Introduction: Navigating the Global Market for vacuum flask water bottle

In an increasingly interconnected world, sourcing high-quality vacuum flask water bottles presents both opportunities and challenges for international B2B buyers. With rising consumer demand for sustainable and versatile hydration solutions, understanding the nuances of this market is crucial. This guide aims to empower businesses, particularly those in regions like Africa, South America, the Middle East, and Europe—countries such as Nigeria and Germany—by providing a comprehensive overview of the vacuum flask water bottle landscape.

We will delve into various types of vacuum flasks, their applications in diverse industries, and the key features that differentiate products on the market, such as insulation technology, material safety, and design aesthetics. Additionally, we will explore best practices for vetting suppliers, evaluating costs, and ensuring compliance with international standards. By equipping buyers with actionable insights and strategic considerations, this guide aims to facilitate informed purchasing decisions, enabling businesses to meet their hydration needs effectively while also addressing consumer preferences for eco-friendly, durable products. Navigating this market doesn’t have to be daunting; with the right information, you can identify reliable partners and select the best vacuum flask water bottles to enhance your product offerings.

Navegação de artigos

- Top 8 Vacuum Flask Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for vacuum flask water bottle

- Understanding vacuum flask water bottle Types and Variations

- Key Industrial Applications of vacuum flask water bottle

- 3 Common User Pain Points for ‘vacuum flask water bottle’ & Their Solutions

- Strategic Material Selection Guide for vacuum flask water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for vacuum flask water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘vacuum flask water bottle’

- Comprehensive Cost and Pricing Analysis for vacuum flask water bottle Sourcing

- Alternatives Analysis: Comparing vacuum flask water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for vacuum flask water bottle

- Navigating Market Dynamics and Sourcing Trends in the vacuum flask water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vacuum flask water bottle

- Aviso importante e termos de utilização

- Strategic Sourcing Conclusion and Outlook for vacuum flask water bottle

Understanding vacuum flask water bottle Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Garrafa de água isolada | Double-wall vacuum insulation, stainless steel, various sizes | Outdoor activities, corporate gifts | Prós: Excellent temperature retention, durable. Contras: May be heavier than plastic alternatives. |

| Food Flask | Designed for transporting food, vacuum insulated, leak-proof | Catering, food delivery services | Prós: Keeps food hot/cold for hours, versatile. Contras: Limited to food storage, not suitable for drinks. |

| Explorer Flask | Larger capacity for shared use, rugged design | Team outings, camping | Prós: Ideal for groups, sturdy construction. Contras: Bulkier, may not fit standard cup holders. |

| Travel Mug | Designed for hot beverages, often with a sip lid | Coffee shops, corporate events | Prós: Convenient for on-the-go drinking, spill-resistant. Contras: Smaller capacity, not ideal for cold drinks. |

| Specialty Flasks | Unique designs or features (e.g., built-in infuser) | Fitness, wellness industries | Prós: Attracts niche markets, customizable. Contras: May have a higher price point, limited universal appeal. |

What Are the Characteristics of Insulated Water Bottles?

Insulated water bottles are crafted from high-quality stainless steel with double-wall vacuum insulation, making them highly effective at maintaining the temperature of liquids for extended periods. They are available in various sizes, catering to different hydration needs, from personal use to group activities. B2B buyers often favor these bottles for outdoor events, corporate gifting, and employee incentives due to their durability and functionality. When purchasing, consider the weight and size, as larger bottles may be bulkier but offer greater capacity.

How Do Food Flasks Differ from Regular Water Bottles?

Food flasks are specifically designed for transporting food rather than beverages. They feature vacuum insulation to keep meals hot or cold for hours, making them ideal for catering companies and food delivery services. B2B buyers should assess the capacity and leak-proof capabilities of food flasks, as these factors are crucial for maintaining food quality during transport. While versatile, food flasks are limited to solid and semi-solid foods, which may restrict their use in beverage-focused markets.

Why Choose Explorer Flasks for Group Activities?

Explorer flasks are larger vacuum bottles designed for shared use, often featuring rugged designs suitable for outdoor adventures. They are particularly beneficial for team outings, camping, and other group activities where hydration is shared. B2B buyers should evaluate the flask’s capacity and durability, as these features can enhance the experience for users. Although they provide excellent capacity, the bulkiness may pose challenges for transport and storage in tighter spaces.

What Are the Benefits of Travel Mugs in B2B Settings?

Travel mugs are designed for hot beverages and often come with spill-resistant lids, making them perfect for busy professionals on the go. They are commonly used in coffee shops and corporate events, where convenience and functionality are paramount. B2B buyers should consider the ease of cleaning and the mug’s insulation capabilities, as these features significantly impact user satisfaction. While travel mugs are practical, their smaller size may limit their appeal for those looking to carry larger quantities of liquid.

How Can Specialty Flasks Attract Niche Markets?

Specialty flasks often feature unique designs or added functionalities, such as built-in fruit infusers or customizable branding options. These products can effectively target niche markets, such as fitness enthusiasts or environmentally conscious consumers. B2B buyers should assess the potential for customization and the flask’s appeal to specific demographics when considering these products. While they can attract a dedicated customer base, the higher price points may deter budget-conscious buyers.

Key Industrial Applications of vacuum flask water bottle

| Indústria/Setor | Specific Application of vacuum flask water bottle | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Food Service | Catering and Event Management | Ensures food and beverages maintain optimal temperature for extended periods, enhancing customer satisfaction. | Durability, leak-proof design, and ease of cleaning are critical. |

| Outdoor and Adventure Gear | Camping and Hiking Supplies | Provides a reliable hydration solution for outdoor enthusiasts, encouraging brand loyalty through high-quality products. | Lightweight materials, insulation performance, and portability are essential. |

| Presentes para empresas | Employee Wellness Programs | Promotes healthy hydration habits among employees, improving overall workplace productivity and morale. | Custom branding options, sustainable materials, and bulk pricing are important. |

| Cuidados de saúde | Patient Care and Rehabilitation | Keeps medical fluids at required temperatures, crucial for patient comfort and care quality. | Compliance with health regulations, BPA-free materials, and ease of sterilization are key. |

| Educação | School and University Supplies | Offers students and staff a practical solution for staying hydrated throughout the day, promoting health and wellness. | Safety standards, size options for children and adults, and affordability are vital. |

How Is the Vacuum Flask Water Bottle Used in the Food Service Industry?

In the food service industry, vacuum flask water bottles are essential for catering and event management. They help maintain food and beverage temperatures during events, ensuring that meals remain hot and drinks cold for hours. This capability not only enhances the dining experience but also minimizes food safety risks. For B2B buyers, sourcing high-quality, leak-proof, and easy-to-clean flasks is crucial, as these features ensure reliability and customer satisfaction in high-volume service scenarios.

What Role Do Vacuum Flasks Play in Outdoor and Adventure Gear?

For companies in the outdoor and adventure gear sector, vacuum flask water bottles serve as vital products for camping and hiking supplies. They provide outdoor enthusiasts with dependable hydration solutions, keeping drinks cold or hot during long treks. This reliability fosters brand loyalty among consumers who value quality and performance in extreme conditions. B2B buyers should prioritize lightweight construction and superior insulation performance when sourcing these products, as they significantly impact usability in outdoor settings.

How Can Vacuum Flask Water Bottles Enhance Corporate Gifting?

In corporate settings, vacuum flask water bottles are increasingly used in employee wellness programs. They encourage healthy hydration habits among staff, contributing to improved productivity and morale. Businesses can leverage these flasks as part of their corporate gifting strategy, showcasing their commitment to employee well-being. When sourcing for this application, buyers should look for customizable branding options, sustainable materials, and competitive bulk pricing to maximize impact and value.

Why Are Vacuum Flasks Important in Healthcare?

In the healthcare sector, vacuum flask water bottles are crucial for patient care and rehabilitation. They ensure that medical fluids, such as water or electrolyte solutions, are kept at the appropriate temperatures, which is vital for patient comfort. Compliance with health regulations and the use of BPA-free materials are significant considerations for B2B buyers in this field. Additionally, the ability to easily sterilize these flasks is essential to maintain hygiene standards in healthcare environments.

How Are Vacuum Flask Water Bottles Utilized in Education?

Vacuum flask water bottles are valuable assets in educational settings, providing students and staff with practical hydration solutions throughout the day. They promote health and wellness by encouraging regular water consumption, which is particularly important in schools and universities. When sourcing these products, B2B buyers should consider safety standards, size options suitable for both children and adults, and affordability to ensure that they meet the diverse needs of educational institutions effectively.

3 Common User Pain Points for ‘vacuum flask water bottle’ & Their Solutions

Scenario 1: Ensuring Leak-Proof Performance in Harsh Conditions

O problema: B2B buyers often face challenges with product reliability, particularly in extreme environments. For companies distributing vacuum flask water bottles to outdoor enthusiasts, construction workers, or remote workers, ensuring that the products remain leak-proof during rugged use is crucial. A single instance of leakage can lead to customer dissatisfaction, product returns, and potential damage to other goods being transported alongside the flask.

A solução: To address this issue, it’s essential to source vacuum flasks that are explicitly marketed as 100% leak-proof and have undergone rigorous testing. When evaluating suppliers, inquire about their quality assurance processes and request detailed specifications on the sealing mechanisms used. Look for models with screw-top lids that feature silicone sealing rings, as these tend to offer superior leak prevention. Additionally, consider investing in prototypes for testing in real-world conditions to ensure that the product meets your expectations before full-scale procurement. Providing clear usage instructions to customers, including the importance of securely sealing the lid after each use, can further mitigate potential issues.

Scenario 2: Maintaining Temperature Control During Long Journeys

O problema: Another common pain point for B2B buyers is the challenge of maintaining the desired temperature of beverages or food during extended travel. This is particularly relevant for companies catering to industries such as catering, outdoor events, and logistics, where products may need to remain hot or cold for several hours. Failing to meet temperature expectations can lead to customer dissatisfaction and harm brand reputation.

A solução: To ensure effective temperature control, prioritize sourcing vacuum flasks with high-quality double-wall vacuum insulation, which can keep beverages hot for up to 12-24 hours or cold for an equivalent duration. When selecting products, look for those that specify their thermal performance metrics. Additionally, consider products that allow for pre-conditioning—filling the flask with hot water to preheat or cold water to pre-chill before adding the actual beverage. This practice enhances thermal efficiency. Offering a range of sizes can cater to various customer needs, from individual servings to larger quantities for group settings.

Scenario 3: Ensuring Food Safety and Compliance with Regulations

O problema: B2B buyers in food and beverage sectors face stringent regulations regarding food safety and material compliance. As they source vacuum flasks for beverages or food storage, they must ensure that the materials used do not leach harmful chemicals, are BPA-free, and comply with local and international safety standards. Non-compliance can lead to legal issues and costly product recalls.

A solução: It is vital to select suppliers who provide clear documentation about the materials used in their vacuum flasks. Look for products made from food-grade stainless steel, which is known for its safety and durability. Request certifications that confirm compliance with relevant health and safety regulations, such as FDA or EU standards. Engaging with manufacturers who can demonstrate transparency in their sourcing and production processes enhances trust and allows you to confidently market these products to your clients. Additionally, training your sales team on the features and benefits of compliant products will empower them to effectively communicate safety advantages to potential customers, reinforcing your brand’s commitment to quality and safety.

Strategic Material Selection Guide for vacuum flask water bottle

What Are the Key Materials Used in Vacuum Flask Water Bottles?

When selecting materials for vacuum flask water bottles, it is crucial to consider properties that influence performance, durability, and cost. The most common materials used in the manufacturing of these products include stainless steel, glass, plastic, and aluminum. Each material presents unique advantages and challenges that can affect the decision-making process for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

How Does Stainless Steel Perform in Vacuum Flask Applications?

Stainless steel is the most widely used material for vacuum flasks due to its excellent thermal insulation properties and durability. Key properties include high corrosion resistance, temperature retention capabilities, and structural integrity under pressure. Stainless steel flasks can keep beverages hot for up to 12-24 hours and cold for 24-48 hours, depending on the design.

Prós: Stainless steel is highly durable, resistant to rust and corrosion, and does not impart flavors to the contents. It is also relatively easy to clean and maintain.

Contras: The initial cost of stainless steel can be higher than other materials, and its manufacturing process may involve more complexity due to the need for precision welding and finishing.

Impacto na aplicação: Stainless steel is compatible with a wide range of beverages, including acidic and alkaline liquids, making it suitable for various markets.

Considerations for International Buyers: Buyers should ensure compliance with food safety standards such as FDA or EU regulations. Additionally, they should consider local preferences for aesthetics, as finishes and colors can vary significantly by region.

What Role Does Glass Play in Vacuum Flask Water Bottles?

Glass is often used in vacuum flasks due to its non-reactive nature and ability to maintain the purity of beverages. Key properties include excellent thermal insulation and resistance to chemical leaching. However, glass is more fragile than metal options.

Prós: Glass does not leach chemicals, ensuring that the taste and quality of the beverage remain intact. It is also recyclable and environmentally friendly.

Contras: The fragility of glass makes it susceptible to breakage, which can be a significant drawback in rugged environments. Additionally, glass vacuum flasks can be heavier than their stainless steel counterparts.

Impacto na aplicação: Glass is ideal for hot beverages like tea and coffee but may not be suitable for outdoor use or in regions where breakage is a concern.

Considerations for International Buyers: Buyers should be aware of shipping and handling challenges associated with glass products. Compliance with international safety standards is also essential, particularly in regions with stringent regulations.

How Does Plastic Compare in Vacuum Flask Manufacturing?

Plastic vacuum flasks are gaining popularity due to their lightweight and cost-effective nature. Key properties include moderate thermal insulation and resistance to impact. However, they typically do not retain temperature as effectively as metal or glass.

Prós: Plastic is lightweight, making it easier to transport and handle. It is also often less expensive than metal options, which can be appealing for bulk purchases.

Contras: Plastic may not provide the same level of thermal insulation, and concerns over chemical leaching (e.g., BPA) can affect consumer perception.

Impacto na aplicação: Plastic flasks are suitable for casual use and are often preferred in markets where affordability is a priority.

Considerations for International Buyers: Buyers should ensure that the plastic used is BPA-free and compliant with relevant safety standards. Preferences for eco-friendly materials are also increasing, particularly in Europe.

What Advantages Does Aluminum Offer in Vacuum Flask Design?

Aluminum is another material used in vacuum flasks, known for its lightweight properties and good thermal conductivity. Key properties include resistance to corrosion and a relatively low weight, which makes it ideal for portable applications.

Prós: Aluminum flasks are lightweight and can be produced with a variety of coatings for aesthetics and additional protection against corrosion.

Contras: Aluminum is more prone to denting and may not retain temperature as effectively as stainless steel. It can also react with acidic beverages unless treated.

Impacto na aplicação: Aluminum is suitable for outdoor and sports applications, where weight is a critical factor.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings and ensure compliance with food safety standards. Market preferences for design and functionality can vary widely, necessitating research into local trends.

Summary Table of Material Properties for Vacuum Flask Water Bottles

| Material | Typical Use Case for vacuum flask water bottle | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço inoxidável | Hot and cold beverages, outdoor activities | Excelente durabilidade e isolamento | Maior complexidade de fabrico | Elevado |

| Vidro | Hot beverages, home use | Non-reactive, preserves taste | Frágil, pesado | Médio |

| Plástico | Casual use, children’s products | Leve e económico | Lower insulation, potential leaching | Baixa |

| Alumínio | Outdoor, sports activities | Lightweight, corrosion-resistant | Prone to denting, less effective insulation | Médio |

This guide provides a comprehensive overview of the materials used in vacuum flask water bottles, equipping B2B buyers with the knowledge needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for vacuum flask water bottle

What Are the Main Stages of Manufacturing Vacuum Flask Water Bottles?

The manufacturing process for vacuum flask water bottles involves several critical stages, each designed to ensure the final product meets high standards of quality and functionality.

1. Material Preparation

The primary material used in vacuum flasks is high-grade stainless steel, often 304 or 316 types, chosen for their corrosion resistance and durability. The material preparation phase includes sourcing and verifying the quality of stainless steel, which is essential for ensuring the flask’s longevity and safety. Suppliers may conduct tests to check for impurities and compliance with international food safety standards.

2. Forming

During the forming stage, the stainless steel is cut and shaped into the desired flask components. This may involve processes such as stamping, deep drawing, or spinning, depending on the design specifications. Advanced techniques like hydroforming may also be employed to create complex shapes while maintaining material integrity. The forming stage is crucial, as it sets the foundation for the flask’s insulation performance and overall durability.

3. Assembly

In the assembly phase, the individual components, including the inner and outer shells, lids, and seals, are brought together. This stage often involves welding or bonding the two walls of stainless steel to create a vacuum between them, which is essential for insulation. The assembly process is typically automated to enhance precision and efficiency, although some intricate components may require manual assembly.

4. Finishing

The finishing stage encompasses surface treatment, polishing, and coating. The exterior may undergo powder coating to enhance aesthetics and durability, making it scratch-resistant and easier to grip. Additionally, quality control measures are implemented during this stage to ensure that the finish meets the required specifications for both visual appeal and functionality.

How Is Quality Assurance Implemented in Vacuum Flask Manufacturing?

Quality assurance is a vital component of the manufacturing process for vacuum flask water bottles. This ensures that the final products not only meet safety and performance standards but also fulfill customer expectations.

Relevant International Standards for Quality Assurance

Manufacturers often adhere to international quality management standards such as ISO 9001, which focuses on consistent quality and continual improvement. Compliance with these standards helps manufacturers streamline processes and ensure customer satisfaction. In addition, certifications like CE mark and FDA compliance are essential for products intended for international markets, signifying that they meet safety and health standards.

Quais são os principais pontos de verificação do controlo de qualidade?

Quality control is integrated at multiple checkpoints throughout the manufacturing process:

-

Controlo de qualidade de entrada (IQC): This initial stage involves inspecting raw materials for compliance with specifications. Suppliers should provide certificates of analysis (CoA) to verify material quality.

-

Controlo de qualidade durante o processo (IPQC): During production, various inspections are conducted to ensure that each stage adheres to quality standards. This includes monitoring equipment performance and ensuring that assembly processes are executed correctly.

-

Controlo de qualidade final (FQC): At the end of the manufacturing process, the finished products undergo thorough testing. This may include leak tests, thermal performance tests, and durability assessments to ensure they function as intended.

What Testing Methods Are Commonly Used for Vacuum Flasks?

Several testing methods are employed to verify the quality and safety of vacuum flask water bottles:

-

Thermal Performance Testing: This assesses how well the flask maintains the temperature of its contents. Tests are conducted to measure how long hot and cold beverages retain their temperatures under various conditions.

-

Teste de fugas: This ensures that the flask is completely leak-proof. Manufacturers may use pressure testing or visual inspection methods to check for any defects in seals and lids.

-

Ensaio de materiais: This verifies the quality of stainless steel and other materials used in production. Common tests include tensile strength, corrosion resistance, and impact resistance tests.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

For B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are actionable steps to ensure supplier credibility:

Auditorias a fornecedores

Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their adherence to international standards and the effectiveness of their quality management systems.

Pedido de relatórios de qualidade

Buyers should request detailed quality reports from suppliers, including results from IQC, IPQC, and FQC. These documents should outline any issues encountered during production and how they were resolved.

Engaging Third-Party Inspection Services

Using third-party inspection services can add an extra layer of assurance. These independent entities can conduct thorough inspections of the manufacturing facilities, processes, and final products, providing an unbiased evaluation of quality.

Quais são as nuances do CQ e da certificação para os compradores internacionais B2B?

When sourcing vacuum flasks, international buyers should be aware of specific certification requirements and quality nuances in their respective regions:

-

Regional Compliance: Different markets may have varying compliance requirements. For example, European buyers should ensure that their products meet CE standards, while buyers in the Middle East may need to comply with GCC regulations.

-

Documentation: Ensure that all documentation related to quality control, testing, and certification is available and verifiable. This includes CoAs, inspection reports, and compliance certificates.

-

Cultural and Market Differences: Understand that quality perceptions may vary across cultures. What is considered high quality in one market may differ in another, necessitating a tailored approach when sourcing products for different regions.

By understanding the manufacturing processes and quality assurance measures in the vacuum flask industry, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet their specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vacuum flask water bottle’

Introdução

This practical sourcing guide is designed to assist B2B buyers in procuring vacuum flask water bottles efficiently and effectively. As demand for high-quality, insulated beverage containers rises globally, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the sourcing process is essential for making informed purchasing decisions. This checklist outlines critical steps to ensure that you select the best products and suppliers for your needs.

1. Identificar as necessidades do seu mercado-alvo

Understanding the specific needs of your target market is crucial. Consider factors such as local climate, consumer preferences, and usage scenarios. For instance, markets in hotter regions may prioritize bottles that maintain cold temperatures for extended periods, while colder climates might demand flasks that keep beverages hot longer.

2. Definir as suas especificações técnicas

Clearly outline the technical requirements for the vacuum flask water bottles you intend to source. This includes capacity (e.g., 500ml, 1L), insulation performance (duration for hot and cold retention), material safety (BPA-free, food-safe stainless steel), and design features (leak-proof, ease of cleaning). Establishing these specifications upfront will streamline the supplier selection process.

3. ✅ Verify Supplier Certifications

Before engaging with a supplier, ensure they possess the necessary certifications that guarantee product quality and safety. Look for ISO certifications, compliance with food safety standards, and any regional certifications relevant to your market. These credentials are vital in ensuring the products meet international safety and quality standards.

4. Avaliar potenciais fornecedores

Conduct thorough evaluations of potential suppliers. Request detailed company profiles, product samples, and case studies from buyers in similar markets. Assess their manufacturing capabilities, quality control processes, and past performance to gauge their reliability. This step helps mitigate risks associated with supplier selection.

5. Pedido de amostras para teste

Always request samples before placing bulk orders. Testing samples allows you to assess the actual product quality, insulation effectiveness, and overall user experience. Pay attention to aspects such as durability, ease of use, and whether the product meets your defined specifications.

6. Negociar condições e preços

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that the pricing aligns with your budget while considering the quality of the product. It’s also beneficial to discuss potential bulk order discounts or long-term partnership agreements.

7. Establish a Quality Assurance Process

Implement a quality assurance process to monitor the products upon receipt. Define your criteria for quality checks and ensure that your suppliers are aware of these standards. This step is essential for maintaining product consistency and minimizing returns or complaints from your customers.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for vacuum flask water bottles, ensuring they make informed decisions that meet their operational needs and market demands.

Comprehensive Cost and Pricing Analysis for vacuum flask water bottle Sourcing

What Are the Key Cost Components for Sourcing Vacuum Flask Water Bottles?

When sourcing vacuum flask water bottles, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materiais: The choice of materials significantly impacts cost. High-quality stainless steel, which is commonly used for vacuum flasks, tends to be more expensive but offers better durability and insulation. Additional materials like BPA-free plastics for caps and silicone seals also contribute to the overall cost.

-

Trabalho: Labor costs vary by region and the complexity of the manufacturing process. Regions with lower labor costs can provide a competitive edge, but it’s essential to ensure that quality is not compromised.

-

Despesas gerais de fabrico: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs, impacting the final price.

-

Ferramentas: Custom molds and tools for specific designs can be a significant upfront investment. This cost is often amortized over larger production runs, making minimum order quantities (MOQs) a critical factor in pricing.

-

Controlo de qualidade (CQ): Implementing stringent quality control measures adds to costs but is necessary to ensure product reliability, particularly when entering international markets with strict compliance regulations.

-

Logística: Shipping costs, including freight, insurance, and handling, can vary widely based on the origin of the goods and destination. Incoterms play a vital role in determining who bears these costs and risks.

-

Margem: Suppliers typically add a margin to cover their operational costs and profit. Understanding the expected margin in your sourcing region can help in negotiating better prices.

How Do Price Influencers Impact Vacuum Flask Sourcing?

Several factors can influence the pricing of vacuum flasks significantly:

-

Volume/MOQ: Larger orders generally lead to lower per-unit costs due to economies of scale. Suppliers often provide discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Especificações e personalização: Unique designs, sizes, and features (like double-wall insulation or specialized coatings) can increase production costs. Customization may also require additional tooling, impacting the overall price.

-

Materiais e certificações de qualidade: The use of premium materials and adherence to international quality certifications (like ISO standards) can raise costs. However, these attributes are often necessary for ensuring product safety and compliance in various markets.

-

Factores do fornecedor: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven quality and service, while newer or less reputable manufacturers may offer lower prices but at higher risk.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. For example, choosing FOB (Free on Board) might lower initial costs but could lead to higher logistics costs later on.

What Are the Best Negotiation Tips for International B2B Buyers?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies to enhance their sourcing experience:

-

Research and Benchmarking: Understanding the market price range for vacuum flasks can empower buyers during negotiations. Utilizing industry reports and competitor pricing can provide leverage.

-

Custo total de propriedade (TCO): Consider not just the purchase price but the entire lifecycle cost, including shipping, tariffs, potential returns, and disposal. This holistic view can reveal the true cost of sourcing decisions.

-

Establishing Long-term Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Loyalty can also foster more favorable negotiations for future orders.

-

Flexibility in Order Quantities: Being open to adjusting order sizes can help negotiate better rates. Suppliers may be more willing to offer discounts for orders that allow them to optimize production schedules.

-

Awareness of Regional Market Trends: Understanding local economic conditions and trade regulations in sourcing countries can help buyers anticipate price fluctuations and plan accordingly.

Declaração de exoneração de responsabilidade sobre os preços indicativos

Prices for vacuum flask water bottles can vary widely based on the factors mentioned above. The figures provided in the reference data serve as a guideline but may not reflect current market conditions or specific supplier quotes. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing for your sourcing needs.

Alternatives Analysis: Comparing vacuum flask water bottle With Other Solutions

Exploring Alternative Solutions to Vacuum Flask Water Bottles

When considering hydration solutions for diverse environments, vacuum flask water bottles stand out due to their efficiency and durability. However, several alternatives exist that might better suit specific needs or preferences. This analysis compares vacuum flask water bottles against insulated tumblers and traditional plastic bottles, focusing on key performance metrics relevant to B2B buyers.

| Aspeto de comparação | Vacuum Flask Water Bottle | Insulated Tumbler | Traditional Plastic Bottle |

|---|---|---|---|

| Desempenho | Excellent insulation, keeps drinks hot/cold for up to 24 hours | Good insulation, maintains temperature for 4-6 hours | No insulation, temperature changes quickly |

| Custo | Moderate ($30 – $70) | Lower ($15 – $40) | Very low ($1 – $5) |

| Facilidade de implementação | Requires initial investment; easy to use | Simple to use; often lighter | Readily available, no setup needed |

| Manutenção | Requires occasional deep cleaning; generally dishwasher safe | Easy to clean; often dishwasher safe | Minimal maintenance; disposable options available |

| Melhor caso de utilização | Outdoor activities, long trips, professional settings | Short outings, casual use, office settings | Everyday use, low-cost options, single use |

What Are the Pros and Cons of Insulated Tumblers?

Insulated tumblers offer a lightweight alternative to vacuum flasks, providing decent temperature retention for hot or cold beverages, typically lasting 4-6 hours. Their cost is generally lower, making them appealing for businesses seeking budget-friendly options. However, they may not retain temperature as effectively over extended periods, making them less ideal for long outdoor activities. Their ease of cleaning and lightweight design are advantages in casual settings but may compromise performance for serious hydration needs.

How Do Traditional Plastic Bottles Compare?

Traditional plastic bottles are the most cost-effective solution, often used for short-term hydration needs. They are readily available and require minimal maintenance, making them a popular choice for everyday use. However, they lack insulation, meaning beverages can quickly lose their desired temperature. Additionally, concerns over environmental impact and potential health risks associated with certain plastics may deter eco-conscious businesses. While they serve as a practical choice for events or casual outings, they do not match the performance of vacuum flasks for temperature retention.

Conclusion: Choosing the Right Hydration Solution for Your Business Needs

Selecting the right hydration solution depends on the specific requirements of your business and the environments in which your products will be used. For long-lasting temperature control and durability, vacuum flask water bottles are unmatched, particularly for outdoor and professional applications. Insulated tumblers can offer a balance of performance and cost for shorter outings, while traditional plastic bottles provide a budget-friendly option for casual use. By evaluating these alternatives against your operational needs, you can make an informed decision that aligns with both functionality and budget considerations.

Essential Technical Properties and Trade Terminology for vacuum flask water bottle

What Are the Key Technical Properties of Vacuum Flask Water Bottles?

When considering vacuum flask water bottles for B2B procurement, understanding their technical properties is crucial. Here are the essential specifications that impact performance, durability, and overall value:

1. Material Grade: Why is Stainless Steel Preferred?

Most high-quality vacuum flasks are constructed from food-grade stainless steel, typically 304 or 316 grades. These materials are highly resistant to corrosion, ensuring the longevity of the product. For B2B buyers, selecting stainless steel flasks guarantees safety, as they do not leach harmful chemicals like BPA. Furthermore, the choice of material affects the product’s resistance to impacts and scratches, which is vital for durability in various environments.

2. Insulation Technology: What is Double-Wall Vacuum Insulation?

The insulation technology used in vacuum flasks, such as double-wall vacuum insulation, is designed to maintain temperature. This technology creates a vacuum between two layers of stainless steel, minimizing heat transfer. For businesses, this means that beverages can stay hot for up to 12-20 hours or cold for 24-48 hours, providing exceptional performance that meets customer expectations for quality.

3. Leak-Proof Design: Why is it Essential?

A critical feature of vacuum flasks is their leak-proof design, often achieved through advanced sealing mechanisms and high-quality caps. This property is essential for B2B buyers as it enhances user experience, reduces product waste, and minimizes the risk of damage during transportation. Ensuring that the flask is leak-proof is especially important for outdoor and travel-related applications.

4. Size and Capacity: How Do They Affect Usage?

Vacuum flasks come in various sizes, typically ranging from 350 ml to 2.5 liters. The choice of size impacts marketability, as different consumer segments have varying hydration needs. For B2B buyers, understanding the capacity preferences of target customers helps in making informed purchasing decisions. Larger flasks are suitable for group activities, while smaller ones cater to individual use.

5. Surface Finish: What is Powder Coating?

The exterior finish of a vacuum flask, such as powder coating, enhances aesthetic appeal while providing scratch resistance. This finish can also improve grip and prevent condensation, which is particularly beneficial in humid climates. For buyers, a high-quality finish can be a differentiating factor in competitive markets, appealing to consumers looking for both functionality and style.

What Common Trade Terms Should B2B Buyers Know in the Vacuum Flask Industry?

Navigating the procurement landscape involves familiarizing oneself with industry-specific terminology. Here are some common terms relevant to vacuum flask water bottles:

1. OEM (Fabricante de equipamento original)

OEM refers to companies that produce products that can be branded and sold by other businesses. Understanding OEM relationships is crucial for B2B buyers looking to source custom-branded vacuum flasks.

2. MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest order size a supplier will accept. Knowing the MOQ helps businesses manage inventory costs and ensures that they meet supplier requirements without over-committing.

3. RFQ (Pedido de Cotação)

An RFQ is a formal process where buyers solicit price quotes from multiple suppliers. This is essential for B2B buyers to compare costs and ensure they receive competitive pricing for vacuum flasks.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international trade transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to understand the total cost and risk associated with importing vacuum flasks.

5. Sustainability Certifications

These certifications indicate that a product meets specific environmental standards. For B2B buyers, sourcing vacuum flasks with sustainability certifications can enhance brand reputation and appeal to eco-conscious consumers.

Understanding these technical properties and industry terms can empower B2B buyers to make informed decisions, ensuring they select high-quality vacuum flask water bottles that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the vacuum flask water bottle Sector

What Are the Current Market Dynamics and Key Trends in the Vacuum Flask Water Bottle Sector?

The vacuum flask water bottle sector is experiencing robust growth driven by increasing health consciousness and a shift towards sustainable living. Consumers globally are becoming more aware of the environmental impact of single-use plastics, leading to heightened demand for reusable options like vacuum flasks. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where there is a growing emphasis on eco-friendly products.

Key B2B tech trends influencing sourcing include the integration of smart technology in vacuum flasks, such as temperature tracking and hydration reminders. Manufacturers are increasingly adopting advanced materials that enhance insulation properties while reducing weight. Additionally, automation in production processes is gaining traction, allowing for greater efficiency and cost-effectiveness in manufacturing.

International B2B buyers should consider the evolving preferences of end consumers, who are now favoring products that combine functionality with aesthetics. For instance, stylish designs and customizable options are becoming essential for brands to differentiate themselves in a competitive market. Moreover, the rise of e-commerce platforms has transformed sourcing strategies, enabling buyers to access a broader range of suppliers and negotiate better pricing.

How Important Is Sustainability and Ethical Sourcing in the Vacuum Flask Water Bottle Industry?

Sustainability is no longer a buzzword; it has become a core principle for businesses in the vacuum flask water bottle sector. The environmental impact of production processes and materials is under scrutiny, prompting buyers to seek suppliers who prioritize ethical sourcing. This includes using recycled materials and ensuring that the manufacturing processes minimize carbon footprints.

Ethical supply chains are critical for building brand loyalty, especially among environmentally conscious consumers. Brands that emphasize transparency in their sourcing practices and demonstrate a commitment to sustainability tend to resonate more with consumers. Certifications such as Fair Trade and ISO 14001 for environmental management can enhance a brand’s credibility and appeal to buyers looking to align with ethical suppliers.

Furthermore, the use of sustainable materials, such as BPA-free stainless steel and eco-friendly coatings, is becoming a significant factor in purchasing decisions. Buyers should prioritize suppliers that invest in sustainable practices, as this not only contributes to a healthier planet but also ensures compliance with increasing regulatory demands across various regions.

What Is the Brief Evolution and History of Vacuum Flask Water Bottles?

The vacuum flask, invented in the late 19th century, was initially designed for the preservation of temperature-sensitive liquids. Over the decades, advancements in materials and technology have significantly transformed the design and functionality of vacuum flasks. Originally made from glass, modern vacuum flasks are predominantly crafted from stainless steel, which enhances durability and insulation capabilities.

The early 2000s marked a turning point as awareness of environmental issues surged. Consumers began seeking reusable alternatives to plastic bottles, leading to a boom in the vacuum flask market. Today, the sector is characterized by innovation, with manufacturers continuously improving insulation technology and product aesthetics to meet the diverse needs of global consumers. This evolution has positioned vacuum flask water bottles as essential lifestyle products, appealing to a wide demographic, including outdoor enthusiasts and everyday users.

Frequently Asked Questions (FAQs) for B2B Buyers of vacuum flask water bottle

-

How do I ensure the quality of vacuum flask water bottles from suppliers?

To ensure quality, request samples from potential suppliers before placing bulk orders. Verify that the materials used are food-safe and BPA-free, and confirm that the products meet international quality standards. Additionally, consider conducting factory audits or third-party inspections to assess manufacturing processes. Documentation such as quality assurance certificates and compliance with ISO standards can also provide reassurance about product quality. -

What is the best size of vacuum flask water bottle for corporate gifting?

The best size for corporate gifting typically ranges from 500ml to 1 liter. This size is practical for daily use, making it suitable for employees and clients alike. Larger sizes (1.5 liters and above) may also be beneficial for outdoor events or team-building activities. Consider customizing the flasks with your company logo for branding purposes, ensuring a lasting impression. -

What customization options are available for vacuum flask water bottles?

Customization options usually include printing logos, selecting colors, and adding personalized messages. Some manufacturers also offer unique shapes or sizes based on your specifications. Discuss with suppliers about their capabilities for customization to align with your branding needs. Minimum order quantities (MOQs) may vary based on the complexity of the customization, so clarify these details upfront. -

What are the typical minimum order quantities (MOQs) for vacuum flask water bottles?

MOQs can vary significantly depending on the supplier and the type of product. Generally, MOQs for vacuum flask water bottles range from 100 to 1,000 units. Larger or specialized orders may come with higher MOQs. When negotiating, be sure to ask about price breaks for larger quantities, which can help in budgeting and cost management. -

What payment terms should I expect when ordering vacuum flask water bottles internationally?

Payment terms can vary by supplier, but common practices include a 30% deposit upfront with the balance due before shipment. Some suppliers may offer net terms, allowing payment within a specified period after delivery. Always ensure that payment methods are secure, and consider using escrow services for large transactions to mitigate risks associated with international trade. -

How do I handle logistics and shipping for vacuum flask water bottles?

When arranging logistics, clarify who will handle shipping—your company or the supplier. Discuss shipping methods, estimated delivery times, and costs. For international shipping, consider working with freight forwarders who specialize in your target regions to streamline customs clearance and ensure compliance with import regulations. Always factor in potential delays and plan accordingly. -

What are the advantages of sourcing vacuum flask water bottles from different regions?

Sourcing from different regions can offer advantages such as cost efficiency, access to unique designs, and varied material options. For instance, manufacturers in Asia may provide competitive pricing, while European suppliers might offer superior quality and design innovation. Researching regional strengths can help you find the best fit for your needs, balancing cost, quality, and lead times. -

How can I verify the reliability of a vacuum flask water bottle supplier?

To verify a supplier’s reliability, check their reputation through online reviews, industry certifications, and references from previous clients. Conducting background checks and visiting the manufacturing facility, if possible, can also provide insights into their operational capabilities. Participating in trade shows or industry events can further facilitate connections with reputable suppliers and help establish trust.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.

Top 8 Vacuum Flask Water Bottle Manufacturers & Suppliers List

1. ThermoFlask – 16oz Soft Touch Sip-N-Lok™ Travel Coffee Tumbler

Domínio: mythermoflask.com

Registada: 2014 (11 anos)

Introdução: ThermoFlask offers a variety of highly rated drinkware and accessories including water bottles, tumblers, coffee and tea containers, and insulated food jars. Key products include: 16oz Soft Touch Sip-N-Lok™ Travel Coffee Tumbler ($24.99), 24oz Neon Water Bottle with Spout Lid ($26.99), 25oz Soft Touch Traveler Bottle ($29.99), 16oz Chameleon Shine Sip-N-Lok™ Travel Coffee Tumbler ($24.99), 25oz Ne…

2. Thermos - Garrafas de água estanques

Domínio: thermos.com

Registada: 1997 (28 anos)

Introdução: Water Bottles from Thermos are tough, leakproof, and dishwasher safe. Available sizes include 16oz, 18oz, 24oz, 32oz, 40oz, and 64oz. Color options include Beige, Black, Blue, Brown, Green, Grey, Orange, Pink, Purple, Red, Stainless Steel, White, Yellow, Alpine Green, Bright Blue, Bright Lime, Clear, Hyper Green, Mocha, Smoke, Ultra Pink. Lid types include Slide Lock Lid and Push Button with Spout…

3. Hydro Flask – Insulated Water Bottles

Domínio: hydroflask.com

Registada: 2009 (16 anos)

Introdução: Insulated & Stainless Steel Water Bottles from Hydro Flask. Labor Day Sale: 25% off summer styles. Free shipping on orders over $39. New Limited Edition Campus Collection available. Various sizes and colors of bottles including 16 oz Coffee with Flex Sip™ Lid ($32.95), 21 oz Standard Mouth with Flex Straw Cap ($34.95), and multiple Remix options in 24 oz and 32 oz sizes with Flex Straw Caps, disco…

4. Smith Creek – Vacuum Insulated Beverage Flask

Domínio: smithcreek.co

Registado: 2010 (15 anos)

Introdução: Vacuum Insulated Beverage Flask

– Capacity: 22 ounces

– Insulation: Double-wall vacuum insulated

– Material: Premium 304 stainless steel

– Finish: Rugged powder-coated with laser etching

– Colors available: Light Olive, Matte Black

– Hot drinks stay hot for up to 12 hours

– Cold drinks stay cold for up to 24 hours

– Cap: Leak-proof, BPA-free, dishwasher safe, with an attached screw-top drinking sp…

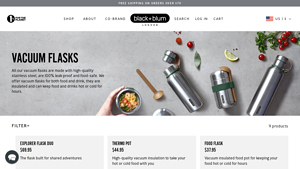

5. Black Blum – Vacuum Flasks

Domínio: blackblum.com

Registada: 2001 (24 anos)

Introdução: All vacuum flasks are made with high-quality stainless steel, 100% leak proof and food-safe. They are insulated to keep food and drinks hot or cold for hours. Available colors include Ocean, Olive, Orange, and Slate. Products include:

1. EXPLORER FLASK DUO – $69.95

2. THERMO POT – $44.95

3. FOOD FLASK – $37.95

4. EXPLORER BOTTLE – $37.95

5. EXPLORER BOTTLE LARGE – $42.95

6. INSULATED WATER B…

6. Stanley – Vacuum Bottles

Domínio: stanley1913.com

Registado: 2019 (6 anos)

Introdução: Stanley vacuum bottles feature double-wall vacuum insulation with two layers of stainless-steel metal, keeping beverages hot for at least 20 hours, cold for at least 24 hours, and iced for 4 days. They range in size from 16 oz to 2.5 qt, with larger sizes recommended for sharing and smaller sizes for commuting. The Master and Legacy Series include QuadVac™ technology for enhanced insulation. The b…

7. Hydro Flask – Wide Mouth Trail Series

Domínio: reddit.com

Registada: 2005 (20 anos)

Introdução: Lightweight vacuum flask / insulating water bottle suitable for two months of walking the Camino Santiago. Requires a capacity of around 700ml (24 oz.) with a preference for a wide mouth. Needs to keep water cool for 4-6 hours. Best option found is the Hydro Flask Wide Mouth Trail Series weighing 281g. Another option considered is the Sport Insulated by Polar Bottle weighing 128g.

8. Zojirushi – Vacuum Insulated Bottles & Mugs

Domínio: store.zojirushi.com

Registada: 1997 (28 anos)

Introdução: Vacuum Insulated Stainless Steel Bottles & Mugs from Zojirushi Store. Features include: lightweight and compact design, keeps drinks hot or cold, available in various colors (Beige, Black, Blue, Brown, Gold, Gray, Green, Navy, Orange, Pink, Purple, Red, Silver, White, Yellow), multiple capacities ranging from 7 oz. to 68 oz., and products include GoCafe™ Insulated Mugs and Stainless Mugs with pric…

Strategic Sourcing Conclusion and Outlook for vacuum flask water bottle

In the rapidly evolving market for vacuum flask water bottles, strategic sourcing emerges as a pivotal factor for B2B buyers aiming to leverage quality, sustainability, and cost-effectiveness. This guide has underscored the importance of selecting high-quality materials, such as BPA-free stainless steel, which not only ensure safety but also enhance the durability and insulation capabilities of the products. By aligning with reputable suppliers who prioritize innovative design and functionality, businesses can meet growing consumer demand for sustainable hydration solutions.

Moreover, understanding regional preferences and market trends in areas like Africa, South America, the Middle East, and Europe is essential for tailoring offerings that resonate with local consumers. As competition intensifies, investing in strategic partnerships and sourcing practices can provide a significant competitive edge.

Looking ahead, B2B buyers are encouraged to embrace a proactive approach to sourcing. By staying informed about emerging technologies and consumer preferences, businesses can not only optimize their supply chains but also contribute to a more sustainable future. Engage with trusted suppliers today to ensure your offerings remain at the forefront of this dynamic market.