Introduction: Navigating the Global Market for 1.5 lt bottle

In today’s fast-paced global market, sourcing a reliable supplier for 1.5 lt bottles can be a daunting challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. As businesses increasingly prioritize sustainability, functionality, and cost-effectiveness, the demand for high-quality bottles that cater to various applications—from beverage packaging to outdoor activities—has surged. This guide serves as an essential resource, meticulously outlining the different types of 1.5 lt bottles available, their applications across industries, and key considerations for supplier vetting.

Navigating the complexities of international trade can be overwhelming, especially when evaluating cost structures, quality standards, and compliance regulations. Our comprehensive exploration will empower you to make informed purchasing decisions by providing actionable insights into market trends, innovative designs, and material options that meet your specific business needs. Whether you are looking to enhance your product line with insulated options for outdoor enthusiasts or lightweight, collapsible bottles for convenience, this guide is tailored to equip you with the knowledge to thrive in the competitive landscape of bottled products. By understanding the nuances of the 1.5 lt bottle market, you can confidently forge partnerships with suppliers that align with your sustainability goals and operational requirements.

Navegação de artigos

- Top 8 1.5 Lt Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 1.5 lt bottle

- Understanding 1.5 lt bottle Types and Variations

- Key Industrial Applications of 1.5 lt bottle

- 3 Common User Pain Points for ‘1.5 lt bottle’ & Their Solutions

- Strategic Material Selection Guide for 1.5 lt bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 1.5 lt bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘1.5 lt bottle’

- Comprehensive Cost and Pricing Analysis for 1.5 lt bottle Sourcing

- Alternatives Analysis: Comparing 1.5 lt bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 1.5 lt bottle

- Navigating Market Dynamics and Sourcing Trends in the 1.5 lt bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 1.5 lt bottle

- Aviso importante e termos de utilização

- Strategic Sourcing Conclusion and Outlook for 1.5 lt bottle

Understanding 1.5 lt bottle Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Insulated Stainless Steel | Double-wall construction, vacuum insulation, leak-resistant lid | Eventos ao ar livre, presentes para empresas | Prós: Excellent temperature retention; durable. Contras: Mais pesado do que as opções de plástico. |

| Foldable Anti-Bottle | Collapsible design, lightweight, and portable with carabiner attachment | Travel, promotional giveaways | Prós: Space-saving; easy to carry. Contras: Less rigid; may not be suitable for all liquids. |

| Lightweight Plastic | Made from BPA-free recycled materials, shatter-resistant, and lightweight | Everyday hydration, schools | Prós: Affordable; easy to handle. Contras: Limited insulation; may not retain temperature well. |

| Bottled Spring Water | Pre-packaged spring water in 1.5L bottles | Retail, hospitality | Prós: Convenient; ready-to-drink. Contras: Higher cost for single-use; environmental concerns. |

| Garrafa de água desportiva | Designed for active use, often features multiple cap options | Sports teams, fitness centers | Prós: Ergonomic; easy to drink from. Contras: May require frequent cleaning; can leak if not sealed properly. |

What Are the Characteristics of Insulated Stainless Steel Bottles?

Insulated stainless steel bottles, like the 1.5L insulated water bottle, are designed for durability and temperature retention. These bottles feature a double-wall construction that keeps beverages hot or cold for extended periods, making them ideal for outdoor events and corporate gifts. B2B buyers should consider the weight and cost, as these bottles tend to be pricier and heavier than plastic alternatives but offer superior performance in temperature control.

How Do Foldable Anti-Bottles Enhance Portability?

Foldable anti-bottles are innovative products that collapse when empty, making them highly portable and space-efficient. With a carabiner attachment, they can easily clip onto bags or belts, making them suitable for travel and promotional giveaways. B2B buyers may find these bottles appealing for their convenience, but should also be aware that their flexibility may not make them suitable for all types of liquids, especially carbonated beverages.

Why Choose Lightweight Plastic Bottles for Everyday Use?

Lightweight plastic bottles are crafted from BPA-free materials and are designed to be shatter-resistant, making them a practical choice for everyday hydration. They are commonly used in schools and for general consumer purposes due to their affordability and ease of handling. However, B2B buyers should keep in mind that while these bottles are cost-effective, they offer limited insulation capabilities, which may not meet the needs of all consumers.

What Are the Benefits of Bottled Spring Water in 1.5L Sizes?

Bottled spring water in 1.5L containers is a convenient solution for retail and hospitality sectors, providing ready-to-drink hydration options. These bottles are often sourced from natural springs, appealing to health-conscious consumers. B2B buyers should consider the ongoing costs associated with single-use bottles and the environmental implications, balancing convenience with sustainability goals.

How Do Sports Water Bottles Cater to Active Lifestyles?

Sports water bottles are specifically designed for active users, often incorporating features like ergonomic shapes and various cap options for easy drinking. These bottles are ideal for sports teams and fitness centers, promoting hydration during physical activities. B2B buyers should evaluate the ease of cleaning and the sealing mechanisms, as frequent use can lead to wear and tear, impacting their longevity and functionality.

Key Industrial Applications of 1.5 lt bottle

| Indústria/Setor | Specific Application of 1.5 lt bottle | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Beverage Manufacturing | Packaging for bottled water and flavored drinks | Enhances product visibility and brand recognition | Compliance with local regulations, sustainability, cost-effectiveness |

| Recreação ao ar livre | Hydration solutions for camping and sports events | Durable and portable design meets consumer needs | Material quality, insulation capabilities, weight |

| Hospitality & Catering | Serving water in restaurants and events | Provides a premium experience for guests | Custom branding options, ease of cleaning, availability |

| Cuidados de saúde | Patient hydration solutions in hospitals | Supports patient care and hydration needs | Sterility, BPA-free materials, ease of disposal |

| Retalho | Consumer sales of reusable bottles | Promotes sustainability and reduces single-use plastics | Supply chain reliability, branding potential, pricing |

How is the 1.5 lt bottle used in beverage manufacturing, and what are the key buyer considerations?

In the beverage manufacturing industry, the 1.5 lt bottle serves as a primary packaging option for bottled water and flavored beverages. Its size is ideal for consumers seeking hydration on the go, making it a popular choice for retailers. Businesses benefit from increased brand visibility due to the ample labeling space. International buyers should consider compliance with local food safety regulations, sourcing sustainable materials, and ensuring cost-effectiveness to remain competitive in their markets.

What role does the 1.5 lt bottle play in outdoor recreation?

For outdoor recreation, the 1.5 lt bottle is essential for hydration during activities such as camping, hiking, and sports events. Its durable and portable design ensures that users can easily carry it without adding excessive weight to their gear. Buyers in this sector should prioritize materials that can withstand rugged conditions, insulation capabilities to keep beverages cold, and user-friendly features like leak-proof lids. Sourcing from manufacturers that provide reliable supply chains is also crucial to meet seasonal demand.

How is the 1.5 lt bottle utilized in the hospitality and catering sector?

In hospitality and catering, the 1.5 lt bottle is often used to serve water at restaurants, events, and hotels. Its elegant design enhances the dining experience, providing a touch of sophistication while ensuring guests stay hydrated. Buyers in this sector should consider custom branding options to promote their establishments and the ease of cleaning to maintain hygiene standards. Availability in bulk and the ability to source eco-friendly options are also significant factors for B2B buyers in hospitality.

What are the benefits of using the 1.5 lt bottle in healthcare?

In healthcare settings, the 1.5 lt bottle is crucial for ensuring patients remain hydrated. Hospitals utilize these bottles for easy access to water, promoting better health outcomes. Key considerations for buyers include ensuring the bottles are made from BPA-free materials to avoid chemical leaching, as well as their sterility and ease of disposal. Sourcing from manufacturers that offer reliable supply and compliance with healthcare regulations can significantly impact patient care.

How does the retail sector benefit from the 1.5 lt bottle?

The retail sector leverages the 1.5 lt bottle for selling reusable water bottles, appealing to environmentally conscious consumers. This size is convenient for consumers, promoting a shift away from single-use plastics. Retailers benefit from the opportunity to enhance their sustainability profile while providing a product that meets consumer demand. Buyers should focus on supply chain reliability, branding potential, and competitive pricing when sourcing these bottles to ensure profitability.

3 Common User Pain Points for ‘1.5 lt bottle’ & Their Solutions

Scenario 1: Difficulty in Maintaining Product Temperature

O problema: B2B buyers often face challenges with maintaining the temperature of beverages in 1.5-liter bottles during transportation or outdoor events. In regions with extreme weather conditions, such as the sweltering heat of South America or the harsh winters in parts of Europe, beverages can become unpalatable if they are not kept at the desired temperature. This can lead to customer dissatisfaction, increased waste, and potential loss of sales.

A solução: To tackle this issue, buyers should consider sourcing insulated 1.5-liter bottles made from double-wall stainless steel with vacuum insulation. Products like the 4-H Insulated Water Bottle are designed to keep drinks cold for hours, significantly improving the user experience. When placing orders, specify that your bottles must have insulation features to ensure optimal temperature control. Additionally, consider including a mix of wide-mouth and straw caps, which enhance usability for various consumer preferences, making it easier to hydrate quickly during events.

Scenario 2: Space Constraints in Transportation and Storage

O problema: B2B buyers often encounter logistical issues related to the storage and transportation of 1.5-liter bottles, particularly when dealing with bulk orders. Standard rigid bottles take up considerable space, leading to higher shipping costs and inefficient use of storage areas. This becomes particularly problematic for distributors who need to maximize space while ensuring product availability.

A solução: Buyers should explore flexible bottle options, such as foldable or collapsible 1.5-liter bottles like the Vapur Anti-Bottle. This product can be easily rolled or flattened when empty, allowing for efficient packing and storage. When negotiating with suppliers, emphasize the need for space-efficient designs in your specifications. Additionally, consider incorporating a clear communication strategy with your logistics team to optimize loading processes and ensure that space-saving bottles are prioritized in your shipments.

Scenario 3: Concerns About Durability and Leakage

O problema: Many B2B buyers worry about the durability of 1.5-liter bottles, especially when they are subject to rough handling during transport or in outdoor environments. Leaks can lead to product loss, damage to other goods, and a tarnished reputation. This concern is magnified in markets where buyers expect high-quality products that can withstand varied conditions, such as outdoor events or extensive travel.

A solução: To mitigate these concerns, it’s essential to source bottles with proven durability and leakproof features. For instance, the YETI Yonder 1.5L bottle comes with a 100% leakproof tether cap, which is vital for ensuring that no liquid escapes during transit. When sourcing these bottles, request samples to assess their durability firsthand. Additionally, consider offering a warranty or guarantee from the manufacturer, which can reassure your customers about the quality of the product and help reduce returns. Highlighting these features in your marketing materials can also attract buyers who prioritize reliability in their purchases.

By addressing these common pain points with strategic sourcing and product specifications, B2B buyers can enhance their offerings and improve customer satisfaction in the competitive beverage market.

Strategic Material Selection Guide for 1.5 lt bottle

What Are the Key Materials for 1.5 lt Bottles?

When selecting materials for 1.5 lt bottles, it’s essential to consider properties that affect performance, durability, and compliance with international standards. Below, we analyze four common materials used in the production of these bottles: stainless steel, plastic (PET), glass, and aluminum.

How Does Stainless Steel Perform in 1.5 lt Bottle Applications?

Stainless steel is renowned for its durability and resistance to corrosion. It can withstand high temperatures and pressures, making it suitable for a variety of applications. The key properties of stainless steel include a high tensile strength and excellent thermal conductivity, which helps maintain the temperature of the contents.

Prós: Stainless steel bottles are highly durable, resistant to impact, and do not leach chemicals into beverages. They are also easy to clean and can be reused multiple times, making them environmentally friendly.

Contras: The manufacturing process for stainless steel can be complex and costly, which may increase the retail price of the final product. Additionally, stainless steel bottles can be heavier than their plastic counterparts, which may not be ideal for all consumers.

Impacto na aplicação: Stainless steel is compatible with a wide range of beverages, including hot and cold liquids. However, it is essential to ensure that the bottle design accommodates thermal expansion.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the stainless steel used complies with ASTM or DIN standards for food safety. Additionally, they may need to consider the logistics of shipping heavier products.

What Are the Advantages of Using Plastic (PET) for 1.5 lt Bottles?

Polyethylene terephthalate (PET) is a widely used plastic for beverage bottles due to its lightweight and shatter-resistant properties. PET bottles are typically rated for moderate temperatures and pressures, making them suitable for most non-carbonated beverages.

Prós: PET bottles are cost-effective to produce and lightweight, which reduces shipping costs. They are also recyclable, aligning with sustainability goals.

Contras: While PET is durable, it can be prone to deformation under high temperatures and may leach chemicals if exposed to certain conditions. Its barrier properties are not as robust as those of glass or stainless steel.

Impacto na aplicação: PET bottles are primarily suitable for cold beverages. They may not be ideal for hot liquids or beverages requiring long shelf lives without preservatives.

Considerations for International Buyers: Compliance with food safety standards is crucial, especially in regions like Europe where regulations are stringent. Buyers should also consider local recycling capabilities when selecting PET bottles.

How Does Glass Compare as a Material for 1.5 lt Bottles?

Glass is a traditional choice for beverage containers, known for its non-reactive nature and ability to preserve flavor. It can withstand high temperatures and is often used for both hot and cold beverages.

Prós: Glass bottles are chemically inert, ensuring that no flavors or chemicals leach into the beverage. They also provide excellent barrier properties against oxygen and light, enhancing product shelf life.

Contras: Glass is heavier and more fragile than other materials, which can lead to higher shipping costs and breakage during transport. The manufacturing process is also more energy-intensive.

Impacto na aplicação: Glass bottles are suitable for a wide range of beverages, including juices, sodas, and even some alcoholic drinks. However, their weight may limit their use in outdoor or active settings.

Considerations for International Buyers: Buyers should ensure that glass bottles meet international safety standards to prevent breakage during shipping. Additionally, local regulations regarding glass recycling and disposal should be considered.

What Are the Benefits of Using Aluminum for 1.5 lt Bottles?

Aluminum is increasingly popular for beverage containers due to its lightweight and recyclable properties. It is often used in combination with a lining to prevent interaction with acidic beverages.

Prós: Aluminum bottles are lightweight, making them easy to transport. They are also highly recyclable, aligning with sustainability initiatives.

Contras: Aluminum can be prone to denting and may require a protective lining to prevent corrosion and leaching. The manufacturing process can also be more complex than that of plastic.

Impacto na aplicação: Aluminum is suitable for a variety of beverages, but compatibility with acidic drinks must be assessed. The lining used can affect the taste and quality of the beverage.

Considerations for International Buyers: Buyers should ensure compliance with international standards for food safety and recycling. In regions like the Middle East, where aluminum is commonly used, understanding local recycling practices is essential.

Summary Table of Material Selection for 1.5 lt Bottles

| Material | Typical Use Case for 1.5 lt bottle | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço inoxidável | Bebidas quentes e frias | Highly durable and reusable | Custo de fabrico mais elevado | Elevado |

| Plastic (PET) | Cold beverages | Leve e económico | Prone to deformation under heat | Baixa |

| Vidro | Juices, sodas, alcoholic drinks | Chemically inert, preserves flavor | Pesado e frágil | Médio |

| Alumínio | Carbonated and non-carbonated drinks | Lightweight and recyclable | Prone to denting, requires lining | Médio |

This strategic material selection guide provides a comprehensive overview of the materials used in 1.5 lt bottles, offering valuable insights for B2B buyers looking to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 1.5 lt bottle

What are the Key Manufacturing Processes for a 1.5-Liter Bottle?

The manufacturing of a 1.5-liter bottle involves several critical stages, each requiring specialized techniques to ensure that the final product meets quality standards. The main stages of the manufacturing process include material preparation, forming, assembly, and finishing.

Material Preparation: How is the Right Material Chosen and Processed?

The first step in manufacturing a 1.5-liter bottle is selecting the appropriate material, typically high-density polyethylene (HDPE), polycarbonate, or stainless steel, depending on the intended use. For example, HDPE is often chosen for its lightweight and durability, while stainless steel is preferred for insulated bottles. Once the material is selected, it undergoes a thorough cleaning and drying process to eliminate any impurities that could affect the final product’s quality.

Next, the material is prepared for forming. This may involve melting the plastic pellets or treating the metal to make it malleable. The preparation phase is crucial as any contamination or improper handling can lead to defects in the final product.

What Techniques are Used in the Forming Stage?

The forming process varies based on the material used. For plastic bottles, techniques such as blow molding or injection molding are common. In blow molding, heated plastic is inflated within a mold to create the desired shape, while injection molding involves injecting melted plastic into a mold to solidify.

For stainless steel bottles, deep drawing is often employed, where a flat sheet of metal is drawn into a mold to achieve the desired form. This technique requires precision to ensure that the bottle has uniform thickness and strength.

How is the Assembly Process Conducted?

After the forming stage, the next step is assembly, particularly for bottles with multiple components, such as caps or straws. Automated systems often handle this stage to ensure consistency and efficiency. The assembly process must also include quality checks to confirm that each component fits properly and functions as intended.

During assembly, leak-proof seals may be applied, and any additional features, such as handles or grips, are integrated. This stage is critical for ensuring that the final product is user-friendly and meets market demands.

What Finishing Touches are Required Before Packaging?

Finishing involves applying any necessary coatings or treatments to enhance the bottle’s appearance and functionality. This could include printing logos or branding, applying a protective layer for scratch resistance, or ensuring that the bottle is dishwasher safe.

After finishing, the bottles are subjected to a final inspection to check for surface defects, color consistency, and overall quality. Once they pass these inspections, the bottles are ready for packaging and distribution.

What Quality Assurance Measures are Essential for 1.5-Liter Bottles?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the bottles meet international standards and customer expectations. For B2B buyers, understanding the QA measures in place is crucial for making informed purchasing decisions.

Which International Standards Should Buyers Consider?

When sourcing 1.5-liter bottles, buyers should look for compliance with international standards such as ISO 9001, which focuses on quality management systems. Compliance with industry-specific standards, such as CE marking for safety or API standards for materials, may also be essential, particularly for buyers in regulated markets.

These standards help ensure that the manufacturing processes are efficient, and the products are safe and reliable. Buyers should inquire about the manufacturer’s certifications and how they align with these standards.

What are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to catch defects early. The primary checkpoints include:

-

Controlo de qualidade de entrada (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

Controlo de qualidade durante o processo (IPQC): During manufacturing, regular checks are conducted to monitor processes and detect any deviations in real-time.

-

Controlo de qualidade final (FQC): After assembly and finishing, the final products undergo thorough inspections, including functionality tests and visual assessments.

B2B buyers should inquire about the specific QC processes employed by suppliers and request access to QC reports that detail findings from these checkpoints.

How Can Buyers Verify Supplier Quality Control?

To ensure that a supplier adheres to robust quality control measures, B2B buyers should consider several verification methods:

-

Audits: Conducting regular audits of the supplier’s facilities can provide insights into their manufacturing processes and quality assurance protocols. Buyers may also choose to engage third-party auditing firms for an unbiased assessment.

-

Reports: Requesting detailed QC reports can help buyers understand the supplier’s performance over time. These reports should include information on defect rates, corrective actions taken, and compliance with relevant standards.

-

Third-party Inspections: Utilizing third-party inspection services can offer additional assurance regarding the quality of the products being supplied. This is particularly important for international transactions, where local regulations may differ.

Que nuances devem os compradores internacionais ter em conta?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are several nuances to consider:

-

Conformidade regulamentar: Different countries have varying regulations regarding materials and safety standards. Buyers must ensure that their suppliers are compliant with both local and international laws.

-

Cultural Expectations: Understanding cultural expectations related to product quality and safety can influence purchasing decisions. Buyers should engage with suppliers to clarify any concerns.

-

Supply Chain Transparency: International buyers should prioritize suppliers that maintain transparency throughout their supply chain. This includes clear communication regarding sourcing, manufacturing processes, and quality assurance measures.

In conclusion, understanding the manufacturing processes and quality assurance measures for 1.5-liter bottles is essential for B2B buyers. By focusing on material selection, forming techniques, assembly, finishing, and robust quality control practices, buyers can make informed decisions that align with their operational needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1.5 lt bottle’

In this guide, we provide a practical checklist for B2B buyers looking to procure 1.5-liter bottles. This section will help you navigate the complexities of sourcing and ensure you make informed decisions tailored to your business needs.

Passo 1: Definir as suas especificações técnicas

Start by outlining the technical specifications that are essential for your business requirements. Consider factors such as material (e.g., BPA-free plastic, stainless steel), insulation properties, and design features like leak-proof lids or portability. This clarity will guide your supplier discussions and help you avoid costly mistakes.

Passo 2: Identify Your Target Market and Use Cases

Understanding your target market is crucial. Are you supplying to outdoor enthusiasts, health-conscious consumers, or industrial clients? Each segment may prioritize different features. For instance, collapsible bottles may appeal to travelers, while insulated options are ideal for those needing temperature control.

Passo 3: Avaliar potenciais fornecedores

Before making a commitment, thoroughly vet your suppliers. Request company profiles, case studies, and references from other buyers in similar industries or regions. Look for suppliers who have a proven track record in quality and reliability, as this will minimize risks associated with your procurement.

- Check Certifications: Ensure suppliers have relevant certifications (e.g., ISO, FDA) that demonstrate compliance with safety and quality standards.

- Review Product Samples: Request samples to assess the quality firsthand, including material durability and design functionality.

Passo 4: Negociar preços e condições

Once you have shortlisted potential suppliers, initiate negotiations. Discuss pricing, minimum order quantities, and payment terms. Be prepared to leverage your research on market rates and competitors to secure the best deal.

- Consider Bulk Discounts: Inquire about volume pricing to maximize your budget.

- Clarify Lead Times: Ensure you understand the production and shipping timelines to align with your inventory needs.

Passo 5: Assess Logistics and Delivery Options

Evaluate the logistics involved in transporting the bottles from the supplier to your location. Consider shipping methods, costs, and delivery times. It’s crucial to confirm that suppliers can meet your delivery requirements to avoid disruptions in your supply chain.

- Inquire About Packaging: Ensure that the packaging is robust to prevent damage during transit.

- Evaluate Import Regulations: Be aware of any import duties or regulations that may apply in your region.

Passo 6: Implement Quality Control Measures

Establish a quality control process to ensure that the bottles received meet your specifications. This could include setting up inspections at the supplier’s facility or conducting quality checks upon receipt.

- Develop a Testing Protocol: Create a checklist for functionality, safety, and durability.

- Document Findings: Keep records of quality assessments to address any issues with the supplier promptly.

Passo 7: Build a Long-Term Relationship with Suppliers

Finally, focus on building a strong, long-term relationship with your suppliers. Open communication can lead to better pricing, priority service, and improved product offerings. Regularly review performance and provide feedback to foster collaboration.

- Schedule Regular Check-Ins: Maintain ongoing discussions to address any concerns and discuss future needs.

- Explore Co-Development Opportunities: Consider collaborating on new product designs or features that could benefit both parties.

By following this checklist, you can streamline your sourcing process for 1.5-liter bottles, ensuring you select the right suppliers and products for your business needs.

Comprehensive Cost and Pricing Analysis for 1.5 lt bottle Sourcing

What Are the Key Cost Components in Sourcing 1.5 Liter Bottles?

When sourcing 1.5-liter bottles, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materiais: The choice of materials—such as stainless steel, BPA-free plastics, or other composites—significantly affects the cost. High-quality, durable materials typically incur higher upfront costs but can lead to long-term savings through durability and reduced replacement rates.

-

Trabalho: Labor costs vary depending on the manufacturing location. Countries with lower labor costs can reduce overall production expenses, but this may impact quality and compliance with international standards.

-

Despesas gerais de fabrico: This encompasses utilities, equipment maintenance, and factory management costs. Efficient manufacturing processes can lower these overheads, thereby affecting the unit price.

-

Ferramentas: Initial tooling costs for molds and machinery can be substantial, particularly for customized designs. It’s essential to assess how these costs distribute over larger order volumes.

-

Controlo de qualidade (CQ): Implementing robust QC processes is vital, particularly for international shipments where compliance with safety standards is mandatory. These costs should be factored into the overall pricing strategy.

-

Logística: Shipping costs, including freight and insurance, vary significantly depending on the origin and destination. Understanding the most cost-effective shipping methods and routes can lead to substantial savings.

-

Margem: Suppliers typically add a profit margin that varies based on market demand, competition, and the perceived value of their products.

How Do Price Influencers Impact the Cost of 1.5 Liter Bottles?

Several factors influence the pricing of 1.5-liter bottles beyond the base cost structure:

-

Volume/MOQ: Minimum Order Quantities (MOQ) often dictate pricing tiers. Larger orders usually yield lower per-unit costs, making it crucial for buyers to negotiate optimal order sizes.

-

Especificações e personalização: Custom designs, colors, or features can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materiais e certificações de qualidade: Bottles made from certified, eco-friendly materials may come at a premium. Buyers should consider the long-term benefits of investing in higher-quality products.

-

Factores do fornecedor: Supplier reputation, reliability, and service quality can influence pricing. Established suppliers may charge more but offer better assurance of quality and compliance.

-

Incoterms: The terms of shipping and responsibility for costs can significantly impact overall pricing. Familiarity with Incoterms can help buyers negotiate better terms.

What Are Some Effective Buyer Tips for Sourcing 1.5 Liter Bottles?

International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiate: Always negotiate pricing, especially when placing large orders. Suppliers may have flexibility in pricing that can lead to significant savings.

-

Considerar o custo total de propriedade (TCO): Evaluate not just the purchase price but also the long-term costs associated with the product, such as shipping, durability, and maintenance.

-

Compreender as nuances dos preços: Be aware that prices may vary significantly by region due to local manufacturing capabilities, labor costs, and supply chain logistics.

-

Research Local Regulations: Compliance with local regulations and standards can affect sourcing decisions. Ensure that suppliers can meet these requirements to avoid costly delays or fines.

-

Criar relações: Establishing strong relationships with suppliers can facilitate better pricing, improved service, and quicker resolution of issues.

Declaração de exoneração de responsabilidade sobre os preços

Prices for 1.5-liter bottles can fluctuate based on market conditions, material costs, and supplier capabilities. The figures mentioned are indicative and should be verified with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing 1.5 lt bottle With Other Solutions

Exploring Alternatives to the 1.5 Liter Bottle for Effective Hydration Solutions

In the realm of hydration solutions, the 1.5-liter bottle has established itself as a popular choice for many businesses. However, various alternatives offer unique advantages and cater to different user needs. This analysis will compare the 1.5-liter bottle against two viable alternatives: the collapsible water bottle and the insulated water container. Understanding these options helps B2B buyers make informed decisions that align with their operational requirements.

| Aspeto de comparação | 1.5 Lt Bottle | Collapsible Water Bottle (Vapur Anti-Bottle) | Insulated Water Container (YETI Yonder) |

|---|---|---|---|

| Desempenho | Holds a standard 1.5L of liquid; durable | Stands when full; collapsible when empty | Keeps drinks cold or hot; lightweight |

| Custo | Approximately $20 | Approximately $15.99 | Approximately $30 |

| Facilidade de implementação | Simple design; easy to use | Requires initial learning for folding | User-friendly with intuitive cap design |

| Manutenção | Dishwasher safe; standard cleaning | Dishwasher safe; easy to clean | Dishwasher safe; durable materials |

| Melhor caso de utilização | Hidratação diária, actividades ao ar livre | Travel, hiking, and compact storage | Outdoor adventures, where temperature control is needed |

Pros and Cons of Each Alternative Solution

Collapsible Water Bottle (Vapur Anti-Bottle)

The Vapur Anti-Bottle offers a unique solution for those who prioritize portability. When full, it stands upright, but once emptied, it can be rolled or folded, making it easy to store in bags or pockets. This feature is particularly beneficial for travelers or outdoor enthusiasts who want to minimize bulk. However, it may not provide the same robustness as a traditional bottle, potentially affecting long-term durability.

Insulated Water Container (YETI Yonder)

The YETI Yonder is designed with insulation in mind, keeping beverages at the desired temperature for extended periods. Its lightweight construction makes it ideal for outdoor activities where hydration is essential. The bottle’s 100% leakproof tether cap adds an extra layer of security, preventing spills. However, its higher price point may be a consideration for budget-conscious buyers, and it is not designed for hot or carbonated beverages.

Conclusion: Making the Right Choice for Your Business Needs

When selecting the most appropriate hydration solution, B2B buyers should consider their specific needs, such as the intended use, budget, and required features. The 1.5-liter bottle serves as a reliable option for everyday hydration, while the collapsible water bottle offers unmatched portability for those on the go. On the other hand, the insulated container is perfect for outdoor activities where temperature control is critical. By evaluating these alternatives against their operational requirements, businesses can make informed choices that enhance their hydration strategies.

Essential Technical Properties and Trade Terminology for 1.5 lt bottle

What are the Key Technical Properties of a 1.5 L Bottle?

Understanding the technical specifications of a 1.5-liter bottle is crucial for B2B buyers in sectors such as beverage manufacturing, packaging, and retail. Here are several essential properties to consider:

-

Composição do material

The most common materials used for 1.5 L bottles include polyethylene terephthalate (PET), stainless steel, and high-density polyethylene (HDPE). Each material has unique benefits: PET is lightweight and offers excellent clarity, stainless steel provides durability and insulation, while HDPE is flexible and resistant to impact. Selecting the right material impacts not only the bottle’s functionality but also its recycling capabilities, which can be a crucial consideration for environmentally-conscious companies. -

Capacity and Dimensions

The stated capacity of 1.5 liters is a standard measurement, but it’s essential to verify the exact dimensions of the bottle, including height, width, and weight. This is particularly important for logistics and storage solutions. Bottles that are too tall or wide may not fit standard shipping containers or retail displays, affecting supply chain efficiency. -

Resistência à fuga

A reliable leak-proof design is vital for maintaining product integrity during transport and storage. Features such as dual-threaded caps and silicone gaskets can enhance leak resistance. For buyers, understanding the engineering behind these features can help mitigate risks related to product loss and customer dissatisfaction. -

Thermal Properties

For insulated bottles, thermal retention capabilities are important. Double-wall vacuum insulation can keep liquids cold or hot for extended periods. This property is particularly beneficial in markets where beverage temperature is a critical selling point. Buyers should consider the insulation performance claims and how they align with their target customer needs. -

Reciclabilidade

Sustainability is becoming a key factor in purchasing decisions. The recyclability of the bottle material affects both environmental impact and compliance with regulations in various markets. B2B buyers should inquire about the recycling processes and certifications associated with the materials used in the bottles to ensure they meet corporate sustainability goals.

What are Common Trade Terms Related to 1.5 L Bottles?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should know:

-

OEM (Fabricante de Equipamento Original)

This refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of 1.5 L bottles, OEM relationships can influence quality control and customization options, allowing businesses to tailor products to their specifications. -

MOQ (Quantidade mínima de encomenda)

MOQ represents the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and cost efficiency. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess stock or missed opportunities. -

RFQ (Pedido de Cotação)

An RFQ is a document that buyers send to suppliers to request pricing and terms for a specific quantity of products. This process is essential for obtaining competitive pricing and understanding the financial implications of potential purchases. -

Incoterms (Termos Comerciais Internacionais)

These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and risks during international transactions, particularly relevant in regions like Africa and South America where logistics can be complex. -

Prazo de execução

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is critical for inventory planning and ensuring that supply chains run smoothly. Buyers should communicate clearly with suppliers about expected lead times to align with their operational needs. -

Customs Compliance

This term involves adhering to the regulations governing the import and export of goods. For international buyers, understanding customs compliance is vital to avoid delays and penalties. Ensuring that bottles meet local regulations can facilitate smoother transactions and market entry.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their supply chain efficiency and product offerings in the competitive market of 1.5 L bottles.

Navigating Market Dynamics and Sourcing Trends in the 1.5 lt bottle Sector

What Are the Key Market Dynamics Influencing the 1.5 lt Bottle Sector?

The 1.5-liter bottle sector is experiencing significant growth, driven by several global factors. Increased consumer awareness regarding hydration and health is pushing demand across various regions, particularly in Africa, South America, the Middle East, and Europe. The rising trend of outdoor activities and fitness regimes has led to a surge in the purchase of reusable water bottles, which are seen as both practical and environmentally friendly. Additionally, the growing emphasis on convenience and portability has led to innovations in bottle design, including collapsible and lightweight options, appealing to both individual consumers and businesses.

Emerging B2B technologies are also reshaping sourcing trends in this sector. The integration of e-commerce platforms and digital supply chain management systems is streamlining procurement processes, making it easier for international buyers to source products from manufacturers worldwide. Furthermore, data analytics is being utilized to forecast demand, optimize inventory levels, and enhance customer experience. As sustainability becomes a focal point, manufacturers are investing in advanced materials that are not only lightweight but also environmentally sustainable, thus catering to the increasing consumer demand for eco-friendly products.

How Is Sustainability Shaping the Sourcing of 1.5 lt Bottles?

Sustainability is no longer a mere trend; it has become a critical factor in the sourcing of 1.5-liter bottles. The environmental impact of plastic waste is prompting businesses to seek alternatives that minimize their carbon footprint. Ethical sourcing practices are gaining traction, with companies increasingly favoring suppliers who demonstrate a commitment to sustainable production methods. This includes using recycled materials, reducing energy consumption, and implementing waste management strategies.

Certifications such as the Global Recycled Standard (GRS) and the Forest Stewardship Council (FSC) are becoming essential for businesses that wish to assure their customers of their environmental responsibility. In addition, many manufacturers are adopting bioplastics and other sustainable materials that reduce reliance on fossil fuels, thereby appealing to eco-conscious consumers and businesses alike. As international B2B buyers prioritize sustainability in their procurement strategies, the demand for 1.5-liter bottles made from eco-friendly materials will likely continue to rise.

What Has Been the Evolution of the 1.5 lt Bottle Market?

The 1.5-liter bottle has evolved significantly over the decades, transitioning from traditional glass and rigid plastic designs to more innovative, user-friendly options. Initially popularized for bottled water, these bottles have expanded into various sectors, including sports drinks and personal hydration solutions. The introduction of features such as collapsibility, insulation, and multi-functionality has broadened their appeal.

Technological advancements have also played a crucial role in this evolution. The development of lightweight, durable materials has made it feasible for manufacturers to create bottles that are not only functional but also environmentally sustainable. As a result, the market has seen a shift towards brands that prioritize design and sustainability, aligning with consumer preferences for products that enhance their lifestyle while minimizing environmental impact.

Frequently Asked Questions (FAQs) for B2B Buyers of 1.5 lt bottle

-

How do I choose the right supplier for 1.5 lt bottles?

Selecting the right supplier involves assessing several key factors. Start by verifying the supplier’s credentials, including certifications for quality and safety standards. Check their experience in the industry, particularly in your target market regions such as Africa or South America. Additionally, request samples to evaluate product quality and understand their manufacturing capabilities. It’s also beneficial to read reviews and testimonials from other B2B buyers. Establishing clear communication and responsiveness during initial interactions can indicate their reliability and customer service standards. -

What is the best material for 1.5 lt bottles?

The best material depends on your target market and intended use. For durability and temperature retention, stainless steel is highly recommended, particularly for insulated bottles. If lightweight and portability are priorities, consider BPA-free plastics. For eco-conscious consumers, look for suppliers offering recycled materials. Additionally, consider the environmental regulations in your target regions, as some markets may favor sustainable options. Ultimately, assessing the specific needs of your customer base will guide you to the most suitable material. -

What are the typical minimum order quantities (MOQs) for 1.5 lt bottles?

Minimum order quantities for 1.5 lt bottles can vary significantly based on the supplier and product type. Generally, MOQs can range from 500 to 5,000 units. Factors influencing MOQs include production capabilities, customization requests, and material sourcing. When negotiating, inquire about flexibility with MOQs, especially if you are a smaller business or testing a new product line. Establishing a good relationship with suppliers can sometimes lead to lower MOQs for future orders. -

How can I customize my 1.5 lt bottles for branding?

Customization options for 1.5 lt bottles often include printing logos, selecting colors, and choosing specific materials. Discuss your branding goals with suppliers, as many offer various printing techniques such as screen printing or laser engraving. Additionally, consider custom shapes or features that enhance usability, like unique caps or handles. Be sure to request a mock-up before finalizing orders to ensure the design aligns with your brand identity. Understanding the additional costs associated with customization is also crucial for budget planning. -

What payment terms should I expect when sourcing internationally?

Payment terms can vary widely between suppliers, but common options include 30% upfront deposit with the balance due upon shipment, or full payment before production. Always clarify terms in writing to avoid misunderstandings. Consider using secure payment methods such as letters of credit or escrow services, especially for large transactions, to mitigate risks. Additionally, familiarize yourself with currency exchange rates and any transaction fees that may apply when dealing with international suppliers. -

How can I ensure quality assurance (QA) for my 1.5 lt bottles?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request that suppliers provide documentation of their QA processes, including material certifications and inspection reports. It’s advisable to conduct a factory audit or hire third-party inspection services to verify compliance with your quality standards. Implementing a sample approval process before mass production is also crucial. Continuous communication during the production phase can help address any potential quality issues promptly. -

What logistics considerations should I be aware of when importing 1.5 lt bottles?

Logistics for importing 1.5 lt bottles involve several critical factors, including shipping methods, customs regulations, and lead times. Determine the most cost-effective shipping option—air freight is faster but more expensive, while sea freight is economical but takes longer. Familiarize yourself with import duties and taxes applicable in your country to avoid unexpected costs. Additionally, ensure that your supplier provides proper documentation to facilitate smooth customs clearance. Planning ahead for lead times can help manage inventory effectively. -

Are there specific regulations for importing 1.5 lt bottles in different regions?

Yes, regulations for importing 1.5 lt bottles vary by region and can include safety standards, material restrictions, and labeling requirements. For instance, the European Union has stringent regulations regarding BPA and other harmful substances in plastic products. Similarly, some African and South American countries may impose specific environmental guidelines. Research the import regulations for your target markets thoroughly, and consult with legal or trade experts to ensure compliance. This proactive approach can prevent costly delays and fines during the import process.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.

Top 8 1.5 Lt Bottle Manufacturers & Suppliers List

1. Hydrapak – Flux™ 1.5L

Domínio: hydrapak.com

Registada: 1996 (29 anos)

Introdução: {“product_name”:”Flux™ 1.5L”,”capacity”:”1.5 liters”,”features”:[“Flexible design”,”Easy to fill and clean”,”Durable materials”,”Compatible with standard water filters”],”dimensions”:”Not specified”,”weight”:”Not specified”,”color_options”:[“Clear”,”Blue”,”Green”],”usage”:”Ideal for outdoor activities such as hiking and camping.”}

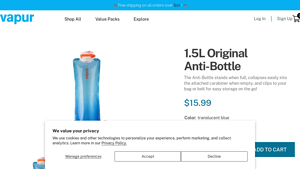

2. Vapur – 1.5L Original Anti-Bottle

Domínio: vapur.us

Registada: 2009 (16 anos)

Introdução: {“name”: “1.5L Original Anti-Bottle”, “price”: “$15.99”, “color”: “Translucent Blue”, “features”: [“Collapsible design that stands when full and collapses when empty”, “Integrated carabiner for easy attachment”, “Spill-proof with a tough seal and flip open spout”, “Wide mouth design for easy filling”, “Lightweight (under 2 ounces when empty)”, “Dishwasher safe”, “BPA-free, BPS-free, and Phthalate-…

3. Arrowhead® – 1.5 Liter Bottled Spring Water

Domínio: arrowheadwater.com

Registada: 1999 (26 anos)

Introdução: {“product_name”: “1.5 Liter Bottled Spring Water”, “brand”: “Arrowhead®”, “type”: “100% Mountain Spring Water”, “bottle_size”: “50.7 fl oz (1.5L)”, “serving_size”: “Per serving”, “calories”: “0mg”, “total_fat”: “0mg”, “sodium”: “0mg”, “protein”: “0mg”, “ingredients”: “Spring water”, “packaging_options”: [“Single”, “12 Pack”], “usage”: “Great for a crowd or keeping yourself hydrated!”}

4. SIGG – 1.5 Litre Reusable Water Bottles

Domínio: sigg.com

Registada: 2003 (22 anos)

Introdução: SIGG 1.5 litre water bottles are reusable, environmentally friendly, and made with high-quality standards. They are designed for hydration during work, school, and outdoor activities. The bottles are leak-proof, suitable for carbonated and non-carbonated drinks, and lightweight, making them ideal for outdoor use. The aluminum bottles are free from harmful substances like estrogenic substances and …

5. Evian – 1.5 Liter Bottle

Domínio: evian.com

Registada: 1997 (28 anos)

Introdução: {“product_name”:”evian® 1.5 Liter Bottle”,”description”:”Keep the whole family hydrated with the evian 1.5L bottle. It’s perfect for sharing at home, hydrating at work, or simply replenishing you throughout the day.”,”packaging”:”Available in a pack of six”,”mineral_composition”:{“calcium_mg_per_L”:”80″,”magnesium_mg_per_L”:”26″,”potassium_mg_per_L”:”1″,”bicarbonates_mg_per_L”:”360″,”silica_mg_per…

6. Stanley – Classic Legendary Vacuum Insulated Bottle

Domínio: stanley1913.com

Registado: 2019 (6 anos)

Introdução: Classic Legendary Vacuum Insulated Bottle | 1.5 QT | Stanley

– Price: $33.75 (Regular price: $45.00, Discount: $11.25)

– Size: 1.5 QT

– Material: Recycled 18/8 stainless steel, BPA-free

– Insulation: Double-wall vacuum insulation

– Features: Leakproof, packable, insulated lid doubles as a cup, twist-and-pour stopper for smoother pouring, collapsible handle for easy grab-and-go

– Weight: 2 lb.

– Di…

7. Poland Spring® – 1.5 Liter Bottled Spring Water

Domínio: polandspring.com

Registada: 1996 (29 anos)

Introdução: {“Product Name”: “1.5 Liter Bottled Spring Water”, “Brand”: “Poland Spring®”, “Size”: “1.5 Liter”, “Bottle Material”: “100% recycled plastic (excluding label and cap)”, “Calories”: “0mg”, “Total Fat”: “0mg”, “Sodium”: “0mg”, “Protein”: “0mg”, “Ingredients”: “Spring Water, Naturally occurring electrolytes for a crisp taste”, “Recyclable”: “Yes, bottles are recyclable (excluding cap and label)”}

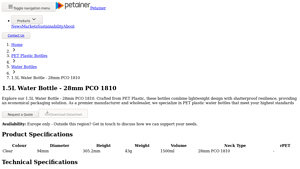

8. Petainer – 1.5L Water Bottle

Domínio: petainer.com

Registada: 2006 (19 anos)

Introdução: {‘name’: ‘1.5L Water Bottle – 28mm PCO 1810’, ‘material’: ‘PET (up to 100% rPET)’, ‘colour’: ‘Clear’, ‘diameter’: ’94mm’, ‘height’: ‘305.2mm’, ‘weight’: ’43g’, ‘volume’: ‘1500ml’, ‘neck_type’: ’28mm PCO 1810′, ‘compliance’: ‘FDA Compliant / EU Food Contact Compliant’, ‘manufacturing_process’: ‘Blow Molding’, ‘energy_source’: ‘100% Renewable’, ‘recyclable’: ‘Fully recyclable’, ‘UV_protection’: ‘Opt…

Strategic Sourcing Conclusion and Outlook for 1.5 lt bottle

In the rapidly evolving landscape of 1.5-liter bottles, strategic sourcing emerges as a pivotal component for B2B buyers aiming to enhance their supply chain efficiency and product offerings. The diverse range of options—from insulated stainless steel to foldable designs—presents unique opportunities to cater to varying consumer preferences across different markets. Buyers should prioritize suppliers that offer innovative features, such as leak-proof designs and portability, which are increasingly valued in regions like Africa, South America, and Europe.

Moreover, understanding regional demand dynamics and sustainability trends is crucial. As consumers become more environmentally conscious, sourcing products made from recycled materials or those that promote reusable solutions will not only align with market expectations but also enhance brand loyalty.

Looking ahead, international buyers are encouraged to forge partnerships with manufacturers that prioritize quality, sustainability, and innovation. By doing so, they can stay ahead of market trends and meet the growing demand for versatile hydration solutions. Embrace the opportunity to enhance your product line with strategic sourcing—it’s a decisive step toward future-proofing your business in the global marketplace.