Introduction: Navigating the Global Market for bottle silk screen

In today’s competitive global market, sourcing high-quality bottle silk screen solutions can pose significant challenges for B2B buyers. Navigating the nuances of printing techniques, material compatibility, and supplier reliability is crucial for companies looking to enhance their product packaging and branding. This guide serves as a comprehensive resource for international buyers, exploring various silk screening methods, applications across industries, and tips for effectively vetting suppliers.

From single-color designs to intricate multi-color prints, the options available can seem overwhelming, particularly for those in regions like Africa, South America, the Middle East, and Europe, including countries such as Vietnam and Germany. Understanding the cost implications and the specific requirements for different bottle types is vital for making informed purchasing decisions that align with business goals.

Additionally, this guide delves into the latest trends in bottle silk screening, offering insights into innovative techniques and materials that can elevate product presentation. By equipping B2B buyers with actionable knowledge and strategies, we empower them to confidently navigate the complexities of the market, ultimately enhancing their product offerings and achieving greater success in their respective industries.

Navegação de artigos

- Top 9 Bottle Silk Screen Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle silk screen

- Understanding bottle silk screen Types and Variations

- Key Industrial Applications of bottle silk screen

- 3 Common User Pain Points for ‘bottle silk screen’ & Their Solutions

- Strategic Material Selection Guide for bottle silk screen

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle silk screen

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle silk screen’

- Comprehensive Cost and Pricing Analysis for bottle silk screen Sourcing

- Alternatives Analysis: Comparing bottle silk screen With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle silk screen

- Navigating Market Dynamics and Sourcing Trends in the bottle silk screen Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle silk screen

- Aviso importante e termos de utilização

- Strategic Sourcing Conclusion and Outlook for bottle silk screen

Understanding bottle silk screen Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Single Color Silk Screen | Uses one ink color for a clean, minimalist design. | Beverage, cosmetics, and pharmaceuticals | Prós: Cost-effective, quick production. Contras: Limited design complexity. |

| Multi-Color Silk Screen | Incorporates multiple ink colors, allowing for intricate designs. | Cosmetics, food packaging, promotional items | Prós: Visually appealing, versatile. Contras: Higher costs, longer lead times. |

| Halftone Silk Screen | Utilizes varying ink densities to create depth and shading. | Artisanal beverages, premium products | Prós: Enhanced visual impact, unique aesthetics. Contras: More complex setup, potential for color variance. |

| UV Cured Silk Screen | Uses UV inks that cure instantly, providing a glossy finish. | High-end cosmetics, glass packaging | Prós: Durable finish, vibrant colors. Contras: Requires specialized equipment, potentially higher costs. |

| In-Mold Labeling (IML) | Labels are integrated into the bottle mold for a seamless look. | Food containers, household products | Prós: High durability, seamless appearance. Contras: Higher initial tooling costs, less flexibility in design changes. |

What Are the Characteristics of Single Color Silk Screen?

Single color silk screen printing is characterized by its use of a single ink hue to create a straightforward yet effective design. This method is particularly suitable for businesses looking for a cost-effective solution, as it typically requires less setup time and lower material costs. B2B buyers should consider this option for products that benefit from a clean and minimalist aesthetic, such as beverage bottles or pharmaceutical containers. However, it is important to note that while this approach is economical, it limits design complexity and may not suit brands aiming for a more elaborate visual identity.

How Does Multi-Color Silk Screen Enhance Branding?

Multi-color silk screen printing allows businesses to utilize several ink colors, creating detailed and eye-catching designs. This technique is ideal for cosmetic packaging, food products, and promotional materials, where visual appeal is crucial for attracting customers. B2B buyers should evaluate the potential for increased brand recognition and consumer engagement through vibrant, multi-colored graphics. However, this method often comes with higher production costs and longer lead times, making it essential for buyers to balance their budget with branding needs.

What Is Unique About Halftone Silk Screen Printing?

Halftone silk screen printing distinguishes itself by using varying densities of ink to produce depth and shading, resulting in a visually dynamic output. This method is particularly well-suited for artisanal beverages and premium products, where unique aesthetics can significantly impact consumer perception. B2B buyers should consider the artistic possibilities this technique offers, as it can enhance the overall visual impact of their products. However, the complexity of setup and the potential for color variance should be factored into purchasing decisions.

Why Choose UV Cured Silk Screen for High-End Products?

UV cured silk screen printing employs ultraviolet light to instantly cure inks, resulting in a glossy finish that enhances durability and vibrancy. This method is often used in high-end cosmetics and glass packaging, where a polished appearance is essential. B2B buyers should assess the benefits of using UV inks, which provide a superior aesthetic and longevity. However, the need for specialized equipment and potentially higher costs may require careful consideration of the overall production budget.

What Are the Advantages of In-Mold Labeling (IML)?

In-mold labeling (IML) integrates labels directly into the bottle mold, creating a seamless look that enhances product durability. This technique is commonly used in food containers and household products, where aesthetics and functionality are equally important. B2B buyers should weigh the long-term benefits of durability and a polished appearance against the higher initial tooling costs associated with IML. Additionally, the reduced flexibility in design changes may influence decision-making for brands that frequently update their packaging.

Key Industrial Applications of bottle silk screen

| Indústria/Setor | Specific Application of bottle silk screen | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Beverage Industry | Custom branding on glass and plastic bottles | Enhances brand recognition and consumer appeal | Ensure compatibility with bottle materials and printing methods |

| Cosmetics and Personal Care | Decorative printing on cosmetic containers | Elevates product aesthetics and perceived value | Focus on color accuracy and durability of inks used |

| Food and Condiments | Silk screening on jars and bottles for sauces and spreads | Provides a professional look that can attract consumers | Consider food-safe inks and compliance with regulatory standards |

| Produtos farmacêuticos | Labeling for medication bottles | Ensures clear communication of product information | Must meet strict regulatory requirements for labeling |

| Household Products | Branding on cleaning product containers | Differentiates products in a competitive market | Evaluate ink resistance to chemicals and environmental factors |

How is bottle silk screen used in the Beverage Industry?

In the beverage industry, bottle silk screening is a popular method for applying custom branding to glass and plastic containers. This technique provides a high-quality finish that enhances brand visibility and consumer appeal. B2B buyers in this sector must consider the compatibility of inks with different bottle materials to ensure durability and adherence. Additionally, the ability to match Pantone colors accurately is crucial for maintaining brand consistency across various products.

What are the applications of bottle silk screen in Cosmetics and Personal Care?

Silk screen printing is widely used in the cosmetics and personal care industry for decorating bottles, jars, and tubes. This process not only enhances the aesthetic appeal of products but also elevates their perceived value among consumers. For international buyers, especially from regions like Africa and Europe, it’s essential to focus on the durability and color accuracy of inks to withstand handling and usage. The use of UV inks can provide a glossy finish that further enhances the product’s attractiveness.

Why is bottle silk screening vital for Food and Condiments?

In the food industry, silk screening is applied to jars and bottles used for sauces, dressings, and spreads. This method offers a professional look that can significantly influence consumer purchasing decisions. B2B buyers should prioritize food-safe inks and ensure compliance with local and international regulatory standards to avoid potential health risks. Additionally, the ability to print intricate designs and vibrant colors can help differentiate products in a crowded market.

How does bottle silk screen apply to Pharmaceuticals?

Silk screen printing plays a critical role in the pharmaceutical sector, particularly for labeling medication bottles. This application ensures that essential product information is clearly communicated, which is vital for consumer safety and compliance with regulations. Buyers in this industry must navigate strict labeling requirements, including font size, clarity, and color contrast. Sourcing partners should be able to provide inks that are resistant to fading and smudging, ensuring the labels remain legible throughout the product’s shelf life.

What advantages does bottle silk screen offer for Household Products?

In the household products sector, silk screening is used for branding on containers for cleaning supplies and other household items. This method helps to differentiate products in a competitive market by providing a professional and cohesive look. B2B buyers need to evaluate the resistance of inks to various chemicals and environmental factors, ensuring that the printed designs remain intact during usage. Additionally, the option for multiple color applications allows for more creative branding solutions that can attract consumers.

3 Common User Pain Points for ‘bottle silk screen’ & Their Solutions

Scenario 1: Navigating Quality Control Issues in Silk Screening

O problema: B2B buyers often face significant challenges in ensuring consistent quality across batches of silk-screened bottles. Issues such as color mismatches, uneven application, and ink adherence can lead to costly reprints and delays. This is particularly frustrating when buyers are working on tight timelines and need to ensure that their branding remains consistent across all products. Furthermore, variations in quality can tarnish a brand’s reputation, especially in competitive markets in regions like Africa and South America, where brand loyalty is hard-won.

A solução: To mitigate quality control issues, it is crucial for buyers to establish clear specifications with their silk-screening provider before production begins. Utilizing the Pantone Matching System (PMS) can help ensure color consistency. Buyers should request sample proofs before large-scale production to assess the quality and ensure that the colors and designs meet their expectations. Additionally, implementing a quality assurance protocol that includes multiple proofing stages can help catch errors early. This includes checking for ink adhesion and evenness across the entire surface of the bottles. Establishing a feedback loop with the printing company can also facilitate improvements and adjustments in real-time, ensuring that each batch adheres to the desired quality standards.

Scenario 2: Limited Customization Options for Niche Markets

O problema: Many B2B buyers, particularly those in specialized sectors like cosmetics or pharmaceuticals, struggle to find silk-screening services that offer the level of customization they require. This can include specific bottle shapes, sizes, or complex graphic designs that not all providers can accommodate. Buyers often find themselves restricted by the capabilities of their current suppliers, which can limit their product appeal and market competitiveness, especially in diverse markets across Europe and the Middle East.

A solução: To overcome limitations in customization, buyers should seek out suppliers who specialize in custom bottle printing and have a proven track record of flexibility in their services. Engaging with companies that offer both silk screening and alternative decoration methods, such as in-mold labeling (IML) or applied ceramic labeling (ACL), can provide more options for unique designs. Buyers should also communicate their specific needs early in the process, allowing suppliers to propose tailored solutions. Additionally, exploring partnerships with local manufacturers can help in creating unique bottle designs that align with regional preferences, ultimately enhancing product differentiation.

Scenario 3: Cost Management for Low-Volume Orders

O problema: For startups or smaller businesses, managing costs associated with low-volume orders for silk-screened bottles can be a significant pain point. Many suppliers have high minimum order quantities (MOQs), which can lead to excess inventory and wasted resources. This is particularly challenging for companies testing new products or entering new markets, where demand is uncertain and financial resources may be limited.

A solução: Buyers can alleviate cost concerns by negotiating with suppliers who are willing to accommodate lower MOQs, particularly those who have experience working with startups or smaller brands. Another effective strategy is to explore cooperative buying with other businesses to meet MOQ requirements without the burden of excess inventory. Furthermore, buyers should inquire about bulk repacking options that can simplify handling and reduce costs. Utilizing services that offer a range of silk-screening options—such as single-color designs or limited-run promotional prints—can also provide flexibility and minimize financial risk. Investing in a solid relationship with a supplier that understands the dynamics of low-volume orders can lead to more favorable terms and better pricing structures over time.

Strategic Material Selection Guide for bottle silk screen

When selecting materials for bottle silk screening, it is essential to consider their properties, advantages, disadvantages, and how they align with international standards. Here, we analyze four common materials used in the bottle silk screen process, providing insights tailored for B2B buyers in diverse global markets.

What Are the Key Properties of Glass Bottles in Silk Screening?

Glass is a widely used material for bottles due to its excellent clarity and ability to showcase vibrant colors. It has high temperature and pressure resistance, making it suitable for various applications, including beverages and cosmetics. Additionally, glass is chemically inert, ensuring that it does not react with the contents, preserving product integrity.

Prós: Glass bottles provide a premium look and feel, enhancing brand perception. They are highly durable against UV light and do not leach chemicals into the product.

Contras: The fragility of glass can lead to breakage during handling or transportation. Moreover, glass bottles tend to be heavier than plastic alternatives, increasing shipping costs.

Impacto na aplicação: Glass is compatible with a wide range of inks, including UV and solvent-based options, which can provide a glossy finish.

Considerações para compradores internacionais: Compliance with standards such as ASTM and DIN is crucial. Buyers in regions like Europe may prefer glass due to environmental regulations favoring recyclable materials.

How Do Plastic Bottles Compare in Silk Screening Applications?

Plastic bottles, commonly made from PET or HDPE, are lightweight and versatile. They offer good temperature resistance but may not withstand high pressures as effectively as glass.

Prós: Plastic is less prone to breakage, making it safer for shipping and handling. It is also generally more cost-effective than glass, allowing for lower production costs.

Contras: Plastic may not provide the same premium aesthetic as glass and can be susceptible to scratching or fading over time. Additionally, certain inks may not adhere well to plastic surfaces without proper treatment.

Impacto na aplicação: Plastic bottles are compatible with a variety of inks, but the choice of ink must account for the specific type of plastic to ensure durability and adherence.

Considerações para compradores internacionais: Buyers should be aware of regulations regarding plastic use, especially in regions like Africa and South America, where sustainability is becoming increasingly important.

What Are the Benefits of Using Aluminum Bottles for Silk Screening?

Aluminum bottles are gaining popularity due to their lightweight and recyclable nature. They offer good resistance to corrosion and can withstand various environmental conditions.

Prós: Aluminum provides a modern and sleek appearance, appealing to brands targeting upscale markets. It is also highly recyclable, aligning with sustainability goals.

Contras: The cost of aluminum bottles can be higher than plastic, and they may require specific inks to ensure adhesion and durability.

Impacto na aplicação: Aluminum is compatible with UV inks, which cure quickly and provide a durable finish, ideal for high-volume production.

Considerações para compradores internacionais: Compliance with local recycling regulations and standards is crucial. In Europe, for instance, there are stringent rules regarding the recyclability of packaging materials.

What Role Does Ceramic Play in Bottle Silk Screening?

Ceramic bottles, while less common, offer unique aesthetic benefits and durability. They are often used for high-end products, such as specialty beverages or luxury cosmetics.

Prós: Ceramic provides a premium look and feel, with excellent resistance to chemical interactions. It can also be printed with vibrant colors that last.

Contras: The weight and fragility of ceramic can be significant drawbacks, making transportation more challenging and costly.

Impacto na aplicação: Ceramic bottles require specialized inks and curing processes, which can increase manufacturing complexity.

Considerações para compradores internacionais: Buyers should consider the higher shipping costs associated with ceramic and ensure compliance with local regulations regarding glass and ceramic materials.

Summary Table of Material Selection for Bottle Silk Screening

| Material | Typical Use Case for bottle silk screen | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Vidro | Beverages, cosmetics, high-end products | Premium look, chemical inertness | Fragile, heavier weight | Elevado |

| Plástico | Personal care, household products | Leve e económico | Less premium feel, scratching | Médio |

| Alumínio | Upscale beverages, modern cosmetics | Sleek design, recyclable | Higher cost, specific ink needs | Médio |

| Ceramic | Luxury beverages, specialty cosmetics | Premium aesthetics, durability | Heavy, fragile | Elevado |

This analysis should assist international B2B buyers in making informed decisions regarding material selection for bottle silk screening, ensuring that their choices align with product requirements and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for bottle silk screen

What Are the Key Stages in the Manufacturing Process of Bottle Silk Screen?

The manufacturing process for bottle silk screen printing encompasses several critical stages, ensuring both quality and efficiency. The primary stages include material preparation, forming, assembly, and finishing.

-

Preparação do material: This initial phase involves selecting the right type of bottles—whether glass or plastic—based on customer specifications and intended use. Once the material is chosen, it undergoes thorough cleaning and surface treatment to ensure optimal adhesion of inks. For instance, glass bottles may be cleaned using chemical solvents, while plastic bottles often require corona treatment to increase surface energy.

-

Formação: In this stage, the selected bottles are molded into their final shapes. This process often involves high-precision machinery that guarantees consistency in size and design. The forming stage is crucial as any defects can affect the subsequent printing process.

-

Montagem: Depending on the complexity of the order, this stage may involve additional components, such as closures or labels. Bottles may be assembled with other parts to create a complete product. This step requires careful handling to prevent any damages that could compromise quality.

-

Acabamento: The final stage involves the actual silk screen printing. This process can utilize both single and multi-color techniques, including halftone printing for added depth. Advanced printing machines ensure precise application of inks, often using the Pantone Matching System to achieve exact color matches. After printing, bottles may undergo a curing process, typically involving UV light, to ensure that the inks are durable and visually appealing.

What Are the Key Techniques Employed in Bottle Silk Screen Printing?

Several key techniques are employed to ensure high-quality silk screen printing on bottles:

-

Halftone Printing: This technique allows for the creation of images with gradients and depth. By varying the size and spacing of dots, printers can achieve a wide range of tones and shades, making it suitable for complex designs.

-

Multi-Color Printing: This involves layering multiple colors to create a final design. Each color is printed separately, requiring precise alignment to avoid misregistration. This can be enhanced with tooling for improved accuracy.

-

Use of Specialized Inks: High-quality inks, such as UV-curable inks, provide durability and a glossy finish. These inks are formulated to adhere effectively to different bottle materials, ensuring long-lasting results.

How is Quality Assurance Managed in Bottle Silk Screen Printing?

Quality assurance (QA) is a critical aspect of the bottle silk screen printing process. Effective QA ensures that the final product meets both international standards and customer expectations.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which outline the requirements for a quality management system. This certification ensures that processes are continuously improved and that customer satisfaction is prioritized. Additionally, industry-specific certifications, such as CE marking for European markets or API standards for pharmaceutical applications, may apply based on the product type.

-

Pontos de controlo de qualidade: Various checkpoints are established throughout the manufacturing process, including:

– Controlo de qualidade de entrada (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

– Controlo de qualidade durante o processo (IPQC): Continuous monitoring during the production process helps identify defects early. This may include regular checks on print quality, color accuracy, and adhesion.

– Controlo de qualidade final (FQC): Before products are shipped, a final inspection is conducted to ensure all specifications are met. This may involve visual inspections and testing for durability and adhesion. -

Common Testing Methods: Various testing methods are employed to assess the quality of printed bottles. These may include:

– Adhesion Testing: This ensures that the ink adheres properly to the bottle surface and can withstand handling and environmental conditions.

– Color Matching Tests: Using spectrophotometers, manufacturers can verify that printed colors match the approved samples.

– Durability Tests: This assesses how well the printed designs withstand wear and tear, including exposure to chemicals and abrasion.

Como podem os compradores B2B verificar as práticas de controlo de qualidade dos fornecedores?

For B2B buyers, especially those in international markets, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

-

Auditorias a fornecedores: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This includes assessing their adherence to international standards and their internal QA protocols.

-

Pedido de relatórios de qualidade: Buyers should request documentation of quality control processes, including IQC, IPQC, and FQC reports. These documents should outline the methods used for testing and inspection, as well as any certifications achieved.

-

Inspecções por terceiros: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can evaluate the supplier’s operations and provide unbiased assessments of quality standards.

Quais são as nuances do controlo de qualidade para os compradores internacionais B2B?

International B2B buyers must navigate several nuances when it comes to quality control:

-

Conformidade regulamentar: Different regions may have varying regulatory requirements that affect quality assurance. For example, products sold in the European market must comply with CE standards, while those in the U.S. may be subject to FDA regulations.

-

Cultural Differences in Quality Perception: Understanding that quality expectations may vary across cultures is essential. For example, buyers from Germany may have stringent expectations regarding precision and reliability, while buyers in some African or South American markets might prioritize cost-effectiveness.

-

Supply Chain Considerations: Disruptions in the supply chain can affect quality control. Buyers should establish strong communication channels with suppliers to ensure that quality is maintained even during unexpected changes.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing bottle silk screen printing services, ultimately enhancing their product offerings and ensuring customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle silk screen’

Introdução

This guide provides a practical checklist for B2B buyers interested in procuring bottle silk screening services. Silk screening is a valuable process for enhancing brand visibility and product aesthetics, making it essential to approach sourcing strategically. By following this step-by-step checklist, you can ensure a successful procurement process that meets your business needs.

Passo 1: Definir as suas especificações técnicas

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of bottles (glass or plastic), size specifications, and desired print colors. Having a well-defined scope helps suppliers provide accurate quotes and ensures that the final product aligns with your branding needs.

- Considerações:

- Identify any specific design elements, such as logos or graphics.

- Decide on the quantity and whether you need single-color or multi-color prints.

Passo 2: Pesquisa de potenciais fornecedores

Conduct thorough research to identify reputable suppliers in the bottle silk screening industry. Look for companies with a solid track record and positive reviews from previous clients. Supplier reputation is crucial, as it reflects their reliability and quality of service.

- Where to Look:

- Online marketplaces, industry directories, and trade shows.

- Social media platforms and professional networks for firsthand feedback.

Passo 3: Avaliar as certificações dos fornecedores

Ensure that potential suppliers have the necessary certifications and compliance with industry standards. Certifications can indicate adherence to quality control processes and environmental practices, which are vital for maintaining product integrity.

- What to Check:

- ISO certifications related to quality management.

- Compliance with local regulations, especially in different regions such as Africa, South America, or Europe.

Passo 4: Request Samples and Proofs

Before finalizing a supplier, request samples of their previous work and proofs of your specific design. This step is essential to assess the quality of the silk screening and to ensure that the colors and finishes meet your expectations.

- Key Actions:

- Evaluate the clarity and precision of the prints.

- Check for color accuracy using the Pantone Matching System.

Passo 5: Discuss Pricing and Payment Terms

Engage suppliers in discussions about pricing structures and payment terms. Understanding the cost breakdown and payment options is crucial for budgeting and ensuring financial feasibility.

- Points to Clarify:

- Inquire about additional costs, such as setup fees or minimum order quantities.

- Discuss payment methods and terms, including deposits and credit options.

Passo 6: Assess Production Capabilities and Lead Times

Inquire about the supplier’s production capabilities and lead times. This information is vital for planning your inventory and ensuring that you can meet market demand promptly.

- Important Factors:

- Ask about their capacity for handling large orders versus smaller runs.

- Confirm turnaround times for your specific order volume.

Passo 7: Finalize the Contract and Terms

Once you have selected a supplier, carefully review and finalize the contract. Ensure that all terms, including quality expectations, timelines, and payment agreements, are clearly stated to avoid any misunderstandings.

- Contract Essentials:

- Include clauses on quality assurance and penalties for delays.

- Specify the process for handling any discrepancies or issues with the final product.

By following this checklist, B2B buyers can navigate the complexities of sourcing bottle silk screening services effectively, ensuring they find a reliable partner that meets their needs.

Comprehensive Cost and Pricing Analysis for bottle silk screen Sourcing

What Are the Key Cost Components in Bottle Silk Screen Printing?

When sourcing bottle silk screen printing services, it’s crucial to understand the various cost components involved. The primary elements include:

-

Materiais: The choice of inks, substrates (glass or plastic), and any additional materials (like coatings or finishes) significantly impacts cost. High-quality inks, such as UV-cured options, can enhance durability and aesthetics but may also raise expenses.

-

Trabalho: Skilled labor is essential for quality silk screening, particularly for complex designs or multiple colors. Labor costs can vary based on the region, with higher rates often found in developed markets compared to emerging economies.

-

Despesas gerais de fabrico: This includes the costs associated with operating machinery, maintaining facilities, and other indirect expenses. Efficient production processes can mitigate these costs, making it vital to choose suppliers with streamlined operations.

-

Ferramentas: For customized designs, tooling costs for screens and setup can be significant. While some suppliers may absorb these costs for larger orders, smaller buyers should be prepared for upfront charges.

-

Controlo de qualidade (CQ): Ensuring that each print meets quality standards involves additional checks and balances, impacting overall pricing. Suppliers that emphasize quality may charge more but often provide better long-term value.

-

Logística: Shipping and handling costs can vary widely based on location and order size. International buyers should factor in customs duties and potential delays, which can affect pricing and delivery timelines.

-

Margem: Suppliers typically mark up costs to ensure profitability. Understanding the supplier’s pricing structure can help buyers negotiate better terms.

How Do Volume and Customization Affect Pricing?

Volume plays a critical role in determining pricing for silk screen printing. Suppliers often have minimum order quantities (MOQs), and larger orders can lead to economies of scale, reducing the per-unit cost. Conversely, low-volume orders may incur higher per-piece costs due to fixed setup charges.

Customization also influences pricing. Unique designs or specialized inks require additional resources, which can increase costs. Buyers should assess whether the added value of customization justifies the higher price point.

What Factors Should International Buyers Consider?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several factors can influence the total cost of ownership:

-

Specifications and Certifications: Ensuring that products meet local regulations or industry standards can incur additional costs. Certifications may also be necessary for specific markets, affecting sourcing decisions.

-

Factores do fornecedor: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers may offer better quality and service, potentially reducing long-term costs despite higher upfront prices.

-

Incoterms: Understanding the delivery terms is essential. Buyers should clarify responsibilities for shipping, insurance, and customs clearance to avoid unexpected expenses.

What Are Effective Tips for Negotiating Costs?

-

Research and Compare: Conduct thorough market research to compare pricing structures among different suppliers. This knowledge can empower buyers during negotiations.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to more favorable terms and pricing. Regular communication can also help in understanding the supplier’s cost structure.

-

Focus on Total Cost of Ownership (TCO): Consider not just the upfront costs but the long-term implications, including quality, durability, and support. A slightly higher initial price might be offset by lower maintenance or replacement costs.

-

Seja transparente em relação às suas necessidades: Clearly communicate your requirements and expectations with potential suppliers. Transparency can foster trust and lead to more tailored pricing options.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It’s essential to note that pricing for bottle silk screen printing can vary widely based on numerous factors. Indicative prices may not reflect the final cost, as they depend on specific requirements, order volume, and supplier terms. Therefore, it’s advisable for buyers to obtain detailed quotes and clarify all aspects of the pricing structure before proceeding with orders.

Alternatives Analysis: Comparing bottle silk screen With Other Solutions

Exploring Alternative Solutions for Bottle Decoration

In the competitive landscape of product packaging, businesses often seek effective methods to enhance brand visibility and product appeal. While bottle silk screen printing is a popular choice for its high-quality finish and customization options, several alternative solutions can also meet specific business needs. This section compares bottle silk screen with two viable alternatives: labeling and in-mold labeling (IML).

| Aspeto de comparação | Bottle Silk Screen | Labeling | In-Mold Labeling (IML) |

|---|---|---|---|

| Desempenho | High-quality, durable graphics | Good quality but less durable than silk screen | Excellent durability; graphics integrated into the product |

| Custo | Moderate to high, depending on volume | Generally lower cost, especially for high volumes | Higher upfront costs due to molds |

| Facilidade de implementação | Requires specialized equipment and expertise | Easier to implement with basic printing equipment | Complex process, requires specialized equipment |

| Manutenção | Minimal, but requires precision in setup | Low maintenance; simple equipment | Low maintenance; integrated into production |

| Melhor caso de utilização | Premium products needing high visibility | Economical for mass production | Ideal for high-volume production with complex designs |

What Are the Advantages and Disadvantages of Labeling as an Alternative?

Labeling is a widely used method for decorating bottles, employing adhesive labels printed with product information and branding. Its primary advantage is cost-effectiveness, especially for large production runs. Labeling can be done quickly, making it an appealing choice for businesses looking to scale up their output without significant investment in equipment. However, the main drawback is that labels can peel or fade over time, which may compromise the product’s aesthetic appeal and durability compared to silk-screened graphics.

Why Choose In-Mold Labeling (IML) for Bottle Decoration?

In-mold labeling (IML) involves placing a label inside the mold during the manufacturing process, allowing the label to become part of the container. This method offers exceptional durability and a seamless finish, making it ideal for high-quality products. The graphics are resistant to scratches and chemicals, enhancing the product’s longevity. However, IML has a higher initial cost due to the need for specialized molds and equipment. It is best suited for high-volume production where the upfront investment can be justified by the long-term benefits.

Conclusion: How to Choose the Right Bottle Decoration Solution?

Selecting the appropriate bottle decoration method depends on various factors, including budget, production volume, and desired product quality. For businesses focused on premium branding and durability, bottle silk screen printing is an excellent choice despite its higher costs. Conversely, if cost-efficiency and speed are priorities, labeling might be the better option. For companies aiming for a high-end product with integrated designs, in-mold labeling could provide the best long-term value. Ultimately, understanding the specific needs and goals of your packaging strategy is crucial for making an informed decision.

Essential Technical Properties and Trade Terminology for bottle silk screen

What Are the Essential Technical Properties of Bottle Silk Screen?

When selecting a silk screen printing solution for bottles, understanding the technical properties is crucial for ensuring quality and durability. Here are some key specifications to consider:

-

Material Compatibility

Silk screen printing can be performed on various materials including glass, plastic, and metal. Understanding the compatibility of inks with these materials is essential to achieve vibrant colors and durability. For instance, UV inks are often used for plastics due to their quick curing properties and resistance to fading, while ceramic inks are preferred for glass to enhance durability. -

Ink Adhesion and Durability

The ability of the ink to adhere to the bottle surface is a critical property. High adhesion ensures that the print withstands handling, washing, and exposure to elements without fading or peeling. For B2B buyers, choosing a supplier that uses high-quality inks with proven adhesion properties can significantly reduce returns and improve customer satisfaction. -

Color Matching System

The Pantone Matching System (PMS) is widely used in the industry for color consistency. It allows businesses to accurately reproduce specific colors in their branding. For international buyers, understanding how a supplier utilizes PMS can help ensure that the printed products align with their brand identity across different markets. -

Print Tolerance and Quality Control

Print tolerance refers to the allowable variation in the placement and alignment of the printed design. High-quality silk screen printing should maintain tight tolerances to ensure that designs are accurately positioned on bottles. Implementing rigorous quality control measures, such as proofing stations, is vital for maintaining print quality, especially for multi-color designs. -

Curing Methods

Different curing methods, such as UV curing or heat curing, affect the finish and durability of the print. UV curing, for example, provides a glossy finish and quick drying time, which is beneficial for high-volume production. Understanding these methods helps buyers select the right process for their product’s application and shelf life.

What Are Common Trade Terms Related to Bottle Silk Screen?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms:

-

OEM (Fabricante de Equipamento Original)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, engaging with OEMs can simplify the supply chain by ensuring that the silk screen printing aligns with the original product specifications. -

MOQ (Quantidade mínima de encomenda)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for businesses to manage inventory and cash flow effectively. Suppliers often set MOQs to ensure cost-effectiveness in production runs. -

RFQ (Pedido de Cotação)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is an effective way to compare offerings from different vendors, ensuring they secure the best price and terms. -

Incoterms (Termos Comerciais Internacionais)

These are a set of predefined commercial terms published by the International Chamber of Commerce, used in international transactions. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers engaging in global trade, as it affects cost and risk management. -

Prazo de execução

This refers to the amount of time it takes from placing an order to receiving the finished product. For businesses, knowing lead times helps in planning production schedules and inventory levels, ensuring that products are available when needed.

By grasping these essential properties and terms, B2B buyers can make informed decisions regarding bottle silk screen printing, optimizing their supply chain and enhancing product quality.

Navigating Market Dynamics and Sourcing Trends in the bottle silk screen Sector

What Are the Current Market Dynamics and Key Trends in the Bottle Silk Screen Sector?

The bottle silk screen market is experiencing significant growth, driven by various global factors. The increasing demand for personalized packaging solutions, particularly in the beverage and cosmetic industries, is a primary driver. Customization allows brands to differentiate themselves in competitive markets, particularly in regions like Africa and South America, where emerging markets are rapidly evolving. Furthermore, advancements in printing technology, such as the use of UV inks and digital integration, have made it possible to achieve high-quality, durable prints at competitive prices, appealing to both small and large-scale manufacturers.

B2B tech trends are also reshaping sourcing strategies. Automation and digital platforms are streamlining order processes and inventory management, allowing buyers to access a wider range of suppliers globally. The rise of e-commerce has led to the need for faster turnaround times and smaller batch productions, compelling manufacturers to adapt to these demands. International buyers, particularly from Europe, are increasingly looking for suppliers who can offer flexibility in production volumes and quick delivery options.

In addition, sustainability is becoming a crucial factor in sourcing decisions. Buyers are not only focused on price and quality but also on the environmental impact of their packaging choices. This shift is prompting suppliers to adopt eco-friendly materials and processes, creating a more sustainable bottle silk screen market.

How Is Sustainability and Ethical Sourcing Impacting the Bottle Silk Screen Sector?

Sustainability in the bottle silk screen sector is gaining traction as companies recognize their role in minimizing environmental impact. The production process can generate significant waste, prompting buyers to seek partners who prioritize sustainable practices. This includes utilizing recycled materials, reducing water usage, and minimizing energy consumption during production.

Moreover, the importance of ethical supply chains cannot be overstated. International buyers are increasingly scrutinizing their suppliers for compliance with fair labor practices and ethical sourcing standards. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are becoming prerequisites for many buyers, particularly in Europe and North America. These certifications not only enhance brand reputation but also assure consumers of the sustainability of the products they purchase.

In response to growing environmental concerns, many suppliers are exploring alternative inks and printing techniques that reduce harmful emissions. For instance, water-based and soy-based inks are becoming popular as they are less toxic and easier to recycle. The shift towards sustainable packaging solutions is not just a trend; it’s becoming a critical factor in the decision-making process for B2B buyers across the globe.

What Is the Brief Evolution of the Bottle Silk Screen Sector?

The bottle silk screen sector has evolved significantly over the decades. Initially, the process was labor-intensive and limited to simple designs. However, advancements in technology have transformed silk screening into a sophisticated art form. The introduction of automated machinery and high-quality inks has allowed for intricate designs and faster production times, catering to the growing demand for customized packaging solutions.

In the late 20th century, the globalization of supply chains enabled manufacturers to source materials and production services from various regions, enhancing competitiveness. Today, the industry is characterized by a diverse range of printing techniques, including multi-color and halftone silk screening, which provide enhanced visual appeal and durability. This evolution has positioned bottle silk screen printing as a vital component of branding strategies for companies in various sectors, including cosmetics, beverages, and food packaging.

Overall, as the market continues to evolve, B2B buyers must stay informed about emerging trends and innovations to make strategic sourcing decisions that align with their business goals and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle silk screen

-

How do I choose the right supplier for bottle silk screening?

Selecting the right supplier involves evaluating their experience, quality standards, and service offerings. Look for suppliers with a proven track record in silk screening, especially in your product category. Request samples of their previous work to assess print quality and durability. Additionally, check customer reviews and testimonials to gauge reliability. Engage in direct communication to discuss your specific needs, ensuring they can accommodate your volume and customization requirements. -

What are the typical minimum order quantities (MOQs) for bottle silk screen printing?

Minimum order quantities can vary significantly among suppliers, typically ranging from 100 to 1,000 units. For B2B buyers, it’s essential to clarify MOQs upfront, especially if you are testing a new product. Some suppliers may offer lower MOQs for specific services or during promotional periods. Consider discussing your project scale and negotiating terms that suit your needs, as flexibility may be possible with certain suppliers. -

What customization options are available for silk-screened bottles?

Customization options often include color selection, graphics, and bottle shapes. Most suppliers utilize the Pantone Matching System for color accuracy, allowing you to choose from a wide range of hues. Additionally, you can opt for single or multi-color printing, as well as special effects like metallic or fluorescent inks. Discuss your design ideas with the supplier to explore the best printing techniques that will elevate your product’s visual appeal. -

How can I ensure quality assurance (QA) in my silk-screening order?

To ensure quality, select suppliers who have robust QA processes in place, including pre-production samples and multiple proofing stages. Ask about their inspection methods and whether they provide detailed documentation of quality checks. Establish clear communication about your quality expectations and any specific requirements you may have. Regular updates and the ability to review samples during production can further guarantee that your standards are met. -

What payment terms should I expect when sourcing bottle silk screen printing?

Payment terms can vary widely among suppliers. Typical arrangements include a deposit upfront (often 30-50%) with the balance due upon completion or before shipment. Some suppliers may offer net terms for established clients, while others may require full payment in advance for smaller orders. Clarify payment options and any additional fees, such as for shipping or customs, to ensure transparency and avoid surprises. -

How do logistics work for international shipments of silk-screened bottles?

Logistics for international shipments involve coordinating with freight forwarders, understanding customs regulations, and selecting appropriate shipping methods. Ensure your supplier has experience with international shipping and can provide options for expedited delivery if needed. Discuss the packaging standards to protect your products during transit and confirm who will handle customs clearance. Being proactive about these details can minimize delays and ensure smooth delivery. -

What are the advantages of silk screening over other labeling methods?

Silk screening offers several advantages, including durability and a high-quality finish that enhances brand perception. Unlike labels that can peel or fade, silk-screened designs are often more resistant to wear and tear, making them ideal for products exposed to handling or moisture. Additionally, silk screening allows for vibrant colors and intricate designs that can elevate your product’s aesthetic appeal, making it stand out in the marketplace. -

How can I evaluate the environmental impact of my silk-screening supplier?

To assess the environmental impact, inquire about the supplier’s materials and processes. Look for suppliers using eco-friendly inks, such as water-based or UV-cured options, which are less harmful than solvent-based inks. Additionally, check if they have certifications for sustainable practices or a commitment to reducing waste. Engaging suppliers who prioritize sustainability can enhance your brand’s image and appeal to environmentally conscious consumers.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.

Top 9 Bottle Silk Screen Manufacturers & Suppliers List

1. SKS Bottle – Customized Silkscreening Solutions

Domínio: sks-bottle.com

Registada: 1997 (28 anos)

Introdução: Customized Silkscreening for containers and closures, including options for various materials such as metal tins, plastic jars, glass vials, and bottles. Minimum order quantities can be as low as 10,000 pieces per production run. Silkscreening uses a range of inks, including epoxy and UV curable inks. A one-time setup fee is required for each customized screen, but this fee does not apply to futur…

2. WBBottle – Custom Silk Screening Services

Domínio: wbbottle.com

Registada: 1997 (28 anos)

Introdução: Custom silk screening for glass and plastic bottles and jars up to one gallon. Services include single color, multi-color, and halftone silk screening. Color matching using the Pantone Matching System (PMS). Additional services include flame treating, labeling, sleeve labeling, and repacking. Capable of handling low to high volume orders with blanket ordering available. Local delivery in Southeast…

3. SkinCareCo – Direct Printing Solutions

Domínio: reddit.com

Registada: 2005 (20 anos)

Introdução: Small business making skincare products; currently using labels on plastic bottles; interested in direct screen printing on plastic or glass bottles; seeking advice on whether to print in-house or outsource; concerns about minimum order quantities (e.g., 1000 bottles) being unaffordable.

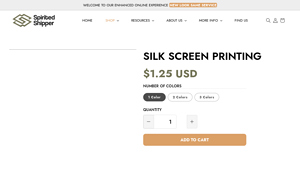

4. Spirited Shipper – Silk Screen Printing Services

Domínio: spiritedshipper.com

Registada: 1999 (26 anos)

Introdução: Silk Screen Printing services offered by Spirited Shipper. Regular price: $1.25 USD per unit. Minimum order requirement: 25 units. Options available: 1 Color, 2 Colors, 3 Colors. Setup cost: $30.00 for silk screen printing, additional $10 for PMS color matching. Orders typically fulfilled in less than a week. Ideal for wine retailers, spirits manufacturers, and beer distillers looking for effectiv…

5. Kaufman Container – Bottle Screen Printing Services

Domínio: kaufmancontainer.com

Registada: 2001 (24 anos)

Introdução: Kaufman Container offers bottle screen printing services as part of their packaging solutions. They provide custom solutions tailored to specific business needs, utilizing a robust in-house decorating facility. Screen printing is available on glass, plastic, and metal materials. The process involves direct ink application onto containers, cured under UV or LED lights to ensure durability. Kaufman …

6. BJ Silkscreen – Custom Bottle Printing

Domínio: bjsilk.com

Registado: 2019 (6 anos)

Introdução: This company, BJ Silkscreen – Custom Bottle Printing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

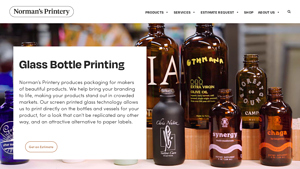

7. Norman’s Printery – Glass Bottle Printing

Domínio: normansprintery.com

Registado: 2010 (15 anos)

Introdução: Norman’s Printery offers glass bottle and vessel printing services using screen printing technology. Key features include:

– Direct printing on glass for a unique look, as opposed to paper labels.

– Permanent, waterproof labels that resist tearing and staining.

– Suitable for various types of glass vessels including candle jars, beverage bottles, makeup containers, CBD oil bottles, reed diffuser b…

8. Mepco Deco – Key Bottle Decorating Projects

Domínio: mepcodeco.com

Registado: 2011 (14 anos)

Introdução: Mepco Deco specializes in bottle decorating projects using various methods including silk screening, pad printing, hot stamping, and labeling. Key projects include:

1. **Silk Screening**:

– **Rahua**: Screen printing in white ink on brown glass containers.

– **June Jacobs**: Single color (orange) screen printing on plastic tube containers.

– **Zinsser**: Single color large silk screen on…

9. Amen Packaging – Turnkey Silk Screen Service

Domínio: amenpackaging.com

Registada: 2004 (21 anos)

Introdução: Amen Packaging offers a turnkey silk screen service that provides a complete finished product, including packaging, containers, and customized labeling for various products. The service includes selecting the proper container, caps, and sealers, as well as assisting with labeling needs such as colors, layouts, and designs. The silkscreening process involves creating screens and inks to produce uni…

Strategic Sourcing Conclusion and Outlook for bottle silk screen

Why is Strategic Sourcing Essential for Bottle Silk Screen?

In the competitive landscape of bottle silk screen printing, strategic sourcing emerges as a critical factor for success. By carefully selecting suppliers and optimizing procurement processes, businesses can enhance product quality while managing costs effectively. The ability to leverage diverse printing techniques—such as single and multi-color silk screening—along with innovative options like in-mold lettering, enables companies to meet varied market demands across different regions, including Africa, South America, the Middle East, and Europe.

What Should International Buyers Consider in Their Sourcing Strategy?

B2B buyers must prioritize suppliers that offer flexibility in volume and customization, ensuring their specific branding needs are met without compromising on quality. Understanding the nuances of different printing technologies, such as the use of UV inks for superior finishes, can significantly elevate the perceived value of the products. Furthermore, engaging with suppliers who emphasize quality control through rigorous proofing processes guarantees that the end product aligns with customer expectations.

How Can You Prepare for Future Trends in Bottle Silk Screen?

Looking ahead, the demand for sustainable and visually appealing packaging solutions is set to rise. International buyers should proactively seek suppliers that align with eco-friendly practices while maintaining high-quality silk screening capabilities. As the market evolves, staying informed about new printing technologies and trends will empower businesses to adapt and thrive.

Make the strategic choice today—partner with the right suppliers to not only enhance your product line but also solidify your market presence in an increasingly globalized economy.