Introduction: Navigating the Global Market for two gallon water bottle

In today’s global market, sourcing the right two-gallon water bottle can be a daunting task for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality products but also in navigating the complexities of different suppliers, materials, and pricing structures. This comprehensive guide aims to equip international buyers with the necessary insights to make informed purchasing decisions.

Within these pages, we will explore a variety of two-gallon water bottles—including BPA-free options, polycarbonate materials, and insulated designs—while delving into their specific applications across various sectors such as hospitality, outdoor events, and office environments. Additionally, we will provide strategies for effectively vetting suppliers to ensure compliance with international quality standards, alongside a breakdown of costs to help you budget effectively.

By the end of this guide, B2B buyers will gain a clear understanding of the market landscape, empowering them to choose the best products that align with their operational needs and customer expectations. Whether you’re based in bustling urban centers or remote locales, this resource will help streamline your sourcing process, ensuring you secure reliable and durable water bottles that meet your business requirements.

Navegação de artigos

- Top 7 Two Gallon Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for two gallon water bottle

- Understanding two gallon water bottle Types and Variations

- Key Industrial Applications of two gallon water bottle

- 3 Common User Pain Points for ‘two gallon water bottle’ & Their Solutions

- Strategic Material Selection Guide for two gallon water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for two gallon water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘two gallon water bottle’

- Comprehensive Cost and Pricing Analysis for two gallon water bottle Sourcing

- Alternatives Analysis: Comparing two gallon water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for two gallon water bottle

- Navigating Market Dynamics and Sourcing Trends in the two gallon water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of two gallon water bottle

- Aviso importante e termos de utilização

- Strategic Sourcing Conclusion and Outlook for two gallon water bottle

Understanding two gallon water bottle Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Plástico sem BPA | Lightweight, impact-resistant, and cost-effective. | Retail, hospitality, outdoor events | Prós: Affordable, easy to transport. Contras: Less durable than glass. |

| Policarbonato | High durability, FDA-approved, retains shape under heat. | Water delivery services, corporate offices | Prós: Long-lasting, suitable for various temperatures. Contras: Heavier than plastic. |

| Insulated Water Jug | Double-wall insulation, keeps beverages cold/hot. | Construction sites, outdoor activities | Prós: Temperature retention, rugged design. Contras: Preço mais elevado. |

| Glass Water Bottle | Eco-friendly, aesthetic appeal, non-leaching. | Premium retail, health-focused businesses | Prós: Safe for health, reusable. Contras: Frágil, mais pesado para transportar. |

| Collapsible Water Bottle | Space-saving, flexible design for easy storage. | Travel, events, emergency supplies | Prós: Portable, lightweight. Contras: Limited capacity, may not be as durable. |

What Are the Characteristics of BPA-Free Plastic Two Gallon Water Bottles?

BPA-free plastic water bottles are a popular choice among B2B buyers due to their lightweight and cost-effective nature. These bottles are typically made from high-density polyethylene (HDPE) or Tritan, making them impact-resistant and suitable for various applications. Commonly used in retail settings and for outdoor events, these bottles are easy to transport and can be printed with branding for promotional purposes. However, while they offer affordability, they may not withstand extreme temperatures as effectively as more durable materials.

Why Choose Polycarbonate Two Gallon Water Bottles for Your Business?

Polycarbonate water bottles are known for their strength and durability, making them ideal for businesses that require long-lasting solutions. These bottles are FDA-approved and can maintain their shape under high temperatures, making them suitable for water delivery services and corporate offices. The key B2B purchasing consideration is their higher weight compared to plastic options, which may impact shipping costs. However, their longevity often outweighs the initial investment for businesses focused on sustainability and quality.

How Do Insulated Water Jugs Benefit Outdoor and Construction Businesses?

Insulated water jugs are designed with double-wall foam insulation, which keeps beverages cold for extended periods. This feature is particularly beneficial for construction sites and outdoor activities where access to chilled drinks is crucial. Businesses should consider the rugged design and high-flow spigot, which facilitates easy pouring and cleaning. While these jugs are generally priced higher than standard options, their durability and functionality make them a worthy investment for companies prioritizing employee hydration.

What Are the Advantages of Using Glass Water Bottles in Premium Retail?

Glass water bottles offer an eco-friendly alternative that appeals to health-conscious consumers. Their aesthetic appeal and non-leaching properties make them ideal for premium retail and health-focused businesses. B2B buyers should evaluate the branding opportunities, as glass bottles can be elegantly designed and labeled. However, the fragility of glass poses a challenge in transport and storage, which may necessitate additional protective measures, thereby increasing overall costs.

Why Are Collapsible Water Bottles a Practical Choice for Events and Travel?

Collapsible water bottles provide a space-saving solution for businesses that require portable hydration options, especially during travel or events. Their flexible design allows them to be easily stored when not in use, making them a practical choice for emergency supplies as well. While they are lightweight and convenient, buyers should be aware of the limited capacity and potential durability concerns compared to more rigid options. This trade-off can be significant for companies prioritizing versatility in their product offerings.

Key Industrial Applications of two gallon water bottle

| Indústria/Setor | Specific Application of Two Gallon Water Bottle | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Alimentação e bebidas | Catering and Event Services | Ensures ample hydration for guests, reducing waste | Look for BPA-free materials and easy-to-clean designs |

| Construction and Outdoors | Job Sites and Outdoor Events | Provides hydration for workers in remote locations | Durable construction and high-temperature resistance |

| Cuidados de saúde | Medical Facilities and Emergency Services | Supplies water for patients and staff in critical areas | Compliance with health regulations and sterilization options |

| Hospitalidade | Hotels and Resorts | Enhances guest experience with convenient water access | Custom branding options and sustainable materials |

| Agricultura | Livestock and Crop Irrigation | Ensures adequate water supply for livestock or crops | UV protection and impact resistance for outdoor use |

How is the Two Gallon Water Bottle Used in Catering and Event Services?

In the food and beverage sector, two gallon water bottles are essential for catering and event services. They provide a practical solution for keeping guests hydrated during large gatherings, reducing the need for single-use plastic bottles. These bottles can be easily transported and refilled, allowing businesses to minimize waste while maintaining a steady supply of water. Buyers in this sector should prioritize BPA-free options that are easy to clean and refill, ensuring both safety and convenience for event staff.

What Role Does the Two Gallon Water Bottle Play in Construction and Outdoor Events?

For construction sites and outdoor events, two gallon water bottles serve as vital hydration sources for workers. They withstand rugged conditions and provide a reliable supply of water in remote locations. This is particularly important in regions with extreme weather, where hydration is critical for worker safety and productivity. Buyers should consider bottles made from durable materials that can resist high temperatures and impacts, ensuring longevity in challenging environments.

How Can Healthcare Facilities Benefit from Two Gallon Water Bottles?

In healthcare settings, two gallon water bottles are used to supply water in patient care areas and emergency services. These bottles can be strategically placed in waiting rooms, patient rooms, and staff break areas to ensure easy access to hydration. Compliance with health regulations is crucial, so buyers should seek bottles that allow for easy sterilization and are made from materials that meet safety standards. This enhances patient care while promoting staff well-being.

Why Are Two Gallon Water Bottles Important for the Hospitality Industry?

In the hospitality sector, hotels and resorts utilize two gallon water bottles to enhance guest experiences. They can be placed in guest rooms or common areas, providing convenient access to hydration without the need for costly mini-bars or room service. Additionally, offering branded bottles can serve as a marketing tool. Buyers should look for customization options and sustainable materials, as eco-conscious consumers increasingly prefer businesses that prioritize environmental responsibility.

How Do Two Gallon Water Bottles Support Agricultural Practices?

Two gallon water bottles are also beneficial in agriculture, particularly for livestock and crop irrigation. They ensure that animals have a consistent water supply, which is crucial for health and productivity. In crop management, these bottles can be used for localized irrigation in areas where water access is limited. Buyers in this sector should focus on bottles that offer UV protection and are resistant to environmental wear, ensuring that they can withstand outdoor conditions while delivering reliable performance.

3 Common User Pain Points for ‘two gallon water bottle’ & Their Solutions

Scenario 1: Challenges with Durability in Harsh Environments

O problema: B2B buyers in industries such as construction or outdoor events often face issues with the durability of two-gallon water bottles. In rugged environments, these bottles may crack or become damaged due to exposure to extreme temperatures or rough handling. This not only leads to product loss but also increases operational costs due to the need for frequent replacements. Buyers are particularly concerned about sourcing bottles that can withstand their specific conditions while ensuring safety and reliability for their teams.

A solução: To effectively address durability concerns, buyers should prioritize sourcing two-gallon water bottles made from high-quality, impact-resistant materials such as BPA-free plastic or polycarbonate. These materials are specifically designed to endure extreme conditions and temperature fluctuations without degrading. When selecting suppliers, buyers should request product specifications that highlight the impact resistance and thermal stability of the bottles. Additionally, consider investing in insulated models that offer double-wall construction, which can help maintain beverage temperatures while providing extra durability. Regular training for employees on proper handling and storage can also reduce damage and extend the lifespan of the bottles.

Scenario 2: Managing Water Quality and Safety Concerns

O problema: In regions where water quality may be a concern, such as areas with limited access to clean drinking water, B2B buyers must ensure that the two-gallon water bottles they use do not compromise water safety. Bottles that leach harmful chemicals or fail to maintain the integrity of the water can lead to health risks for employees and customers. This is particularly critical for businesses in the food and beverage industry, where compliance with health regulations is paramount.

A solução: To mitigate water quality concerns, buyers should exclusively source two-gallon water bottles that are certified for food safety and made from FDA-approved materials. Look for bottles that are specifically labeled as BPA-free, as this indicates they do not contain harmful chemicals that could leach into the water. Furthermore, implementing a regular cleaning and sanitizing schedule for the bottles will ensure that they remain safe for use. Buyers should also consider investing in additional filtration systems that can be integrated with the bottles to further enhance water quality. When purchasing, verify the supplier’s certifications and request documentation that confirms the safety standards of the materials used.

Scenario 3: Logistics and Transportation Challenges

O problema: For B2B buyers involved in logistics or supply chain management, transporting two-gallon water bottles can present significant challenges. Bottles are often bulky and can be prone to leakage if not packed properly, leading to wasted resources and potential damage to other products during transit. Additionally, the weight of the bottles can increase shipping costs, impacting overall profitability.

A solução: To streamline logistics, buyers should consider sourcing two-gallon water bottles designed for efficient transportation. Opt for bottles that feature a compact design and are stackable, which can maximize space in transport vehicles. Investing in leak-proof models is crucial to prevent spills during transit. Moreover, suppliers should be evaluated based on their ability to provide secure packaging that minimizes movement and protects against damage. Buyers can also explore bulk purchasing options to reduce per-unit shipping costs, thus optimizing logistics expenses. Regular assessments of the transportation process can identify areas for improvement, ensuring that the bottles reach their destination safely and efficiently.

Strategic Material Selection Guide for two gallon water bottle

What Are the Key Materials for Two Gallon Water Bottles?

When selecting materials for two-gallon water bottles, various factors impact performance, durability, and cost. Below, we analyze four common materials: BPA-free plastic, polycarbonate, stainless steel, and glass, providing insights relevant to international B2B buyers.

What Are the Properties of BPA-Free Plastic for Two Gallon Water Bottles?

BPA-free plastic is a popular choice for water bottles due to its lightweight nature and impact resistance. It typically withstands temperatures up to 100°C (212°F) and is designed to be shatterproof, making it suitable for various environments. However, it may not be as resistant to UV light, which can lead to degradation over time.

Prós: This material is cost-effective and easy to manufacture, allowing for mass production. Its lightweight nature makes it convenient for transportation and handling.

Contras: While BPA-free plastics are generally durable, they can be prone to scratching and may not withstand extreme temperatures as well as other materials. Additionally, concerns about long-term chemical leaching persist.

Impacto na aplicação: BPA-free plastic is compatible with cold and room-temperature water but may not be ideal for hot liquids.

Considerações para compradores internacionais: Compliance with local regulations regarding food safety and material safety standards is crucial. Buyers should ensure products meet ASTM standards and check for certifications relevant to their regions.

How Does Polycarbonate Compare for Two Gallon Water Bottles?

Polycarbonate is a high-performance plastic known for its clarity and strength. It can endure high temperatures (up to 120°C or 248°F) and is resistant to impact and shattering, making it ideal for rugged use.

Prós: Polycarbonate bottles are durable and can handle extreme conditions, making them suitable for outdoor and industrial applications. They are also lightweight and can be molded into various shapes.

Contras: The manufacturing process can be more complex and costly compared to other plastics. Moreover, concerns about BPA in some polycarbonate products may deter eco-conscious buyers.

Impacto na aplicação: Polycarbonate is suitable for both cold and hot liquids, ensuring versatility in usage.

Considerações para compradores internacionais: Buyers should verify that polycarbonate products comply with local food safety regulations and standards, such as those set by DIN or JIS.

What Are the Benefits of Using Stainless Steel for Two Gallon Water Bottles?

Stainless steel offers excellent durability and resistance to corrosion, making it a premium choice for water bottles. It can withstand high temperatures and is generally safe for food and beverage contact.

Prós: This material is highly durable, resistant to rust, and can maintain the temperature of liquids for extended periods. Its long lifespan adds to its cost-effectiveness over time.

Contras: Stainless steel bottles tend to be heavier and more expensive than plastic options. The manufacturing process can also be more complex, requiring specialized equipment.

Impacto na aplicação: Stainless steel is suitable for both hot and cold liquids, making it versatile for various uses.

Considerações para compradores internacionais: Compliance with health and safety standards is crucial. Buyers should ensure that the stainless steel used is of food-grade quality and meets relevant international standards.

What Advantages Does Glass Offer for Two Gallon Water Bottles?

Glass is a premium material known for its aesthetic appeal and inert properties, meaning it does not leach chemicals into liquids. It can handle high temperatures and is easy to clean.

Prós: Glass bottles are reusable and recyclable, appealing to environmentally conscious buyers. They do not impart flavors or odors to the contents.

Contras: The primary drawback is their fragility; glass can break easily, making it less suitable for rough handling. Additionally, glass bottles are heavier than their plastic counterparts.

Impacto na aplicação: Glass is ideal for storing cold liquids but may not be suitable for high-pressure applications due to the risk of shattering.

Considerações para compradores internacionais: Buyers should ensure that glass products comply with safety standards and are manufactured to withstand the rigors of transportation and use.

Summary of Material Selection for Two Gallon Water Bottles

| Material | Typical Use Case for Two Gallon Water Bottle | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Plástico sem BPA | General consumer use, outdoor events | Leve e económico | Prone to scratches and UV degradation | Baixa |

| Policarbonato | Industrial and rugged outdoor applications | Highly durable and temperature resistant | Potential BPA concerns | Médio |

| Aço inoxidável | Premium consumer and commercial use | Long-lasting and temperature retaining | Heavier and more expensive | Elevado |

| Vidro | Eco-friendly consumer use, upscale markets | Não reativo e reciclável | Frágil e pesado | Médio |

This guide aims to assist B2B buyers in making informed decisions regarding material selection for two-gallon water bottles, ensuring compliance with regional standards and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for two gallon water bottle

What Are the Main Stages of Manufacturing a Two Gallon Water Bottle?

The manufacturing process of a two-gallon water bottle typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets quality and safety standards essential for B2B buyers.

How Is Material Prepared for Two Gallon Water Bottles?

Material preparation is the first step in the manufacturing process. Common materials used for two-gallon water bottles include BPA-free plastics, polycarbonate, and glass. The selected material must undergo rigorous quality checks to ensure it meets safety and performance specifications. For instance, polycarbonate materials are often chosen for their impact resistance and durability, making them suitable for high-usage environments.

During this stage, suppliers may also carry out tests to confirm the absence of harmful chemicals, ensuring compliance with international standards such as FDA regulations and European Union directives. This is particularly important for international B2B buyers who may have specific regulatory requirements in their markets.

What Techniques Are Used in Forming Two Gallon Water Bottles?

The forming stage involves shaping the prepared materials into the desired bottle form. Common techniques include blow molding and injection molding. Blow molding is particularly favored for plastic bottles, as it allows for the creation of lightweight yet sturdy containers.

Injection molding can also be used, especially for components such as caps and valves. Both methods require precise temperature and pressure controls to achieve uniform wall thickness and structural integrity. This is vital for ensuring that the bottles can withstand the rigors of transport and use, reducing the likelihood of leaks or breakage.

How Are Two Gallon Water Bottles Assembled?

Once the bottles have been formed, the assembly process begins. This includes attaching any necessary components such as caps, handles, and spigots. Depending on the design, assembly may also involve adding features like easy-pour spouts or internal valves that facilitate dispensing.

Quality assurance checks are integral during this phase to ensure that all components fit properly and function as intended. Misaligned or poorly fitted parts can lead to product failures, which are particularly detrimental in B2B transactions where reliability is paramount.

What Finishing Processes Are Applied to Two Gallon Water Bottles?

The finishing stage includes surface treatment, labeling, and packaging. Surface treatments may involve applying coatings that enhance the bottle’s durability and aesthetic appeal. Labels must be affixed in compliance with local regulations, often requiring information on the material, recycling instructions, and safety warnings.

Packaging is also crucial, as it protects the bottles during transportation and storage. B2B buyers should pay attention to the packaging quality, as it can impact the product’s arrival condition. Ensuring that packaging is robust and designed to prevent damage during transit is essential for maintaining quality.

What Quality Assurance Standards Are Relevant for Two Gallon Water Bottles?

Quality assurance (QA) is an essential aspect of the manufacturing process, particularly for B2B buyers seeking reliable suppliers. International standards such as ISO 9001 provide frameworks for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

Which International and Industry-Specific Standards Apply?

In addition to ISO 9001, other standards may be relevant depending on the market. For instance, the CE marking is vital for products sold in the European market, indicating compliance with health and safety standards. Similarly, the American Petroleum Institute (API) standards may apply if the bottles are intended for use in oil and gas operations, emphasizing the need for rigorous testing and certification.

For B2B buyers from regions like Africa and South America, understanding these standards can be crucial in selecting suppliers who adhere to recognized quality benchmarks. This not only ensures product safety but also facilitates smoother cross-border trade.

What Quality Control Checkpoints Should B2B Buyers Be Aware Of?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Controlo de qualidade de entrada (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet specified standards.

- Controlo de qualidade durante o processo (IPQC): During the manufacturing stages, ongoing checks are conducted to monitor production parameters and identify potential defects early.

- Controlo de qualidade final (FQC): Before packaging, each batch of water bottles undergoes a final inspection to verify that they meet all quality and safety requirements.

These checkpoints help in identifying issues at various stages, reducing the likelihood of defective products reaching the market.

What Testing Methods Are Commonly Used for Two Gallon Water Bottles?

Various testing methods are employed to ensure that two-gallon water bottles meet safety and performance standards. Common tests include:

- Testes de queda: Assessing impact resistance by dropping bottles from specified heights to simulate real-world usage.

- Leak Tests: Ensuring that caps and seals are airtight by pressurizing bottles and checking for leaks.

- Chemical Resistance Tests: Verifying that the material does not degrade when exposed to common substances that may be stored in the bottle.

B2B buyers should request documentation of these tests from suppliers to validate the quality and safety of the products being offered.

Como podem os compradores B2B verificar o controlo de qualidade dos fornecedores?

B2B buyers can implement several strategies to verify the quality control processes of potential suppliers:

- Audits: Conducting regular audits of the manufacturing facility can provide insights into the supplier’s adherence to quality standards.

- Relatórios de qualidade: Requesting detailed quality reports that outline testing results and compliance with international standards can help buyers assess product reliability.

- Inspecções por terceiros: Engaging third-party inspection agencies can further validate the supplier’s claims regarding quality and safety.

In regions like Europe and the Middle East, where regulatory compliance is stringent, these practices can safeguard against potential liabilities and ensure that purchased products align with market expectations.

Quais são as nuances do controlo de qualidade e da certificação para os compradores internacionais B2B?

International B2B buyers face unique challenges in navigating quality control and certification nuances. Understanding the regulatory landscape of the target market is crucial, as different regions may have varying standards. Additionally, language barriers and differing practices can complicate communication with suppliers.

Buyers should consider local regulations when sourcing products, ensuring that suppliers are aware of and compliant with these requirements. Establishing clear communication channels and utilizing technology for real-time updates can help mitigate risks associated with international trade.

In summary, understanding the manufacturing processes and quality assurance protocols for two-gallon water bottles is essential for B2B buyers. By focusing on key stages of manufacturing, relevant standards, and effective verification methods, buyers can make informed decisions that align with their quality and safety expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘two gallon water bottle’

To assist B2B buyers in sourcing two-gallon water bottles effectively, this practical guide outlines essential steps to ensure a successful procurement process. By following these steps, buyers can make informed decisions that align with their operational needs and market demands.

Passo 1: Definir as suas especificações técnicas

Establishing clear technical specifications is crucial in ensuring the selected water bottles meet your operational needs. Consider factors such as material (e.g., BPA-free plastic, glass, or stainless steel), capacity, and design features like handles or spouts. Specific requirements can help streamline your search and avoid miscommunications with suppliers.

Passo 2: Identify Your Target Market

Understanding the preferences and requirements of your target market is vital. Different regions may have varying needs based on climate, usage (e.g., outdoor activities, office use), and health regulations. Tailoring your product offerings to meet these regional demands can enhance your competitiveness and customer satisfaction.

Passo 3: Avaliar potenciais fornecedores

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, product certifications, and references from other buyers in similar industries or regions. Look for suppliers who demonstrate reliability, quality control processes, and a history of successful deliveries.

- Check for Certifications: Ensure that suppliers comply with international quality standards, such as ISO or FDA certifications, especially for food-grade materials.

- Assess Production Capacity: Evaluate if the supplier can meet your volume requirements consistently.

Passo 4: Pedido de amostras para avaliação da qualidade

Obtaining samples is a critical step in the sourcing process. This allows you to assess the quality, durability, and design of the bottles firsthand. Pay attention to aspects such as the sturdiness of the material, ease of use, and any functional features like leak-proof designs or insulation.

Passo 5: Analyze Pricing and Payment Terms

Pricing structures can vary significantly among suppliers, making it essential to compare quotes effectively. Look beyond the initial cost; consider bulk pricing, shipping fees, and potential discounts for long-term contracts. Additionally, clarify payment terms to avoid any cash flow issues, especially if dealing with international suppliers.

Passo 6: Negotiate Contracts Carefully

Once you have selected a supplier, negotiate the contract terms meticulously. Ensure that all specifications, delivery schedules, and payment terms are clearly outlined to avoid misunderstandings. Discuss penalties for non-compliance or delays, and consider including clauses for product returns and warranties.

Passo 7: Plano de logística e distribuição

Finally, develop a logistics plan that aligns with your distribution strategy. Consider how the bottles will be transported, stored, and delivered to your customers. Evaluate the supplier’s ability to support your logistics needs, including packaging options and delivery timelines, to ensure a smooth supply chain process.

By following these steps, B2B buyers can navigate the complexities of sourcing two-gallon water bottles effectively, ensuring they choose products that meet their specifications while maintaining quality and cost-efficiency.

Comprehensive Cost and Pricing Analysis for two gallon water bottle Sourcing

When sourcing two-gallon water bottles, understanding the cost structure and pricing nuances is essential for international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe. This analysis delves into the cost components involved, the factors influencing pricing, and strategic tips for buyers.

What Are the Key Cost Components in Sourcing Two-Gallon Water Bottles?

The cost structure for two-gallon water bottles can be broken down into several key components:

-

Materiais: The choice of materials significantly impacts costs. Common options include BPA-free plastic, polycarbonate, and glass. Each material has varying costs, with glass generally being more expensive due to its manufacturing process and fragility.

-

Trabalho: Labor costs can vary based on the region of production. For example, manufacturers in countries with higher labor costs may charge more for their products. Understanding local wage standards can help buyers assess potential costs.

-

Despesas gerais de fabrico: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, thus impacting overall pricing.

-

Ferramentas: If customization is required, tooling costs can be significant. This involves the creation of molds or specific designs tailored to the buyer’s specifications.

-

Controlo de qualidade (CQ): Implementing robust QC processes ensures product reliability but adds to the overall cost. Certifications like ISO or FDA approvals also contribute to increased costs but are crucial for compliance and quality assurance.

-

Logística: Shipping costs vary widely based on distance, shipping methods, and import/export tariffs. Understanding Incoterms (International Commercial Terms) is vital for determining who bears these costs.

-

Margem: Suppliers typically include a profit margin in their pricing. This margin can fluctuate based on the supplier’s position in the market, competition, and their overall business strategy.

How Do Volume and Customization Affect Pricing for Two-Gallon Water Bottles?

Pricing is heavily influenced by several factors:

-

Volume/MOQ (Quantidade mínima de encomenda): Larger orders typically lead to lower per-unit costs due to economies of scale. Suppliers often offer tiered pricing, incentivizing bulk purchases.

-

Especificações e personalização: Custom features such as branding, unique designs, or added functionalities (like built-in dispensers) can elevate costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Qualidade dos materiais e certificações: Higher quality materials and certifications can increase costs but also enhance product durability and safety. Buyers should weigh the benefits against the additional expenses.

-

Factores do fornecedor: The supplier’s reputation, reliability, and production capabilities play a significant role in pricing. Established suppliers with robust quality control may charge more but offer assurance of product quality.

What Are the Key Buyer Tips for Cost-Efficient Sourcing of Two-Gallon Water Bottles?

International buyers can adopt several strategies to enhance cost-efficiency:

-

Negociação: Engaging in negotiations can lead to better pricing, especially for larger orders. Suppliers may be open to adjusting prices based on commitment or loyalty.

-

Custo total de propriedade (TCO): Consider not just the purchase price but all associated costs, including shipping, storage, and potential waste. A lower initial price may lead to higher TCO if the product has a shorter lifespan.

-

Nuances de preços para compradores internacionais: Understanding local market conditions, currency fluctuations, and regional tariffs can help buyers make informed decisions. Buyers from regions like Africa or South America should also be aware of potential logistical challenges that may impact delivery times and costs.

-

Declaração de exoneração de responsabilidade para preços indicativos: It’s crucial to note that prices can vary widely based on the aforementioned factors. Buyers should seek quotes directly from suppliers to obtain accurate pricing tailored to their specific needs.

By carefully analyzing these components and employing strategic sourcing practices, international B2B buyers can effectively navigate the complexities of two-gallon water bottle procurement, ensuring they achieve both quality and cost efficiency.

Alternatives Analysis: Comparing two gallon water bottle With Other Solutions

In today’s market, businesses often seek efficient hydration solutions that cater to diverse needs. While the two-gallon water bottle is a popular choice for various applications, it’s essential to consider alternative options that may provide better performance or cost-efficiency depending on specific requirements. This section examines the two-gallon water bottle in comparison to other viable alternatives, including the 2.5-gallon water jug and water filtration systems.

| Aspeto de comparação | Two Gallon Water Bottle | 2.5-Gallon Water Jug | Water Filtration System |

|---|---|---|---|

| Desempenho | Suitable for group hydration; easy to transport | Larger capacity for group use; offers similar portability | Provides purified water on-demand; eliminates contaminants |

| Custo | Moderate initial cost; reusable | Slightly higher cost; reusable | Higher upfront investment; ongoing filter replacement costs |

| Facilidade de implementação | Simple to use; requires no setup | Straightforward usage; requires minimal maintenance | Installation may be needed; user-friendly interfaces available |

| Manutenção | Low maintenance; requires occasional cleaning | Low maintenance; cleaning spout recommended | Regular filter changes necessary; system maintenance required |

| Melhor caso de utilização | Ideal for events, picnics, and outdoor activities | Great for family gatherings, camping, or large groups | Best for daily use in homes or offices needing purified water |

What Are the Advantages and Disadvantages of a 2.5-Gallon Water Jug?

The 2.5-gallon water jug is an excellent alternative for businesses that require larger quantities of water without the need for frequent refills. Its larger capacity makes it suitable for group settings, such as events or campsites. However, it may be slightly bulkier and heavier than a two-gallon bottle, which could pose challenges in transport. The cost is generally higher, yet its reusability can offset initial expenses over time.

How Do Water Filtration Systems Compare?

Water filtration systems provide a distinct advantage by ensuring access to purified water on-demand. This method is particularly useful for businesses seeking to eliminate contaminants from their water supply, making it a preferred choice for offices or facilities where water quality is paramount. While the initial investment may be higher, the ongoing costs can be minimized with proper maintenance. On the downside, these systems require regular filter replacements and may involve more complex installation processes.

Conclusion: How Can B2B Buyers Make an Informed Decision?

When selecting the right hydration solution, B2B buyers should carefully evaluate their specific needs, including capacity, portability, and water quality requirements. The two-gallon water bottle is a versatile option for casual use, while the 2.5-gallon jug offers more capacity for larger gatherings. Conversely, water filtration systems are ideal for businesses prioritizing water purity. By weighing these factors against their operational needs, buyers can choose the most suitable solution that aligns with their goals and budget.

Essential Technical Properties and Trade Terminology for two gallon water bottle

What Are the Key Technical Properties of Two Gallon Water Bottles?

When evaluating two-gallon water bottles for your business, understanding their technical specifications is crucial for ensuring quality, safety, and functionality. Below are several essential properties that should be considered:

1. Composição do material

Two-gallon water bottles can be made from various materials, including BPA-free plastic, polycarbonate, glass, and stainless steel. Each material has its advantages: BPA-free plastic is lightweight and impact-resistant, polycarbonate is known for its durability and resistance to heat, while glass offers purity and is easy to clean. For B2B buyers, selecting the right material affects the product’s longevity, safety standards, and the target market’s preferences.

2. Capacity and Dimensions

While the capacity of two-gallon water bottles is standardized at approximately 7.57 liters, dimensions can vary based on design and material. Understanding the dimensions is vital for logistics, as it affects storage, transportation, and shelf space requirements. Buyers should assess whether the bottle fits standard dispensers or storage solutions to optimize operational efficiency.

3. Peso

The weight of a two-gallon water bottle can influence shipping costs and handling logistics. Lighter bottles made from plastic are often preferred for transport, while heavier glass options may be more suitable for stationary applications. Businesses should calculate the total weight during transportation to manage costs effectively.

4. Seal Type and Leak Resistance

The type of seal or cap used in two-gallon water bottles is crucial for preventing leaks. Options include screw caps, flip-top lids, and spigots. A robust leak-proof design is essential for safety during transit and storage, especially when dealing with large quantities of water. Buyers should prioritize designs that have been tested for leak resistance to avoid costly damages.

5. Propriedades de isolamento térmico

Some two-gallon water bottles feature insulation, which can keep contents cold or hot for extended periods. Insulated bottles are particularly valuable in hot climates or for outdoor activities, appealing to businesses catering to these markets. Understanding insulation capabilities can help businesses market their products more effectively.

6. Conformidade e certificações

Ensure that the two-gallon water bottles meet relevant safety and quality standards, such as FDA regulations for food contact materials. Certifications can enhance product credibility and are often a requirement for entry into certain markets. B2B buyers should verify compliance to minimize legal risks and maintain quality assurance.

What Are Common Trade Terms Related to Two Gallon Water Bottles?

Understanding industry jargon is essential for smooth communication and successful transactions in the B2B sector. Here are several key terms:

1. OEM (Fabricante de Equipamento Original)

OEM refers to companies that manufacture products that are then sold under another company’s brand. For two-gallon water bottles, working with an OEM allows businesses to create customized products tailored to their brand specifications, enhancing market presence.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For two-gallon water bottles, MOQs can vary significantly among manufacturers. Buyers must consider MOQs when planning inventory levels and budgeting for initial purchases.

3. RFQ (Pedido de Cotação)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. When sourcing two-gallon water bottles, submitting an RFQ helps businesses compare prices and terms from various suppliers, aiding in cost-effective decision-making.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers of two-gallon water bottles, as they clarify shipping responsibilities, insurance, and risk management.

5. Prazo de execução

Lead time refers to the amount of time it takes from placing an order to receiving the product. For two-gallon water bottles, understanding lead times is critical for inventory planning and meeting customer demand, especially in seasonal markets.

6. Opções de personalização

Customization refers to the ability to alter product specifications, such as color, branding, and material choices. Offering customizable two-gallon water bottles can create a competitive advantage, appealing to businesses looking to differentiate their products in the market.

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring they select the right two-gallon water bottles for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the two gallon water bottle Sector

What Are the Key Trends Influencing the Two Gallon Water Bottle Market?

The global two-gallon water bottle market is experiencing notable shifts driven by increasing health consciousness and environmental sustainability. As consumers become more aware of hydration’s importance, the demand for larger water bottles, particularly those that are reusable, is on the rise. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where access to clean drinking water remains a priority.

Emerging technologies are transforming the sourcing landscape. Companies are leveraging e-commerce platforms to reach international buyers, streamlining the procurement process. In addition, innovations in materials, such as BPA-free plastics and sustainable alternatives like glass and stainless steel, are gaining traction. This not only enhances product appeal but also aligns with consumer preferences for eco-friendly options.

Market dynamics are also influenced by regulatory changes and economic factors. For instance, import tariffs and trade agreements can affect pricing structures and availability. Buyers must navigate these complexities, considering factors like lead times and shipping costs to ensure competitive pricing. Collaborating with reliable suppliers who understand local market conditions is essential for mitigating risks associated with international sourcing.

How Is Sustainability Shaping B2B Sourcing for Two Gallon Water Bottles?

Sustainability has become a cornerstone of B2B sourcing in the two-gallon water bottle sector. The environmental impact of single-use plastics has prompted businesses to seek out products that minimize waste. Suppliers are increasingly offering bottles made from recycled materials or biodegradable options, appealing to eco-conscious consumers and businesses alike.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are prioritizing partnerships with manufacturers who demonstrate transparency in their sourcing practices. Certifications such as Green Seal or FSC (Forest Stewardship Council) can serve as indicators of a supplier’s commitment to environmental stewardship. By aligning purchasing decisions with sustainability goals, businesses can enhance their brand reputation and appeal to a growing segment of eco-aware consumers.

The shift towards sustainability also entails investing in durable products that reduce the need for frequent replacements. Two-gallon water bottles designed for longevity and usability not only contribute to waste reduction but also offer significant cost savings in the long run. As such, B2B buyers should consider the lifecycle of products when making sourcing decisions.

What Is the Historical Context of Two Gallon Water Bottles in B2B Markets?

The evolution of the two-gallon water bottle can be traced back to the growing demand for convenient hydration solutions in both commercial and residential settings. Initially popularized for home use, these bottles have increasingly found applications in various sectors, including outdoor recreation, sports events, and industrial workplaces.

Over the years, advancements in manufacturing processes have led to the development of more robust and versatile products. The introduction of BPA-free plastics and insulated designs has enhanced the functionality and appeal of two-gallon water bottles, making them indispensable for a wide range of consumers. As the market continues to evolve, understanding this historical context helps B2B buyers appreciate the product’s journey and its relevance in today’s sustainability-focused landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of two gallon water bottle

-

1. How do I select the right supplier for two gallon water bottles?

To choose the right supplier, evaluate their credibility by checking for certifications (like ISO or FDA approval), customer reviews, and years of operation. Request product samples to assess quality firsthand. Additionally, verify their production capacity and adherence to international standards, especially regarding BPA-free materials. It’s crucial to communicate with suppliers to understand their responsiveness and willingness to accommodate your specific needs, such as customization options or bulk orders. -

2. What customization options are available for two gallon water bottles?

Many suppliers offer customization options, including branding, color, and design features. You can request printed logos, specific cap types (like screw caps or valves), and even unique shapes. Discussing your requirements with potential suppliers can help you understand their capabilities. Additionally, inquire about the minimum order quantities (MOQs) for customized products, as these may vary based on the complexity of the customization. -

3. What are the typical payment terms for purchasing two gallon water bottles in bulk?

Payment terms can vary significantly among suppliers. Common practices include a deposit upfront (usually 30-50%) with the balance due upon delivery or before shipment. Some suppliers may offer net payment terms (e.g., 30, 60, or 90 days) for established businesses. Always clarify payment methods accepted, such as wire transfers or letters of credit, and ensure that the terms are documented in the purchase agreement to avoid disputes. -

4. How do I ensure quality assurance for two gallon water bottles?

To ensure quality, request a detailed quality assurance (QA) plan from your supplier, outlining their testing procedures and standards. Consider third-party inspections or certifications that validate the product quality. It is beneficial to establish a clear agreement on acceptable quality levels and to conduct random inspections during production and before shipment. Understanding the supplier’s return policy is also crucial in case the products do not meet your specifications. -

5. What are the logistics considerations for importing two gallon water bottles?

Logistics involve planning for shipping methods, customs clearance, and warehousing. Decide between air freight for faster delivery or sea freight for cost-effectiveness. Ensure your supplier can provide necessary documentation for customs, including invoices and certificates of origin. Collaborate with a reliable freight forwarder to navigate international shipping regulations and minimize delays. Understanding local import tariffs and duties in your destination country is also essential to calculate total costs. -

6. Are there specific regulations I need to be aware of when sourcing two gallon water bottles for international markets?

Yes, different countries have regulations concerning food and beverage containers, including materials used and safety standards. For instance, the European Union has strict guidelines on plastic materials, while countries in Africa may have varying standards. Researching the specific regulations in your target market is essential. Additionally, ensure that your supplier complies with these regulations, as non-compliance can lead to costly fines or product recalls. -

7. What is the typical lead time for manufacturing and shipping two gallon water bottles?

Lead times can vary based on factors such as order size, supplier location, and production capacity. Generally, manufacturing may take anywhere from 2 to 6 weeks, while shipping can take an additional 1 to 4 weeks, depending on the shipping method and distance. It’s advisable to discuss and confirm lead times with your supplier early in the negotiation process to manage expectations and plan your inventory accordingly. -

8. How do I handle issues with defective two gallon water bottles after purchase?

If you encounter defective products, promptly contact your supplier to report the issue. Document the defects with photos and detailed descriptions to support your claim. Familiarize yourself with the supplier’s return policy before purchase, as this will guide you on how to proceed. Most reputable suppliers will offer replacements or refunds for defective items, but it’s crucial to address the issue quickly to minimize disruption to your business.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.

Top 7 Two Gallon Water Bottle Manufacturers & Suppliers List

1. New Wave Enviro – 2 Gallon Water Jugs

Domínio: thewaterbottlestore.com

Registada: 2005 (20 anos)

Introdução: 2 Gallon Water Jugs | Bottles | Containers | Dispenser | TheWaterBottleStore.com. Products include: New Wave Enviro 2 Gallon Stainless Steel Crock – Price: $78.88; 2 Gallon BPA Free Refrigerator Bulk Water Container with Spigot by New Wave Enviro – Dimensions: 13-5/8″ x 6-5/8″ x 9″ tall, Price: $32.88; Geo 2 Gallon PET Reusable Water Bottle with Screw Cap, Blue – Price: $27.88; 2.5 Gallon BPA Free…

2. Briowater – 2-Gallon BPA-Free Water Bottle

Domínio: briowater.com

Registada: 2015 (10 anos)

Introdução: {“product_name”: “2-Gallon BPA-Free Water Bottle w/ Screw Cap”, “price”: “$24.99”, “original_price”: “$29.99”, “SKU”: “BT205ET”, “features”: {“high_quality”: “durable plastic withstands rough wear and tear and frequent usage”, “resealable”: “screw-on lid included to safely store water and avoid leaks”, “large_capacity”: “stores 2 gallons of fresh water for home, school, or office environments”, “e…

3. Stanley – Adventure Fast Flow Water Jug 2G

Domínio: stanley1913.com

Registado: 2019 (6 anos)

Introdução: Jarro de água de fluxo rápido Adventure 2G

– Price: $55.00

– Size: 2 Gallons

– Colors Available: Lichen, Conch, Rose Quartz, Cream, Royal Cream, Dried Pine, Azure, Pomelo, Twilight, Lilac, Charcoal

– SKU: 10-01938-180

– Features:

- Sem BPA

- Isolamento de espuma de parede dupla

- Design à prova de fugas

- Fechos e pega robustos

– High-flow spigot (easy to clean)

– Weight: 4.4 lbs

– Dimensions: 11.69 x 11.69 …

4. Briowt – 2 Gallon BPA Free & Polycarbonate Water Bottles

Domínio: briowt.com

Registado: 2020 (5 anos)

Introdução: 2 Gallon BPA Free Reusable Plastic Water Bottle with Screw Cap: Made of high-quality BPA-free plastic, impact resistant, maintains shape in hot temperatures.\n2 Gallon Polycarbonate Plastic Reusable Water Bottle with Screw Cap: Made of FDA-approved polycarbonate plastic, impact resistant, does not degrade in hot temperatures.\n2 Gallon BPA Free Reusable Plastic Water Bottle with Screw Cap & Valve:…

5. Arrowhead® – 2.5 Gallon Jug Spring Water

Domínio: arrowheadwater.com

Registada: 1999 (26 anos)

Introdução: {“product_name”: “2.5 Gallon Jug Spring Water”, “brand”: “Arrowhead®”, “type”: “100% Mountain Spring Water”, “size”: “2.5 Gallon”, “description”: “Great for the home or your next camping trip, this jug is just the right size to keep everyone hydrated and refreshed. Think of it as your very own mountain spring.”, “nutrition_facts”: {“calories”: “0mg”, “total_fat”: “0mg”, “sodium”: “0mg”, “protein”:…

6. Alive Waters – Empty 2.5 Gallon Jug

Domínio: alivewaters.com

Registado: 2019 (6 anos)

Introdução: {“name”:”Empty 2.5 Gallon Jug (generic silicone cap)”,”regular_price”:”$44.00 USD”,”sale_price”:”$41.00 USD”,”weight”:”4536 grams”,”sku”:”860053000552″,”dimensions”:”10.5 inches wide and 10 inches tall”,”features”:”Manufactured in Italy with high-quality glass formula, uniform thickness for durability and safety, pre-rinsed with spring water, compact for easy transport, includes generic silicone c…

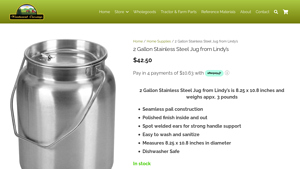

7. Lindy’s – 2 Gallon Stainless Steel Jug

Domínio: woodwardcrossingscountrybasics.com

Registado: 2010 (15 anos)

Introdução: 2 Gallon Stainless Steel Jug from Lindy’s

Price: $42.50

Dimensions: 8.25 x 10.8 inches

Weight: approx. 3 pounds

Material: 304 Surgical Stainless Steel, Heavy 18/8 Stainless Steel

Construction: Seamless pail construction, Polished finish inside and out, Spot welded ears for strong handle support

Features: Easy to wash and sanitize with large opening, Dishwasher Safe, Tight fitting lid to prevent sp…

Strategic Sourcing Conclusion and Outlook for two gallon water bottle

In the competitive landscape of the two-gallon water bottle market, strategic sourcing emerges as a vital component for international B2B buyers. By leveraging insights from diverse suppliers, businesses can secure high-quality products that meet safety standards, such as BPA-free materials and durability for various applications, from outdoor events to industrial uses. The growing demand for sustainable and reusable options further emphasizes the importance of sourcing practices that align with environmental considerations.

Investing in strategic sourcing not only ensures access to the best pricing and product availability but also fosters long-term partnerships with reliable manufacturers. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate flexibility in meeting diverse market needs, including customization and rapid delivery options.

As we look to the future, the potential for innovation in this sector is significant. Buyers are encouraged to explore emerging trends, such as smart water bottles and eco-friendly materials, to stay ahead of consumer preferences. Embrace strategic sourcing today to enhance your competitive edge and ensure your offerings resonate with the evolving demands of the global marketplace.