Introduction: Navigating the Global Market for custom stainless steel water bottle

Navigating the global market for custom stainless steel water bottles presents both opportunities and challenges for B2B buyers. As the demand for eco-friendly and personalized hydration solutions grows, sourcing the right products can be daunting, especially for international buyers from regions like Africa, South America, the Middle East, and Europe, including Germany and Nigeria. This guide aims to demystify the complexities of selecting custom stainless steel water bottles, offering insights into various types, applications, and supplier vetting processes.

By delving into aspects such as cost considerations, customization options, and sustainability features, this comprehensive resource empowers B2B buyers to make informed purchasing decisions. Understanding the nuances of the market will enable you to identify suppliers who not only meet your quality standards but also align with your brand values. Whether you’re looking to enhance your promotional offerings or meet corporate sustainability goals, this guide equips you with the knowledge to navigate the landscape effectively.

With the growing emphasis on reducing plastic waste, investing in custom stainless steel water bottles is not just a trend but a strategic move towards sustainability and brand differentiation. Engage with this guide to unlock actionable insights that will elevate your procurement strategy and strengthen your market position.

Navegação de artigos

- Top 7 Custom Stainless Steel Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom stainless steel water bottle

- Understanding custom stainless steel water bottle Types and Variations

- Key Industrial Applications of custom stainless steel water bottle

- 3 Common User Pain Points for ‘custom stainless steel water bottle’ & Their Solutions

- Strategic Material Selection Guide for custom stainless steel water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for custom stainless steel water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom stainless steel water bottle’

- Comprehensive Cost and Pricing Analysis for custom stainless steel water bottle Sourcing

- Alternatives Analysis: Comparing custom stainless steel water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for custom stainless steel water bottle

- Navigating Market Dynamics and Sourcing Trends in the custom stainless steel water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom stainless steel water bottle

- Aviso importante e termos de utilização

- Strategic Sourcing Conclusion and Outlook for custom stainless steel water bottle

Understanding custom stainless steel water bottle Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Insulated Sports Bottles | Double-wall vacuum insulation; designed for active use | Corporate gifts, sports events | Prós: Keeps beverages hot/cold for hours; durable. Contras: Heavier than standard bottles. |

| Customizable Tumblers | Available in various sizes and colors; branding options | Promotional giveaways, events | Prós: High visibility for branding; versatile use. Contras: Limited capacity options compared to bottles. |

| Eco-Friendly Options | Made from recycled materials; BPA-free; sustainable | Green initiatives, corporate responsibility | Prós: Appeals to eco-conscious consumers; enhances brand image. Contras: May have higher upfront costs. |

| Multi-Functional Bottles | Combines water bottle and tumbler; often includes straws | Retail, hospitality, and events | Prós: Versatile use; increases customer engagement. Contras: Can be more complex to manufacture. |

| Travel-Sized Bottles | Compact design; fits in bags and cup holders | Travel-related promotions, giveaways | Prós: Convenient for on-the-go; ideal for events. Contras: Smaller capacity may not suit all users. |

What Are Insulated Sports Bottles and Their B2B Applications?

Insulated sports bottles are designed with double-wall vacuum insulation, ensuring that beverages remain at their desired temperature for extended periods. These bottles are particularly popular in the corporate gifting sector, especially for sports events and health-focused promotions. When considering these products, B2B buyers should prioritize durability, ease of cleaning, and the potential for branding. Their robust construction makes them ideal for both indoor and outdoor activities, appealing to companies looking to promote an active lifestyle.

How Do Customizable Tumblers Serve Businesses?

Customizable tumblers offer a canvas for branding, available in various sizes and colors. They are frequently used for promotional giveaways and events where visibility is key. For B2B buyers, the ability to personalize these products enhances brand recognition and loyalty. Considerations include the imprint area for logos and the durability of the materials. Tumblers can also serve dual purposes, functioning as both drinkware and promotional items, making them an attractive choice for businesses.

Why Choose Eco-Friendly Options for Corporate Responsibility?

Eco-friendly stainless steel water bottles are manufactured using recycled materials and are BPA-free, aligning with corporate sustainability goals. These options are increasingly popular among businesses looking to enhance their green initiatives and appeal to environmentally conscious consumers. When purchasing, B2B buyers should evaluate the certifications of the materials used and the overall lifecycle of the product. While they may have a higher initial cost, the positive brand image and consumer appeal can yield significant long-term benefits.

What Are the Benefits of Multi-Functional Bottles?

Multi-functional bottles combine the features of a water bottle and a tumbler, often equipped with straws or lids that cater to various drinking preferences. These products are ideal for retail environments, hospitality settings, and event promotions. B2B buyers should consider the versatility of these bottles, as they can increase customer engagement and satisfaction. While they may require more complex manufacturing processes, the multifunctionality can justify the investment by appealing to a broader audience.

How Do Travel-Sized Bottles Fit into B2B Marketing Strategies?

Travel-sized bottles are compact and designed to fit conveniently in bags and cup holders, making them perfect for travel-related promotions and giveaways. These products are particularly suitable for businesses targeting frequent travelers or those in the tourism and hospitality sectors. B2B buyers should assess the capacity and design to ensure they meet the needs of on-the-go consumers. Despite their smaller size, these bottles can drive brand awareness, especially when distributed at events or included in travel kits.

Key Industrial Applications of custom stainless steel water bottle

| Indústria/Setor | Specific Application of Custom Stainless Steel Water Bottle | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Corporate Branding | Employee gifts or promotional giveaways with company logos | Enhances brand visibility and employee engagement | Customization options, minimum order quantities, lead times |

| Fitness and Wellness | Gym memberships or health programs offering branded hydration solutions | Promotes healthy lifestyles and brand loyalty | Durability, insulation properties, and eco-friendly materials |

| Hospitality and Events | Custom bottles for hotels, resorts, or events as part of guest amenities | Adds value to guest experience and promotes sustainability | Design flexibility, volume discounts, and quick turnaround |

| Educational Institutions | School or university merchandise for students and staff | Encourages school spirit and environmental responsibility | Safety certifications, customization options, and pricing |

| Outdoor and Adventure Gear | Customizable bottles for outdoor events or adventure tours | Enhances brand presence in niche markets | Functionality, material quality, and branding opportunities |

How Are Custom Stainless Steel Water Bottles Used in Corporate Branding?

In the corporate sector, custom stainless steel water bottles serve as effective promotional items or employee gifts. Businesses can imprint their logos and branding messages, enhancing visibility and fostering a sense of community among employees. This approach not only promotes brand loyalty but also emphasizes a commitment to sustainability, as stainless steel bottles are reusable and environmentally friendly. For international buyers, key considerations include ensuring that the design aligns with brand identity and that the bottles meet local regulations regarding material safety.

What Role Do Custom Stainless Steel Water Bottles Play in Fitness and Wellness?

Fitness centers and wellness programs often utilize custom stainless steel water bottles as part of their branding strategy. By offering these bottles to members, they promote a healthy lifestyle while also enhancing their brand image. These bottles are durable, insulated, and can be customized with logos, making them ideal for gyms and health clubs. Buyers in regions like Africa and South America should prioritize sourcing bottles that are not only functional but also eco-friendly to align with growing consumer preferences for sustainable products.

How Can Hospitality Businesses Benefit from Custom Stainless Steel Water Bottles?

In the hospitality industry, custom stainless steel water bottles can be used as part of guest amenities in hotels and resorts. Providing guests with high-quality, branded bottles enhances their overall experience and reinforces the establishment’s commitment to sustainability. This practice also encourages guests to reduce plastic waste during their stay. Buyers should consider design flexibility and volume discounts when sourcing these products to ensure they meet the aesthetic and functional needs of their clientele.

Why Are Custom Bottles Important for Educational Institutions?

Educational institutions can leverage custom stainless steel water bottles as merchandise for students and staff. These bottles not only foster school spirit but also promote environmental responsibility among students. By providing a practical solution for hydration, schools can encourage healthy habits. Key sourcing considerations for educational buyers include safety certifications and the availability of customization options that reflect the institution’s branding.

How Are Custom Stainless Steel Water Bottles Used in Outdoor and Adventure Gear?

Outdoor brands and adventure tour companies can utilize custom stainless steel water bottles to enhance their offerings. These bottles are perfect for outdoor events, providing hydration solutions that are both practical and stylish. Customization options allow businesses to create unique designs that appeal to their target audience. When sourcing these products, businesses should focus on the durability and insulation properties of the bottles to ensure they withstand various outdoor conditions while promoting their brand effectively.

3 Common User Pain Points for ‘custom stainless steel water bottle’ & Their Solutions

Scenario 1: Sourcing Sustainable Custom Bottles for Eco-Conscious Brands

O problema: As global awareness of environmental issues rises, many B2B buyers are under pressure to source sustainable products that align with eco-friendly practices. Custom stainless steel water bottles are a popular choice, but buyers often face challenges in verifying the sustainability claims of manufacturers. They may encounter suppliers who use subpar materials, leading to concerns about product safety and environmental impact. This uncertainty can complicate procurement decisions, especially for companies that aim to project a green image.

A solução: To effectively source sustainable custom stainless steel water bottles, buyers should prioritize suppliers that provide transparency in their production processes. Look for manufacturers who offer certifications, such as BPA-free, eco-friendly materials, and energy-efficient production practices. Engaging in direct communication with suppliers to inquire about sourcing methods, recycling policies, and material origins can help ensure that the products meet sustainability standards. Additionally, consider suppliers that offer a range of customization options, allowing your brand to stand out while adhering to eco-conscious principles. Utilizing platforms that aggregate eco-friendly suppliers can also streamline the search process, ensuring that you are working with companies dedicated to sustainability.

Scenario 2: Navigating Design Options for Customization

O problema: B2B buyers often struggle with the myriad design options available for custom stainless steel water bottles. With various sizes, colors, and personalization options like logos or custom etching, the decision-making process can become overwhelming. Additionally, buyers may worry about whether the chosen designs will resonate with their target audience, leading to potential misalignment between the product and brand identity.

A solução: To navigate the design landscape effectively, buyers should begin by conducting market research to understand their target audience’s preferences and behaviors. Use surveys or focus groups to gather insights on color schemes, sizes, and features that appeal to your customer base. Collaborating with design experts or utilizing design software provided by suppliers can help visualize the final product before placing an order. It’s also beneficial to request prototypes from manufacturers, allowing for adjustments based on feedback. This iterative process not only helps refine the design but also ensures that the final product resonates with your audience, enhancing brand loyalty and customer satisfaction.

Scenario 3: Overcoming Quality Assurance Challenges

O problema: Quality assurance is a critical concern for B2B buyers of custom stainless steel water bottles, particularly when purchasing in bulk. Issues such as inconsistent product quality, varying insulation performance, and durability can lead to customer complaints and damage to brand reputation. Buyers may find it difficult to establish quality standards and communicate these effectively with suppliers, leading to further complications during production.

A solução: To overcome quality assurance challenges, B2B buyers should implement a robust supplier evaluation process that includes quality control measures. Establish clear specifications and quality benchmarks before engaging with manufacturers. Request samples to evaluate the quality of materials, insulation capabilities, and overall craftsmanship. Additionally, consider establishing a partnership with suppliers that have established quality control protocols and can provide detailed reports on production standards. Implementing regular audits or inspections during the production process can also help ensure that the final products meet your quality expectations. This proactive approach minimizes the risk of receiving subpar products and protects your brand’s reputation in the marketplace.

Strategic Material Selection Guide for custom stainless steel water bottle

When selecting materials for custom stainless steel water bottles, several factors must be considered, including performance properties, manufacturing complexity, and compliance with international standards. Below is an analysis of four common materials used in the production of stainless steel water bottles, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of 304 Stainless Steel for Water Bottles?

304 stainless steel is one of the most commonly used grades for manufacturing water bottles. It offers excellent corrosion resistance and is suitable for both hot and cold beverages. With a temperature rating of up to 870°C (1600°F), it can withstand significant thermal stress without warping. This material is also non-reactive, meaning it won’t impart any flavors or odors to the contents.

Prós: The durability of 304 stainless steel makes it ideal for long-term use, and its resistance to rust and corrosion ensures longevity. It is also relatively easy to manufacture and can be polished to a high shine, enhancing aesthetic appeal.

Contras: The primary drawback is the cost, which can be higher than other materials. Additionally, while it is durable, it can be prone to scratches, which may affect its appearance over time.

How Does 316 Stainless Steel Compare for Custom Water Bottles?

316 stainless steel is another popular choice, particularly for applications requiring enhanced corrosion resistance, such as in marine environments. It has a similar temperature rating to 304 but includes molybdenum, which provides additional protection against chloride corrosion.

Prós: This material is exceptionally durable and resistant to pitting and crevice corrosion, making it suitable for various climates and conditions. It is also non-reactive, ensuring that beverages maintain their original taste.

Contras: The cost of 316 stainless steel is significantly higher than 304, which may not be feasible for all buyers. Additionally, its increased density can make the final product heavier.

What Role Does Aluminum Play in Water Bottle Manufacturing?

While not stainless steel, aluminum is often used in combination with stainless steel for lightweight designs. Aluminum bottles are typically coated to prevent reaction with acidic beverages.

Prós: Aluminum is lightweight and can be produced at a lower cost than stainless steel. It is also easily shaped, allowing for more design flexibility.

Contras: The primary disadvantage is its susceptibility to corrosion if the protective coating is damaged. Additionally, aluminum can impart a metallic taste to beverages unless properly coated.

How Do BPA-Free Plastics Integrate with Stainless Steel Bottles?

BPA-free plastics are often used for components like lids and seals in stainless steel water bottles. These plastics are designed to withstand a range of temperatures and are resistant to impact.

Prós: The use of BPA-free plastics reduces health risks associated with traditional plastics and adds versatility to bottle designs. They are also lightweight and can be produced at a lower cost.

Contras: While they are durable, plastics can degrade over time, especially with exposure to UV light and heat. They also may not be as environmentally friendly as stainless steel.

Summary of Material Selection for Custom Stainless Steel Water Bottles

| Material | Typical Use Case for custom stainless steel water bottle | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço inoxidável 304 | General-purpose bottles for hot and cold beverages | Excelente resistência à corrosão | Higher cost, prone to scratches | Médio |

| Aço inoxidável 316 | Marine and harsh environment applications | Resistência superior à corrosão | Very high cost, heavier weight | Elevado |

| Alumínio | Lightweight bottles, often for sports and outdoor use | Lightweight, lower cost | Susceptible to corrosion | Baixa |

| BPA-Free Plastics | Lids and seals for stainless steel bottles | Reduces health risks | Degrades over time | Baixa |

This analysis provides a comprehensive overview of the materials available for custom stainless steel water bottles, helping international B2B buyers make informed decisions based on their specific requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for custom stainless steel water bottle

What Are the Main Stages of Manufacturing Custom Stainless Steel Water Bottles?

The manufacturing of custom stainless steel water bottles involves several critical stages that ensure the final product meets both aesthetic and functional requirements. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Custom Stainless Steel Water Bottles?

The process begins with the selection of high-quality stainless steel, typically 304 or 316 grades, known for their corrosion resistance and durability. Steel sheets are sourced from reputable suppliers, ensuring they meet international quality standards. The material is then cut into specific sizes and shapes, depending on the design of the water bottle. This preparation stage is crucial, as it lays the foundation for the strength and longevity of the final product.

What Techniques Are Used in Forming Custom Stainless Steel Water Bottles?

Once the material is prepared, the forming process begins. This stage typically employs techniques such as deep drawing, spinning, or hydroforming to shape the stainless steel into the desired bottle form. Deep drawing involves using a die to pull the steel into the shape of the bottle, while spinning uses a rotating mandrel to mold the material. Hydroforming uses high-pressure fluid to achieve complex shapes. Each technique has its advantages, and the choice often depends on the bottle design and production volume.

How Is the Assembly Process Conducted for Custom Water Bottles?

After forming, the assembly stage involves adding components such as lids, caps, and insulation layers. This is where customization comes into play. Buyers can opt for various lid styles, including flip-top or screw-on caps, and can choose insulation options that enhance temperature retention. The assembly is done using automated machinery for precision and consistency, but skilled labor is also employed to ensure quality, especially in custom designs.

What Finishing Techniques Are Commonly Used in Custom Stainless Steel Bottles?

The finishing process enhances both the appearance and functionality of the water bottles. Techniques such as polishing, sandblasting, or powder coating are commonly used. Polishing gives the stainless steel a shiny finish, while sandblasting creates a matte texture. Powder coating allows for a wide range of colors and custom designs, making the bottles visually appealing for branding purposes. This stage also includes the application of any custom logos or designs through methods like laser engraving or screen printing, ensuring that the branding is durable and resistant to wear.

How Is Quality Assurance Implemented in the Manufacturing of Stainless Steel Water Bottles?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that each bottle meets industry standards and customer expectations. Various international standards, such as ISO 9001, guide the QA processes in manufacturing. This standard focuses on maintaining consistent quality through well-defined processes.

Quais são os principais pontos de verificação do controlo de qualidade no processo de fabrico?

Quality control (QC) checkpoints are established throughout the manufacturing process, typically categorized into three main phases:

-

Controlo de qualidade de entrada (IQC): This checkpoint occurs at the beginning of the process when materials are received. Inspections ensure that all raw materials meet specified quality standards before they are used in production.

-

Controlo de qualidade durante o processo (IPQC): During the forming and assembly stages, regular inspections are conducted to monitor dimensions, tolerances, and the quality of welds or joints. This ensures any deviations are caught early, minimizing waste.

-

Controlo de qualidade final (FQC): After assembly and finishing, the bottles undergo a final inspection. This includes functionality tests, such as leak tests, and visual inspections for defects. Only products that pass this stage are packaged and shipped.

What Testing Methods Are Commonly Used in Quality Assurance for Water Bottles?

Various testing methods are employed to ensure the quality and safety of custom stainless steel water bottles. Common tests include:

- Teste de fugas: Ensures that bottles do not leak under normal use conditions.

- Thermal Insulation Testing: Verifies the effectiveness of insulation materials in maintaining temperature.

- Ensaios de durabilidade: Involves subjecting bottles to drops or impacts to assess their resilience.

- Chemical Resistance Testing: Ensures that the materials used do not leach harmful substances when in contact with liquids.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is vital. Here are several strategies:

-

Auditorias a fornecedores: Conducting regular audits can help assess the supplier’s compliance with quality standards. This can be done through third-party auditing firms that specialize in manufacturing.

-

Pedido de relatórios de qualidade: Suppliers should provide detailed quality reports that outline their QA processes, results from recent inspections, and certifications obtained.

-

Inspecções por terceiros: Engaging third-party inspection services before shipment can offer additional assurance that the products meet the required standards and specifications.

What Are the Quality Assurance Nuances for International Buyers?

International B2B buyers should be aware of specific quality assurance nuances when dealing with suppliers from different regions. For instance, certifications like CE (Conformité Européenne) for the European market or API (American Petroleum Institute) for specific industrial applications are essential for compliance. Understanding local regulations and standards can facilitate smoother transactions and ensure that products are market-ready.

In conclusion, the manufacturing processes and quality assurance measures for custom stainless steel water bottles are intricate and require a thorough understanding of both technical and regulatory aspects. By grasping these processes, B2B buyers can make informed decisions, ensuring they partner with suppliers that meet their quality and customization needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom stainless steel water bottle’

Introdução

This guide serves as a comprehensive checklist for B2B buyers looking to source custom stainless steel water bottles. With the increasing demand for eco-friendly products, understanding the nuances of sourcing these items is essential for making informed purchasing decisions. This checklist will help you navigate the complexities of procurement and ensure that you select the best suppliers and products for your needs.

Passo 1: Definir as suas especificações técnicas

Before starting the sourcing process, clearly outline the technical specifications for your custom stainless steel water bottles. This includes size, shape, insulation type, and any specific features like lids or straws. By defining these parameters, you can streamline your search and ensure that potential suppliers meet your exact requirements.

- Consider capacity options: Common sizes range from 12oz to 36oz.

- Decide on insulation: Choose between single-wall and double-wall insulation depending on the intended use.

Passo 2: Pesquisar potenciais fornecedores

Conduct thorough research to identify suppliers specializing in custom stainless steel water bottles. Look for companies with a proven track record in manufacturing and customization, particularly those with experience in your target markets like Africa, South America, the Middle East, and Europe.

- Utilize B2B platforms: Websites like Alibaba, ThomasNet, and Global Sources can help you find reputable suppliers.

- Check for reviews and testimonials: This will provide insights into the supplier’s reliability and product quality.

Etapa 3: Avaliar as certificações do fornecedor

Before making a commitment, verify that potential suppliers hold necessary certifications. Certifications such as ISO 9001 (quality management) or FDA approval for food-grade materials are crucial for ensuring product safety and compliance.

- Solicitar documentação: Ask for copies of relevant certifications and quality control processes.

- Inquire about material sourcing: Ensure that the stainless steel used is of high quality and meets international standards.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of their custom stainless steel water bottles. This step is critical to evaluate the quality of materials, craftsmanship, and customization options available.

- Assess the samples: Pay attention to weight, finish, and insulation performance.

- Test functionality: Ensure that lids seal properly and that the bottles are easy to clean.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing and terms. Ensure that the pricing structure includes all costs associated with customization, shipping, and any potential taxes or tariffs.

- Look for bulk order discounts: Many suppliers offer reduced rates for larger orders.

- Review payment terms: Understand the payment methods accepted and any upfront deposit requirements.

Step 6: Confirm Production and Delivery Timelines

Discuss production timelines and delivery schedules with your chosen supplier. Timeliness is crucial, especially if you have specific deadlines for marketing campaigns or events.

- Establish clear timelines: Confirm lead times for both production and shipping.

- Inquire about rush orders: If you need products sooner, check if the supplier can accommodate expedited production.

Step 7: Establish Communication Protocols

Effective communication is key to a successful sourcing relationship. Establish clear protocols for updates, inquiries, and issue resolution with your supplier.

- Designate a point of contact: Ensure you have a dedicated representative for smooth communication.

- Set up regular check-ins: Schedule updates to discuss production progress and any potential challenges.

By following this checklist, B2B buyers can confidently source custom stainless steel water bottles that align with their specifications, budgets, and timelines.

Comprehensive Cost and Pricing Analysis for custom stainless steel water bottle Sourcing

What Are the Key Cost Components in Custom Stainless Steel Water Bottle Manufacturing?

When sourcing custom stainless steel water bottles, understanding the cost structure is crucial for B2B buyers. The main cost components include:

-

Materiais: Stainless steel quality significantly impacts the overall cost. Higher-grade stainless steel (like 304) is more expensive but offers better durability and corrosion resistance. Eco-friendly and BPA-free materials can also add to costs.

-

Trabalho: Labor costs vary by region and can be influenced by local wage standards. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure quality standards are met.

-

Despesas gerais de fabrico: This encompasses utilities, facility maintenance, and administrative expenses. Efficient production processes can reduce overhead, impacting the final pricing.

-

Ferramentas: Custom designs may require specific molds or machinery adjustments, leading to higher initial setup costs. These costs can be amortized over larger orders, making higher volume purchases more economical.

-

Controlo de qualidade (CQ): Implementing rigorous QC processes ensures product consistency and safety, but adds to the overall cost. For international buyers, certifications (like ISO or FDA compliance) may be necessary and could influence pricing.

-

Logística: Shipping costs are often a significant part of the total expenditure. Factors such as distance, mode of transport, and any tariffs or duties will affect overall logistics costs.

-

Margem: Suppliers will include a profit margin in their pricing, which varies based on market conditions and competition.

How Do Price Influencers Affect Custom Stainless Steel Water Bottle Costs?

Several factors can influence the pricing of custom stainless steel water bottles:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect unit prices. Larger orders often lead to volume discounts, making it more cost-effective for buyers.

-

Especificações e personalização: Custom designs, colors, and sizes can increase costs. The complexity of the design and the techniques used for personalization (like etching or printing) will also impact pricing.

-

Materiais: The choice of materials not only affects durability but also pricing. Specialty finishes or eco-friendly materials typically command higher prices.

-

Qualidade e certificações: Products that meet specific quality standards or certifications may have a higher price point. Buyers should weigh the importance of these certifications against potential cost savings.

-

Factores do fornecedor: Supplier reputation, reliability, and production capacity can influence prices. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the final cost.

What Are the Best Practices for Negotiating Custom Stainless Steel Water Bottle Prices?

To maximize value and minimize costs, B2B buyers should consider the following tips:

-

Negotiate Terms: Engage in negotiations to secure favorable terms. This may include better pricing for larger volumes or longer-term agreements that ensure consistency.

-

Focus on Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, duties, and potential storage costs. This holistic view can help identify the best value.

-

Compreender as nuances dos preços: International buyers should be aware of currency fluctuations, regional market trends, and local economic conditions that may affect pricing.

-

Criar relações com os fornecedores: Developing strong relationships with suppliers can lead to better pricing, priority service, and flexibility in negotiations.

-

Pedir amostras: Before finalizing orders, request samples to evaluate quality and ensure that the products meet specifications. This can prevent costly mistakes down the line.

Declaração de exoneração de responsabilidade

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and order specifics. Always conduct thorough research and consult multiple suppliers to ensure the best pricing strategy.

Alternatives Analysis: Comparing custom stainless steel water bottle With Other Solutions

When considering options for hydration solutions in a B2B context, it’s essential to evaluate various alternatives to custom stainless steel water bottles. This analysis will help international buyers identify the most suitable product for their needs, taking into account factors such as performance, cost, and practicality.

| Aspeto de comparação | Custom Stainless Steel Water Bottle | Garrafa de água de plástico reutilizável | Aluminum Water Bottle |

|---|---|---|---|

| Desempenho | Excellent insulation; durable | Good for short-term use; less insulation | Lightweight; decent insulation |

| Custo | Mid to high-range | Low to mid-range | Mid-range |

| Facilidade de implementação | Customization options available | Easy to source and stock | Requires careful sourcing |

| Manutenção | Low; easy to clean | Moderate; potential staining | Low; easy to clean |

| Melhor caso de utilização | Brindes para empresas, artigos promocionais | Events, giveaways | Outdoor activities, sports |

What Are the Pros and Cons of Reusable Plastic Water Bottles?

Reusable plastic water bottles are a popular alternative, especially in promotional contexts. They are generally more affordable than stainless steel options, making them attractive for bulk purchases. However, they lack the insulation properties of stainless steel, which may be a drawback for brands emphasizing sustainability and quality. Additionally, while plastic bottles can be customized, they may not convey the same premium feel as stainless steel, potentially impacting brand perception.

How Do Aluminum Water Bottles Compare?

Aluminum water bottles offer a lightweight solution that is easy to carry, making them suitable for outdoor events and activities. They provide reasonable insulation but can dent easily, which may affect durability in rugged conditions. While they are generally more affordable than stainless steel, they may not have the same level of customization available, limiting branding opportunities. Furthermore, aluminum can react with certain liquids, so it’s crucial to ensure they are lined properly to avoid leaching substances.

Conclusão: Como é que os compradores B2B devem escolher a solução de hidratação correta?

When selecting the appropriate hydration solution, B2B buyers should carefully consider their specific requirements, including budget, branding goals, and the intended use of the product. Custom stainless steel water bottles provide a premium, durable option ideal for corporate gifts and promotional items. In contrast, reusable plastic bottles offer a cost-effective alternative for large events, while aluminum bottles serve well for outdoor activities. By evaluating these factors, businesses can make informed decisions that align with their brand image and operational needs.

Essential Technical Properties and Trade Terminology for custom stainless steel water bottle

What Are the Key Technical Properties of Custom Stainless Steel Water Bottles?

When considering custom stainless steel water bottles for your business needs, understanding the technical specifications is crucial. Here are some essential properties that influence both product quality and consumer satisfaction:

1. Grau do material

The most common material used for stainless steel water bottles is 18/8 stainless steel, also known as 304 stainless steel. This grade contains 18% chromium and 8% nickel, providing excellent corrosion resistance and durability. For B2B buyers, selecting the right material grade ensures that the bottles can withstand various environmental conditions, making them suitable for outdoor or promotional use.

2. Capacity

Custom stainless steel water bottles come in various capacities, typically ranging from 12 oz to 40 oz. The choice of capacity affects how and where the bottles can be marketed. For instance, larger bottles are ideal for sports events or outdoor activities, while smaller bottles may be more suitable for corporate gifts or travel. Understanding capacity requirements helps align the product with target markets.

3. Insulation Type

Most high-quality stainless steel bottles feature double-wall vacuum insulation, which keeps beverages hot or cold for extended periods. This property is critical for customer satisfaction as it enhances the user experience. In a B2B context, insulated bottles can be positioned as premium products, appealing to environmentally-conscious consumers looking for sustainable hydration solutions.

4. Tolerance and Thickness

The thickness of the stainless steel used in the bottle walls typically ranges from 0.4 mm to 1.0 mm. A thicker wall generally indicates better durability and resistance to dents. Tolerance refers to the allowable variation in the dimensions of the bottle. In B2B, specifying thickness and tolerance is vital for ensuring product consistency and quality during production, which can significantly impact brand reputation.

5. Finish and Coating

The surface finish of stainless steel bottles can vary, with options like matte, polished, or powder-coated finishes. Coatings not only enhance aesthetics but also provide additional protection against scratches and environmental factors. For businesses, understanding finish options allows for better branding and customization, making bottles more appealing to consumers.

What Are the Common Trade Terminology Related to Custom Stainless Steel Water Bottles?

Navigating the world of custom manufacturing involves understanding specific trade terms. Here are some commonly used terms that are essential for B2B buyers:

1. OEM (Fabricante de equipamento original)

OEM refers to a company that produces parts or products that are used in another company’s end product. For custom stainless steel water bottles, working with an OEM can streamline the manufacturing process and ensure high-quality standards, as these manufacturers often specialize in specific product types.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest number of units that a supplier is willing to produce or sell. This term is crucial for B2B buyers as it helps in budgeting and planning inventory. Understanding the MOQ can also influence whether a buyer can afford to customize a product based on their sales projections.

3. RFQ (Pedido de Cotação)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. For custom stainless steel water bottles, an RFQ helps buyers compare prices, lead times, and service levels, enabling informed decision-making.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for B2B buyers to understand shipping costs, risk, and delivery obligations when importing custom stainless steel water bottles from overseas suppliers.

5. Opções de personalização

Customization options refer to the various ways a product can be tailored to meet specific buyer needs, such as colors, logos, and sizes. This is particularly important in a competitive market where branding and unique offerings can differentiate a product.

In summary, understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed purchasing decisions. Whether for promotional use or retail, the right specifications and terminology are key to successful procurement in the custom stainless steel water bottle market.

Navigating Market Dynamics and Sourcing Trends in the custom stainless steel water bottle Sector

What Are the Current Market Dynamics for Custom Stainless Steel Water Bottles?

The custom stainless steel water bottle market is experiencing robust growth, driven by a combination of consumer demand for sustainable products and a shift towards health-conscious lifestyles. Globally, the demand for reusable and eco-friendly water bottles has surged, particularly in regions like Africa, South America, the Middle East, and Europe. As urbanization increases, so does the necessity for convenient, portable hydration solutions, aligning with the rise of outdoor and active lifestyles. This trend is particularly pronounced in countries such as Germany and Nigeria, where environmental awareness and health consciousness are becoming integral to consumer behavior.

B2B buyers are increasingly leveraging technology to streamline sourcing processes. Innovations such as online customization platforms allow businesses to offer personalized products that resonate with their clientele. Additionally, the integration of Artificial Intelligence (AI) in supply chain management is optimizing inventory levels and enhancing demand forecasting, which is crucial for meeting the fluctuating market needs. Furthermore, an emphasis on local sourcing is emerging, as companies seek to reduce lead times and transportation costs while supporting regional economies.

How Does Sustainability Influence Sourcing Decisions in the Custom Stainless Steel Water Bottle Market?

Sustainability is at the forefront of sourcing decisions in the custom stainless steel water bottle sector. The environmental impact of single-use plastics has led to increased regulatory scrutiny and a demand for eco-friendly alternatives. Custom stainless steel bottles present a compelling solution, as they are durable, reusable, and recyclable.

B2B buyers are prioritizing ethical sourcing practices, ensuring that their suppliers adhere to sustainable production methods. Certifications such as ISO 14001 for environmental management and the use of BPA-free materials are critical for companies looking to enhance their brand reputation. Furthermore, transparency in the supply chain is becoming a vital criterion for procurement decisions, as buyers seek to align with suppliers that demonstrate a commitment to corporate social responsibility (CSR). By investing in sustainable products, businesses not only mitigate environmental risks but also tap into the growing market of eco-conscious consumers.

What Is the Historical Context of Custom Stainless Steel Water Bottles?

The evolution of custom stainless steel water bottles can be traced back to the late 20th century when the awareness of environmental issues began to rise. Initially, stainless steel bottles were primarily used in industrial applications. However, as public concern over plastic waste grew in the early 2000s, manufacturers started to recognize the potential of stainless steel as a viable alternative for consumer hydration solutions.

Over the years, advancements in manufacturing techniques and design aesthetics have transformed these bottles into desirable lifestyle products. The introduction of customization options has further propelled their popularity, allowing brands to engage with consumers on a personal level. Today, custom stainless steel water bottles are not just functional items but also serve as powerful marketing tools, representing a brand’s commitment to sustainability and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of custom stainless steel water bottle

-

How do I choose the right supplier for custom stainless steel water bottles?

Choosing the right supplier involves evaluating several key factors. Start by researching suppliers that specialize in custom stainless steel products. Look for their certifications, such as ISO 9001, which indicates quality management. Assess their production capacity, lead times, and past client reviews. It’s also crucial to request samples of their products to verify quality. Finally, ensure they have robust communication channels and are responsive to inquiries, as this indicates a commitment to customer service. -

What customization options are available for stainless steel water bottles?

Most suppliers offer a variety of customization options, including size, color, and design. You can choose from different capacities, typically ranging from 12oz to 36oz. Customization may also include printing your logo, brand colors, or personalized text. Some suppliers provide engraving services for a more premium look. Before placing an order, confirm the available options and any additional costs associated with complex designs or multiple colors. -

What are the minimum order quantities (MOQs) for bulk purchases?

Minimum order quantities can vary widely among suppliers. Typically, MOQs for custom stainless steel water bottles range from 50 to 500 units, depending on the complexity of the customization and the supplier’s production capabilities. It’s advisable to discuss your specific needs with potential suppliers to see if they can accommodate smaller orders or if they offer tiered pricing for larger quantities. Understanding MOQs can help you plan your inventory and budget effectively. -

What payment terms should I expect when sourcing internationally?

Payment terms can differ based on supplier policies and your negotiating power. Common options include a deposit (often 30-50%) upfront, with the balance due before shipment. Some suppliers may also offer net payment terms, allowing you to pay after receiving goods. Ensure you clarify payment methods accepted, such as bank transfers or credit cards, and consider using secure payment platforms to protect your transaction. Always get payment terms in writing to avoid misunderstandings. -

How do I ensure product quality during manufacturing?

To ensure product quality, request a detailed quality assurance plan from your supplier. This should outline their inspection processes, including raw material sourcing, production checks, and final inspections. Consider scheduling factory visits or audits to observe manufacturing practices firsthand. Additionally, asking for third-party inspection reports can provide an unbiased assessment of product quality. Establishing clear quality standards in your contract can also help hold suppliers accountable. -

What are the logistics considerations when importing custom water bottles?

When importing custom stainless steel water bottles, consider shipping methods, costs, and delivery times. Choose between air freight for quicker delivery or sea freight for cost-effectiveness on larger shipments. Be aware of customs regulations in your country, including any tariffs or duties that may apply. Collaborating with a freight forwarder can simplify the logistics process, ensuring compliance with international shipping regulations and smooth delivery to your location. -

What are the environmental impacts of custom stainless steel water bottles?

Custom stainless steel water bottles are an eco-friendly alternative to plastic bottles, significantly reducing environmental impact. They are reusable, which minimizes waste and the carbon footprint associated with single-use plastics. Many suppliers offer products made from recycled materials and emphasize sustainable manufacturing processes. By choosing stainless steel, you contribute to a circular economy, as these bottles can last for years and are fully recyclable at the end of their life cycle. -

How can I effectively market custom stainless steel water bottles to my customers?

To effectively market custom stainless steel water bottles, focus on their unique selling points such as durability, eco-friendliness, and customization options. Leverage social media platforms and influencer partnerships to showcase the product in real-life scenarios. Create compelling content that highlights the benefits of switching from plastic to stainless steel, targeting eco-conscious consumers. Offering promotions, such as bulk discounts or limited-time offers, can also incentivize purchases and boost sales.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.

Top 7 Custom Stainless Steel Water Bottle Manufacturers & Suppliers List

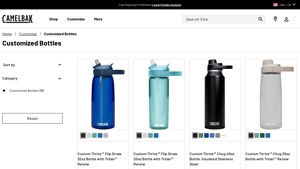

1. CamelBak – Custom Thrive™ Flip Straw 32oz Bottle

Domínio: camelbak.com

Registada: 1996 (29 anos)

Introdução: Customized Bottles: 38 items available. Price range: $0.00 – $24.99 (4), $25.00 – $49.99 (32), $50.00 – $74.99 (2). Examples include: Custom Thrive™ Flip Straw 32oz Bottle with Tritan™ Renew ($28.99), Custom Thrive™ Chug 40oz Bottle, Insulated Stainless Steel ($47.99), Custom Podium® Steel 22oz Bike Bottle ($54.00).

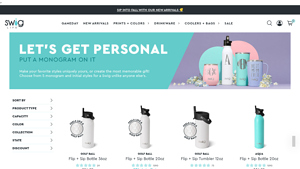

2. Swig Life – Personalized Stainless Steel Water Bottles

Domínio: swiglife.com

Registado: 2018 (7 anos)

Introdução: Personalized Stainless Steel Water Bottles available in various shapes and sizes (12oz, 20oz, 26oz, 36oz). Options for monograms or custom designs. Multiple colors and prints including new arrivals like Boo Crew, Pretty In Pink, and Gameday. Free shipping on orders over $75. Discounts up to 60% off on select items.

3. Customizable Metal Water Bottles – Chilly’s, Impact Zurich

Domínio: reddit.com

Registada: 2005 (20 anos)

Introdução: Customizable metal water bottles that allow for custom text. Suggested brands include Chilly’s, Impact Zurich (sustainable options with custom logos), and recommendations to check Etsy or local sellers for personalized options.

4. iPromo – Custom Drinkware Sizes

Domínio: answers.ipromo.com

Registada: 2003 (22 anos)

Introdução: This company, iPromo – Custom Drinkware Sizes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Liberty Works – Aluminum Bottles

Domínio: snipershide.com

Registada: 2000 (25 anos)

Introdução: US made water bottles mentioned include Nalgene, TruFlask, and Liberty Works. Liberty offers aluminum bottles made in the USA, but they are not double-wall insulated. Nalgene bottles can be frozen and are versatile for various uses. Tervis is mentioned for insulated bottles, but they are made in China. There is a challenge in finding stainless steel insulated water bottles that are not made in Chi…

6. LightBurn – Bottle Etching Template

Domínio: forum.lightburnsoftware.com

Registado: 2017 (8 anos)

Introdução: This company, LightBurn – Bottle Etching Template, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Discount Mugs – Personalized Stainless Steel Water Bottles

Domínio: discountmugs.com

Registered: 2002 (23 years)

Introdução: Personalized Stainless Steel Water Bottles in Bulk | DiscountMugs. Custom Insulated Stainless Steel Water Bottles printed or engraved at wholesale prices. Durable, stylish, and eco-friendly, ideal for brand promotion and everyday use. Suitable for corporate teams, events, and unique giveaways. Elegant alternatives to plastic, long-lasting with superior temperature control. Options for full-color p…

Strategic Sourcing Conclusion and Outlook for custom stainless steel water bottle

In the competitive landscape of custom stainless steel water bottles, strategic sourcing emerges as a critical success factor for international B2B buyers. By prioritizing suppliers that offer eco-friendly options, diverse customization, and robust quality assurance, companies can enhance their brand reputation while meeting the growing consumer demand for sustainable products. The versatility in bottle designs and sizes allows businesses to cater to a variety of market segments, from corporate gifts to promotional merchandise.

Moreover, the global shift towards sustainability and environmental responsibility presents an opportunity for brands to align their product offerings with consumer values. By investing in high-quality, reusable stainless steel bottles, businesses can reduce reliance on single-use plastics and contribute positively to the environment.

Looking ahead, B2B buyers from regions like Africa, South America, the Middle East, and Europe should leverage these insights to make informed sourcing decisions. Establishing partnerships with reliable manufacturers not only facilitates competitive pricing but also fosters innovation in product design. Embrace the potential of custom stainless steel water bottles to elevate your brand and respond proactively to market trends. Start your sourcing journey today to secure a sustainable, profitable future.