Introduction: Navigating the Global Market for lotion bottle manufacturers

In today’s competitive landscape, sourcing high-quality lotion bottles can be a daunting task for international B2B buyers. Whether you are a startup in Africa or an established brand in Europe, the challenge lies in finding reliable manufacturers who can deliver not only quality but also innovation and sustainability. This guide aims to simplify the process of navigating the global market for lotion bottle manufacturers, empowering businesses to make informed purchasing decisions.

Within these pages, you’ll discover a comprehensive overview of various types of lotion bottles, from eco-friendly options to luxurious glass packaging. We delve into the applications of these bottles across diverse industries, including cosmetics, personal care, and pharmaceuticals. Additionally, we provide essential insights into supplier vetting, enabling you to assess potential partners based on quality standards, production capabilities, and compliance with international regulations.

By equipping you with knowledge about cost structures and market trends, this guide serves as an invaluable resource for B2B buyers from South America, the Middle East, and beyond. With actionable insights and expert recommendations, you will be better positioned to select the right lotion bottle manufacturers that align with your brand’s vision and operational needs. Let this guide be your roadmap to successfully navigating the complexities of the global lotion bottle market.

Article Navigation

- Introduction: Navigating the Global Market for lotion bottle manufacturers

- Top 10 Lotion Bottle Manufacturers Manufacturers & Suppliers List

- Understanding lotion bottle manufacturers Types and Variations

- Key Industrial Applications of lotion bottle manufacturers

- 3 Common User Pain Points for ‘lotion bottle manufacturers’ & Their Solutions

- Strategic Material Selection Guide for lotion bottle manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for lotion bottle manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘lotion bottle manufacturers’

- Comprehensive Cost and Pricing Analysis for lotion bottle manufacturers Sourcing

- Alternatives Analysis: Comparing lotion bottle manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for lotion bottle manufacturers

- Navigating Market Dynamics and Sourcing Trends in the lotion bottle manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of lotion bottle manufacturers

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for lotion bottle manufacturers

Top 10 Lotion Bottle Manufacturers Manufacturers & Suppliers List

1. Jarsking – Premium Lotion Bottles

Domain: jarsking.com

Registered: 2022 (3 years)

Introduction: Lotion Bottles – Jarsking offers a premium collection of face lotion bottles designed for modern skincare brands. Key features include:

– Extensive collection engineered for diverse needs, from indie labels to global corporations.

– Focus on product protection, user convenience, and brand enhancement.

– Rigorous testing for optimal preservation of active ingredients.

– State-of-the-art manufacturi…

2. Cosmopacks – Bulk Lotion Pump Bottles

Domain: cosmopacks.com

Registered: 2015 (10 years)

Introduction: Bulk lotion pump bottles and body wash containers from Cosmopacks are high-quality, customizable, and designed for easy dispensing. Key features include:

– Good chemical stability, ensuring reliability for various skin care products.

– Effective air tightness with durable polypropylene closures to prevent leakage.

– Accurate dispensing control for a superior user experience.

– Versatile applicatio…

3. Roetell – Wholesale Glass Lotion Bottles

Domain: roetell.com

Registered: 2019 (6 years)

Introduction: Roetell manufactures and supplies wholesale glass lotion bottles available in multiple colors and styles. Sizes range from 15ml to 120ml, with options for hand pumps and stoppers. The minimum order quantity for in-stock lotion bottles is 3,000 units, while custom orders have a MOQ of 2,000 units. The bottles are designed to be leak-proof, reusable, and made from durable, chemical-free glass. Vario…

4. Uzone Packaging – Lotion Bottles

Domain: uzonepackaging.com

Registered: 2023 (2 years)

Introduction: Lotion Bottle Wholesale, Empty Lotion Containers Bulk Supplier – Uzone Packaging. We are a leading manufacturer and supplier of high-quality lotion containers, offering a wide range of glass, plastic and metal packaging solutions designed for various skincare and cosmetic products. Our lotion containers are available in multiple types, including bottles, jars, and tubes, catering to diverse applic…

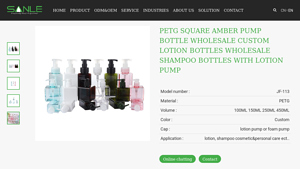

5. Sanle Plastics – JF-113 PETG Bottles

Domain: sanleplastics.com

Registered: 2017 (8 years)

Introduction: {‘model_number’: ‘JF-113’, ‘material’: ‘PETG’, ‘volume_options’: [‘100ML’, ‘150ML’, ‘250ML’, ‘450ML’], ‘color’: ‘Custom’, ‘cap_type’: [‘lotion pump’, ‘foam pump’], ‘applications’: [‘lotion’, ‘shampoo’, ‘cosmetic’, ‘personal care’], ‘certifications’: [‘FDA’, ‘LFGB’, ‘BSCI’], ‘printing_processes’: [‘Silk printing’, ‘hot stamping’, ‘frosting’, ‘coating’, ‘thermal transfer printing’], ‘other_services’…

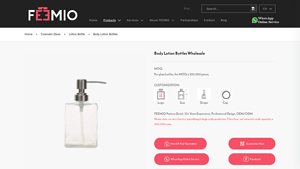

6. FEEMIO – Body Lotion Bottles

Domain: feemio.com

Registered: 2022 (3 years)

Introduction: {‘product_name’: ‘Body Lotion Bottles’, ‘manufacturer’: ‘FEEMIO’, ‘minimum_order_quantity’: ‘300,000 pieces’, ‘customization_options’: {‘logo’: ‘Yes’, ‘size’: ‘Yes’, ‘shape’: ‘Yes’, ‘cap’: ‘Yes’}, ‘bottle_material’: ‘Lead-Free Glass’, ‘pump_material’: ‘Plastic, Aluminum, Stainless Steel’, ‘available_colors’: [‘Black’, ‘White’, ‘Amber’, ‘Clear’, ‘Orange’, ‘Yellow’, ‘Silver’, ‘Frosted’, ‘Green’, ‘Re…

7. Sunrain – Lotion Bottles

8. Bottles Cosmetics – Quality Lotion & Spray Bottles

Domain: m.bottlescosmetics.com

Registered: 2022 (3 years)

Introduction: Quality Cosmetic Lotion Bottle & Cosmetic Spray Bottle factory from China. Recommended Products: White Round Empty Airless Lotion Container (300ml), Mini Lotion Luxury Shampoo Bottle, Cosmetic Lotion Bottle, Cosmetic Spray Bottle, Round Empty Cosmetic Spray Bottles (Luxury 4 Oz Clear Plastic Spray Bottles), 10g 20g 30g Plastic Cosmetic Face Cream Packaging, Pink Round PET Empty Jars Cream Packagin…

Understanding lotion bottle manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Lotion Bottles | Lightweight, cost-effective, customizable sizes | Mass-market skincare, body care | Pros: Affordable, versatile designs; Cons: Less premium feel compared to glass. |

| Glass Lotion Bottles | Premium appearance, excellent for high-end products | Luxury skincare, fragrances | Pros: Enhances brand image, good barrier properties; Cons: Heavier, potentially more fragile. |

| Airless Lotion Bottles | Prevents air exposure, maintains product integrity | High-quality creams, serums | Pros: Extends shelf life, user-friendly; Cons: Generally higher cost. |

| Refillable Lotion Bottles | Eco-friendly, sustainable design, reusable | Eco-conscious brands, skincare lines | Pros: Reduces waste, appeals to green consumers; Cons: Initial investment may be higher. |

| Lotion Pump Bottles | Easy dispensing, various pump types available | Daily-use lotions, body washes | Pros: Convenient for consumers, precise dispensing; Cons: May require more maintenance for pumps. |

What Are the Key Characteristics of Plastic Lotion Bottles?

Plastic lotion bottles are favored for their lightweight and cost-effective nature. They can be easily molded into various shapes and sizes, making them suitable for brands looking for flexibility in design. These bottles are ideal for mass-market skincare and body care applications due to their affordability. However, while they offer versatile designs, they may lack the premium feel that glass bottles provide, potentially impacting brand perception.

How Do Glass Lotion Bottles Stand Out in the Market?

Glass lotion bottles are synonymous with luxury and quality. Their premium appearance makes them a popular choice for high-end skincare and fragrance products. Glass offers excellent barrier properties, preserving the integrity of sensitive formulations. However, the weight and fragility of glass can be a drawback for brands concerned about shipping and handling. Buyers should consider the balance between brand image and logistical challenges when opting for glass packaging.

Why Choose Airless Lotion Bottles for Your Products?

Airless lotion bottles are designed to prevent air exposure, which can degrade product quality over time. They are particularly suitable for high-quality creams and serums that require optimal preservation of active ingredients. The user-friendly design allows for easy dispensing while maintaining hygiene. While airless bottles generally come at a higher cost, the benefits of extended shelf life and enhanced product integrity often justify the investment for quality-conscious brands.

What Are the Benefits of Using Refillable Lotion Bottles?

Refillable lotion bottles are becoming increasingly popular among eco-conscious brands aiming to reduce waste. These sustainable designs appeal to consumers who prioritize environmental responsibility. They can be used multiple times, making them a cost-effective option in the long run. However, the initial investment for refillable systems may be higher, and brands need to ensure they have a solid strategy for refilling and customer engagement.

How Do Lotion Pump Bottles Enhance User Experience?

Lotion pump bottles offer a practical solution for easy dispensing, making them ideal for daily-use lotions and body washes. With various pump types available, brands can provide a tailored user experience that enhances product accessibility. The precise dispensing capability is particularly beneficial for establishing a reputation for quality. However, these bottles may require more maintenance to ensure the pumps function correctly, which is a consideration for brands focused on customer satisfaction.

Key Industrial Applications of lotion bottle manufacturers

| Industry/Sector | Specific Application of lotion bottle manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cosmetics | Packaging for skincare products | Enhances brand visibility and consumer experience | Material quality, customization options, and sustainability |

| Personal Care | Daily moisturizers and lotions | Maintains product integrity and user convenience | Effective sealing, ease of dispensing, and design flexibility |

| Pharmaceutical | Packaging for topical creams and ointments | Ensures product safety and compliance with regulations | Regulatory compliance, material compatibility, and batch consistency |

| Wellness and Spa | Luxury lotion bottles for spa products | Elevates brand perception and customer satisfaction | Aesthetic design, eco-friendly materials, and refill options |

| E-commerce | Bulk lotion bottles for online retailers | Cost savings and efficient logistics | Minimum order quantities, shipping costs, and lead times |

How Are Lotion Bottle Manufacturers Utilized in the Cosmetics Industry?

In the cosmetics sector, lotion bottle manufacturers provide essential packaging solutions for skincare products. These bottles serve not only as containers but also as a means to enhance brand identity. For international B2B buyers, particularly in regions like Africa and South America, sourcing high-quality materials that maintain product integrity is crucial. Additionally, customization options, such as unique shapes and colors, can significantly impact marketability and consumer appeal.

What Role Do Lotion Bottle Manufacturers Play in Personal Care Products?

Personal care brands rely on lotion bottle manufacturers for packaging daily moisturizers and lotions. These bottles are designed for accessibility, featuring wide openings for easy dispensing while maintaining effective barrier properties to prevent contamination. Buyers from Europe and the Middle East should prioritize manufacturers that offer reliable sealing mechanisms and user-friendly designs, as these factors are critical for product preservation and customer satisfaction.

How Do Pharmaceutical Companies Benefit from Lotion Bottle Manufacturers?

In the pharmaceutical industry, lotion bottle manufacturers create packaging for topical creams and ointments. The primary value lies in ensuring product safety and compliance with stringent regulations. For international buyers, especially in markets like Germany and Vietnam, it’s vital to consider the compatibility of materials with active ingredients and the manufacturer’s ability to provide consistent batch quality. Regulatory compliance and effective sealing mechanisms are non-negotiable in this sector.

What Advantages Do Wellness and Spa Brands Gain from Custom Lotion Bottles?

Wellness and spa brands utilize lotion bottle manufacturers to produce luxury packaging that elevates the customer experience. These bespoke solutions not only enhance the perceived value of the product but also cater to eco-conscious consumers by using sustainable materials. Buyers looking for unique designs and refillable options should focus on manufacturers that can provide aesthetic appeal while ensuring functionality and environmental responsibility.

How Do E-commerce Businesses Leverage Lotion Bottle Manufacturers for Bulk Purchases?

E-commerce retailers benefit significantly from lotion bottle manufacturers by sourcing bulk quantities of packaging. This approach allows for cost savings and streamlined logistics, essential for online business operations. International buyers need to consider minimum order quantities, shipping costs, and lead times when sourcing these products. Effective communication with manufacturers regarding customization and delivery timelines can enhance operational efficiency and customer satisfaction.

3 Common User Pain Points for ‘lotion bottle manufacturers’ & Their Solutions

Scenario 1: Struggling with Consistent Quality and Reliability

The Problem: B2B buyers often face challenges with inconsistent product quality when sourcing lotion bottles. For instance, a company might receive a shipment of bottles with varying sizes, shapes, or even material quality, which can disrupt their production line and damage their brand reputation. This issue is particularly significant for companies operating in competitive markets where product consistency is paramount for customer satisfaction. The stakes are higher when dealing with international suppliers where language barriers and time zone differences can further complicate quality assurance processes.

The Solution: To mitigate quality issues, buyers should prioritize manufacturers who offer comprehensive quality assurance protocols. It is advisable to request samples before committing to bulk orders, ensuring that the products meet specified standards. Additionally, establishing clear communication channels with manufacturers is crucial. This includes detailed specifications about materials, dimensions, and design elements. Consider using third-party quality inspection services, especially for international shipments, to ensure that the products adhere to your quality expectations upon arrival. Finally, building a long-term relationship with a reliable manufacturer can foster better consistency over time, as they become more attuned to your specific requirements.

Scenario 2: Navigating the Complexities of Customization

The Problem: Customizing lotion bottles to reflect a brand’s unique identity can be a daunting task for B2B buyers. Many manufacturers offer a range of customization options, but the process can be overwhelming, leading to delays and misalignment between the buyer’s vision and the final product. This challenge is especially pronounced for startups and smaller brands that may lack experience in packaging design and sourcing.

The Solution: To streamline the customization process, buyers should begin with a clear and detailed design brief outlining their vision, including desired materials, colors, and functional features. Engaging with manufacturers that provide design consultancy services can be immensely beneficial. These experts can guide you through the design process, ensuring that your branding aligns with market trends and consumer preferences. Additionally, utilizing 3D modeling tools can help visualize the final product before production, reducing the likelihood of costly revisions. Establishing a timeline with milestones for feedback and adjustments can also facilitate a smoother development process.

Scenario 3: Addressing Sustainability Concerns

The Problem: As environmental awareness rises, many companies are under pressure to adopt sustainable packaging practices. B2B buyers often struggle to find lotion bottle manufacturers that not only offer eco-friendly materials but also ensure that these materials do not compromise the quality and integrity of the product. This dual focus on sustainability and performance can lead to frustration and uncertainty in sourcing decisions.

The Solution: To effectively address sustainability concerns, buyers should conduct thorough research on manufacturers that specialize in eco-friendly packaging solutions. Look for certifications or commitments to sustainability, such as the use of recycled materials or biodegradable options. Engaging manufacturers in discussions about their sourcing practices and material transparency can help buyers make informed choices. Additionally, consider implementing a lifecycle assessment to evaluate the environmental impact of your packaging options from production to disposal. Collaborating with suppliers who share your sustainability goals can lead to innovative solutions that align with your brand’s values while meeting consumer demand for responsible packaging.

Strategic Material Selection Guide for lotion bottle manufacturers

What Are the Key Properties of Common Materials Used in Lotion Bottle Manufacturing?

When selecting materials for lotion bottles, manufacturers often consider several options based on their properties, cost-effectiveness, and suitability for specific applications. Here, we analyze four common materials: PET, HDPE, glass, and aluminum, focusing on their performance characteristics, advantages, disadvantages, and considerations for international buyers.

How Does PET Perform in Lotion Bottle Applications?

Polyethylene Terephthalate (PET) is a widely used plastic in lotion bottle manufacturing due to its excellent clarity and strength. PET bottles can withstand temperatures up to 60°C and are resistant to moisture, making them suitable for lotions that require a stable environment.

Pros: PET is lightweight, shatterproof, and recyclable, which appeals to eco-conscious brands. It is also cost-effective, making it a popular choice for high-volume production.

Cons: However, PET may not be suitable for products that require long-term storage, as it can allow gas and moisture permeation over time, potentially affecting the product’s quality.

Impact on Application: PET is compatible with a variety of lotions and creams but may not be ideal for highly sensitive formulations or products requiring extended shelf life.

International Considerations: Buyers should ensure compliance with local regulations regarding recyclability and food safety, particularly in regions like Europe, which has stringent packaging directives.

What Are the Advantages of Using HDPE for Lotion Bottles?

High-Density Polyethylene (HDPE) is another popular choice for lotion bottles. It boasts a higher chemical resistance compared to PET and can handle temperatures up to 120°C, making it suitable for various formulations.

Pros: HDPE is durable, resistant to impact, and provides excellent barrier properties against moisture and chemicals. Its opaque nature also protects light-sensitive products.

Cons: The primary drawback is that HDPE is less transparent than PET, which may not appeal to brands looking to showcase their products visually.

Impact on Application: HDPE is ideal for thicker lotions and creams, as its robust structure can handle the viscosity without compromising integrity.

International Considerations: Buyers should verify compliance with ASTM standards for food-grade materials, especially in regions like Africa and the Middle East, where regulations may vary.

Why Choose Glass for Lotion Bottles?

Glass is often perceived as a premium option for lotion packaging due to its aesthetic appeal and excellent barrier properties. It can withstand high temperatures and is inert, meaning it won’t react with the contents.

Pros: Glass provides an upscale look and feel, enhancing brand perception. It is fully recyclable and does not leach chemicals, making it suitable for organic and natural products.

Cons: The main disadvantages of glass are its weight and fragility, which can increase shipping costs and the risk of breakage.

Impact on Application: Glass is particularly suited for high-end lotions and serums, especially those with sensitive ingredients that require maximum protection from external factors.

International Considerations: Buyers must consider shipping logistics and the potential for breakage, especially in regions with less developed transportation infrastructure.

What Role Does Aluminum Play in Lotion Bottle Manufacturing?

Aluminum is an increasingly popular material for lotion bottles, especially in eco-friendly packaging solutions. It is lightweight, durable, and offers excellent barrier properties.

Pros: Aluminum is fully recyclable and provides a modern aesthetic. It is also resistant to corrosion, making it suitable for various formulations.

Cons: However, aluminum may require a lining to prevent reactions with certain products, which can complicate manufacturing and increase costs.

Impact on Application: Aluminum is ideal for lotions that require protection from light and air, making it suitable for sensitive formulations.

International Considerations: Buyers should ensure compliance with local recycling regulations and standards, particularly in Europe, where sustainability is a key focus.

Summary Table of Material Selection for Lotion Bottle Manufacturers

| Material | Typical Use Case for lotion bottle manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET | Lightweight lotion bottles for mass production | Cost-effective and recyclable | Not ideal for long-term storage | Low |

| HDPE | Durable bottles for thicker lotions | Excellent chemical resistance | Less visually appealing | Medium |

| Glass | Premium packaging for high-end lotions | Aesthetic appeal and inert | Heavy and fragile | High |

| Aluminum | Eco-friendly options for sensitive formulations | Modern look and recyclable | Requires lining for certain products | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions regarding material selection for lotion bottle manufacturing.

In-depth Look: Manufacturing Processes and Quality Assurance for lotion bottle manufacturers

What Are the Key Stages in the Manufacturing Process of Lotion Bottles?

The manufacturing process for lotion bottles is a multi-stage operation that ensures both efficiency and quality. Each stage plays a crucial role in delivering a product that meets customer expectations while adhering to international standards.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials. Manufacturers typically use plastics such as PET, PP, or HDPE, as well as glass for premium products. The material must be tested for chemical stability and compatibility with skincare products to prevent reactions that could compromise product integrity. For eco-conscious brands, sustainable materials like recycled plastics and biodegradable options are becoming increasingly popular.

-

Forming: In this stage, the prepared materials are shaped into the desired bottle forms. Techniques such as blow molding for plastics or glass forming are commonly used. Blow molding allows for creating hollow bottles from a preform, which is then inflated into the final shape. This process is efficient and minimizes waste, which is essential for keeping costs down.

-

Assembly: Once the bottles are formed, the next step is assembly. This includes attaching closures, pumps, or sprayers. Manufacturers often employ automated machinery to ensure precision and speed during this process. For instance, lotion pumps may require specific torque settings to ensure they function correctly without leaking.

-

Finishing: The final stage involves applying any decorative elements, such as labels, coatings, or printing. This is where brand identity comes into play. High-quality finishes not only enhance aesthetic appeal but also provide additional protection to the product. Techniques such as screen printing or labeling are employed to ensure durability and resistance to wear.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance is paramount in lotion bottle manufacturing, ensuring that the final product meets both regulatory standards and customer expectations. Manufacturers typically adhere to international quality standards, such as ISO 9001, which emphasizes a systematic approach to quality management.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Manufacturers verify that materials meet specified standards before they enter the production line. This step is crucial for preventing defects that could arise from subpar materials.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to monitor production quality. This includes checking the consistency of material flow, the integrity of bottle shapes, and the functionality of closures. Automated systems can track these parameters in real-time, allowing for immediate corrections if deviations are detected.

-

Final Quality Control (FQC): Before products are packaged and shipped, they undergo thorough testing. This includes checking for leaks, proper dispensing, and overall aesthetics. Manufacturers often conduct stress tests to ensure that bottles can withstand transportation and handling without damage.

What International Standards and Certifications Should B2B Buyers Look for?

When sourcing lotion bottles, international buyers should be aware of the various standards and certifications that indicate a manufacturer’s commitment to quality and safety.

-

ISO 9001: This certification is essential as it demonstrates a manufacturer’s adherence to quality management principles. It ensures consistent quality in production processes and customer satisfaction.

-

CE Marking: For manufacturers targeting the European market, CE marking is crucial as it indicates compliance with European health, safety, and environmental protection standards.

-

API Certification: For lotion bottles used in pharmaceuticals or cosmetics, API (Active Pharmaceutical Ingredients) certification assures that the packaging meets strict regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify a manufacturer’s quality control processes and certifications. Here are several strategies:

-

Site Audits: Conducting on-site audits allows buyers to assess manufacturing capabilities firsthand. This process can reveal the level of adherence to quality standards and the overall efficiency of operations.

-

Quality Reports: Requesting detailed quality reports from manufacturers can provide insights into their quality control measures. Reports should include data from IQC, IPQC, and FQC stages, highlighting any issues encountered and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a manufacturer’s quality control processes. These agencies can conduct random inspections and provide certifications that validate a manufacturer’s claims.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, face unique challenges when sourcing lotion bottles. Understanding local regulations and market preferences is crucial.

-

Regulatory Compliance: Different countries have varying regulations regarding packaging materials and safety standards. Buyers should familiarize themselves with local laws and ensure that manufacturers comply with these requirements.

-

Cultural Preferences: Packaging aesthetics can differ significantly across regions. Understanding local consumer preferences can help buyers select manufacturers that offer designs and materials that resonate with their target audience.

-

Sustainability Concerns: With an increasing focus on sustainability, buyers should prioritize manufacturers that offer eco-friendly packaging solutions. This not only aligns with global trends but also appeals to environmentally conscious consumers.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when selecting lotion bottle manufacturers. Prioritizing quality and compliance will not only enhance brand reputation but also ensure customer satisfaction in a competitive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lotion bottle manufacturers’

This guide is designed to assist B2B buyers in effectively sourcing lotion bottle manufacturers. By following this step-by-step checklist, you can ensure that you select a supplier that meets your quality, sustainability, and budgetary requirements.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, clearly outline the technical specifications for your lotion bottles. This includes size, material (e.g., glass, plastic), closure types (pump, screw cap), and design features (e.g., airless technology). Having a detailed specification sheet helps streamline communication with suppliers and ensures that you receive accurate quotes and product samples.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify manufacturers that specialize in lotion bottles. Utilize online directories, trade shows, and industry publications to compile a list of potential suppliers. Look for manufacturers with experience in your target market, as they will better understand regional preferences and regulatory requirements.

Step 3: Evaluate Supplier Certifications

Verify that the manufacturers you are considering possess relevant certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications demonstrate a commitment to quality and sustainability. Additionally, check for compliance with local regulations related to cosmetics packaging, especially if you’re sourcing from international suppliers.

Step 4: Request Product Samples

Before making a bulk order, always request product samples. This allows you to assess the quality of the materials and craftsmanship firsthand. Pay attention to aspects like durability, design aesthetics, and functionality (e.g., ease of dispensing). Samples can also help validate the manufacturer’s claims regarding their production capabilities.

Step 5: Inquire About Customization Options

Discuss customization possibilities with potential suppliers. Many lotion bottle manufacturers offer options for branding, including label design, color choices, and unique shapes. Customization is vital for differentiating your products in a competitive market and can significantly enhance your brand identity.

Step 6: Assess Production Capacity and Lead Times

Understanding the manufacturer’s production capacity and lead times is crucial for planning your inventory and distribution. Ask about their monthly output and typical turnaround times for orders. A manufacturer with adequate capacity can ensure timely delivery, especially during peak seasons or promotional periods.

Step 7: Negotiate Terms and Establish Communication Protocols

Once you have narrowed down your options, initiate negotiations regarding pricing, payment terms, and order minimums. Establish clear communication protocols to ensure smooth collaboration throughout the production process. Regular updates and checkpoints can help address any issues promptly and maintain a strong partnership.

By adhering to this checklist, B2B buyers can effectively navigate the sourcing process and establish fruitful relationships with reliable lotion bottle manufacturers. Making informed decisions in each step will not only enhance product quality but also contribute to the overall success of your skincare brand.

Comprehensive Cost and Pricing Analysis for lotion bottle manufacturers Sourcing

What Are the Key Cost Components in Lotion Bottle Manufacturing?

Understanding the cost structure of lotion bottle manufacturing is essential for B2B buyers looking to optimize their sourcing strategies. The primary components of costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts pricing. Common materials include various plastics (PET, PP, HDPE), glass, and eco-friendly options like bamboo or recycled materials. Higher quality or specialized materials, such as airless packaging systems, can drive costs up.

-

Labor: Labor costs vary by region and manufacturing process. For example, labor-intensive processes such as hand assembly or intricate designs will incur higher costs. Countries with lower labor costs may offer more competitive pricing but could compromise on quality or lead time.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Manufacturers with advanced technology and automation may have lower overhead in the long run, translating to better pricing for buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs are usually amortized over large production runs. Buyers should inquire about minimum order quantities (MOQs) to understand how tooling costs will affect unit pricing.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and compliance with international standards. While it adds to the cost, it protects brands from potential recalls and enhances customer satisfaction.

-

Logistics: Transportation costs depend on the distance from the manufacturer to the buyer, shipping methods, and Incoterms. Buyers should consider logistics as part of their total cost, especially when sourcing from overseas.

-

Margin: Manufacturers typically add a profit margin to cover their costs and generate profit. This margin can vary widely based on brand positioning, market demand, and competition.

How Do Price Influencers Impact Lotion Bottle Sourcing?

Several factors influence the pricing of lotion bottles, making it essential for buyers to understand these nuances:

-

Volume/MOQ: Bulk orders usually lead to lower unit prices. Manufacturers often offer tiered pricing structures, where costs decrease significantly at higher volumes. Buyers should assess their needs carefully to avoid overcommitting while maximizing savings.

-

Specifications and Customization: Custom designs or specific features (like pump types or closure styles) can affect pricing. Customization often leads to additional tooling costs and longer lead times, so it’s crucial to balance the desire for unique packaging with budget constraints.

-

Material Quality and Certifications: Higher quality materials and compliance with certifications (e.g., ISO, FDA) can raise costs. Buyers should weigh the benefits of premium materials against their budget and market positioning.

-

Supplier Factors: The manufacturer’s reputation, experience, and production capabilities can influence pricing. Established suppliers may command higher prices due to their reliability and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms (like FOB, CIF) can affect overall costs. Buyers should clarify who is responsible for freight, insurance, and customs duties to avoid unexpected expenses.

What Are Effective Buyer Tips for Cost-Efficiency in Lotion Bottle Sourcing?

-

Negotiation: Engage in discussions about pricing, especially for large orders. Manufacturers may be willing to negotiate terms, particularly if they see long-term partnership potential.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront costs. This includes logistics, potential returns, and the longevity of the packaging. Investing in higher-quality bottles may reduce replacement costs in the long run.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, import duties, and regional pricing strategies. Establishing relationships with local distributors can also help navigate these challenges.

-

Requesting Indicative Prices: Given the variability in costs based on customization and order size, always ask for indicative pricing before finalizing contracts. This allows for better budgeting and financial planning.

By understanding these cost components and price influencers, B2B buyers can make informed decisions when sourcing lotion bottles, ensuring they achieve both quality and cost-effectiveness.

Alternatives Analysis: Comparing lotion bottle manufacturers With Other Solutions

Exploring Alternatives for Lotion Bottle Solutions

In the competitive landscape of cosmetic packaging, lotion bottle manufacturers represent a key solution for brands seeking quality and customization. However, alternative solutions also exist that may cater to specific business needs or operational strategies. This analysis explores how lotion bottle manufacturers compare against two viable alternatives: refillable packaging systems and automated dispensing systems.

Comparison Table

| Comparison Aspect | Lotion Bottle Manufacturers | Refillable Packaging Systems | Automated Dispensing Systems |

|---|---|---|---|

| Performance | High-quality, customizable options for various products. | Sustainable and eco-friendly; can enhance brand loyalty. | Precise dispensing with minimal waste; ideal for high-traffic environments. |

| Cost | Moderate to high, depending on customization and materials. | Typically lower long-term costs due to reduced waste and reusability. | Initial investment can be high; operational costs vary based on usage. |

| Ease of Implementation | Requires supplier collaboration and logistics management. | Can be integrated into existing supply chains with some adjustments. | Requires specialized equipment and may need staff training. |

| Maintenance | Low maintenance, but quality control is essential. | Requires regular cleaning and refill management. | Requires maintenance of dispensing machines and regular calibration. |

| Best Use Case | Ideal for brands emphasizing aesthetics and product protection. | Best for eco-conscious brands looking to reduce environmental impact. | Suitable for high-volume settings like spas and retail environments where efficiency is key. |

Detailed Breakdown of Alternatives

Refillable Packaging Systems

Refillable packaging is an eco-friendly alternative that promotes sustainability by allowing consumers to refill their containers rather than disposing of them after use. This approach not only reduces waste but also fosters brand loyalty as consumers are encouraged to return for refills. However, implementing a refillable system may require adjustments in logistics and supply chain management, making it a more complex option for some brands. Additionally, brands must invest in consumer education to ensure proper use and hygiene.

Automated Dispensing Systems

Automated dispensing systems offer precise product dispensing, making them ideal for environments where efficiency is critical, such as salons or retail settings. These systems minimize waste and ensure consistent product delivery, enhancing the customer experience. However, the initial cost of purchasing and installing dispensing machines can be significant, and ongoing maintenance is necessary to keep the systems functioning optimally. This solution is best suited for businesses that prioritize efficiency and have the capital to invest in technology.

Conclusion: How to Choose the Right Solution for Your Business

When selecting the right solution for lotion packaging, B2B buyers must consider their specific needs, budget constraints, and brand identity. Lotion bottle manufacturers provide customization and quality, making them a go-to choice for brands focusing on aesthetics and product integrity. In contrast, refillable packaging systems offer sustainability and consumer engagement, while automated dispensing systems enhance efficiency in high-demand environments. Ultimately, the decision should align with the brand’s overall strategy, target audience, and operational capabilities, ensuring that the chosen solution effectively supports business goals.

Essential Technical Properties and Trade Terminology for lotion bottle manufacturers

What Are the Key Technical Properties for Lotion Bottle Manufacturing?

When selecting lotion bottles for cosmetic products, understanding the technical specifications is crucial for ensuring product integrity, user satisfaction, and brand reputation. Here are some essential technical properties to consider:

-

Material Grade

The choice of material directly impacts the durability, safety, and functionality of lotion bottles. Common materials include PET (Polyethylene Terephthalate), PP (Polypropylene), and glass. Each material has distinct properties; for instance, glass offers excellent barrier protection against air and light, making it ideal for preserving active ingredients. In contrast, PET is lightweight and recyclable, appealing for eco-friendly brands. Selecting the right material is vital for compliance with safety regulations and customer preferences. -

Chemical Stability

Lotion bottles must be compatible with the chemical composition of the products they contain. Chemical stability refers to the material’s resistance to reactions with acidic or alkaline substances in lotions. This property ensures that the bottle does not degrade or leach harmful substances into the product, which could affect product safety and efficacy. For B2B buyers, this stability is essential for maintaining product quality over time. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during manufacturing. For lotion bottles, maintaining precise tolerances ensures that caps fit securely and that there are no leaks. Tight tolerances are crucial for automated filling lines where uniformity can affect production efficiency. Buyers should look for manufacturers who guarantee strict adherence to tolerance specifications to minimize production issues. -

Airtightness

Airtightness is essential for preserving the quality of lotions and creams, preventing contamination and evaporation. High-quality lotion bottles feature advanced sealing technologies, such as ribbed closures or vacuum seals, which ensure that products remain securely contained. For brands, effective airtightness translates to longer shelf life and enhanced consumer trust. -

Dispensing Control

Effective dispensing mechanisms allow for controlled release of the product, which is particularly important for lotions and creams. Features such as pump designs or nozzle sizes can significantly impact user experience. Accurate dispensing not only enhances customer satisfaction but also reduces product wastage, making it a critical consideration for manufacturers and brands alike.

Which Trade Terminology Should Lotion Bottle Manufacturers Know?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some key terms relevant to lotion bottle manufacturing:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products based on another company’s specifications and branding. For lotion bottle manufacturers, partnering with an OEM can allow brands to offer customized packaging solutions while leveraging the manufacturer’s expertise and production capabilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of product that a manufacturer is willing to produce or sell. Understanding MOQ is essential for B2B buyers as it impacts initial investment and inventory management. Brands must balance their production needs with their capacity to purchase inventory effectively. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from manufacturers for specific products. When requesting quotes for lotion bottles, providing detailed specifications can lead to more accurate pricing and better alignment with budgetary constraints. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined international rules that clarify the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms is crucial for international B2B transactions, as they dictate who is responsible for costs and risks at various stages of the shipping process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for inventory planning and ensuring that product launches or restocks occur as scheduled. Buyers should inquire about lead times when negotiating contracts to avoid disruptions in their supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing lotion bottles, ensuring that their chosen packaging solutions align with their brand goals and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the lotion bottle manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Lotion Bottle Manufacturers Sector?

The global lotion bottle manufacturing sector is experiencing significant growth, driven by the increasing demand for skincare and personal care products. The rise of e-commerce and online retailing has further accelerated this demand, allowing brands to reach international markets quickly. Key trends include the customization of packaging solutions, with manufacturers offering various sizes, materials, and designs to meet the specific needs of diverse markets. Additionally, the integration of smart technology in packaging, such as QR codes and NFC tags, is gaining traction, providing consumers with interactive experiences and brands with valuable data insights.

Emerging markets in Africa and South America present unique opportunities for lotion bottle manufacturers. The growing middle class in these regions is driving consumer spending on personal care products, prompting manufacturers to adapt their offerings to local preferences and purchasing behaviors. Moreover, the Middle East and Europe are witnessing a shift towards premium and luxury packaging options, leading to increased investments in high-quality materials like glass and sustainable alternatives. Manufacturers are also leveraging automation and advanced manufacturing techniques to enhance production efficiency, ensuring they can meet the rising demand while maintaining quality.

How Are Sustainability and Ethical Sourcing Reshaping the Lotion Bottle Manufacturing Sector?

Sustainability has become a focal point for lotion bottle manufacturers as consumers increasingly demand eco-friendly products. The environmental impact of packaging waste has prompted brands to seek sustainable solutions, leading to a surge in the use of recyclable and biodegradable materials. Manufacturers are responding by offering products made from post-consumer recycled (PCR) plastics, glass, and innovative biodegradable alternatives. The adoption of sustainable practices not only helps reduce carbon footprints but also enhances brand reputation in an increasingly eco-conscious marketplace.

Ethical sourcing is equally critical in the lotion bottle sector. B2B buyers are now prioritizing suppliers who adhere to ethical practices, ensuring that their sourcing chains are transparent and socially responsible. Certifications such as FSC (Forest Stewardship Council) for paper and wood products, and ISO certifications for manufacturing processes, are becoming essential for manufacturers seeking to establish credibility and trust with their clients. This shift towards sustainability and ethical sourcing not only meets consumer demands but also aligns with global initiatives aimed at reducing environmental impact and promoting corporate social responsibility.

What Is the Brief Evolution of the Lotion Bottle Manufacturing Sector?

The lotion bottle manufacturing sector has evolved significantly over the past few decades. Initially dominated by basic plastic designs, the industry has transformed with advancements in materials science and manufacturing technologies. The introduction of airless pump bottles and smart packaging solutions has enhanced product preservation and user experience. Today, manufacturers are not only focused on functionality but also on aesthetics, with a trend towards premium packaging that reflects brand identity. This evolution underscores the importance of innovation in meeting the diverse needs of global markets, positioning manufacturers to better serve international B2B buyers looking for high-quality, sustainable packaging solutions.

Conclusion

Navigating the complexities of the lotion bottle manufacturing sector requires an understanding of market dynamics and sourcing trends. As international B2B buyers increasingly prioritize sustainability and customization, manufacturers must adapt to these changing demands while maintaining high quality and ethical standards. By focusing on these key areas, lotion bottle manufacturers can position themselves for success in a competitive global market.

Frequently Asked Questions (FAQs) for B2B Buyers of lotion bottle manufacturers

-

How do I choose the right lotion bottle manufacturer for my business?

Selecting the right lotion bottle manufacturer involves assessing several key factors. Start by evaluating their production capacity and quality standards, ensuring they can meet your demand without compromising on quality. Look for manufacturers with experience in your specific market segment, such as skincare or cosmetics. It’s also beneficial to request samples to evaluate material quality and design. Finally, consider their customer service and willingness to collaborate on custom solutions, as this will facilitate a smoother partnership. -

What customization options are available for lotion bottles?

Most lotion bottle manufacturers offer a range of customization options to meet your brand’s specific needs. These may include variations in size, shape, color, and material, such as glass, PET, or biodegradable options. Additionally, you can customize closures and dispensers, like pumps or droppers, to enhance user experience. Many manufacturers also provide labeling and printing services, allowing you to create a cohesive brand identity. Always discuss your requirements upfront to ensure the manufacturer can accommodate your vision. -

What are the typical minimum order quantities (MOQs) for lotion bottles?

Minimum order quantities can vary significantly between manufacturers and depend on the type of packaging you require. Generally, MOQs for lotion bottles range from 500 to 10,000 units, with custom designs often requiring higher quantities. It’s essential to clarify these details during initial discussions, as some manufacturers may offer flexibility for first-time orders or established relationships. Understanding MOQs will help you plan your inventory and budget more effectively. -

What quality assurance measures should I expect from lotion bottle manufacturers?

Reputable lotion bottle manufacturers implement stringent quality assurance (QA) processes to ensure product consistency and safety. This typically includes raw material testing, in-process inspections, and final product evaluations against industry standards. You should inquire about their certifications, such as ISO or GMP, which indicate compliance with quality management systems. Additionally, consider requesting third-party testing reports to validate their claims, especially if you are sourcing from international suppliers. -

What payment terms are commonly offered by lotion bottle manufacturers?

Payment terms can vary widely among manufacturers and may depend on factors such as order size and your negotiation leverage. Common payment methods include wire transfers, letters of credit, and PayPal. It’s not unusual for manufacturers to request a deposit (usually 30-50%) upfront, with the balance due before shipping. Discussing payment terms early in the negotiation process is crucial to avoid misunderstandings and ensure a smooth transaction. -

How do I ensure timely delivery of my lotion bottles?

To ensure timely delivery, communicate your timeline and requirements clearly with the manufacturer from the outset. Discuss their production lead times and any potential delays, especially if you are sourcing internationally. Establishing a good relationship with your supplier can also help in prioritizing your orders. Additionally, consider working with a logistics partner familiar with international shipping to navigate customs and other logistical challenges effectively. -

What are the best practices for vetting lotion bottle suppliers?

Vetting suppliers is critical to ensuring you partner with a reliable manufacturer. Start by researching their reputation through online reviews and industry references. Requesting samples can provide insight into their product quality. Additionally, consider visiting their production facilities or conducting virtual audits to assess their capabilities and quality control processes. It’s also wise to verify their certifications and any relevant compliance with international regulations, particularly if you are importing into specific markets. -

How can I manage communication effectively with international lotion bottle manufacturers?

Effective communication is vital when dealing with international suppliers. Utilize clear and concise language, and be mindful of potential language barriers. Establish a primary point of contact within the manufacturer’s team to streamline communication. Regular updates on production status, timelines, and any issues are essential to maintain transparency. Using project management tools or platforms can also help keep all stakeholders informed and facilitate smoother collaboration across time zones.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lotion bottle manufacturers

In today’s competitive landscape, strategic sourcing of lotion bottles is pivotal for brands aiming to enhance their market presence and operational efficiency. By focusing on quality, sustainability, and customization, manufacturers like Jarsking and Cosmopacks provide valuable solutions that align with the evolving demands of consumers. The integration of eco-friendly materials and innovative designs not only enhances product appeal but also reinforces brand identity.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that demonstrate a commitment to quality and sustainability. This approach not only ensures the longevity of products but also fosters consumer trust and loyalty. Furthermore, leveraging bulk purchasing can lead to significant cost savings while maintaining high standards of quality and functionality.

As the market continues to evolve, now is the time to engage with reliable lotion bottle manufacturers who can support your brand’s growth. Embrace the opportunity to innovate and differentiate your products in a crowded market. Start your sourcing journey today to secure the ideal packaging solutions that will elevate your brand and meet the expectations of discerning consumers worldwide.