Introduction: Navigating the Global Market for 2.5 l bottle

In the rapidly evolving global market, sourcing the right 2.5 L bottle can pose significant challenges for B2B buyers. With diverse applications ranging from food and beverage packaging to chemical storage, understanding the nuances of different bottle types is crucial. This guide provides a comprehensive overview, covering various materials such as aluminum, glass, and plastic, along with their respective benefits and limitations. We delve into the critical aspects of supplier vetting, ensuring buyers can identify reliable manufacturers that meet international quality standards.

Additionally, we address cost considerations, shipping logistics, and regulatory compliance, particularly for buyers in regions like Africa, South America, the Middle East, and Europe, including key markets such as Nigeria and Saudi Arabia. As international trade becomes more competitive, making informed purchasing decisions is essential. This guide empowers B2B buyers to navigate the complexities of the 2.5 L bottle market effectively, enabling them to select the best products that align with their operational needs and sustainability goals. By leveraging the insights provided, businesses can enhance their supply chain efficiency and ultimately achieve greater profitability.

Navegação de artigos

- Top 10 2.5 L Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 2.5 l bottle

- Understanding 2.5 l bottle Types and Variations

- Key Industrial Applications of 2.5 l bottle

- 3 Common User Pain Points for ‘2.5 l bottle’ & Their Solutions

- Strategic Material Selection Guide for 2.5 l bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 2.5 l bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘2.5 l bottle’

- Comprehensive Cost and Pricing Analysis for 2.5 l bottle Sourcing

- Alternatives Analysis: Comparing 2.5 l bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 2.5 l bottle

- Navigating Market Dynamics and Sourcing Trends in the 2.5 l bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 2.5 l bottle

- Aviso importante e termos de utilização

- Strategic Sourcing Conclusion and Outlook for 2.5 l bottle

Understanding 2.5 l bottle Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Aluminum Bottle | Lightweight, UN-rated for hazardous materials, leak-proof cap | Chemical shipping, food and beverage storage | Prós: Durable, corrosion-resistant. Contras: Custo mais elevado em comparação com o plástico. |

| Garrafa de vidro | PVC-coated for safety, retains contents if broken | Laboratory use, food and beverage packaging | Prós: Non-reactive, maintains purity. Contras: Heavier, potential breakage risk. |

| Plastic Bottle (PET) | Flexible, lightweight, recyclable, cost-effective | Water and beverage distribution, consumer products | Prós: Low cost, versatile. Contras: Less durable than glass or aluminum. |

| Narrow Mouth Bottle (PVC) | Designed for precise pouring, chemical-resistant | Laboratory settings, chemical storage | Prós: Safer handling of hazardous materials. Contras: Limited capacity for bulk storage. |

| Multi-use Water Bottle | Designed for repeated use, often with ergonomic features | Outdoor activities, corporate wellness programs | Prós: Encourages hydration, reusable. Contras: May require frequent cleaning and maintenance. |

What are the Characteristics and Suitability of Aluminum Bottles?

Aluminum bottles are a popular choice for businesses requiring lightweight, durable packaging solutions. They are often UN-rated, making them suitable for transporting hazardous materials securely. The leak-proof cap ensures that the contents remain uncontaminated, making them ideal for chemicals and beverages. Buyers should consider the higher initial cost but can benefit from the long-term durability and recyclability of aluminum, which aligns with sustainability goals.

Why Choose Glass Bottles for B2B Applications?

Glass bottles, particularly those with a PVC coating, are designed for safety in laboratory and food applications. The coating retains contents in case of breakage, minimizing hazards. Glass is non-reactive, ensuring the purity of sensitive liquids. While they offer excellent protection and product integrity, buyers must weigh the risk of breakage and higher shipping costs due to their weight against the benefits of using a premium packaging solution.

How Do Plastic Bottles Compare in Terms of Cost and Versatility?

Plastic bottles, especially those made from PET, are favored for their cost-effectiveness and versatility in various industries. They are lightweight and recyclable, making them ideal for mass production and distribution of beverages. However, they may lack the durability of glass or aluminum options. Buyers should consider the intended use; while plastic is suitable for everyday consumer products, it may not be ideal for high-value or sensitive contents.

What are the Benefits of Narrow Mouth Bottles in Chemical Handling?

Narrow mouth bottles made from PVC are specifically designed for safe handling of chemicals. Their design facilitates precise pouring, reducing the risk of spills. They are commonly used in laboratory settings where accuracy is paramount. However, they may not be suitable for bulk storage, so businesses should evaluate their specific needs when selecting this type of bottle.

Why Invest in Multi-use Water Bottles for Corporate Wellness?

Multi-use water bottles are increasingly popular in corporate wellness programs, encouraging employees to stay hydrated. Designed for repeated use, these bottles often feature ergonomic designs for ease of handling. While they promote sustainability and health, businesses should factor in the need for regular cleaning and maintenance to ensure hygiene. Investing in such bottles can enhance employee well-being and demonstrate a commitment to health-conscious practices.

Key Industrial Applications of 2.5 l bottle

| Indústria/Setor | Specific Application of 2.5 l bottle | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Alimentação e bebidas | Packaging for beverages (water, juices, etc.) | Ensures safe, hygienic storage and transportation | Compliance with food safety regulations, materials used |

| Chemical Manufacturing | Storage and transport of chemicals | Provides leak-proof containment, protects product quality | UN-rated for hazardous materials, durability, and safety |

| Pharmaceutical | Sample storage for liquid medications | Maintains integrity of samples, prevents contamination | Sterility, compatibility with various substances |

| Agricultura | Fertilizer and pesticide delivery | Facilitates easy application and precise dosing | Material resistance to chemicals, environmental impact |

| Personal Care Products | Packaging for lotions and creams | Enhances product shelf life and consumer appeal | BPA-free materials, user-friendly design |

How is the 2.5 L Bottle Used in the Food and Beverage Industry?

In the food and beverage sector, the 2.5 L bottle is commonly utilized for packaging water, juices, and other beverages. This size is ideal for both retail and catering applications, providing convenience for consumers and businesses alike. The primary challenge addressed by this bottle is ensuring the safe and hygienic storage of liquids, which is critical in maintaining product quality and compliance with health regulations. Buyers in this sector should prioritize bottles made from food-grade materials and those that meet local food safety standards, particularly in regions like Africa and South America where regulations may vary.

What Role Does the 2.5 L Bottle Play in Chemical Manufacturing?

Chemical manufacturers leverage the 2.5 L bottle for the storage and transport of various chemicals, including solvents and reagents. Its leak-proof design and robust construction protect the integrity of the chemicals while preventing environmental contamination. For international buyers, especially in the Middle East and Europe, it is essential to source UN-rated bottles that comply with international shipping regulations for hazardous materials. This ensures safety during transport and storage, which is a critical consideration in this industry.

How is the 2.5 L Bottle Essential for Pharmaceutical Applications?

In the pharmaceutical industry, 2.5 L bottles are often used for storing liquid medications and samples. These bottles help maintain the integrity of sensitive substances, preventing contamination and degradation over time. Buyers must ensure that the bottles are made from materials that comply with pharmaceutical standards, including sterility and chemical compatibility. This is particularly important for B2B buyers in regions with stringent health regulations, such as Europe, to ensure compliance and product safety.

How is the 2.5 L Bottle Used in Agriculture?

Agricultural businesses utilize the 2.5 L bottle for the effective delivery of fertilizers and pesticides. This size allows for easy handling and precise application, which is crucial for optimizing crop yields. The bottles must be resistant to various chemicals and environmentally friendly to minimize ecological impact. Buyers in Africa and South America should consider sourcing bottles that can withstand harsh agricultural conditions while meeting local environmental regulations.

What Benefits Does the 2.5 L Bottle Offer for Personal Care Products?

In the personal care sector, the 2.5 L bottle is frequently used for packaging lotions, creams, and other liquid products. This format not only extends shelf life but also enhances the aesthetic appeal of the product, attracting consumers. For international buyers, especially in regions with diverse consumer preferences, sourcing BPA-free and user-friendly designs is critical to meet market demands while ensuring product safety.

3 Common User Pain Points for ‘2.5 l bottle’ & Their Solutions

Scenario 1: Challenges in Sourcing Quality 2.5 L Bottles

O problema: B2B buyers often struggle to find reliable suppliers who can provide high-quality 2.5 L bottles that meet specific industry standards. In regions like Africa and South America, the options may be limited, leading to concerns about the durability and safety of the bottles. Buyers may face difficulties in verifying the quality of materials used, especially when sourcing for sensitive applications such as food or chemical storage. This can result in potential product contamination, increased costs due to returns, and damage to reputation.

A solução: To overcome sourcing challenges, buyers should conduct thorough research on suppliers, looking for those who provide transparency regarding their manufacturing processes and materials. Request certifications such as food-grade or UN-rated status, which can indicate compliance with international safety standards. Engaging with suppliers who have a strong track record in your industry can also help. Consider ordering samples before committing to large quantities, allowing you to assess the quality firsthand. Additionally, leveraging platforms that specialize in B2B trade can connect you with reliable manufacturers who can meet your specifications.

Scenario 2: Navigating Shipping and Logistics for 2.5 L Bottles

O problema: Shipping costs and logistics can be a significant pain point for B2B buyers, especially when dealing with bulk orders of 2.5 L bottles. This issue is exacerbated in regions with less developed infrastructure, where delays in transport can lead to product spoilage or increased costs. Buyers may find themselves facing unexpected fees, particularly when shipments are heavy or oversized, complicating budgeting and planning.

A solução: To mitigate shipping challenges, buyers should work closely with suppliers to understand shipping options and associated costs. Inquire about freight shipping, which can be more economical for large orders, and clarify any potential surcharges. Establishing a relationship with a logistics partner familiar with your region can streamline the process. Additionally, consider consolidating orders to maximize container space and reduce per-unit shipping costs. It may also be beneficial to explore local suppliers who can provide 2.5 L bottles, thereby minimizing shipping distances and costs.

Scenario 3: Ensuring Compliance and Safety Standards for 2.5 L Bottles

O problema: Compliance with safety standards is a critical concern for B2B buyers, particularly when dealing with bottles intended for hazardous materials or food storage. The risk of non-compliance can lead to legal liabilities, product recalls, and damage to brand reputation. Buyers may find it challenging to navigate the varying regulations across different countries, especially in regions like the Middle East and Europe where standards can differ significantly.

A solução: To ensure compliance, buyers should familiarize themselves with the regulations governing packaging in their specific industry and region. This includes understanding the requirements for food-grade materials or UN regulations for hazardous materials. When sourcing 2.5 L bottles, work with suppliers who can provide documentation proving compliance with relevant standards. Regular audits of suppliers can also help maintain quality and compliance. Additionally, keeping abreast of changes in regulations can help buyers adapt quickly, ensuring that their products remain compliant and safe for use.

Strategic Material Selection Guide for 2.5 l bottle

When selecting materials for 2.5-liter bottles, it’s essential to consider various factors such as durability, cost, and compatibility with the intended contents. Here, we analyze four common materials used in the production of 2.5-liter bottles: plastic (PET), aluminum, glass, and PVC-coated glass. Each material has unique properties that can significantly impact performance and application suitability.

What Are the Key Properties of Plastic (PET) Bottles?

Polyethylene Terephthalate (PET) is widely used for 2.5-liter bottles due to its lightweight nature and excellent barrier properties. PET bottles can withstand temperatures up to 60°C (140°F) and are resistant to impact, making them suitable for various applications, including beverages and household products. However, PET is not suitable for high-pressure applications and may degrade when exposed to UV light over extended periods.

Prós: PET bottles are cost-effective, lightweight, and recyclable, making them a popular choice for mass production. They also offer good clarity, allowing consumers to see the contents.

Contras: Although PET is durable, it can be prone to deformation under high temperatures and may not be suitable for long-term storage of sensitive products.

How Does Aluminum Compare for 2.5-Liter Bottles?

Aluminum bottles, such as UN-rated options, provide excellent durability and corrosion resistance. They can withstand high temperatures and pressures, making them ideal for storing chemicals and hazardous materials. Aluminum is also lightweight, which can reduce shipping costs.

Prós: The leak-proof design of aluminum bottles helps maintain product integrity and prevents contamination. Additionally, aluminum is fully recyclable, aligning with sustainable practices.

Contras: The initial manufacturing cost of aluminum bottles is generally higher than that of plastic options. They may also require special coatings to prevent reactions with certain chemicals.

What Are the Benefits of Using Glass for 2.5-Liter Bottles?

Glass bottles are known for their superior chemical resistance and ability to maintain product purity. They can withstand high temperatures and are ideal for storing beverages, pharmaceuticals, and chemicals. However, glass is heavy and more prone to breakage, which can be a concern during transport.

Prós: Glass bottles do not leach chemicals into their contents, making them suitable for sensitive products. They also have a long shelf life and can be reused multiple times.

Contras: The fragility of glass makes it less suitable for applications where durability is critical. Additionally, the higher cost and weight can lead to increased shipping expenses.

What Advantages Do PVC-Coated Glass Bottles Offer?

PVC-coated glass bottles combine the benefits of glass with added safety features. The PVC coating helps contain any breakage, making them safer for handling and transport. They are suitable for various applications, including laboratory use and chemical storage.

Prós: The PVC coating enhances the durability of glass bottles while maintaining chemical resistance. They offer a good balance between safety and product integrity.

Contras: The manufacturing process for PVC-coated bottles can be more complex and costly. Additionally, the coating may limit the recyclability of the glass.

Summary Table of Material Selection for 2.5-Liter Bottles

| Material | Typical Use Case for 2.5 l bottle | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Plastic (PET) | Beverages, household products | Leve e económico | Prone to deformation under heat | Baixa |

| Alumínio | Chemicals, hazardous materials | Excellent durability and leak-proof design | Higher initial manufacturing cost | Med |

| Vidro | Beverages, pharmaceuticals | Superior chemical resistance | Pesado e com tendência para se partir | Elevado |

| PVC-Coated Glass | Laboratory use, chemical storage | Enhanced safety and durability | More complex manufacturing process | Med |

In conclusion, selecting the right material for 2.5-liter bottles depends on the specific application, cost considerations, and compliance with international standards. Buyers from regions like Africa, South America, the Middle East, and Europe should also consider local regulations and preferences when making their choice.

In-depth Look: Manufacturing Processes and Quality Assurance for 2.5 l bottle

What Are the Main Stages of Manufacturing a 2.5 L Bottle?

The manufacturing process for a 2.5 L bottle typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets the required standards for quality and safety.

Preparação do material

The first step in manufacturing a 2.5 L bottle is the selection and preparation of materials. Common materials include high-density polyethylene (HDPE), polypropylene, glass, and aluminum. Each material is chosen based on its intended use, such as food safety standards for beverage containers or chemical resistance for industrial applications.

During this stage, raw materials undergo various treatments to enhance their properties. For instance, HDPE might be processed to improve its durability and UV resistance, while glass bottles could be treated to increase their thermal stability. Material testing ensures that the selected substances meet the necessary regulatory standards before proceeding to the next stage.

How Are 2.5 L Bottles Formed?

Forming is the next crucial step in the manufacturing process. This can be achieved through several techniques, depending on the material used:

- Blow Molding: Common for plastic bottles, this technique involves inflating a heated plastic preform into a mold to create the bottle shape. It allows for efficient production and is ideal for high-volume outputs.

- Injection Molding: Used primarily for smaller components or caps, this method involves injecting molten material into a mold. For a complete bottle, this can be combined with blow molding.

- Glass Blowing: For glass bottles, the molten glass is shaped using blowing techniques, which require skilled labor to ensure uniform thickness and quality.

- Aluminum Forming: In the case of aluminum bottles, the material is rolled and shaped into the desired form, often utilizing advanced machinery for precision.

These techniques are selected based on the desired characteristics of the final product, such as weight, durability, and aesthetic appeal.

What Is Involved in the Assembly and Finishing Process?

Once the bottles are formed, they enter the assembly stage, where components like caps, labels, and any additional features are integrated. This stage may also involve the application of tamper-evident seals, which are critical for food safety.

The finishing process includes several steps to ensure the bottles are ready for market:

- Cleaning: Bottles are thoroughly cleaned to remove any residues from the manufacturing process. This is especially important for food and beverage applications.

- Quality Inspection: Each batch undergoes a series of inspections to check for defects, such as leaks, structural integrity, and aesthetic flaws.

- Labeling and Packaging: Once inspected, bottles are labeled according to regulatory requirements and packaged for shipment.

How Is Quality Assurance Maintained in 2.5 L Bottle Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet international and industry-specific standards. Various checkpoints throughout the production line are established to maintain quality.

Quais são as normas internacionais relevantes para a garantia da qualidade?

For B2B buyers, understanding the relevant international standards is crucial. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable across industries. Compliance with ISO 9001 demonstrates a commitment to quality and continuous improvement.

- CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For containers used in the pharmaceutical industry, adherence to American Petroleum Institute (API) standards ensures that products are safe for storing and transporting chemicals.

These standards provide a framework for quality assurance and help buyers assess supplier reliability.

Quais são os principais pontos de verificação do controlo de qualidade no processo de fabrico?

The manufacturing process includes several quality control (QC) checkpoints:

- Controlo de qualidade de entrada (IQC): This is the first stage where raw materials are inspected upon arrival. Materials are tested against specifications to ensure they are suitable for production.

- Controlo de qualidade durante o processo (IPQC): During production, random samples are taken at various stages to monitor consistency and detect any deviations from quality standards.

- Controlo de qualidade final (FQC): After assembly and finishing, a final inspection is conducted to ensure that the finished bottles meet all specifications and quality requirements before they are shipped.

Como podem os compradores B2B verificar o controlo de qualidade dos fornecedores?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability. Here are some methods to do so:

- Audits: Conducting regular audits of suppliers helps ensure compliance with quality standards and provides insights into their manufacturing processes.

- Reports: Requesting detailed quality reports can help buyers understand the QC measures in place. This includes documentation of testing methods, results, and any corrective actions taken.

- Inspecções por terceiros: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality practices. These inspections can be particularly valuable for new partnerships or when entering new markets.

Quais são as nuances do controlo de qualidade e da certificação para os compradores internacionais?

International buyers must navigate various nuances in quality control and certification. For instance:

- Diferenças culturais: Different regions may have varying expectations for quality standards and compliance. Understanding these differences can aid in building effective supplier relationships.

- Conformidade regulamentar: Each market may have specific regulations that affect product safety and labeling. Buyers should ensure that their suppliers comply with local and international regulations to avoid legal issues.

- Language Barriers: Communication can be a challenge in international transactions. It is advisable to have clear documentation and possibly translators to avoid misunderstandings regarding quality expectations.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and establish reliable partnerships in the 2.5 L bottle market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2.5 l bottle’

The following guide provides a comprehensive checklist for B2B buyers aiming to source 2.5-liter bottles effectively. By following these steps, you can ensure that you make informed decisions that align with your business needs and compliance requirements.

Passo 1: Definir as suas especificações técnicas

Before you start the sourcing process, it’s essential to clearly define the technical specifications of the bottles you need. Consider factors such as material (plastic, glass, aluminum), dimensions, weight, and intended use (e.g., food-grade, chemical storage). This will help you narrow down your options and communicate effectively with potential suppliers.

Passo 2: Identify Your Target Market and Compliance Needs

Understanding your target market is crucial, especially in regions with specific regulations. For example, if you are sourcing for markets in Africa or the Middle East, familiarize yourself with local safety and environmental regulations. Ensure that the bottles comply with international standards, such as UN ratings for hazardous materials, to avoid legal issues down the line.

Passo 3: Avaliar potenciais fornecedores

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering quality products, as well as those who are responsive to customer inquiries and concerns.

- Check Certifications: Ensure that the suppliers hold relevant certifications, such as ISO standards or food safety certifications, which validate their quality management systems.

- Review Customer Feedback: Seek reviews or testimonials from other businesses that have purchased from them to gauge their reliability and product quality.

Passo 4: Pedido de amostras para avaliação da qualidade

Once you have identified a shortlist of suppliers, request samples of the 2.5-liter bottles. Testing samples allows you to assess the quality, durability, and functionality of the bottles firsthand. Evaluate factors such as:

- Leak-proof Testing: Ensure that the bottles can securely contain liquids without leakage.

- Material Inspection: Check for any defects or inconsistencies in the bottle material.

Passo 5: Negociar preços e condições

Engage in discussions with potential suppliers regarding pricing, payment terms, and delivery timelines. Establishing a good relationship with suppliers can lead to better pricing and flexible terms. Consider:

- Volume Discounts: Inquire about discounts for bulk purchases, which can significantly reduce your overall costs.

- Shipping Options: Discuss shipping methods and costs, especially if you are importing to regions like South America or Africa, where logistics can be challenging.

Passo 6: Finalize Your Order and Monitor Production

After negotiating terms and confirming your order, ensure you have a clear contract that outlines all agreed-upon details. It’s vital to maintain communication with the supplier throughout the production process. This includes:

- Actualizações regulares: Request updates on production timelines to ensure that deadlines are met.

- Controlo de qualidade: Consider arranging for a third-party inspection to verify that the bottles meet your specifications before shipment.

Passo 7: Plano de logística e distribuição

Finally, once your order is ready, plan for logistics and distribution. Determine the best shipping methods based on cost and delivery time. Ensure that your logistics partners are reliable and can handle the specific requirements of transporting your bottles to your target markets.

By following this step-by-step checklist, you can navigate the complexities of sourcing 2.5-liter bottles and make informed decisions that benefit your business operations.

Comprehensive Cost and Pricing Analysis for 2.5 l bottle Sourcing

What Are the Key Cost Components of Sourcing 2.5 L Bottles?

When sourcing 2.5 L bottles, understanding the cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materiais: The choice of material significantly impacts costs. Common materials for 2.5 L bottles include plastic, glass, and aluminum. For instance, aluminum bottles may cost around $23.10 each, whereas glass bottles could be priced around $17.16. The selection of food-grade materials or those meeting specific certifications will also add to the material costs.

-

Trabalho: Labor costs vary by region and are influenced by the complexity of the manufacturing process. In regions with lower labor costs, such as parts of Africa and South America, the overall production costs might be reduced, but this could also affect quality.

-

Despesas gerais de fabrico: This includes costs related to utilities, rent, and equipment maintenance. High overhead can lead to increased pricing for the final product, especially in regions with stringent regulatory compliance.

-

Ferramentas: Initial setup costs for molds and machinery can be significant, particularly for customized bottles. These costs are often distributed over the production run, so larger orders can mitigate the tooling cost per unit.

-

Controlo de qualidade (CQ): Ensuring product quality is essential, especially for food and beverage applications. QC processes add to the overall cost but are necessary to maintain compliance with international standards.

-

Logística: Shipping costs depend on the destination, volume, and method of transport. International shipping can be particularly costly, and buyers should consider Incoterms that define responsibilities for shipping and customs clearance.

-

Margem: Suppliers will add a profit margin to their costs, which can vary widely. Understanding the margin expectations can help buyers negotiate better pricing.

How Do Price Influencers Affect 2.5 L Bottle Sourcing?

Several factors influence the pricing of 2.5 L bottles:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Suppliers often provide discounts for larger orders, which can lead to a lower cost per unit.

-

Especificações e personalização: Custom designs or specific features will usually increase costs. Buyers should weigh the benefits of customization against the potential price increases.

-

Materiais e certificações de qualidade: Higher-quality materials and certifications (such as food-grade or UN-rated for hazardous materials) typically command higher prices. Buyers should assess their specific needs to avoid over-specifying.

-

Factores do fornecedor: The supplier’s location, reputation, and production capabilities can affect pricing. Established suppliers may charge more but offer better reliability and quality assurance.

-

Incoterms: The choice of Incoterms can impact the total cost. Understanding who is responsible for freight, insurance, and duties can help buyers manage costs more effectively.

What Tips Can Help Buyers Optimize Costs When Sourcing 2.5 L Bottles?

-

Negociação: Engage in discussions with suppliers to explore volume discounts, flexible payment terms, or bundled services that can reduce overall costs.

-

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis that considers not just the purchase price but also shipping, duties, storage, and potential wastage.

-

Research Pricing Nuances for International Markets: Different regions may have unique pricing structures influenced by local demand, regulatory requirements, and economic conditions. For instance, buyers in Nigeria and Saudi Arabia should be aware of local market trends and currency fluctuations.

-

Quality vs. Cost: While it may be tempting to opt for the lowest price, consider the long-term implications of quality. A higher upfront cost for a more durable bottle may result in lower replacement and warranty claims over time.

-

Leverage Local Suppliers: Whenever possible, sourcing from local suppliers can reduce logistics costs and lead times, making it a practical option for international buyers.

Declaração de exoneração de responsabilidade sobre os preços indicativos

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to ensure competitive pricing and alignment with your sourcing strategy.

Alternatives Analysis: Comparing 2.5 l bottle With Other Solutions

Exploring Alternatives to the 2.5 L Bottle: A Comparative Analysis

In the competitive landscape of packaging solutions, businesses often seek alternatives to conventional products like the 2.5 L bottle. Understanding the various options available can help B2B buyers make informed decisions that align with their operational needs and cost considerations. Below, we explore two viable alternatives: the aluminum bottle and the glass bottle with PVC coating, comparing them across key aspects.

| Aspeto de comparação | 2.5 L Bottle | Aluminum Bottle | Glass Bottle with PVC Coating |

|---|---|---|---|

| Desempenho | Good for liquids; lightweight | Excellent barrier properties; durable | Safe for chemicals; prevents contamination |

| Custo | Moderate pricing | Higher initial cost but reusable | Mid-range cost, durable but breakable |

| Facilidade de implementação | Simple to use; readily available | Requires careful handling; limited suppliers | Moderate; requires safety measures |

| Manutenção | Low; disposable option | Moderate; requires cleaning | High; needs careful handling and cleaning |

| Melhor caso de utilização | General liquid storage | Shipping chemicals and hazardous materials | Laboratory use and chemical storage |

Pros and Cons of Alternatives

What are the Advantages and Disadvantages of Using Aluminum Bottles?

Aluminum bottles, such as the 2.5L UN-rated option, offer excellent protection against environmental factors and are highly durable. Their lightweight nature makes them easy to transport, making them suitable for shipping and storing chemicals. However, the initial cost is generally higher than that of plastic bottles, which may deter budget-conscious buyers. Additionally, they require careful handling to avoid dents and ensure longevity, potentially increasing operational complexity.

How Does a Glass Bottle with PVC Coating Compare?

Glass bottles with PVC coating provide a robust solution for storing hazardous chemicals, as the PVC layer ensures safety in case of breakage. This design prevents leaks and contamination, making it ideal for laboratory environments. However, the fragility of glass poses a risk, as breakage can lead to hazardous situations. Maintenance is also higher due to the need for meticulous cleaning and handling, which could increase labor costs.

Conclusion: How Should B2B Buyers Choose the Right Packaging Solution?

Selecting the right packaging solution requires a careful assessment of specific business needs, including the type of liquids being stored, budget constraints, and operational capabilities. While the 2.5 L bottle remains a practical choice for general liquid storage, alternatives like aluminum and glass bottles with PVC coating offer specialized benefits that may better serve certain industries, particularly those dealing with chemicals. By weighing the pros and cons of each option, B2B buyers can make a strategic choice that enhances their operational efficiency and aligns with safety standards.

Essential Technical Properties and Trade Terminology for 2.5 l bottle

What Are the Key Technical Properties of a 2.5 L Bottle?

When considering the procurement of 2.5 L bottles, understanding their technical properties is crucial for ensuring product quality and suitability for intended applications. Here are several essential specifications:

-

Grau do material

The material of the bottle significantly influences its durability, chemical resistance, and suitability for different contents. Common materials include polyethylene terephthalate (PET), glass, and aluminum. For instance, aluminum bottles are often UN-rated, indicating they can safely transport hazardous materials. Buyers should choose a material that aligns with their product’s needs and regulatory requirements. -

Closure Type

The closure mechanism is vital for maintaining the integrity of the contents. Options include tamper-evident caps, screw caps, and flip-top closures. A tamper-evident cap, for instance, ensures product safety during shipping and provides assurance to end-users about the product’s integrity. Understanding the closure type helps in assessing the bottle’s usability and security features. -

Tolerância de capacidade

The tolerance level indicates the acceptable variance in bottle capacity, which is crucial for applications requiring precise measurements. For a 2.5 L bottle, a tolerance of ±5% might be standard. This specification is particularly important for industries like pharmaceuticals and food & beverage, where accurate measurements are critical for compliance and quality control. -

Dimensions

The dimensions of the bottle, including height, diameter, and neck size, affect storage, shipping, and compatibility with dispensing equipment. For example, a bottle with a narrow neck may be more suitable for certain filling processes. Buyers should consider their storage and logistics when evaluating bottle dimensions. -

Food Grade Certification

For bottles intended for consumables, ensuring they are food-grade certified is essential. This certification indicates that the materials used in the bottle do not leach harmful chemicals into the contents. Non-compliance can lead to serious health risks and legal issues, making this a critical consideration for B2B buyers in the food and beverage sector. -

Shipping Weight and Packaging

Understanding the shipping weight of bottles and their packaging dimensions can help in calculating transportation costs. Bottles may be sold in cases or bulk, and knowing the case weight and dimensions assists in optimizing logistics and inventory management. This is particularly beneficial for international buyers who must factor in freight costs and regulations.

What Are Common Trade Terms Associated with 2.5 L Bottles?

In the B2B landscape, understanding industry jargon is crucial for effective communication and negotiation. Here are some key terms to familiarize yourself with:

-

OEM (Fabricante de Equipamento Original)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bottles, an OEM might produce bottles that are branded and sold by a different company. Understanding OEM relationships can help buyers find reliable suppliers. -

MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for budgeting and inventory management, as suppliers often set MOQ to ensure profitability. Buyers must evaluate their needs against the MOQ to avoid excess inventory. -

RFQ (Pedido de Cotação)

An RFQ is a formal request to suppliers to provide pricing information for specific products. This process helps buyers compare prices and terms from multiple vendors, facilitating informed purchasing decisions. -

Incoterms (Termos Comerciais Internacionais)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for avoiding disputes and ensuring smooth logistics. -

UN Rating

This refers to the United Nations classification for packaging used to transport hazardous materials. A bottle with a UN rating indicates it meets stringent safety standards for hazardous goods. Buyers in industries dealing with chemicals or dangerous goods should prioritize UN-rated bottles. -

Prazo de execução

Lead time is the period between placing an order and receiving the goods. This metric is critical for supply chain planning, as longer lead times can affect inventory levels and production schedules. Buyers should communicate clearly with suppliers to manage expectations regarding lead times.

In conclusion, understanding both the technical properties and trade terminology associated with 2.5 L bottles is essential for B2B buyers aiming to make informed purchasing decisions. This knowledge can lead to better product selection, cost management, and compliance with industry regulations.

Navigating Market Dynamics and Sourcing Trends in the 2.5 l bottle Sector

What Are the Key Market Trends Impacting the 2.5 L Bottle Sector?

The global 2.5 L bottle market is experiencing significant transformation driven by various factors. One of the primary drivers is the growing consumer awareness of health and hydration, especially in regions like Africa and the Middle East, where access to clean drinking water remains a challenge. B2B buyers are increasingly seeking reliable suppliers who can provide high-quality water bottles that meet international safety and health standards. Additionally, the rise of e-commerce platforms is facilitating easier access to a wider variety of products, allowing businesses to source bottles from manufacturers worldwide.

Emerging technologies are also reshaping sourcing strategies. The use of data analytics and AI in supply chain management enables buyers to make informed decisions based on market demand, production timelines, and cost efficiencies. For example, advanced inventory management systems can help businesses optimize stock levels of 2.5 L bottles, reducing overhead costs. Furthermore, sustainability is becoming an essential factor in purchasing decisions, with buyers prioritizing suppliers who demonstrate eco-friendly practices in their manufacturing processes.

As the market evolves, companies are responding to the demand for customization, offering bottles in various materials such as aluminum, glass, and biodegradable plastics. This trend is particularly relevant in regions like South America and Europe, where consumers are increasingly inclined toward personalized and sustainable products. Overall, understanding these market dynamics is crucial for B2B buyers aiming to stay competitive and meet the needs of their customers.

How Are Sustainability and Ethical Sourcing Shaping the 2.5 L Bottle Market?

Sustainability has emerged as a pivotal focus for B2B buyers in the 2.5 L bottle sector. The environmental impact of plastic waste is prompting businesses to seek alternative materials and sustainable practices. Ethical sourcing not only enhances a company’s reputation but also aligns with consumer preferences, particularly in Europe and North America, where eco-consciousness is on the rise. Companies are increasingly investing in biodegradable and recyclable materials, which appeal to a market that values environmental responsibility.

Moreover, certifications like ISO 14001 (Environmental Management) and various green labels signal to buyers that a manufacturer adheres to sustainable practices. This is essential for businesses looking to build trust and transparency in their supply chains. For example, aluminum bottles are gaining popularity due to their recyclability and lightweight properties, which reduce shipping emissions. B2B buyers must assess the sustainability credentials of their suppliers to ensure they are not only compliant with regulations but also contributing positively to the environment.

In addition, ethical labor practices within the supply chain are becoming a focal point for buyers, especially in regions where labor rights can be a concern. Ensuring that suppliers provide fair wages and safe working conditions is essential for maintaining a responsible and sustainable business model. By prioritizing sustainability and ethical sourcing, companies can enhance their brand value and resonate with a growing base of environmentally and socially conscious consumers.

What Is the Historical Context of the 2.5 L Bottle Market?

The evolution of the 2.5 L bottle market traces back to the increasing demand for convenient, portable packaging solutions. Initially dominated by glass and metal containers, the market saw a significant shift in the late 20th century with the introduction of plastic bottles, which offered lightweight and durable alternatives. As consumer preferences evolved, so did the designs and materials used in bottle manufacturing, leading to the diverse offerings available today.

In recent years, the rise of health-conscious consumers has further propelled the demand for larger bottle sizes, such as the 2.5 L option, which allows for greater hydration without frequent refills. This trend has been particularly pronounced in regions where water scarcity is a concern, driving both local and international manufacturers to innovate their product lines. As the market continues to evolve, the focus on sustainability and ethical practices is likely to shape the future trajectory of the 2.5 L bottle sector, reinforcing the importance of adapting to consumer needs and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of 2.5 l bottle

-

How do I choose the right supplier for 2.5 l bottles?

When selecting a supplier for 2.5 l bottles, consider their experience in the industry, product quality, and compliance with international standards. Look for suppliers who provide certifications (e.g., food grade, UN-rated for hazardous materials) and have a robust quality assurance process. Request samples to evaluate the quality firsthand, and review their production capabilities to ensure they can meet your demand. Additionally, check customer reviews and ratings to gauge reliability and service quality. -

What customization options are available for 2.5 l bottles?

Many suppliers offer customization for 2.5 l bottles, including variations in material (e.g., glass, aluminum, plastic), color, labeling, and packaging. Discuss your specific needs with potential suppliers to understand their capabilities. Custom branding, such as logos and designs on the bottles, can also be arranged to enhance your product’s market presence. Ensure that the supplier can meet both aesthetic and regulatory requirements for your target market. -

What is the minimum order quantity (MOQ) for 2.5 l bottles?

The minimum order quantity (MOQ) for 2.5 l bottles can vary significantly among suppliers, often ranging from 100 to several thousand units. Factors influencing MOQ include the type of bottle, material, and level of customization required. When sourcing, inquire about the MOQ to assess whether it aligns with your inventory needs and budget. Some suppliers may offer flexibility on MOQ for first-time buyers or larger orders. -

What payment terms should I expect when purchasing 2.5 l bottles?

Payment terms for purchasing 2.5 l bottles can vary by supplier and region. Common options include upfront payment, partial payment with balance on delivery, or net payment terms (e.g., net 30 or 60 days). It is crucial to discuss and negotiate payment terms before finalizing your order to avoid any misunderstandings. Consider using secure payment methods and ensure that the terms protect your interests, especially in international transactions. -

How can I ensure the quality of 2.5 l bottles during production?

To ensure quality during production, establish clear communication with your supplier regarding quality standards and specifications. Request regular updates and progress reports throughout the manufacturing process. Implementing a quality assurance (QA) plan, including inspections and testing protocols, is vital. Consider third-party inspections before shipment to validate that the bottles meet your quality requirements and comply with safety standards. -

What logistics options are available for shipping 2.5 l bottles internationally?

International shipping options for 2.5 l bottles typically include air freight, sea freight, and courier services. The choice of logistics provider depends on factors such as urgency, budget, and destination. For larger orders, sea freight may be more cost-effective, while air freight is faster but often more expensive. Discuss shipping terms with your supplier, including delivery timelines, insurance, and customs clearance to ensure a smooth logistics process. -

Are there any regulations I need to be aware of when importing 2.5 l bottles?

Yes, importing 2.5 l bottles may be subject to various regulations depending on the destination country. These may include compliance with safety and health standards, labeling requirements, and import duties or tariffs. It is crucial to research the specific regulations applicable in your target market, including any restrictions on materials used in bottle manufacturing. Engaging a customs broker can help navigate these requirements effectively. -

What are the most common uses for 2.5 l bottles in B2B settings?

2.5 l bottles are commonly used in various B2B applications, including packaging for beverages, chemicals, and personal care products. In the beverage industry, they are ideal for water, juices, and other liquid refreshments. In the chemical sector, UN-rated aluminum and glass bottles are preferred for safely transporting hazardous materials. Understanding the end-use of the bottles can help you select the right supplier and product specifications to meet your business needs.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.

Top 10 2.5 L Bottle Manufacturers & Suppliers List

1. Walmart – 2.5L BPA Free Sports Water Bottle

Domínio: walmart.com

Registada: 1995 (30 anos)

Introdução: This company, Walmart – 2.5L BPA Free Sports Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

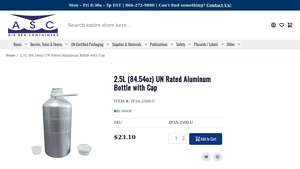

2. Air Sea Containers – UN Rated Aluminum Bottle 2.5L

Domínio: airseacontainers.com

Registada: 1997 (28 anos)

Introdução: {“item_number”:”IP3A-2500-U”,”capacity”:”2.5L (84.54oz)”,”type”:”UN Rated Aluminum Bottle”,”closure”:”White tamper evident plastic cap with foam/aluminum liner and LDPE plug”,”food_grade”:true,”quantity_per_case”:20,”case_weight”:”18 lbs”,”case_dimensions”:”26\” x 21\” x 13\””,”shipping_time”:”Ships within 1-7 Days”,”price”:”$23.10″}

3. Flinn Scientific – Narrow Mouth Glass Bottle 2.5 L

Domínio: flinnsci.com

Registada: 1997 (28 anos)

Introdução: {“Product Name”: “Bottle, Narrow Mouth, Glass, PVC Bottle, 2.5 L”, “Item Number”: “AP1012”, “Price”: “$17.16”, “Availability”: “In Stock”, “Description”: “Glass chemical bottles with PVC coating are constructed for safety. In the event of a breakage, the contents and glass shards are retained in a PVC outer envelope. The bottles are furnished with caps.”, “Dimensions”: {“Volume”: “2.5 L”, “Height”…

4. Mammoth Mug – 2.5 Litre Water Bottle

Domínio: mammothmug.com

Registada: 2014 (11 anos)

Introdução: The Ultimate 2.5 Litre Water Bottle for Daily Hydration – Mammoth Mug. Capacity: 2.5L. In stock: 46 products available. Regular price: $22.00 USD for various colors and designs. Sale price: $19.00 USD for select bundles. Free shipping on orders over $100. Designed to help achieve daily water intake without constant refills. Available colors include Matte Shroom, Matte Tree, Matte Evergreen, Matte …

5. Large Glass Water Bottle – Stainless Steel Handle

Domínio: ebay.com

Registada: 1995 (30 anos)

Introdução: {“title”: “Large 2.5L Gallon Glass Water Bottle – Stainless Steel Handle & Silicone Sleeve”, “price”: “$75.45”, “condition”: “New”, “quantity_available”: 5, “item_number”: “296971575942”, “shipping_estimate”: “Thu, Aug 28 – Thu, Sep 4”, “returns”: “Accepted within 30 days”, “seller_feedback”: “89.9% positive feedback”, “seller_location”: “Spanish Fort, Alabama, United States”}

6. Bellroy – Venture Ready Sling 2.5L

Domínio: reddit.com

Registada: 2005 (20 anos)

Introdução: Bellroy Venture Ready Sling 2.5L; designed for carrying essentials like a phone, wallet, keys, and a 500 mL water bottle; dimensions of the water bottle that fits: 8.25″x2.5″; capacity in practice is about 1.5 to 2L; features a low profile and comfortable design; suitable for short hikes or theme park days; includes a main compartment and a rear panel for organization; some users noted the strap i…

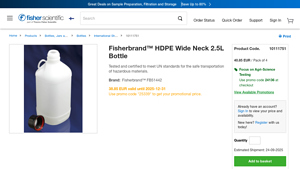

7. Fisherbrand – HDPE Wide Neck 2.5L Bottle

Domínio: fishersci.fi

Registado: 2010 (15 anos)

Introdução: {“Product Name”:”Fisherbrand HDPE Wide Neck 2.5L Bottle”,”Brand”:”Fisherbrand”,”Product Code”:”10111751″,”Price”:”38.85 EUR (valid until 2025-12-31) / 40.85 EUR / Pack of 4″,”Capacity”:”2.5 L”,”Diameter (Outer Neck)”:”45 mm”,”Width”:”130 mm”,”Height”:”295 mm”,”Color”:”Clear”,”Material”:”HDPE”,”Closure Material”:”Polypropylene”,”Certifications”:”Tested and certified to meet UN standards for the saf…

8. Bottle Joy – Classic I Glug Jug

Domínio: bottlejoy.com

Registado: 2017 (8 anos)

Introdução: {“product_name”: “Bottle Joy Classic I Glug Jug Large Capacity Water Bottle”, “capacity”: “2.5L/84OZ”, “material”: “BPA Free PETG”, “price”: “$26.99”, “colors_available”: [“Black”, “Pink”, “Transparent”], “sizes_available”: [“2.5L/84OZ”, “1.5L/50OZ”], “features”: [“All day water bottle”, “Hourly measurement markings from 7am to 7pm”, “No motivational quotes”, “Leak proof with matching carry strap”…

9. WaterBottle – Insulated Stainless Steel Water Jug

Domínio: waterbottle.tech

Registado: 2018 (7 anos)

Introdução: Product Name: Insulated Stainless Steel Water Jug 1.5L 2.5L Big Bottle with Handle 50oz 85oz Gallon Capacity

Model Number / SKU: S11150051

Capacity / Size: 85 oz (2.5 L), 50 oz (1.5L)

Bottle Diameter: 86mm

Height (w/o cap): Not specified

Bottle Material: 18/8 food grade stainless steel (SUS304 stainless steel)

Lid Material: PP + Silicone

Surface Decoration Technical: Powder coating

Insulation Perf…

10. Etsy – Personalizable 2.5 Litre Water Bottle

Domínio: etsy.com

Registada: 2004 (21 anos)

Introdução: 2.5 Litre Water Bottle, Personalizable, Free shipping, Ships from United States, Various sellers and prices, Includes options like 5 Gallon Water Dispenser, rubber hot water bottle, copper water bottle, motivational water bottles, and more.

Strategic Sourcing Conclusion and Outlook for 2.5 l bottle

In conclusion, the strategic sourcing of 2.5-liter bottles is pivotal for businesses aiming to optimize their supply chain while meeting the growing demand for diverse packaging solutions. From aluminum to glass, each material offers unique benefits that cater to specific industry needs, particularly in sectors such as food and beverage, chemicals, and pharmaceuticals. Understanding these advantages can significantly impact product quality, safety, and environmental compliance.

International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should consider not only the cost but also the sustainability and functionality of their packaging choices. By leveraging strategic sourcing, businesses can enhance operational efficiency, reduce waste, and align with global sustainability goals.

As we look ahead, the market for 2.5-liter bottles is set to evolve with innovations in materials and design. Buyers are encouraged to stay informed about emerging trends and technologies that could further enhance their product offerings. Engaging with reliable suppliers who understand these dynamics will be essential for maintaining a competitive edge. Now is the time to invest in strategic partnerships that will drive your business forward in this dynamic landscape.