Introduction: Navigating the Global Market for do water bottles have bpa

In today’s global marketplace, sourcing water bottles that are free from bisphenol A (BPA) presents a unique challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. With increasing consumer awareness about health and safety, understanding the implications of BPA in plastic products is crucial for suppliers aiming to meet market demand. This guide offers a comprehensive overview of the current landscape surrounding BPA in water bottles, including the types of materials used, applications across various industries, effective supplier vetting strategies, and cost considerations.

By navigating the complexities of BPA regulations and consumer preferences, this guide empowers international B2B buyers to make informed purchasing decisions. It delves into the science behind plastic materials, clarifies misconceptions surrounding BPA, and highlights emerging alternatives that cater to health-conscious consumers. Additionally, it provides practical insights on evaluating suppliers, ensuring compliance with safety standards, and understanding market trends.

With this knowledge, businesses can confidently source products that not only align with regulatory requirements but also resonate with the values of their customers. Whether you are a distributor in Saudi Arabia or a retailer in Brazil, this guide equips you with the essential tools to navigate the evolving landscape of water bottle sourcing effectively.

Navegação de artigos

- Top 9 Do Water Bottles Have Bpa Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for do water bottles have bpa

- Understanding do water bottles have bpa Types and Variations

- Key Industrial Applications of do water bottles have bpa

- 3 Common User Pain Points for ‘do water bottles have bpa’ & Their Solutions

- Strategic Material Selection Guide for do water bottles have bpa

- In-depth Look: Manufacturing Processes and Quality Assurance for do water bottles have bpa

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘do water bottles have bpa’

- Comprehensive Cost and Pricing Analysis for do water bottles have bpa Sourcing

- Alternatives Analysis: Comparing do water bottles have bpa With Other Solutions

- Essential Technical Properties and Trade Terminology for do water bottles have bpa

- Navigating Market Dynamics and Sourcing Trends in the do water bottles have bpa Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of do water bottles have bpa

- Aviso importante e termos de utilização

- Strategic Sourcing Conclusion and Outlook for do water bottles have bpa

Understanding do water bottles have bpa Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Polyethylene Terephthalate (PET) | Lightweight, recyclable, and BPA-free; marked with recycling code 1 | Beverage packaging, retail, and catering | Prós: Cost-effective, widely accepted, lightweight. Contras: Less durable than other plastics, potential for leaching over time. |

| Polycarbonate (PC) | Durable, high-impact resistance; can contain BPA; marked with recycling codes 3 or 7 | Industrial applications, reusable bottles | Prós: Strong and long-lasting, ideal for heavy-duty use. Contras: Potential health concerns due to BPA content. |

| BPA-Free Plastics | Specifically manufactured without BPA; often marketed as such | Health-conscious brands, eco-friendly products | Prós: Alleviates health concerns, growing consumer demand. Contras: Often higher cost, varying quality. |

| Aço inoxidável | Non-plastic alternative, highly durable, and BPA-free; insulated options available | Outdoor activities, corporate gifts, health products | Prós: Long-lasting, excellent thermal retention, eco-friendly. Contras: Heavier than plastic, higher initial investment. |

| Glass Water Bottles | Non-toxic, recyclable, and BPA-free; often insulated | Premium brands, health-focused markets | Prós: Safe, preserves taste, environmentally friendly. Contras: Fragile, heavier, and can be more expensive. |

What are the Characteristics and Suitability of PET Water Bottles?

Polyethylene Terephthalate (PET) bottles are the most commonly used plastic water bottles and are recognized for being lightweight and recyclable. They are typically marked with a recycling code of 1, indicating their composition. B2B buyers in the beverage packaging sector often favor PET for its cost-effectiveness and wide acceptance in retail. However, while PET is BPA-free, it is less durable than other materials, which may lead to concerns about leaching over time, especially under heat exposure.

How Do Polycarbonate Bottles Differ from Other Types?

Polycarbonate (PC) bottles are known for their strength and durability, making them suitable for industrial applications and reusable bottles. These bottles, often marked with recycling codes 3 or 7, can contain BPA, raising health concerns among consumers. B2B buyers should weigh the benefits of durability and impact resistance against the potential risks associated with BPA. While they are ideal for heavy-duty use, many companies are now shifting towards BPA-free alternatives due to increasing health awareness.

Why Choose BPA-Free Plastics for Your Business?

BPA-free plastics are specifically manufactured to eliminate bisphenol A, addressing health concerns associated with traditional plastics. Many manufacturers now market their products as BPA-free, appealing to health-conscious brands and eco-friendly markets. For B2B buyers, this offers a significant opportunity to align with consumer demand for safer, environmentally friendly products. However, these plastics may come at a higher cost, and their quality can vary, necessitating thorough supplier evaluations.

What Are the Advantages of Using Stainless Steel Bottles?

Stainless steel bottles present a robust alternative to plastic, offering excellent durability and being completely BPA-free. They are popular in outdoor activities and corporate gifting due to their long-lasting nature and thermal retention capabilities. For B2B buyers, the initial investment may be higher, but the longevity and eco-friendly profile can lead to cost savings over time. Additionally, stainless steel bottles appeal to environmentally conscious consumers, enhancing brand reputation.

What Makes Glass Water Bottles a Premium Choice?

Glass water bottles are an increasingly popular choice among health-focused markets due to their non-toxic nature and ability to preserve taste. They are completely BPA-free and recyclable, aligning well with sustainability goals. However, their fragility and higher price point can deter some buyers. B2B buyers should consider the target market’s preferences and the potential for premium pricing when incorporating glass bottles into their product offerings.

Key Industrial Applications of do water bottles have bpa

| Indústria/Setor | Specific Application of do water bottles have BPA | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Alimentação e bebidas | Distribution of bottled water in retail environments | Ensures consumer safety and compliance with regulations | Verify BPA-free certifications and material safety data sheets |

| Health and Wellness | Use in fitness centers and sports events | Promotes a health-conscious brand image | Assess durability and recyclability of materials used |

| Hospitalidade | In-room bottled water services in hotels | Melhora a experiência e a satisfação dos hóspedes | Consider local regulations regarding plastic usage |

| Recreação ao ar livre | Sales of bottled water for outdoor activities | Provides convenience and hydration options | Evaluate the sustainability and environmental impact of sourcing |

| Manufacturing | Use in production of water bottles for distribution | Streamlines supply chain and reduces costs | Ensure compliance with international safety standards |

How Do Water Bottles Without BPA Serve the Food and Beverage Industry?

In the food and beverage sector, bottled water is a staple product. With increasing consumer awareness about health and safety, ensuring that water bottles are BPA-free is crucial. Businesses can leverage this to enhance their brand reputation by promoting the safety of their products. International buyers, particularly in regions like Africa and South America, should prioritize suppliers that provide certifications confirming the absence of BPA and other harmful chemicals to comply with local health regulations.

What Are the Benefits for Health and Wellness Applications?

Fitness centers and sports events often provide bottled water to promote hydration. Using BPA-free bottles not only aligns with health trends but also helps organizations build a reputation for prioritizing customer safety. Buyers in the health and wellness sector should seek suppliers who offer durable, lightweight, and recyclable options that can withstand various usage scenarios, ensuring the bottles remain safe and effective for repeated use.

How Does the Hospitality Sector Benefit from BPA-Free Bottles?

In the hospitality industry, offering bottled water in rooms or during events can significantly enhance guest satisfaction. BPA-free bottles contribute to a perception of quality and care, which can improve overall guest experience. For international buyers, especially in the Middle East and Europe, it’s vital to source from manufacturers who comply with local environmental regulations and can provide eco-friendly alternatives that resonate with today’s sustainability-focused travelers.

Why Are BPA-Free Bottles Important for Outdoor Recreation?

Outdoor recreation businesses that sell bottled water must ensure their products are BPA-free to cater to health-conscious consumers. This not only addresses safety concerns but also enhances the brand’s appeal in a competitive market. Sourcing considerations should include evaluating the environmental impact of bottle production and the ability to offer recyclable options, particularly for buyers in regions like Brazil, where eco-consciousness is growing.

What Role Do BPA-Free Bottles Play in Manufacturing?

Manufacturers producing bottled water must prioritize BPA-free materials to streamline their supply chain and comply with safety regulations. This focus not only reduces potential liabilities but also positions the brand as a responsible player in the market. International buyers should ensure that their suppliers adhere to rigorous safety standards and can provide transparency in their sourcing practices, particularly in regions where regulatory frameworks may differ significantly.

3 Common User Pain Points for ‘do water bottles have bpa’ & Their Solutions

Scenario 1: Concerns Over Product Safety Compliance

O problema: B2B buyers in the beverage and food packaging sectors often grapple with the fear of potential legal liabilities linked to product safety. The presence of BPA in plastics has raised concerns among consumers and regulatory bodies alike. For businesses exporting products to regions like Europe or North America, where stringent regulations govern food safety, the stakes are even higher. Any misstep can lead to costly recalls, fines, and damage to brand reputation.

A solução: To mitigate these risks, B2B buyers should prioritize sourcing BPA-free materials and verify supplier compliance with safety regulations. This can be achieved by looking for suppliers who provide third-party certifications confirming their products are BPA-free and comply with local and international safety standards. Furthermore, implementing a robust quality assurance program that includes regular testing of materials can help ensure compliance and bolster customer confidence. Buyers should also stay informed about evolving regulations in their target markets, as this knowledge will enable them to adapt their sourcing strategies proactively and maintain compliance.

Scenario 2: Navigating Misleading Marketing Claims

O problema: The market is flooded with misleading marketing claims regarding the safety of plastic water bottles. B2B buyers may find it challenging to distinguish between genuinely BPA-free products and those that use ambiguous language. This confusion can lead to purchasing decisions that do not align with health and safety standards, ultimately putting consumer safety at risk and potentially harming the buyer’s reputation.

A solução: To combat this issue, B2B buyers should adopt a systematic approach to supplier evaluation. This involves asking for clear documentation and testing results that validate claims of BPA-free production. Buyers should seek out manufacturers that provide transparent information about their materials and processes, including resin identification codes on their products. Additionally, creating partnerships with suppliers that are committed to ethical practices and transparent communication can help ensure that the products meet health standards and that buyers can confidently market their offerings.

Scenario 3: Addressing Sustainability Concerns

O problema: As environmental awareness increases globally, B2B buyers are increasingly faced with pressure from consumers and stakeholders to adopt sustainable practices. The use of BPA-containing plastics has come under scrutiny due to potential health risks and environmental impacts. Buyers must balance consumer demand for safe products with the need for sustainable sourcing, particularly in regions like Africa and South America, where environmental regulations may be less stringent but consumer awareness is growing.

A solução: B2B buyers can address sustainability concerns by sourcing from manufacturers that utilize biodegradable or recyclable materials. This includes opting for water bottles made from polyethylene terephthalate (PET), which is widely accepted as a safer alternative. Buyers should also consider establishing take-back programs for used water bottles to promote recycling and reduce environmental impact. Furthermore, engaging in corporate social responsibility initiatives that focus on sustainability can enhance brand image and appeal to environmentally conscious consumers. By prioritizing sustainable sourcing, buyers can meet regulatory demands while satisfying consumer preferences, ultimately leading to a competitive advantage in the marketplace.

Strategic Material Selection Guide for do water bottles have bpa

What Are the Key Materials Used in BPA-Free Water Bottles?

When considering the materials used in water bottles, especially in the context of BPA concerns, several options are prevalent in the market. Understanding these materials from a B2B perspective is essential for buyers looking to make informed purchasing decisions. Below, we analyze four common materials used in water bottle production: Polyethylene Terephthalate (PET), Polycarbonate (PC), Tritan™ Copolyester, and Stainless Steel.

How Does Polyethylene Terephthalate (PET) Perform?

PET is the most widely used plastic for single-use water bottles. It is lightweight, clear, and offers good barrier properties against moisture and gases. PET bottles can withstand temperatures up to about 60°C (140°F) without deforming, making them suitable for cold beverages.

Prós: PET is cost-effective, highly recyclable, and does not contain BPA. Its clarity allows for branding visibility, making it an attractive option for consumer-facing products.

Contras: While PET is durable, it can become brittle over time, especially when exposed to UV light. Additionally, it is not suitable for hot liquids, which limits its versatility.

Impacto na aplicação: PET is compatible with most beverages but should not be used for hot liquids or products requiring a long shelf life without refrigeration.

Considerations for International Buyers: PET is widely accepted and regulated under various standards, including ASTM and ISO. Buyers in regions like Africa and South America should ensure compliance with local recycling regulations, as PET recycling infrastructure varies.

What About Polycarbonate (PC) Water Bottles?

Polycarbonate is a durable plastic known for its high impact resistance and clarity. It can handle higher temperatures than PET, making it suitable for reusable bottles.

Prós: PC is extremely strong and can withstand high-pressure conditions, making it ideal for outdoor and sports applications. It is also dishwasher safe.

Contras: The primary drawback is the potential presence of BPA, which has led to consumer hesitance. Additionally, PC can be more expensive than PET.

Impacto na aplicação: PC is suitable for both cold and hot beverages but may leach BPA if not properly managed.

Considerations for International Buyers: Buyers should verify that the PC used is BPA-free and compliant with health regulations in their respective countries, particularly in Europe, where BPA restrictions are strict.

Why Choose Tritan™ Copolyester for Water Bottles?

Tritan™ copolyester is a BPA-free alternative to polycarbonate that combines the clarity and durability of PC with the safety of PET.

Prós: Tritan is dishwasher safe, resistant to odors and stains, and maintains its clarity over time. It is also lightweight and can handle temperatures up to 90°C (194°F).

Contras: Tritan is typically more expensive than both PET and PC, which may affect pricing strategies for bulk buyers.

Impacto na aplicação: Tritan is versatile and can be used for a wide range of beverages, including hot liquids, without the risk of BPA leaching.

Considerations for International Buyers: Tritan is recognized for its safety and quality, making it appealing in markets with stringent health regulations, such as Europe and North America. Buyers should look for certifications confirming its BPA-free status.

Is Stainless Steel a Viable Option for Water Bottles?

Stainless steel is a highly durable material that is increasingly popular for reusable water bottles. It is resistant to corrosion and can withstand high temperatures.

Prós: Stainless steel is BPA-free, highly durable, and can keep beverages hot or cold for extended periods. It is also easy to clean and does not retain flavors.

Contras: The primary disadvantage is its higher cost compared to plastic options. Additionally, stainless steel bottles are heavier than their plastic counterparts.

Impacto na aplicação: Stainless steel is suitable for a variety of beverages, including both hot and cold drinks, making it a versatile choice for consumers.

Considerations for International Buyers: Buyers should ensure that the stainless steel used is food-grade and compliant with international standards like ASTM and ISO. The demand for sustainable products is rising in regions like Europe and the Middle East, where stainless steel is often preferred.

Summary Table of Material Options

| Material | Typical Use Case for do water bottles have bpa | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Polyethylene Terephthalate (PET) | Single-use water bottles | Económica e reciclável | Not suitable for hot liquids | Baixa |

| Polycarbonate (PC) | Reusable water bottles | Elevada resistência ao impacto | Potential BPA presence | Médio |

| Copoliéster Tritan | Reusable and versatile water bottles | BPA-free and durable | Higher cost compared to PET | Elevado |

| Aço inoxidável | Reusable water bottles for hot and cold drinks | Highly durable and insulated | Heavier and more expensive | Elevado |

This analysis provides B2B buyers with a comprehensive overview of the materials used in water bottles concerning BPA, aiding in the selection of suitable products for their markets.

In-depth Look: Manufacturing Processes and Quality Assurance for do water bottles have bpa

What are the Main Stages in the Manufacturing Process of BPA-Free Water Bottles?

The manufacturing of BPA-free water bottles involves a series of well-defined stages that ensure the final product is safe, durable, and compliant with international standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Processed?

The first step in the manufacturing process is the preparation of raw materials, primarily polyethylene terephthalate (PET). PET is a thermoplastic polymer that is favored for its strength, lightweight nature, and recyclability.

-

Material Selection: Suppliers must ensure that the PET resin used is free from BPA and other harmful substances. This often involves sourcing materials from reputable manufacturers who provide safety data sheets (SDS) and material safety data.

-

Drying and Conditioning: The PET resin is dried to remove moisture, which is critical to prevent defects during the molding process. Proper moisture control is crucial, as excess moisture can lead to hydrolysis, compromising the integrity of the final product.

Forming: What Techniques Are Used to Shape Water Bottles?

The forming stage involves several key techniques to shape the PET into water bottles. The most common methods include:

-

Moldagem por injeção: In this method, melted PET is injected into a mold to create preforms. These preforms are then heated and stretched into the final bottle shape through a blow molding process.

-

Moldagem por sopro: This technique is particularly effective for creating hollow objects like bottles. The preform is heated and inflated using air to take the shape of the mold. This method is efficient and ensures uniform wall thickness, which is essential for durability.

-

Thermoforming: Although less common for water bottles, thermoforming can be used to create lightweight containers. In this process, sheets of heated PET are formed over molds and cut to size.

Assembly: How Are Bottles Assembled and Prepared for Distribution?

Once formed, the bottles undergo assembly and preparation for distribution. This includes:

-

Cap Production: Caps are often made from different plastics, typically polypropylene (PP), which is compatible with PET. They are produced through injection molding and are designed to create a tight seal to prevent leakage.

-

Labeling and Decoration: Bottles may be labeled for branding or compliance purposes. Techniques such as screen printing or shrink sleeve labeling are commonly used.

-

Quality Control Checks: Before packaging, bottles undergo visual inspections and measurements to ensure they meet specifications regarding size, weight, and appearance.

Finishing: What Final Touches Are Applied Before Shipping?

The finishing stage includes cleaning, packaging, and preparing bottles for shipment. This involves:

-

Cleaning: Bottles are typically rinsed to remove any residues from the manufacturing process. This step ensures that the final product is hygienic and ready for consumer use.

-

Packaging: Bottles are grouped and packaged in bulk for shipping. Packaging materials must also comply with safety standards to prevent contamination during transport.

-

Final Quality Assurance: Before leaving the facility, a final quality assurance check ensures that the bottles meet all safety and quality standards.

What Quality Assurance Practices Are Essential for BPA-Free Water Bottles?

Quality assurance (QA) is crucial in ensuring that BPA-free water bottles are safe for consumer use. Various international standards and industry-specific guidelines govern these practices.

What International Standards Should B2B Buyers Consider?

-

ISO 9001: This quality management standard outlines requirements for organizations to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Manufacturers of water bottles should be certified to ISO 9001 to ensure a systematic approach to quality management.

-

Marcação CE: In Europe, products that meet safety, health, and environmental protection standards must bear the CE mark. B2B buyers in Europe should verify that their suppliers have CE certification, ensuring compliance with EU regulations.

-

Normas API: The American Petroleum Institute (API) sets standards for materials used in various industries, including food and beverage. Although primarily focused on petroleum products, API standards can also influence the quality of plastics used in water bottles.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process to ensure that each bottle meets required standards. Common QC checkpoints include:

-

Controlo de qualidade de entrada (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers should provide certification of material safety, particularly for PET resins.

-

Controlo de qualidade durante o processo (IPQC): During the manufacturing process, random samples of bottles are tested for defects such as dimensional accuracy, weight, and visual flaws. This helps catch issues early in the production line.

-

Controlo de qualidade final (FQC): After production, a comprehensive review of the finished bottles is conducted. This includes testing for BPA and other contaminants, as well as ensuring that the bottles meet all specified dimensions and labeling requirements.

Como podem os compradores B2B verificar o controlo de qualidade dos fornecedores?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

-

Conduct Supplier Audits: Regular audits of suppliers’ manufacturing facilities can provide insights into their quality control processes. Audits should assess compliance with international standards like ISO 9001 and verify the implementation of QC checkpoints.

-

Request Quality Assurance Reports: Suppliers should provide documentation of their quality assurance practices, including results from IQC, IPQC, and FQC. This transparency allows buyers to evaluate the effectiveness of the supplier’s QC measures.

-

Contratar inspectores externos: Utilizing third-party inspection services can provide an unbiased assessment of product quality. These inspectors can conduct tests for BPA and other harmful substances, ensuring that the products meet safety standards.

Quais são as nuances do controlo de qualidade para os compradores internacionais B2B?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Conformidade regulamentar: Different regions have varying regulations regarding BPA and plastic safety. Buyers must ensure that their suppliers understand and comply with local regulations to avoid legal complications.

-

Cultural and Logistical Considerations: Language barriers and differing business practices can complicate quality assurance efforts. Establishing clear communication channels and understanding local customs can facilitate smoother collaboration.

-

Sustainability and Environmental Standards: Increasingly, buyers are prioritizing suppliers that adhere to sustainability practices. Understanding how suppliers manage waste, energy use, and recycling can influence purchasing decisions.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing BPA-free water bottles, ensuring both safety and compliance in their supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘do water bottles have bpa’

To assist B2B buyers in sourcing water bottles while addressing the concerns surrounding bisphenol A (BPA), this practical guide provides actionable steps to ensure a safe and effective procurement process. Understanding the materials and regulations involved can help buyers make informed decisions and enhance product quality.

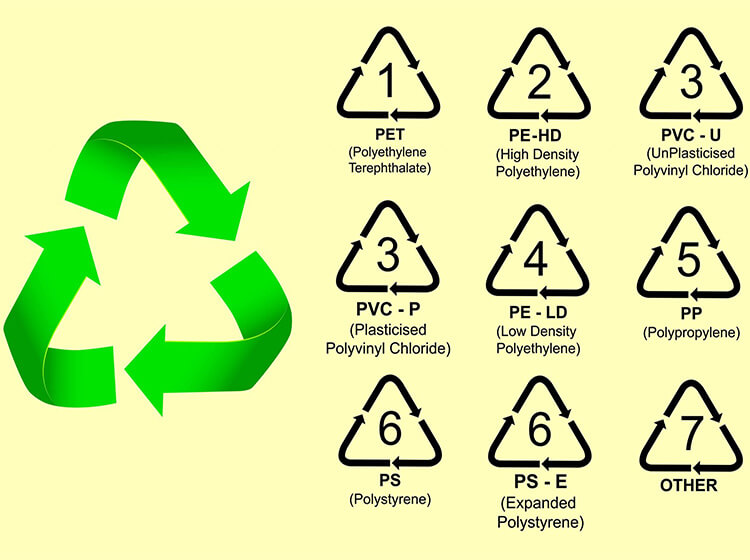

Passo 1: Understand the Material Composition

Begin by familiarizing yourself with the types of plastics used in water bottles. Most plastic water bottles are made from polyethylene terephthalate (PET), which does not contain BPA. Knowing the composition will help you avoid products made from polycarbonate plastics that may contain BPA.

- Key Considerations:

- Look for bottles labeled with the recycling code “1” for PET.

- Ensure that any polycarbonate options are clearly marked and assessed for BPA content.

Passo 2: Check for Certifications and Standards

Before finalizing your supplier choice, verify that the products meet local and international safety standards. Certifications from regulatory bodies such as the FDA, EFSA (European Food Safety Authority), or equivalent agencies in your region indicate compliance with safety measures concerning BPA.

- Key Considerations:

- Request documentation of certifications from suppliers.

- Ensure that the products comply with food safety regulations applicable in your target market.

Passo 3: Evaluate Supplier Transparency

A reputable supplier should provide clear information about their products, including the materials used and any testing done for safety. Transparency fosters trust and allows you to make more informed purchasing decisions.

- Key Considerations:

- Request detailed product specifications and safety data sheets.

- Look for suppliers who openly discuss their sourcing and manufacturing processes.

Passo 4: Inquire About BPA-Free Labels

Many manufacturers now produce BPA-free products in response to consumer demand. When sourcing, specifically ask suppliers for BPA-free certifications or documentation confirming that their products do not contain bisphenol A.

- Key Considerations:

- Confirm that the label is prominent and easy to identify.

- Ensure the BPA-free claim is supported by testing results or certifications.

Passo 5: Assess Product Lifecycle and Recycling Options

Consider the environmental impact of the water bottles you plan to procure. Look for suppliers that offer recyclable options and promote sustainable practices, as these can enhance your brand’s reputation and compliance with global sustainability initiatives.

- Key Considerations:

- Inquire about the recyclability of the bottles.

- Check if the supplier has a take-back program for used bottles.

Passo 6: Review Customer Feedback and Case Studies

Before making a purchase, it’s beneficial to examine customer reviews and case studies related to the supplier’s products. This insight can provide a better understanding of product performance and supplier reliability.

- Key Considerations:

- Seek testimonials from businesses in similar sectors or regions.

- Analyze case studies that highlight successful implementations of the products.

Passo 7: Negociar termos e condições

Finally, ensure that you discuss and agree upon all terms and conditions with your supplier before placing an order. This includes delivery timelines, payment terms, and any warranty or return policies regarding the products.

- Key Considerations:

- Clarify lead times and stock availability.

- Discuss any potential penalties for non-compliance with agreed specifications.

By following these steps, B2B buyers can confidently procure water bottles while ensuring they are safe and compliant with regulations regarding BPA. These practices not only protect consumer health but also enhance brand integrity in increasingly health-conscious markets.

Comprehensive Cost and Pricing Analysis for do water bottles have bpa Sourcing

What Are the Key Cost Components for Sourcing Water Bottles Without BPA?

When evaluating the cost structure for sourcing water bottles, particularly those that are BPA-free, it is essential to consider various components that contribute to the overall price. The primary cost elements include:

-

Materiais: The choice of materials significantly impacts costs. BPA-free bottles are commonly made from polyethylene terephthalate (PET) or other plastics that are considered safe for food contact. The price of raw materials can fluctuate based on market demand, availability, and quality. High-grade PET may be more expensive but offers better safety and recyclability.

-

Trabalho: Labor costs vary by region and can influence the final price. Countries with lower labor costs may offer more competitive pricing, but it’s essential to ensure that the manufacturing practices meet safety and quality standards.

-

Despesas gerais de fabrico: This includes utilities, rent, and operational costs of production facilities. Efficient manufacturing processes can help in reducing overhead, which is crucial for maintaining competitive pricing.

-

Ferramentas: The initial cost of molds and production tools can be substantial, especially for custom designs. This is often amortized over the production run, so larger orders can benefit from reduced per-unit tooling costs.

-

Controlo de qualidade (CQ): Ensuring that products meet safety standards is critical, particularly for food-contact items. Investing in robust QC processes can incur additional costs but is essential for compliance with international regulations.

-

Logística: Transportation and shipping costs can vary significantly, especially for international orders. Factors such as distance, shipping method, and local tariffs can affect overall logistics expenses.

-

Margem: Suppliers will include a profit margin that reflects the perceived value of their products, market competition, and demand.

How Do Price Influencers Impact Sourcing Decisions for BPA-Free Water Bottles?

Several factors influence the pricing of BPA-free water bottles, which are crucial for B2B buyers to consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders typically lead to lower per-unit costs, making it essential for buyers to assess their demand and negotiate favorable terms.

-

Especificações e personalização: Custom designs, colors, and features can increase costs. Buyers should clearly define their requirements to avoid unexpected charges during the production phase.

-

Materials Quality and Certifications: Higher quality materials and certifications (e.g., FDA approval, ISO standards) can command premium prices but ensure safety and reliability, which are vital for maintaining brand integrity.

-

Factores do fornecedor: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is crucial for managing costs. Different Incoterms (like FOB, CIF) can impact total landed costs and should be clearly defined in contracts.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing BPA-Free Water Bottles?

To maximize cost-efficiency and ensure a favorable sourcing experience, B2B buyers should consider the following tips:

-

Negotiate Terms: Engage in discussions with suppliers to negotiate better prices, especially for larger orders. Building a long-term relationship can also lead to discounts on future purchases.

-

Avaliar o custo total de propriedade (TCO): Don’t just focus on the purchase price. Consider the entire lifecycle cost, including logistics, storage, and potential disposal or recycling costs.

-

Research Pricing Nuances for International Markets: Be aware of regional pricing trends and local market conditions. For buyers in Africa, South America, the Middle East, and Europe, understanding local regulations and market dynamics can provide leverage in negotiations.

-

Leverage Technology: Utilize digital platforms for sourcing and procurement to compare prices and suppliers easily. This can lead to more informed decisions and better deals.

-

Mantenha-se informado sobre as tendências do mercado: Keeping abreast of material price fluctuations and regulatory changes can help in making timely purchasing decisions that capitalize on favorable conditions.

Declaração de exoneração de responsabilidade sobre os preços indicativos

Prices for BPA-free water bottles can vary widely based on the aforementioned factors, and the information provided herein is intended for indicative purposes only. Buyers should conduct thorough due diligence and obtain quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing do water bottles have bpa With Other Solutions

Introduction: Exploring Alternatives to BPA in Water Bottles

In recent years, concerns surrounding bisphenol A (BPA) in plastic water bottles have prompted businesses and consumers alike to seek safer alternatives. As international B2B buyers explore options for hydration solutions, understanding the various products available can enhance decision-making. This analysis compares the traditional use of water bottles containing BPA with alternative solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Tabela de comparação

| Aspeto de comparação | Do Water Bottles Have BPA | Stainless Steel Water Bottles | Glass Water Bottles |

|---|---|---|---|

| Desempenho | Generally safe; BPA-free options available | Excellent insulation; long-lasting | Pure taste; no chemical leaching |

| Custo | Low-cost, widely available | Moderate to high, durable investment | Moderate; can be expensive |

| Facilidade de implementação | Ready-to-use; disposable options available | Requires initial investment; reusable | Requires care in handling; reusable |

| Manutenção | Low maintenance; disposable options | Fácil de limpar; pode ser lavado na máquina de lavar louça | Requires careful cleaning; prone to breakage |

| Melhor caso de utilização | Everyday hydration; events | Active lifestyles; outdoor use | Office settings; eco-conscious consumers |

Análise pormenorizada das alternativas

Stainless Steel Water Bottles

Stainless steel water bottles have gained popularity due to their durability and insulating properties. They keep beverages cold or hot for extended periods, making them ideal for outdoor activities or travel. While the initial cost may be higher than plastic bottles, they offer a long-term investment as they are reusable and can significantly reduce waste. Maintenance is straightforward, as many stainless steel options are dishwasher safe. However, B2B buyers should consider that these bottles can be heavier than plastic alternatives, which might be a factor in specific applications.

Glass Water Bottles

Glass water bottles are often regarded as the safest option for hydration, as they do not leach chemicals into beverages. They offer a pure taste and are visually appealing, making them suitable for office environments or premium branding. However, glass bottles can be fragile, requiring careful handling to avoid breakage. The cost can also be a consideration, as high-quality glass bottles may be more expensive than their plastic counterparts. While they are reusable and easy to clean, B2B buyers must weigh the potential downsides, such as weight and fragility, against the benefits of safety and taste.

Conclusão: Como escolher a solução de hidratação correta

When selecting the right hydration solution, B2B buyers should evaluate their specific needs, including cost, intended use, and maintenance requirements. If cost-effectiveness and disposability are priorities, BPA-free plastic water bottles may suffice. However, for businesses focused on sustainability and long-term use, stainless steel or glass alternatives could provide better value despite the higher upfront costs. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational goals and consumer preferences.

Essential Technical Properties and Trade Terminology for do water bottles have bpa

What are the Key Technical Properties of BPA-Free Water Bottles?

Understanding the technical specifications of water bottles is essential for B2B buyers, especially when it comes to safety, quality, and compliance. Here are several critical properties to consider:

1. Grau do material

The most common material used in water bottles is polyethylene terephthalate (PET), identifiable by the recycling code “1”. This material is lightweight, durable, and resistant to impact. For B2B buyers, selecting the correct material grade is crucial as it ensures the product meets regulatory standards and consumer safety requirements. High-quality PET is also recyclable, aligning with sustainability goals.

2. Chemical Composition

Water bottles should be free from harmful chemicals like bisphenol A (BPA). B2B buyers must ensure that their products are compliant with safety regulations set forth by agencies such as the FDA. Ensuring a chemical-free composition not only addresses safety concerns but also enhances marketability, as consumers increasingly prefer BPA-free products.

3. Temperature Tolerance

Temperature tolerance indicates how well a water bottle can withstand various environmental conditions without degrading or leaching chemicals. For example, while PET bottles can typically handle temperatures up to 60°C (140°F), exposure to higher temperatures can lead to potential safety issues. Understanding temperature tolerance helps B2B buyers determine suitable applications and storage conditions for their products.

4. Resin Identification Code

The resin identification code is a crucial specification that provides insight into the type of plastic used. In the case of water bottles, the code “1” indicates PET, which is not associated with BPA. B2B buyers should prioritize products with clear identification codes to ensure compliance and build consumer trust.

5. Reciclabilidade

Recyclability is a key consideration in the selection of water bottles. PET is widely accepted in recycling programs globally, which is increasingly important for brands focusing on sustainability. B2B buyers should assess the recyclability of their products to align with environmental regulations and consumer expectations.

6. Capacity and Size Specifications

Water bottles come in various sizes, typically ranging from 250 ml to 2 liters. Capacity and size specifications can affect shipping costs, shelf space, and consumer preference. B2B buyers should evaluate market demand to select the appropriate sizes for their product lines.

What are Common Trade Terminology and Jargon Related to BPA-Free Water Bottles?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some key terms to understand:

1. OEM (Fabricante de Equipamento Original)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of water bottles, OEMs may provide customized designs or branding options. Understanding OEM relationships can help B2B buyers negotiate better deals and ensure product quality.

2. MOQ (Quantidade mínima de encomenda)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For water bottles, understanding MOQ is vital for inventory management and cost efficiency. It allows B2B buyers to assess whether a supplier aligns with their purchasing capacity and demand forecasts.

3. RFQ (Pedido de Cotação)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. B2B buyers should use RFQs to gather competitive pricing and terms from various manufacturers, ensuring they make informed purchasing decisions.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is crucial for B2B buyers involved in cross-border trade, as they dictate shipping responsibilities, risk management, and cost allocations.

5. Sustainability Certifications

These are labels or certifications that indicate a product meets certain environmental standards. For BPA-free water bottles, certifications can enhance marketability and assure buyers of their eco-friendliness. Familiarity with sustainability certifications can help B2B buyers make choices that align with their corporate social responsibility goals.

6. Compliance Standards

Compliance standards refer to regulations that products must meet to ensure safety and quality. In the context of water bottles, understanding these standards helps B2B buyers ensure their products are legally compliant and safe for consumers, thereby reducing liability risks.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions regarding BPA-free water bottles, ensuring safety, quality, and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the do water bottles have bpa Sector

What Are the Current Market Dynamics in the BPA Water Bottle Sector?

The global market for water bottles, particularly concerning BPA (bisphenol A) materials, is rapidly evolving, driven by consumer awareness and regulatory changes. Key markets in Africa, South America, the Middle East, and Europe are increasingly influenced by health and safety concerns associated with plastic products. Notably, the misconception that most plastic water bottles contain BPA has prompted manufacturers to pivot towards safer materials such as polyethylene terephthalate (PET). This shift is a significant trend, as PET is widely recognized as a BPA-free alternative, aligning with growing consumer demand for safer products.

In addition to health considerations, B2B buyers are increasingly focused on sustainability and ethical sourcing. The rise of e-commerce platforms and digital supply chain solutions has allowed international buyers to access a broader range of BPA-free products. Emerging technologies, such as blockchain for traceability and quality assurance, are enhancing transparency in the supply chain, which is crucial for buyers from regions with stringent regulatory environments. Furthermore, the increasing adoption of reusable water bottles, particularly in urban areas, is reshaping market dynamics, fostering innovation in design and functionality.

How Are Sustainability and Ethical Sourcing Influencing the BPA Water Bottle Market?

Sustainability is a critical factor influencing the sourcing of water bottles in today’s market. The environmental impact of plastic waste, particularly in regions with less robust recycling systems, has heightened the urgency for ethical sourcing practices. Buyers are increasingly seeking suppliers who prioritize eco-friendly materials and sustainable production processes. This trend is not just a response to consumer demand; it is becoming a regulatory requirement in many countries.

In this context, BPA-free certifications and the use of recycled materials are essential for B2B buyers. Certifications such as ISO 14001 for environmental management systems and labels indicating BPA-free status can significantly enhance a product’s marketability. Manufacturers are also exploring bioplastics and other innovative materials that reduce reliance on fossil fuels. As a result, businesses that invest in sustainable practices are likely to gain a competitive edge, appealing to environmentally conscious consumers and meeting regulatory expectations.

How Has the BPA Water Bottle Market Evolved Over Time?

The evolution of the BPA water bottle market reflects broader societal changes regarding health and safety. Initially, BPA was widely used in various plastic products, including water bottles, due to its durability and versatility. However, as scientific research began to reveal potential health risks associated with BPA exposure, consumer sentiment shifted dramatically.

By the early 2010s, regulatory bodies such as the FDA and Health Canada had begun to restrict the use of BPA in products intended for children, leading to a broader reassessment of its safety in consumer goods. This shift prompted manufacturers to innovate and develop BPA-free alternatives, such as PET bottles, which are now the standard in the industry. Today, the focus on health, safety, and sustainability continues to shape market dynamics, creating opportunities for B2B buyers to engage with suppliers who prioritize these values.

Frequently Asked Questions (FAQs) for B2B Buyers of do water bottles have bpa

-

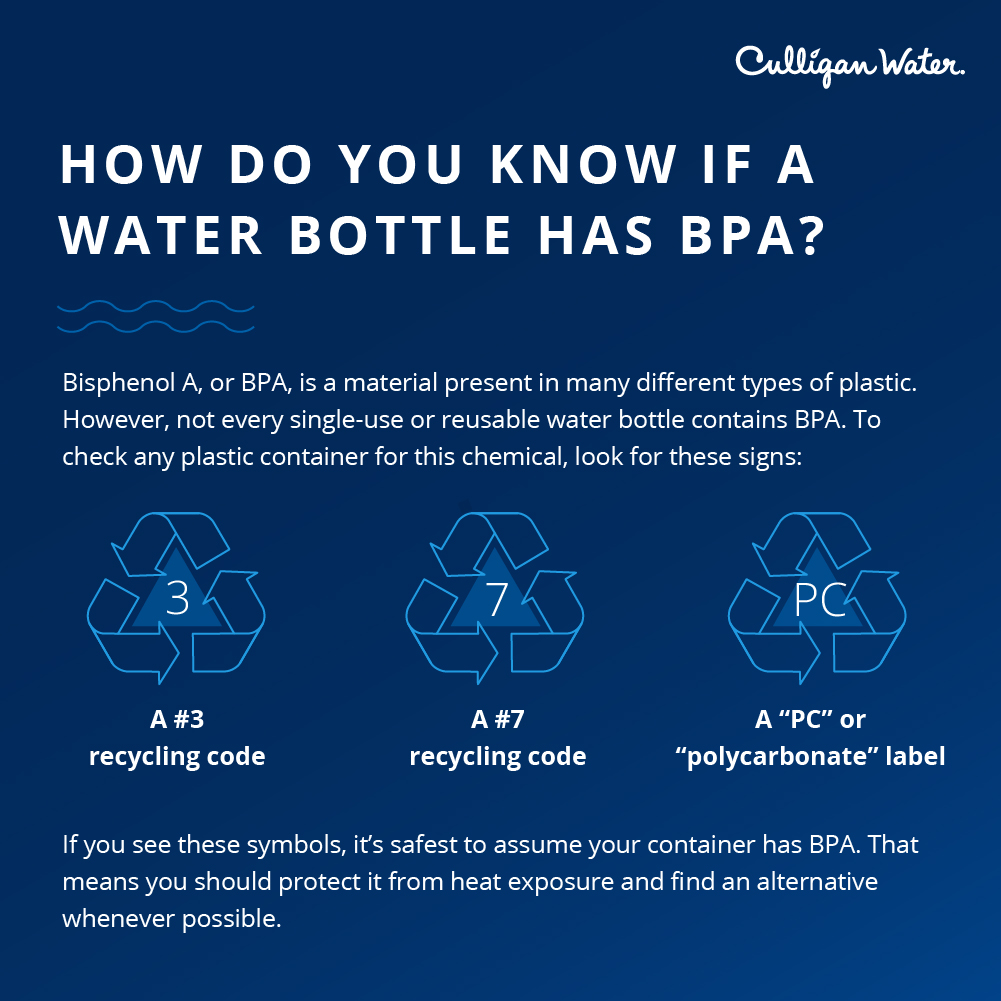

How can I determine if a water bottle contains BPA?

To ascertain whether a water bottle contains BPA, check for the recycling code on the bottom of the bottle. Codes 3 and 7 may indicate the presence of BPA, while code 1 (PET) is BPA-free. Additionally, look for labels that explicitly state “BPA-free.” Many manufacturers now produce BPA-free alternatives due to health concerns, so sourcing from suppliers who offer such products is advisable. When evaluating suppliers, request documentation confirming the absence of BPA in their products. -

What are the health implications of BPA in water bottles?

BPA is primarily associated with polycarbonate plastics and epoxy resins, which are not typically used in single-use water bottles made from PET. Regulatory bodies like the FDA have deemed BPA safe at low levels, but concerns about its potential health effects, such as hormonal disruption, have led to a rise in BPA-free products. For B2B buyers, understanding these implications can guide sourcing decisions and align product offerings with consumer health trends, particularly in regions sensitive to health issues. -

What should I look for in a supplier of BPA-free water bottles?

When sourcing BPA-free water bottles, prioritize suppliers with certifications that guarantee product safety and compliance with international health standards. Inquire about their manufacturing processes, materials used, and whether they can provide third-party testing results. Additionally, assess their production capacity, lead times, and ability to customize designs to meet your market’s needs, especially if you are targeting specific regions like Africa or South America. -

Quais são as quantidades mínimas de encomenda (MOQs) para garrafas de água?

MOQs for water bottles can vary significantly depending on the supplier and the customization required. Many manufacturers set MOQs between 1,000 to 10,000 units for custom designs, while standard products may have lower MOQs. It’s crucial to communicate your specific needs with suppliers to negotiate favorable terms, especially if you are entering new markets where demand may be uncertain. -

What payment terms are typical for international B2B purchases of water bottles?

Payment terms can vary by supplier, but typical arrangements include a deposit (often 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may offer favorable terms like net 30 or net 60 days, especially for established clients. Ensure to clarify these terms before finalizing contracts and consider using secure payment methods that protect both parties, particularly in international transactions. -

How can I ensure quality assurance (QA) for my water bottle orders?

To maintain quality assurance for your water bottle orders, establish a clear QA protocol with your supplier. This should include pre-production samples, regular quality checks during manufacturing, and a final inspection before shipping. Request certifications that demonstrate compliance with relevant safety standards, and consider employing third-party inspection services for added assurance, particularly when sourcing from regions with varying quality standards. -

What are the logistics considerations for importing water bottles?

Logistics for importing water bottles involve several factors, including shipping methods, customs clearance, and distribution channels. Assess the most cost-effective shipping options, such as sea freight for bulk orders, and ensure your supplier can meet your delivery timelines. Familiarize yourself with import regulations in your target market, including tariffs and labeling requirements, to avoid delays and additional costs. -

How can I customize water bottles to meet specific market demands?

Customization of water bottles can include size, shape, color, and branding options such as logos or labels. Engage with suppliers who offer flexible manufacturing capabilities and are open to collaboration. Conduct market research to identify preferences in your target regions, such as eco-friendly materials or specific designs, to ensure your products resonate with local consumers. Establish clear communication with your supplier to ensure that your customization requirements are met efficiently.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.

Top 9 Do Water Bottles Have Bpa Manufacturers & Suppliers List

1. Reddit – BPA-Free Water Bottle Alternatives

Domínio: reddit.com

Registada: 2005 (20 anos)

Introdução: BPA-free water bottles are recommended due to concerns about BPA in plastic. The user is looking for alternatives to bottled water that may contain BPA and is considering using a stainless steel bottle. They also mention having well water that hasn’t been tested.

2. HowStuffWorks – BPA in Everyday Products

Domínio: science.howstuffworks.com

Registada: 1998 (27 anos)

Introdução: BPA (Bisphenol A) is a key component in polycarbonate plastics used in various products including water bottles, baby bottles, food storage containers, contact lenses, CDs, receipts, and electronic devices. BPA is also found in epoxy resins that line tin cans and in dental sealants. Products labeled “BPA free” do not contain bisphenol A, but may contain other bisphenols like bisphenol F and bisphe…

3. Cancer Council – Safe Water Bottles

Domínio: cancer.org.au

Introdução: It’s safe to drink water out of plastic bottles without a risk of cancer, even when left in hot cars, frozen, or reused. There is no scientific evidence to dispute this. BPA and materials used in water bottles are safe according to Food Standards Australia New Zealand. Bacteria and fungi can grow in bottled water if left for a long time, so it’s best to clean them with hot, soapy water before refi…

4. Hydrocell – BPA Free Water Bottles

Domínio: hydrocellusa.com

Registado: 2017 (8 anos)

Introdução: This company, Hydrocell – BPA Free Water Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Apec Water – Whole House Systems & Tankless RO

Domínio: apecwater.com

Registada: 2004 (21 anos)

Introdução: Labor Day Sale: Extra 8% Off Entire Order + $75/$150 Off Single/Dual Tank Whole House Systems. New! Shop the Latest Tankless RO and Alkaline Tankless RO System! Free Shipping on Orders $49+. Subscribe & Save: Save Up to Extra 10% on Replacement Filters Subscription Orders.

6. Nestlé Pure Life – Bottled Water Products

Domínio: nestlepurelife.com

Registada: 2005 (20 anos)

Introdução: Nestlé Pure Life bottled water products are designed with safety and quality as top priorities. The packaging has been reduced in plastic to be more environmentally friendly, particularly in the half-liter and 24-ounce sports bottles, which have smaller caps that pose a choking hazard for children. The water is purified through reverse osmosis, UV, and ozone disinfection, and enhanced with mineral…

7. BBC – Plastic Water Bottle Concerns

Domínio: bbc.co.uk

Registada: 1996 (29 anos)

Introdução: The text discusses concerns about plastic water bottles and their potential link to cancer, particularly focusing on the chemical bisphenol A (BPA). BPA is found in various plastic products, including polycarbonate containers and food can linings. Claims suggest that BPA can mimic female hormones and may be linked to health issues, though there is no conclusive evidence that everyday exposure is h…

8. Water Boy, Inc. – BPA-Free Tritan™ Water Bottles

Domínio: waterboyinc.com

Registada: 1998 (27 anos)

Introdução: BPA-free water bottles from Water Boy, Inc. are Tritan™ copolyester bottles manufactured by Eastman. They are designed to be eco-friendly, less likely to leech chemicals into water, recyclable (with a #7 recycling rating), and healthier for young children. These bottles are built from a material similar to polyethylene terephthalate (PET) plastic, offering similar weight and durability as traditio…

9. BottleStore – BPA Free Plastic Bottles and Jars

Domínio: blog.bottlestore.com

Registada: 1998 (27 anos)

Introdução: BPA Free Plastic Bottles, Jars, and Jugs available at BottleStore. Materials that are BPA free include PET, HDPE, LDPE, PP, and PS. To identify if a plastic bottle is BPA free, check the recycling code on the bottom: codes 1, 2, 4, 5, or 6 indicate BPA free; code 3 (PVC) likely contains BPA; code 7 is inconclusive. BottleStore provides a selection of BPA free plastic containers.

Strategic Sourcing Conclusion and Outlook for do water bottles have bpa

In summary, understanding the implications of BPA in water bottles is crucial for international B2B buyers seeking safe and sustainable product options. Key insights reveal that most plastic water bottles are made from polyethylene terephthalate (PET), which does not contain BPA. Regulatory bodies, including the FDA, affirm the safety of BPA at low exposure levels, although concerns regarding long-term health effects persist. As buyers prioritize sustainability and health in their sourcing strategies, it is essential to seek out BPA-free products and reliable suppliers.

Strategic sourcing not only mitigates potential health risks associated with BPA but also aligns with the growing demand for environmentally friendly packaging solutions. For businesses in Africa, South America, the Middle East, and Europe, this is an opportune moment to reevaluate supply chains and invest in high-quality, BPA-free water bottles.

Looking ahead, companies should proactively engage with manufacturers who prioritize safety and sustainability. By doing so, you can ensure compliance with international standards while catering to the evolving preferences of health-conscious consumers. Embrace this opportunity to enhance your product offerings and foster long-term partnerships in the global market.