerisme | Geïntegreerd in reispakketten voor avontuurlijk toerisme | Verbetert de klantervaring door hydratatie onderweg te bevorderen | Lichtgewicht ontwerp, compatibel met verschillende dragers |

| Detailhandel en e-commerce | Los verkrijgbaar of gebundeld met fietsaccessoires | Verhoogt de gemiddelde orderwaarde en klantloyaliteit | Concurrerende prijzen, unieke kenmerken en markttrends |

Hoe worden geïsoleerde bidons gebruikt in sport en recreatie?

In de sport- en recreatiesector zijn geïsoleerde bidons onmisbaar voor professionele wielerteams en atleten. Deze bidons houden dranken voor langere periodes koud, wat cruciaal is tijdens lange ritten of wedstrijden. Het ontwerp met hoge stroomsnelheid zorgt voor snelle hydratatie zonder te hoeven knijpen, wat essentieel is voor het behouden van prestaties. Kopers in deze sector moeten prioriteit geven aan duurzaamheid, gewicht en de mogelijkheid om deze bidons gemakkelijk schoon te maken, zodat ze bestand zijn tegen intensief gebruik.

Welke rol spelen geïsoleerde bidons bij outdooravonturen?

Outdoormerken nemen geïsoleerde bidons op in hun kampeer- en wandeluitrusting om de hydratatie onder avonturiers te bevorderen. Deze bidons zijn ontworpen om de temperatuur vast te houden, zodat dranken koud blijven in warme klimaten of warm in koelere omstandigheden, wat een belangrijk voordeel is voor outdoorliefhebbers. Bij het inkopen voor deze toepassing moeten bedrijven rekening houden met de duurzaamheid van materialen en isolatie-efficiëntie, omdat consumenten steeds meer de voorkeur geven aan milieuvriendelijke producten die aansluiten bij hun waarden.

Hoe kunnen welzijnsprogramma's profiteren van geïsoleerde bidons?

Initiatieven op het gebied van bedrijfswelzijn omvatten vaak het uitdelen van geïsoleerde bidons aan werknemers. Deze bidons moedigen hydratatie aan, wat bijdraagt aan het algehele welzijn en een hogere productiviteit. Bedrijven kunnen deze trend gebruiken om een gezonde werkomgeving te promoten en de tevredenheid van hun werknemers te vergroten. Bij het inkopen moeten organisaties op zoek gaan naar aangepaste merkopties en kortingen voor bulkaankopen om hun investering te maximaliseren en tegelijkertijd hun bedrijfsidentiteit te versterken.

Hoe worden geïsoleerde bidons geïntegreerd in reizen en toerisme?

In de reis- en toerisme-industrie zijn geïsoleerde fietsflessen populaire toevoegingen aan reispakketten voor avontuurlijk toerisme. Ze bieden reizigers een handige manier om gehydrateerd te blijven tijdens excursies, wat hun algehele ervaring verbetert. Lichtgewicht ontwerpen die gemakkelijk in verschillende bagagedragers passen zijn essentieel voor deze markt. Kopers moeten zich richten op kenmerken die compatibel zijn met verschillende reisuitrustingen en het vermogen om de temperatuur gedurende langere perioden te behouden.

Wat zijn de verkoopkansen voor geïsoleerde fietsflessen?

Detailhandelaren en e-commerce platforms kunnen profiteren van de verkoop van geïsoleerde bidons als zelfstandige producten of als onderdeel van fietsaccessoirebundels. Deze bidons verhogen niet alleen de gemiddelde orderwaarde, maar helpen ook om klantenloyaliteit op te bouwen door middel van kwaliteitsaanbiedingen. Belangrijke overwegingen bij de inkoop zijn een concurrerende prijsstelling, unieke kenmerken die de producten onderscheiden in een overvolle markt, en op de hoogte blijven van opkomende trends om effectief te voldoen aan de vraag van de consument.

3 veelvoorkomende pijnpunten voor 'geïsoleerde bidon' en hun oplossingen

Scenario 1: Worstelen met productconsistentie in verschillende markten

Het probleem: B2B inkopers worden vaak geconfronteerd met uitdagingen bij het inkopen van geïsoleerde bidons die voldoen aan verschillende kwaliteitsnormen in verschillende regio's, vooral wanneer ze producten importeren in markten zoals Afrika, Zuid-Amerika en het Midden-Oosten. Discrepanties in de productiekwaliteit kunnen leiden tot ontevredenheid bij klanten en meer retourzendingen, omdat producten mogelijk niet presteren zoals verwacht onder lokale klimaatomstandigheden. Bovendien kan het voor kopers moeilijk zijn om ervoor te zorgen dat de flessen voldoen aan de lokale regelgeving met betrekking tot materialen en veiligheidsnormen.

De oplossing: Om deze uitdaging het hoofd te bieden, moeten B2B inkopers grondig onderzoek doen bij het selecteren van leveranciers. Dit omvat het aanvragen van monsters om de productprestaties onder lokale omstandigheden te evalueren en het controleren van de naleving van regionale voorschriften. Het is van cruciaal belang om partnerschappen aan te gaan met fabrikanten die transparantie bieden in hun inkoop- en productieprocessen. Kopers kunnen ook overwegen om vóór verzending kwaliteitsinspecties door derden te laten uitvoeren om er zeker van te zijn dat de producten aan de gespecificeerde normen voldoen. Door zich te richten op leveranciers met een bewezen staat van dienst op het gebied van consistente kwaliteit, kunnen inkopers de risico's beperken die samenhangen met productprestaties en naleving.

Scenario 2: De uitdaging van gebruikerservaring en functionaliteit

Het probleem: Een ander belangrijk pijnpunt voor B2B inkopers is ervoor zorgen dat geïsoleerde bidons een uitzonderlijke gebruikerservaring bieden. Eigenschappen zoals stroomsnelheid, reinigingsgemak en ergonomisch ontwerp zijn van cruciaal belang, omdat ze een directe invloed hebben op de klanttevredenheid. Als de bidons moeilijk te gebruiken of schoon te maken zijn, kan dit leiden tot negatieve beoordelingen en verminderde merkloyaliteit. Dit is vooral relevant in concurrerende markten waar consumenten tal van alternatieven hebben.

De oplossing: Om de gebruikerservaring te verbeteren, moeten kopers de voorkeur geven aan geïsoleerde bidons met gebruikersgerichte functies. Dit omvat het selecteren van modellen met sproeikoppen met een hoog debiet zodat je gemakkelijk kunt hydrateren zonder te knijpen, en modellen die gemakkelijk uit elkaar kunnen worden gehaald voor grondige reiniging. Het uitvoeren van gebruikersonderzoeken of focusgroepen kan waardevolle inzichten opleveren in consumentenvoorkeuren en pijnpunten. Daarnaast moeten inkopers nauw samenwerken met fabrikanten om functies aan te passen die voldoen aan specifieke marktbehoeften, zodat het eindproduct goed aanslaat bij eindgebruikers en aanzet tot herhaalaankopen.

Scenario 3: Milieuoverwegingen en duurzaamheid

Het probleem: Nu het milieubewustzijn toeneemt, staan B2B-inkopers onder druk om producten te kopen die niet alleen functioneel maar ook duurzaam zijn. Veel consumenten zijn nu op zoek naar geïsoleerde fietsflessen die gemaakt zijn van milieuvriendelijke materialen en geproduceerd zijn met een minimale impact op het milieu. Als deze problemen niet worden aangepakt, kan dat leiden tot omzetverlies en een beschadigde merkreputatie, vooral bij milieubewuste consumenten in Europa en andere regio's.

De oplossing: Om de bezorgdheid over duurzaamheid aan te pakken, moeten inkopers zich richten op het inkopen van geïsoleerde bidons die gemaakt zijn van recyclebare materialen en geproduceerd zijn via milieuvriendelijke processen. Dit betekent ook dat je in zee moet gaan met fabrikanten die duurzame praktijken hanteren, zoals een lager waterverbruik en koolstofneutrale productie. Kopers kunnen ook de mogelijkheden onderzoeken om flessen aan te passen met biologisch afbreekbare of gerecyclede materialen. Daarnaast kan het promoten van de milieuvriendelijke aspecten van de producten via marketingstrategieën een breder klantenbestand aantrekken. Kopers moeten ook overwegen om terugnameprogramma's voor gebruikte flessen op te zetten, om hun inzet voor duurzaamheid te versterken en consumentenloyaliteit aan te moedigen.

Strategische materiaalselectiegids voor geïsoleerde fietsfles

Wat zijn de belangrijkste materialen voor geïsoleerde fietsflessen?

Geïsoleerde bidons zijn ontworpen om de temperatuur van dranken te behouden en tegelijkertijd duurzaamheid en gebruiksgemak te bieden aan fietsers. De materiaalkeuze heeft een grote invloed op de prestaties, de gebruikservaring en het voldoen aan internationale normen. Hieronder analyseren we vier veelgebruikte materialen die worden gebruikt bij de productie van geïsoleerde fietsflessen.

Hoe presteert roestvrij staal in geïsoleerde fietsflessen?

Belangrijkste eigenschappen: Roestvrij staal biedt een uitstekende corrosiebestendigheid, hoge sterkte en goede thermische isolatie bij gebruik in dubbelwandige vacuümontwerpen. Het is bestand tegen hoge temperaturen en drukken, waardoor het geschikt is voor zowel warme als koude dranken.

Voor- en nadelen: De duurzaamheid van roestvrij staal is een groot voordeel, omdat het beter bestand is tegen deuken en krassen dan plastic. Het is echter relatief zwaarder dan andere materialen, wat een nadeel kan zijn voor competitieve fietsers die het gewicht tot een minimum willen beperken. Het productieproces kan complexer zijn omdat er gelast en afgewerkt moet worden.

Invloed op de toepassing: Roestvrij staal is compatibel met een breed scala aan dranken, waaronder zure dranken, zonder schadelijke stoffen uit te lekken. Het voldoet ook aan verschillende internationale normen, zoals ASTM en DIN, waardoor veiligheid en kwaliteit gegarandeerd zijn.

Overwegingen voor internationale kopers: In regio's zoals Afrika en Zuid-Amerika, waar de klimaatomstandigheden kunnen variëren, is roestvrij staal vanwege zijn duurzaamheid en isolerende eigenschappen een goede keuze. Kopers moeten ervoor zorgen dat leveranciers voldoen aan de lokale regelgeving met betrekking tot voedselveiligheid en milieueffecten.

Welke rol speelt BPA-vrij plastic in geïsoleerde fietsflessen?

Belangrijkste eigenschappen: BPA-vrij plastic is licht van gewicht, flexibel en schokbestendig. Het kan in verschillende vormen worden gegoten, waardoor innovatieve ontwerpen mogelijk zijn die de gebruikerservaring verbeteren.

Voor- en nadelen: Het belangrijkste voordeel van BPA-vrij plastic is het lichte gewicht, waardoor het ideaal is voor sporters. Over het algemeen is het echter minder thermisch isolerend dan roestvrij staal en kan het de temperatuur minder goed vasthouden. Bovendien is het minder duurzaam en kan het na verloop van tijd gevoelig zijn voor krassen en slijtage.

Invloed op de toepassing: Hoewel BPA-vrij plastic geschikt is voor koude dranken, is het niet ideaal voor hete vloeistoffen, omdat het kan vervormen bij hoge temperaturen. Naleving van internationale veiligheidsnormen is cruciaal, vooral in markten waar de regelgeving met betrekking tot het gebruik van plastic streng is.

Overwegingen voor internationale kopers: In het Midden-Oosten en Europa, waar duurzaamheid steeds meer prioriteit krijgt, geven kopers mogelijk de voorkeur aan BPA-vrij plastic dat recyclebaar is en voldoet aan milieunormen. Inzicht in lokale regelgeving met betrekking tot plasticgebruik is essentieel voor naleving.

Hoe verhoudt aluminium zich tot geïsoleerde bidons?

Belangrijkste eigenschappen: Aluminium is licht van gewicht en biedt een goede thermische geleiding. Als het geanodiseerd is, is het bestand tegen corrosie en kan het effectief dranktemperaturen behouden.

Voor- en nadelen: Het lichte gewicht van aluminium maakt het een populaire keuze onder fietsers. Het is echter over het algemeen minder duurzaam dan roestvrij staal en kan gemakkelijk deuken. Het fabricageproces van aluminium kan ook duurder zijn omdat het geanodiseerd en gecoat moet worden.

Invloed op de toepassing: Aluminium is geschikt voor een reeks dranken, maar niet ideaal voor zure dranken tenzij het goed gecoat is. Naleving van de normen voor voedselveiligheid is essentieel om ervoor te zorgen dat er geen schadelijke stoffen in dranken terechtkomen.

Overwegingen voor internationale kopers: In regio's zoals Europa, waar de zorg om het milieu voorop staat, kunnen aluminium flessen die recyclebaar zijn en voldoen aan de EU-regelgeving een sterk verkoopargument zijn. Kopers moeten ook rekening houden met de beschikbaarheid van lokale leveranciers die aan hun specifieke behoeften kunnen voldoen.

Hoe zit het met glas in geïsoleerde fietsflessen?

Belangrijkste eigenschappen: Glas biedt uitstekende thermische isolatie en loogt geen chemicaliën uit in dranken. Het is inert, wat betekent dat het niet reageert met zure of alkalische dranken.

Voor- en nadelen: Het belangrijkste voordeel van glas is dat het de smaak van dranken kan behouden zonder smaken af te geven. Het is echter zwaarder en breekbaarder dan andere materialen, waardoor het minder geschikt is voor activiteiten met veel impact, zoals fietsen.

Invloed op de toepassing: Glas is ideaal voor consumenten die smaak en gezondheid belangrijker vinden dan gewicht. De breekbaarheid beperkt echter de toepassing in ruige omgevingen.

Overwegingen voor internationale kopers: In regio's waar gezondheid en welzijn centraal staan, kunnen glazen flessen aantrekkelijk zijn voor consumenten die op zoek zijn naar veilige, chemicaliënvrije opties. Kopers moeten ervoor zorgen dat glazen flessen voldoen aan de veiligheidsnormen om breuk te voorkomen.

Overzicht van materiaalselectie voor geïsoleerde fietsflessen

| Materiaal | Typische toepassing voor geïsoleerde fietsfles | Belangrijkste voordeel | Belangrijkste nadeel/beperking | Relatieve kosten (laag/gemiddeld/hoog) |

|---|---|---|---|---|

| Roestvrij staal | Krachtige fietsflessen voor warme en koude dranken | Uitstekende duurzaamheid en isolatie | Zwaarder dan andere materialen | Hoog |

| BPA-vrij plastic | Lichtgewicht fietsflessen voor informeel gebruik | Lichtgewicht en flexibel | Lagere thermische isolatie | Medium |

| Aluminium | Lichtgewicht fietsflessen voor wedstrijdrenners | Lichtgewicht en goede thermische geleidbaarheid | Minder duurzaam, vatbaar voor deuken | Medium |

| Glas | Op gezondheid gerichte bidons voor smaakbehoud | Behoudt smaak, zonder chemicaliën | Zwaar en breekbaar | Medium |

Diepgaande blik: Productieprocessen en kwaliteitsborging voor geïsoleerde bidons

Wat zijn de belangrijkste stappen in het productieproces van geïsoleerde fietsflessen?

Het productieproces van geïsoleerde bidons bestaat uit verschillende kritieke stappen die ervoor zorgen dat het eindproduct voldoet aan de prestatie- en veiligheidsnormen. Elke fase is ontworpen om de kwaliteit en functionaliteit van het product te optimaliseren.

Materiaalvoorbereiding: Welke materialen worden gebruikt?

De eerste stap in de productie van geïsoleerde bidons is de selectie en voorbereiding van het materiaal. Hoogwaardige materialen zijn essentieel voor het produceren van duurzame en effectieve geïsoleerde bidons. Gangbare materialen zijn onder andere:

- Roestvrij staal: Wordt vaak gebruikt vanwege de duurzaamheid, corrosiebestendigheid en het vermogen om de temperatuur op peil te houden.

- Silicone van levensmiddelenkwaliteit: Gebruikt in spuitmonden en afdichtingen om de veiligheid te garanderen en verontreiniging te voorkomen.

- Isolatiematerialen: Meestal wordt dubbelwandige vacuümisolatie gebruikt om vloeistoffen gedurende langere tijd warm of koud te houden.

Voordat het productieproces begint, worden de materialen geïnspecteerd op kwaliteit, zodat ze voldoen aan de industrienormen en specificaties.

Hoe worden geïsoleerde fietsflessen gemaakt?

Zodra de materialen zijn voorbereid, gaan ze over naar de vormfase. Hierbij wordt het roestvrij staal in de gewenste flesvorm gegoten. De belangrijkste technieken zijn:

- Diep tekenen: Een proces waarbij een metalen plaat in de vorm van een beker wordt gevormd en vervolgens in de vorm van een fles wordt gegoten. Deze techniek zorgt voor een uniforme dikte en sterkte.

- Lassen en verbinden: Onderdelen zoals de basis en de hals worden aan elkaar gelast met behulp van zeer nauwkeurige technieken om luchtdichte afdichtingen te garanderen.

Deze fase is van cruciaal belang, omdat eventuele onvolkomenheden kunnen leiden tot lekken of isolatiefouten.

Wat houdt het assemblageproces in?

Na het vormen is de volgende stap assemblage. Dit omvat:

- Isolatie aanbrengen: De vacuüm isolatielaag wordt in dit stadium toegevoegd en creëert de thermische barrière die essentieel is voor het behouden van de temperatuur.

- Componenten toevoegen: Er worden functies zoals mondstukken, doppen en handgrepen bevestigd. De spuitmonden maken vaak gebruik van geavanceerde ontwerpen om hoge stroomsnelheden mogelijk te maken zonder te knijpen, wat de gebruikerservaring verbetert.

Kwaliteitscontroles tijdens de assemblage zorgen ervoor dat alle onderdelen correct passen en werken zoals bedoeld.

Hoe wordt het afwerkingsproces voltooid?

De afwerkingsfase omvat oppervlaktebehandeling en laatste kwaliteitscontroles. Dit omvat:

- Coaten en schilderen: Veel fabrikanten brengen een beschermende coating of verf aan om de esthetiek en duurzaamheid te verbeteren.

- Eindinspectie: Flessen ondergaan een grondige inspectie op visuele defecten en functionele controles om er zeker van te zijn dat ze aan de specificaties voldoen.

Deze fase is cruciaal voor het leveren van een product dat niet alleen goed presteert, maar ook consumenten aanspreekt.

Welke maatregelen voor kwaliteitsborging zijn essentieel voor geïsoleerde fietsflessen?

Kwaliteitsborging (QA) is een essentieel aspect van het productieproces en zorgt ervoor dat producten voldoen aan internationale normen en aan de verwachtingen van de klant.

Welke internationale standaarden moeten B2B inkopers overwegen?

Voor geïsoleerde bidons is het essentieel dat ze voldoen aan verschillende internationale normen. Gangbare normen zijn onder andere:

- ISO 9001: Deze norm beschrijft de principes van kwaliteitsmanagement, waaronder klantgerichtheid, leiderschap en voortdurende verbetering. Fabrikanten moeten ISO 9001-gecertificeerd zijn om hun inzet voor kwaliteit aan te tonen.

- CE-markering: De CE-markering is met name relevant in Europa en geeft aan dat het product voldoet aan de Europese eisen op het gebied van veiligheid, gezondheid en milieubescherming.

- Normen voor voedselveiligheid: Naleving van voedselveiligheidsvoorschriften, zoals LFGB (Duitsland) of FDA (VS), garandeert dat materialen veilig zijn voor contact met voedingsmiddelen.

B2B-inkopers moeten controleren of hun leveranciers zich aan deze normen houden om productveiligheid en -betrouwbaarheid te garanderen.

Wat zijn de belangrijkste controlepunten voor kwaliteitscontrole?

Kwaliteitscontrole (QC) omvat verschillende controlepunten tijdens het productieproces:

- Inkomende kwaliteitscontrole (IQC): Grondstoffen worden bij aankomst geïnspecteerd om er zeker van te zijn dat ze aan de specificaties voldoen voordat de productie begint.

- Kwaliteitscontrole tijdens het proces (IPQC): Dit omvat het bewaken van productieprocessen en het uitvoeren van in-line inspecties om eventuele problemen vroegtijdig te identificeren.

- Final Quality Control (FQC): Na de productie worden de eindproducten uitgebreid getest en geïnspecteerd voordat ze worden goedgekeurd voor verzending.

Deze controlepunten helpen bij het handhaven van hoge kwaliteitsnormen en het minimaliseren van defecten.

Hoe kunnen B2B-inkopers de kwaliteitscontrole van leveranciers controleren?

B2B-inkopers moeten actief de kwaliteitscontroleprocessen van hun leveranciers controleren. Hier volgen enkele effectieve strategieën:

Welke auditpraktijken moeten worden geïmplementeerd?

Het uitvoeren van leveranciersaudits kan inzicht geven in hun productiepraktijken en maatregelen voor kwaliteitsborging. Kopers kunnen:

- Regelmatige audits plannen: Periodieke audits helpen ervoor te zorgen dat leveranciers zich aan de kwaliteitsnormen houden en hun processen voortdurend verbeteren.

- Kwaliteitsbeheersystemen beoordelen: De documentatie over kwaliteitsbeheer van de leverancier beoordelen om ervoor te zorgen dat deze voldoet aan de relevante normen.

Welke rapporten en certificaten moeten worden aangevraagd?

Kopers moeten verschillende rapporten en certificeringen opvragen om te controleren of de leverancier zich inzet voor kwaliteit:

- Testrapporten: Deze rapporten bevatten de resultaten van producttests die zijn uitgevoerd om te garanderen dat ze voldoen aan de veiligheids- en prestatienormen.

- Certificaten van overeenstemming: Leveranciers moeten certificaten overleggen waaruit blijkt dat ze voldoen aan relevante internationale en industriespecifieke normen.

Hoe kunnen inspecties door derden de kwaliteitsborging verbeteren?

Het inschakelen van inspectiediensten van derden kan de kwaliteitsgarantie verder verbeteren. Deze onafhankelijke organisaties kunnen:

- Onpartijdige inspecties uitvoeren: Inspecteurs van derden bieden een onpartijdige beoordeling van productkwaliteit en naleving.

- Productieprocessen controleren: Ze kunnen evalueren of de leverancier zich houdt aan de overeengekomen kwaliteitsnormen en -praktijken.

Wat zijn de unieke QC-overwegingen voor internationale kopers?

B2B-kopers uit verschillende regio's, waaronder Afrika, Zuid-Amerika, het Midden-Oosten en Europa, kunnen te maken krijgen met unieke uitdagingen op het gebied van kwaliteitscontrole:

- Variatie in regionale normen: Verschillende regio's kunnen specifieke voorschriften en normen hebben voor geïsoleerde producten. Kopers moeten ervoor zorgen dat hun leveranciers voldoen aan de plaatselijke voorschriften.

- Logistiek en verzending: De kwaliteit kan worden beïnvloed tijdens het transport. Kopers moeten maatregelen nemen om de producten tijdens het transport te beschermen, waaronder richtlijnen voor de juiste verpakking en behandeling.

Door deze nuances te begrijpen en grondige due diligence uit te voeren, kunnen B2B inkopers effectief risico's beperken en hoogwaardige geïsoleerde bidons garanderen die voldoen aan hun marktbehoeften.

Praktische inkoopgids: Een stap-voor-stap checklist voor 'geïsoleerde bidon'.

Inleiding

Deze inkoopgids biedt een gestructureerde aanpak voor B2B inkopers die geïsoleerde bidons willen inkopen. Met de toenemende vraag naar hoogwaardige, duurzame en prestatiegerichte fietsaccessoires helpt deze checklist je om weloverwogen beslissingen te nemen die in lijn zijn met je bedrijfsdoelen.

Stap 1: Uw technische specificaties definiëren

Het vaststellen van duidelijke technische specificaties is van fundamenteel belang om geïsoleerde bidons te vinden die aan je behoeften voldoen. Denk aan factoren zoals inhoud (bijv. 17 oz, 21 oz), isolatietechnologie (dubbelwandig vacuüm) en materiaal (bijv. roestvrij staal). Deze stap zorgt ervoor dat je producten kiest die voldoen aan de voorkeuren en prestatie-eisen van je doelmarkt.

Stap 2: Onderzoek markttrends en consumentenvoorkeuren

Inzicht in markttrends is cruciaal voor het nemen van strategische aankoopbeslissingen. Analyseer de feedback en voorkeuren van consumenten met betrekking tot functies zoals stroomsnelheid, reinigingsgemak en duurzaamheid. Deze kennis zal u helpen om producten te identificeren die niet alleen voldoen aan de technische specificaties, maar ook aanslaan bij uw klanten.

Stap 3: Potentiële leveranciers evalueren

Voordat je je aan een leverancier verbindt, is het essentieel om grondige evaluaties uit te voeren. Zoek naar bedrijfsprofielen, getuigenissen van klanten en casestudy's van bedrijven in vergelijkbare markten. Besteed aandacht aan hun productiemogelijkheden, kwaliteitsborgingsprocessen en levertijden om er zeker van te zijn dat ze op betrouwbare wijze aan je eisen kunnen voldoen.

- Vraag monsters aan: Vraag altijd om productmonsters om de kwaliteit uit eerste hand te kunnen beoordelen.

- Controleer certificeringen: Zorg ervoor dat leveranciers relevante certificeringen hebben (bijv. BPA-vrij, ISO-normen) waaruit hun inzet voor kwaliteit en veiligheid blijkt.

Stap 4: Productnaleving en veiligheidsnormen controleren

Over naleving van internationale veiligheids- en gezondheidsnormen valt niet te onderhandelen. Controleer of de geïsoleerde bidons voldoen aan de relevante regelgeving in je doelmarkten, zoals LFGB-conformiteit voor materialen die geschikt zijn voor levensmiddelen. Deze stap helpt risico's in verband met productveiligheid te beperken en vergroot de geloofwaardigheid van je merk.

Stap 5: Aanpassingsopties beoordelen

Maatwerk kan je bedrijf onderscheiden in een concurrerende markt. Informeer of leveranciers opties bieden voor branding, kleurvariaties of extra functies zoals speciale deksels of doppen. Maatwerk vergroot niet alleen de aantrekkingskracht van je product, maar stemt het ook af op je merkidentiteit.

Stap 6: Prijs en betalingsvoorwaarden evalueren

Prijsstructuren en betalingsvoorwaarden kunnen je inkoopstrategie aanzienlijk beïnvloeden. Vergelijk prijzen van verschillende leveranciers en houd daarbij rekening met de totale eigendomskosten, inclusief verzendkosten en mogelijke tarieven. Onderhandel over gunstige betalingsvoorwaarden die een flexibele cashflow mogelijk maken en financiële risico's minimaliseren.

Stap 7: Een communicatie- en ondersteuningsplan opstellen

Effectieve communicatie is de sleutel tot een succesvolle leveranciersrelatie. Zorg voor duidelijke communicatielijnen voor het volgen van bestellingen, productupdates en het oplossen van problemen. Een proactief ondersteuningsplan kan helpen om uitdagingen snel aan te pakken, zodat het inkoopproces soepel verloopt en er een langdurig partnerschap ontstaat.

Door deze uitgebreide checklist te volgen, kunnen B2B inkopers ervoor zorgen dat ze geïsoleerde bidons aanschaffen die niet alleen voldoen aan de vraag van de markt, maar ook in lijn zijn met hun bedrijfsstrategieën en -waarden.

Uitgebreide kosten- en prijsanalyse voor geïsoleerde fietsflessen Sourcing

Wat zijn de belangrijkste kostencomponenten bij het inkopen van geïsoleerde fietsflessen?

Bij het evalueren van de kostenstructuur voor het inkopen van geïsoleerde bidons spelen verschillende componenten een rol. De primaire kostenelementen zijn materialen, arbeid, productieoverhead, gereedschap, kwaliteitscontrole (QC), logistiek en winstmarges.

-

Materialen: De materiaalkeuze heeft een grote invloed op de kosten. Hoogwaardig roestvrij staal, voedingssiliconen en BPA-vrije kunststoffen leiden meestal tot hogere initiële kosten, maar vergroten de duurzaamheid en veiligheid van het product. Producten zoals de Bivo Trio maken gebruik van dubbelwandige vacuüm isolatietechnologie, wat de materiaalkosten ook kan doen stijgen.

-

Arbeid: De arbeidskosten variëren sterk afhankelijk van het land van productie. In regio's met lagere arbeidskosten, zoals delen van Zuidoost-Azië, kunnen de totale productiekosten omlaag. Internationale kopers moeten deze besparingen echter afwegen tegen mogelijke kwaliteitsvariaties.

-

Productie Overhead: Dit omvat de indirecte kosten die verband houden met productie, zoals nutsvoorzieningen, huur en afschrijving van apparatuur. Efficiënte fabrikanten hebben vaak lagere overheadkosten, waardoor ze concurrerender zijn in hun prijzen.

-

Gereedschap: De initiële gereedschapskosten voor aangepaste mallen of ontwerpen kunnen aanzienlijk zijn, maar worden meestal afgeschreven over een grotere productie. Voor flessen op maat moet u rekening houden met deze kosten als onderdeel van de algemene prijsstrategie.

-

Kwaliteitscontrole: Het garanderen van productkwaliteit door middel van strenge QC-processen kan de kosten verhogen, maar is essentieel voor het behoud van de merkreputatie en klanttevredenheid. Certificeringen zoals LFGB-conformiteit kunnen ook van invloed zijn op de prijs.

-

Logistiek: Transportkosten, waaronder verzendkosten, tarieven en douanerechten, spelen een cruciale rol, vooral voor internationale kopers. Verschillende Incoterms (International Commercial Terms) kunnen van invloed zijn op wie deze kosten draagt.

-

Marge: Leveranciers voegen meestal een marge toe op basis van hun operationele kosten en marktpositionering. Deze marge kan sterk variëren tussen fabrikanten en moet een belangrijke overweging zijn bij de onderhandelingen.

Hoe beïnvloeden prijsbeïnvloeders de kosten van geïsoleerde fietsflessen?

Verschillende factoren kunnen de prijs van geïsoleerde bidons in de B2B-markt beïnvloeden:

-

Volume/MOQ: Minimum bestelhoeveelheden (MOQ) kunnen de prijs per eenheid aanzienlijk beïnvloeden. Grotere orders leveren doorgaans lagere kosten per eenheid op, waardoor het voor inkopers van cruciaal belang is om hun voorraadbehoeften zorgvuldig te beoordelen.

-

Specificaties en aanpassingen: Aangepaste ontwerpen, kleuren of branding kunnen de kosten verhogen. Kopers moeten de noodzaak van deze aangepaste functies afwegen tegen hun budget en de marktvraag.

-

Materialen en kwaliteit: Hoogwaardiger materialen hebben vaak een hoger prijskaartje. Kopers moeten het verlangen naar kwaliteit afwegen tegen budgetbeperkingen, vooral in prijsgevoelige markten.

-

Factoren van leveranciers: De reputatie en betrouwbaarheid van leveranciers kan de prijs beïnvloeden. Gevestigde leveranciers met een bewezen staat van dienst kunnen meer in rekening brengen, maar bieden betere garanties voor kwaliteit en levering.

-

Incoterms: Inzicht in de implicaties van verschillende Incoterms is essentieel voor kostenbeheer. Zo kan de keuze voor een DDP-regeling (Delivered Duty Paid) de logistiek vereenvoudigen, maar ook kostenverhogend werken.

Wat zijn essentiële kooptips voor het kostenefficiënt inkopen van geïsoleerde fietsflessen?

Internationale B2B inkopers, met name uit regio's als Afrika, Zuid-Amerika, het Midden-Oosten en Europa, moeten de volgende strategieën overwegen voor kosteneffectieve inkoop:

-

Onderhandelen over voorwaarden: Ga in gesprek met leveranciers over prijzen, betalingsvoorwaarden en MOQ's. Het opbouwen van een goede relatie kan vaak leiden tot betere deals. Het opbouwen van een goede relatie kan vaak leiden tot betere deals.

-

Focus op totale eigendomskosten (TCO): Houd rekening met alle kosten van het product, inclusief verzendkosten, tarieven en mogelijke kwaliteitsproblemen. Een lagere initiële prijs betekent niet altijd een betere deal als de totale kosten hoger zijn.

-

Onderzoek lokale regelgeving: Begrijp de invoerregels en mogelijke tarieven in je land. Deze kennis kan onverwachte kosten en vertragingen helpen voorkomen.

-

Evalueer de betrouwbaarheid van leveranciers: Voer grondig due diligence-onderzoek uit naar potentiële leveranciers. Kijk naar beoordelingen, certificeringen en eerdere prestaties om er zeker van te zijn dat u een betrouwbare partner kiest.

-

Blijf op de hoogte van markttrends: Blijf op de hoogte van de marktdynamiek, materiaalkosten en opkomende technologieën. Inzicht in deze factoren kan een hefboom zijn bij onderhandelingen en helpen bij het nemen van weloverwogen aankoopbeslissingen.

Samengevat houdt het inkopen van geïsoleerde fietsflessen in dat je moet navigeren door een complexe kostenstructuur die wordt beïnvloed door verschillende factoren. Door deze componenten te begrijpen en strategische inkoopmethoden toe te passen, kunnen inkopers hun inkoopprocessen verbeteren en betere prijsresultaten behalen.

Alternatieven Analyse: Geïsoleerde bidons vergelijken met andere oplossingen

Alternatieven voor geïsoleerde bidons onderzoeken voor hydratatieoplossingen

Als je nadenkt over hydratatieoplossingen voor fietsers, zijn geïsoleerde bidons een populaire keuze omdat ze de drank gedurende langere perioden op temperatuur kunnen houden. Er zijn echter verschillende bruikbare alternatieven die aan verschillende behoeften of voorkeuren kunnen voldoen. In deze analyse worden geïsoleerde bidons vergeleken met twee andere hydratatieoplossingen: traditionele plastic bidons en hydratatiepakketten.

Vergelijkende tabel

| Vergelijkingsaspect | Geïsoleerde fietsfles | Traditionele Plastic Fietsfles | Hydratatie-pack |

|---|---|---|---|

| Prestaties | Uitstekende thermische retentie; houdt drankjes meer dan 12 uur koud | Beperkte isolatie; drinktemperatuur kan snel variëren | Biedt continue toegang tot hydratatie; geen isolatie |

| Kosten | $30 – $50 | $5 – $15 | $20 – $100 |

| Gemak van implementatie | Gemakkelijk te gebruiken en opnieuw te vullen; past in standaard fietskooien | Zeer gebruiksvriendelijk; overal verkrijgbaar | Moet worden aangepast om te passen; moet worden schoongemaakt |

| Onderhoud | Moet regelmatig worden schoongemaakt; heeft mogelijk speciale zorg nodig voor isolatie | Eenvoudig te reinigen; vaak vaatwasmachinebestendig | Grondig reinigen vereist; kan geuren ontwikkelen |

| Beste gebruikscasus | Lange ritten in een warm klimaat; ideaal voor prestatiegerichte fietsers | Korte ritten; informeel gebruik; budgetvriendelijk | Duuractiviteiten waarbij handsfree hydratatie nuttig is |

Gedetailleerd overzicht van alternatieven

Traditionele Plastic Fietsflessen

Traditionele plastic fietsflessen zijn licht, betaalbaar en overal verkrijgbaar. Ze bieden een eenvoudige oplossing voor hydratatie tijdens ritten, waardoor ze ideaal zijn voor gelegenheidsfietsers of korte tochten. Ze zijn echter niet geïsoleerd, waardoor drankjes snel warm kunnen worden in warme omstandigheden. Ze zijn gemakkelijk schoon te maken en te onderhouden en kunnen vaak in de vaatwasser, wat bijdraagt aan hun gemak. Hoewel ze goed voldoen aan de basisbehoeften, zijn ze misschien niet geschikt voor prestatiegerichte fietsers die de temperatuur van hun drankjes willen regelen.

Hydratatie Pakken

Hydratatiepakketten zijn veelzijdige oplossingen waarmee fietsers water direct op hun rug kunnen dragen. Ze bieden hydratatie zonder handen, waardoor ze vooral nuttig zijn voor langeafstandsritten of mountainbiken. Veel modellen hebben een geïsoleerde blaas, hoewel de prestaties kunnen variëren. Hydration packs worden meestal geleverd met extra opbergruimte voor uitrusting, wat een pluspunt is voor avontuurlijke fietsers. Ze kunnen echter duurder zijn en vereisen regelmatig onderhoud om geurtjes te voorkomen en schoon te blijven. Bovendien vinden sommige fietsers ze onhandig, vooral bij warm weer.

Conclusie: De juiste oplossing kiezen voor uw behoeften

Voor B2B inkopers die hydratatieoplossingen voor fietsers evalueren, hangt de keuze tussen geïsoleerde bidons, traditionele plastic bidons en hydratatiepakketten grotendeels af van de specifieke behoeften van hun doelmarkt. Geïsoleerde bidons zijn het meest geschikt voor serieuze fietsers die prestaties en temperatuurregeling belangrijk vinden. Traditionele plastic bidons zijn daarentegen ideaal voor prijsbewuste consumenten die op zoek zijn naar eenvoud. Hydration packs zijn bedoeld voor mensen die handsfree hydratatie en extra opslagruimte nodig hebben tijdens langere ritten. Door deze alternatieven en hun respectieve voordelen te begrijpen, kunnen kopers weloverwogen beslissingen nemen die aansluiten bij de voorkeuren en rijomstandigheden van hun klanten.

Essentiële technische eigenschappen en handelsterminologie voor geïsoleerde fietsflessen

Wat zijn de belangrijkste technische eigenschappen van geïsoleerde bidons?

Als je geïsoleerde bidons overweegt voor B2B-inkoop, is inzicht in de technische eigenschappen cruciaal om weloverwogen beslissingen te kunnen nemen. Hier zijn enkele essentiële specificaties om in overweging te nemen:

1. Materiaalklasse

Geïsoleerde bidons zijn meestal gemaakt van hoogwaardig roestvrij staal, vaak geclassificeerd als 304 of 316 roestvrij staal. Deze kwaliteiten bieden een uitstekende corrosiebestendigheid en duurzaamheid, waardoor ze geschikt zijn voor verschillende omgevingen. Voor B2B-kopers zorgt de keuze van het juiste materiaal voor een lange levensduur en goede prestaties, zodat ze minder vaak vervangen hoeven te worden.

2. Isolatietechnologie

De meeste geïsoleerde flessen maken gebruik van dubbelwandige vacuüm isolatietechnologie. Dit ontwerp vermindert de warmteoverdracht aanzienlijk, waardoor dranken meer dan 12 uur koud kunnen blijven. Inzicht in isolatietechnologie is van vitaal belang voor kopers in regio's met extreme temperaturen, omdat het een directe invloed heeft op productprestaties en klanttevredenheid.

3. Capaciteit en afmetingen

Veelgebruikte capaciteiten voor geïsoleerde fietsflessen variëren van 500 ml tot 750 ml. De afmetingen, inclusief hoogte en diameter, zijn van invloed op de compatibiliteit met verschillende bidonhouders. Kopers moeten deze specificaties evalueren om er zeker van te zijn dat de producten voldoen aan de behoeften van de beoogde markt, vooral in regio's waar fietsontwerpen kunnen verschillen.

4. Doorstromingsmechanisme

De stroomsnelheid verwijst naar hoe snel vloeistof uit de fles komt. Geavanceerde ontwerpen hebben sportdopjes met een hoge stroomsnelheid die een snelle hydratatie mogelijk maken zonder te knijpen. Deze eigenschap is essentieel voor fietsers die efficiënt moeten hydrateren tijdens ritten. Inzicht in de mechanismen van de stroomsnelheid kan kopers helpen bij het beoordelen van de bruikbaarheid van het product en het aanspreken van prestatiegerichte klanten.

5. Naleving en veiligheidsnormen

Geïsoleerde bidons moeten voldoen aan verschillende veiligheidsnormen, waaronder LFGB (Duitse voedselveiligheid) en BPA-vrije certificeringen. Deze voorschriften zorgen ervoor dat de gebruikte materialen geen schadelijke stoffen aan dranken afgeven. Voor B2B inkopers is naleving cruciaal voor verkoopbaarheid en consumentenvertrouwen, vooral in gezondheidsbewuste regio's.

6. Recyclebaarheid en milieueffecten

Duurzaamheid wordt steeds belangrijker bij het ontwerpen van producten. Flessen gemaakt van 100% recyclebare materialen verminderen de impact op het milieu en spreken milieubewuste consumenten aan. Kopers moeten rekening houden met de recyclebaarheid van producten om aan te sluiten bij markttrends ten gunste van duurzame praktijken.

Wat zijn veelgebruikte vaktermen en jargon in de sector voor geïsoleerde fietsflessen?

Vertrouwd zijn met de terminologie van de sector helpt om de communicatie en onderhandelingen te stroomlijnen. Hier zijn de belangrijkste termen die relevant zijn voor B2B-kopers:

1. OEM (Original Equipment Manufacturer)

OEM verwijst naar bedrijven die producten maken die vervolgens door een ander bedrijf onder hun merk op de markt worden gebracht. Inzicht in OEM-relaties is essentieel voor inkopers die huismerkproducten willen kopen of met fabrikanten willen samenwerken voor aangepaste ontwerpen.

2. MOQ (minimale bestelhoeveelheid)

MOQ is de kleinste hoeveelheid die een leverancier bereid is te verkopen. Deze term is van cruciaal belang voor B2B inkopers omdat hij van invloed is op voorraadbeheer en cashflow. Inzicht in MOQ's helpt inkopers hun aankopen te plannen op basis van de marktvraag.

3. RFQ (Offerteaanvraag)

Een RFQ is een document dat naar leveranciers wordt gestuurd met een verzoek om prijsoffertes voor specifieke producten of diensten. Inkopers moeten RFQ's gebruiken om concurrerende prijzen te verzamelen en ervoor te zorgen dat ze kosteneffectieve beslissingen nemen.

4. Incoterms (internationale handelsvoorwaarden)

Incoterms definiëren de verantwoordelijkheden van kopers en verkopers bij internationale transacties, zoals verzending, verzekering en tarieven. Bekendheid met Incoterms helpt kopers bij het navigeren door de logistiek en het begrijpen van hun aansprakelijkheid tijdens verzending.

5. Doorlooptijd

Doorlooptijd verwijst naar de tijd die verstrijkt tussen het plaatsen van een bestelling en de ontvangst van de goederen. Inzicht in doorlooptijden is cruciaal voor effectief voorraadbeheer en om ervoor te zorgen dat producten beschikbaar zijn wanneer ze nodig zijn.

6. Certificeringen

Certificeringen, zoals ISO (International Organization for Standardization), geven aan dat een fabrikant voldoet aan specifieke normen voor kwaliteitsbeheer. Kopers moeten op zoek gaan naar gecertificeerde fabrikanten om een consistente productkwaliteit en betrouwbaarheid te garanderen.

Door deze technische eigenschappen en handelsterminologieën te begrijpen, kunnen B2B-kopers weloverwogen aankoopbeslissingen nemen en succesvolle relaties met leveranciers op de markt van geïsoleerde fietsflessen onderhouden.

Navigeren door marktdynamiek en inkooptrends in de sector van geïsoleerde bidons

Wat zijn de belangrijkste drijfveren en trends die de markt voor geïsoleerde bidons vormgeven?

De markt voor geïsoleerde fietsflessen groeit aanzienlijk als gevolg van de toenemende wereldwijde aandacht voor duurzaamheid, gezondheid en buitenactiviteiten. Nu steeds meer consumenten de voorkeur geven aan milieuvriendelijke producten, passen fabrikanten hun aanbod aan om aan deze eisen te voldoen. Met name de opkomst van fietsen als een populaire recreatieve en woon-werkactiviteit heeft geleid tot innovaties in het ontwerp van bidons, waarbij de nadruk ligt op prestaties en gebruikerservaring. Belangrijke trends zijn de toepassing van lichtgewicht materialen, geavanceerde isolatietechnologieën en ergonomische ontwerpen die de gebruiksvriendelijkheid verbeteren. Merken als Bivo en Tiibo maken bijvoorbeeld gebruik van lucht- en ruimtevaarttechnische inzichten om sproeikoppen met een hoog debiet te ontwikkelen, zodat fietsers kunnen drinken zonder in hun bidon te hoeven knijpen.

Internationale B2B inkopers, vooral in regio's als Afrika, Zuid-Amerika, het Midden-Oosten en Europa, moeten ook rekening houden met de dynamiek van de lokale markt. In opkomende markten neemt bijvoorbeeld de vraag naar betaalbare maar hoogwaardige geïsoleerde flessen toe, waardoor leveranciers op zoek gaan naar kosteneffectieve productie zonder afbreuk te doen aan duurzaamheid. Bovendien veranderen technologische ontwikkelingen, zoals online marktplaatsen en tools voor supply chain management, de manier waarop bedrijven deze producten inkopen en zorgen ze voor meer transparantie en efficiëntie.

Hoe belangrijk is duurzaamheid en ethisch verantwoord inkopen in de sector van geïsoleerde fietsflessen?

Duurzaamheid is niet zomaar een trend; het wordt een cruciale factor in de aankoopbeslissingen van zowel consumenten als B2B-inkopers. De sector van geïsoleerde bidons richt zich steeds meer op het verminderen van de impact op het milieu door materialen te gebruiken die recyclebaar zijn en geen schadelijke stoffen bevatten zoals BPA en ftalaten. Bedrijven gebruiken ook ethische bevoorradingspraktijken om ervoor te zorgen dat hun toeleveringsketens transparant en verantwoordelijk zijn.

Certificeringen zoals de Global Recycle Standard (GRS) en certificeringen voor voedselveilige materialen worden steeds belangrijker voor merken om zich te onderscheiden in een drukke markt. Merken als CamelBak en HydraPak benadrukken bijvoorbeeld hun inzet voor het gebruik van milieuvriendelijke materialen, wat goed aanslaat bij milieubewuste consumenten. B2B-inkopers moeten de voorkeur geven aan leveranciers die zich inzetten voor duurzaamheid, omdat dit niet alleen de merkreputatie verbetert, maar ook aansluit bij een groeiende groep consumenten die waarde hecht aan verantwoord ondernemen.

Wat is de evolutie van geïsoleerde fietsflessen en de relevantie voor B2B kopers?

De geïsoleerde fietsfles is sinds zijn ontstaan sterk geëvolueerd, van eenvoudige plastic houders naar geavanceerde, hoogwaardige flessen. Deze bidons zijn in eerste instantie ontworpen voor hydratatie, maar bevatten nu geavanceerde isolatietechnologieën die dranken langdurig koud of warm kunnen houden. Deze evolutie weerspiegelt bredere trends in consumentenvoorkeuren voor kwaliteit en prestaties.

Historisch gezien betekende de introductie van roestvrij staal en vacuümisolatie in het begin van de jaren 2000 een keerpunt, waardoor de temperatuur beter kon worden vastgehouden en de flessen duurzamer werden. De huidige geïsoleerde flessen zijn niet alleen ontworpen met het oog op functionaliteit, maar ook met het oog op esthetiek, met verschillende kleuren en afwerkingen die inspelen op uiteenlopende consumentenvoorkeuren. Voor B2B-inkopers is het van cruciaal belang om deze evolutie te begrijpen; het informeert over inkoopstrategieën die zijn afgestemd op de eisen van de markt en de verwachtingen van de consument, waardoor uiteindelijk het productaanbod in hun respectieve markten wordt verbeterd.

Door op de hoogte te blijven van deze dynamiek, kunnen internationale B2B-inkopers weloverwogen beslissingen nemen die de bedrijfsgroei stimuleren en tegelijkertijd voldoen aan de veranderende behoeften van hun klanten.

Veelgestelde vragen (FAQ's) voor B2B-kopers van geïsoleerde fietsflessen

-

Hoe kies ik de juiste geïsoleerde bidon voor mijn bedrijf?

Om de juiste geïsoleerde bidon te kiezen, moet je kijken naar de voorkeuren van je doelmarkt, het klimaat in je verkoopregio's en de specifieke kenmerken die je klanten aanspreken. Ga op zoek naar bidons met duurzame materialen, effectieve isolatie (om dranken gedurende langere tijd koud of warm te houden) en gebruiksvriendelijke ontwerpen zoals sproeikoppen met een hoog debiet. Denk ook aan de mogelijkheden voor branding; aanpasbare opties kunnen de zichtbaarheid van het merk vergroten. Evalueer tot slot het prijspunt ten opzichte van je budget en de gewenste winstmarges. -

Wat zijn de belangrijkste kenmerken van geïsoleerde bidons?

Als je geïsoleerde fietsflessen zoekt, geef dan de voorkeur aan eigenschappen zoals dubbelwandige vacuümisolatie, die ervoor zorgt dat de temperatuur maximaal wordt vastgehouden, en materialen zoals BPA-vrij roestvrij staal voor veiligheid en duurzaamheid. Een hoog debiet mondstuk is cruciaal voor drinkgemak en een lichtgewicht ontwerp verbetert de draagbaarheid. Houd ook rekening met de esthetische aantrekkingskracht, inclusief kleuropties en brandingmogelijkheden, omdat dit de keuze van de consument aanzienlijk kan beïnvloeden. -

Wat zijn de minimale bestelhoeveelheden (MOQ's) voor geïsoleerde bidons?

Minimale bestelhoeveelheden voor geïsoleerde bidons kunnen per leverancier en productspecificatie sterk verschillen. Over het algemeen variëren MOQ's van 500 tot 2000 stuks, afhankelijk van de capaciteit van de fabrikant en de mate van maatwerk die vereist is. Het is essentieel om je behoeften te bespreken met potentiële leveranciers om gunstige voorwaarden te bedingen, vooral als je een kleiner bedrijf bent of een nieuwe markt aan het testen bent. -

Hoe kan ik de kwaliteit van geïsoleerde bidons van leveranciers garanderen?

Om de kwaliteit van het product te garanderen, is het raadzaam om de leveranciers grondig door te lichten. Vraag monsters aan voordat je grote bestellingen plaatst om de materialen, isolatieprestaties en het algemene ontwerp te beoordelen. Controleer of ze voldoen aan internationale veiligheids- en kwaliteitsnormen, zoals LFGB- of FDA-certificeringen. Het opstellen van een duidelijk kwaliteitsgarantieproces, inclusief regelmatige audits en inspecties, kan helpen om de normen tijdens het hele productieproces te handhaven. -

Welke betalingsvoorwaarden moet ik verwachten als ik geïsoleerde fietsflessen internationaal inkoop?

De betalingsvoorwaarden in de internationale handel kunnen sterk variëren. Gebruikelijke regelingen zijn een aanbetaling vooraf (meestal 30%) en het saldo te betalen vóór verzending of bij levering. Sommige leveranciers bieden kredietbrieven of escrow-diensten aan voor extra zekerheid. Het is cruciaal om de betalingsvoorwaarden vooraf te bespreken en overeen te komen om misverstanden te voorkomen en een soepel transactieproces te garanderen. -

Hoe beïnvloeden logistiek en verzending de inkoop van geïsoleerde bidons?

Logistiek speelt een cruciale rol in het sourcingproces en heeft invloed op de levertijd en de kosten. Overweeg de beschikbare verzendmethoden (lucht, zee of land) op basis van urgentie en budget. Werk samen met leveranciers om inzicht te krijgen in hun verzendmogelijkheden en kies een betrouwbare expediteur die bekend is met de douaneregels in je doelmarkt. Neem mogelijke tarieven en heffingen mee in je totale kostenanalyse. -

Welke aanpassingsmogelijkheden zijn er voor geïsoleerde bidons?

Veel fabrikanten bieden aanpassingsopties zoals kleurselectie, logodruk en unieke ontwerpen op maat van je merk. Daarnaast kun je verschillende dopstijlen, maten en zelfs isolatietechnologie onderzoeken. Bespreek je specifieke behoeften met leveranciers om inzicht te krijgen in de mate van maatwerk die beschikbaar is en de eventuele kosten die hieraan verbonden zijn, aangezien deze de aantrekkingskracht van je product op de markt aanzienlijk kunnen vergroten. -

Wat zijn de beste manieren om geïsoleerde bidons op de internationale markt te brengen?

Effectieve marketing van geïsoleerde bidons vereist inzicht in het gedrag en de voorkeuren van de lokale consument. Gebruik digitale marketingstrategieën, waaronder campagnes op sociale media en partnerschappen met influencers, om je doelgroep te bereiken. Neem deel aan internationale beurzen en fietsevenementen om uw producten onder de aandacht te brengen. Samenwerken met lokale distributeurs kan ook de marktpenetratie en merkbekendheid verbeteren, zodat uw producten aanslaan bij regionale consumenten.

Belangrijke disclaimer en gebruiksvoorwaarden

⚠️ Belangrijke disclaimer

De informatie in deze gids, inclusief inhoud over fabrikanten, technische specificaties en marktanalyses, is uitsluitend bedoeld voor informatieve en educatieve doeleinden. Het is geen professioneel aankoopadvies, financieel advies of juridisch advies.

Hoewel we al het mogelijke hebben gedaan om de nauwkeurigheid en actualiteit van de informatie te garanderen, zijn we niet verantwoordelijk voor eventuele fouten, weglatingen of verouderde informatie. Marktomstandigheden, bedrijfsgegevens en technische normen kunnen veranderen.

B2B-kopers moeten hun eigen onafhankelijke en grondige due diligence uitvoeren voordat je een aankoopbeslissing neemt. Dit houdt in dat u rechtstreeks contact moet opnemen met leveranciers, certificeringen moet controleren, monsters moet aanvragen en professioneel advies moet inwinnen. Het risico van het vertrouwen op informatie in deze gids wordt uitsluitend gedragen door de lezer.

Top 7 geïsoleerde fietsfles fabrikanten en leveranciers lijst

1. Bivo - Geïsoleerde Roestvrijstalen Fietsfles

Domein: drankbivo.nl

Geregistreerd: 2019 (6 jaar)

Inleiding: Bivo Geïsoleerde Fietsfles - Roestvrij Staal - 21 oz

- Prijs: $49

- Kleuren: Zwart, Raw, True Blue, Strawberry, Sun, Tomato, Turquoise

- Inhoud: 621 ml (21 oz)

- Droog gewicht: 270 g

- Afmetingen: 10,23″ hoogte (260 mm), maximale diameter 3″ (77 mm)

- Kenmerken:

- Eerste geïsoleerde roestvrijstalen bidon met een mondstuk met hoge stroomsnelheid, ontworpen door een ex-NASA ingenieur

- Siliconen antislip buitenkant ...

2. CamelBak - Podium® 15oz fietsfles

Domein: camelbak.nl

Geregistreerd: 1996 (29 jaar)

Inleiding: {"producten":[{"naam":"Podium® 15oz Bike Bottle","prijs":"$12,00″},{"naam":"Podium® Dirt Series 15oz Bike Bottle","prijs":"$15,00″},{"naam":"Podium® Dirt Series Chill™ 21oz Bike Bottle","prijs":"$19,00 - $21.00″},{"naam":"Podium® Titanium 18oz Bike Bottle","prijs":"$100.00″},{"naam":"Podium® Steel 22oz Bike Bottle","prijs":"$44.00″},{"naam":"Podium® Chill™ 21oz Bike Bottle","prijs":"$16.00 - $20.00...

3. Camelbak - Podium Geïsoleerde Fietsfles

Domein: reddit.nl

Geregistreerd: 2005 (20 jaar)

Inleiding: Camelbak Podium geïsoleerde fietsfles: Quick flow-mondstuk, vaatwasmachinebestendig, gemakkelijk schoon te maken, duurzaam, verkrijgbaar in vele kleuren en maten. Het Podium model is gewoon, terwijl de Podium Insulated een betere isolatie biedt. Het Podium Chill-model is nog beter geïsoleerd, maar is groter voor dezelfde inhoud.

4. Fietsen - Beste geïsoleerde waterflessen

Domein: fietsen.nl

Geregistreerd: 1999 (26 jaar)

Inleiding: Beste Roestvrij Geïsoleerd: CamelBak Podium Steel (ongekoeld, 3 uur)\Beste Plastic Geïsoleerd: Specialized Purist Insulated (voorgekoeld, 90 min)\Best Riding Stainless Insulated: Bivo Geïsoleerd Trio: Elite IceFly 500ml en RockBros Geïsoleerd. We hebben 5 metalen geïsoleerde, 7 plastic geïsoleerde en 3 niet-geïsoleerde bidons getest: Plastic en metaal.\St...

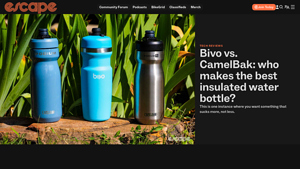

5. Escape Collective - Bivo Trio & CamelBak Podiumflessen

Domein: escapecollective.com

Geregistreerd: 2017 (8 jaar)

Inleiding: Bivo Trio: 500 mL (17 oz) en 620 mL (21 oz), verkrijgbaar in 3 kleuren (Mini) en 5 kleuren (groter). Prijs: US$39-49. CamelBak Podium geïsoleerd roestvrij staal: 530 mL (18 oz) en 650 mL (22 oz), verkrijgbaar in 6 kleuren. Prijs: US$35-40. CamelBak Podium geïsoleerd titanium: 530 mL (18 oz) maat, ruwe geborstelde afwerking. Prijs: US$100. Alle flessen zijn vacuümgeïsoleerd en ontworpen om dranken...

6. TrainerRoad - Kwaliteit SS fles

Domein: trainerweg.nl

Geregistreerd: 2010 (15 jaar)

Inleiding: Dit bedrijf, TrainerRoad - Quality SS Bottle, is een opmerkelijke entiteit op de markt. Voor specifieke productdetails kun je het beste rechtstreeks naar hun website gaan.

7. REI - geïsoleerde bidons voor op de fiets

Domein: rei.com

Geregistreerd: 1996 (29 jaar)

Inleiding: Dit bedrijf, REI - Insulated Bike Water Bottles, is een opmerkelijke entiteit op de markt. Voor specifieke productgegevens kun je het beste rechtstreeks naar hun website gaan.

Strategische Sourcing Conclusie en Vooruitzichten voor geïsoleerde fietsflessen

In het concurrerende landschap van geïsoleerde bidons voor fietsen is strategische inkoop een cruciale factor voor internationale B2B-kopers. Inzicht in het diverse aanbod - van innovatieve ontwerpen zoals die van Bivo en Tiibo tot gevestigde merken zoals CamelBak - stelt inkopers in staat producten te identificeren die zowel aan prestatie- als duurzaamheidscriteria voldoen. Belangrijke overwegingen zijn onder andere de gebruikte materialen (zoals BPA-vrije kunststoffen en recyclebaar roestvrij staal), isolatietechnologie en gebruikerservaringen zoals spuitmonden met hoge stroomsnelheid en ergonomische ontwerpen.

Investeren in geïsoleerde bidons van hoge kwaliteit verhoogt niet alleen de klanttevredenheid, maar sluit ook aan bij de groeiende wereldwijde vraag naar milieuvriendelijke producten. Naarmate de markten in Afrika, Zuid-Amerika, het Midden-Oosten en Europa zich uitbreiden, is de kans om in te spelen op deze vraag aanzienlijk.

Met het oog op de toekomst is het essentieel voor B2B inkopers om partnerschappen aan te gaan met fabrikanten die innovatie en duurzaamheid hoog in het vaandel hebben staan. Op die manier kunnen ze een concurrentievoordeel op de markt behalen. Ga in zee met leveranciers die zich inzetten voor kwaliteit en milieuvriendelijkheid en onderzoek hoe deze relaties groei en klantenbinding in uw regio kunnen stimuleren. De toekomst van fietshydratatie is rooskleurig - bent u klaar om er deel van uit te maken?