Introduction: Navigating the Global Market for water bottle bulk custom

The global market for bulk custom water bottles presents a myriad of opportunities and challenges for B2B buyers. As companies strive to enhance their branding through promotional products, the task of sourcing high-quality, custom water bottles can often feel overwhelming. With a vast array of materials, designs, and suppliers available, international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Vietnam—face the critical challenge of making informed decisions that align with their specific needs and budgets.

This comprehensive guide delves into the essential aspects of the bulk custom water bottle market. It covers a variety of bottle types—including metal, plastic, glass, insulated, and collapsible options—tailored for diverse applications from corporate gifting to event promotions. Buyers will also gain insights into effective supplier vetting strategies, cost considerations, and the latest trends in customization techniques.

By equipping international B2B buyers with actionable information and expert insights, this guide empowers them to navigate the complexities of sourcing custom water bottles effectively. Understanding these factors not only enhances purchasing decisions but also ensures that businesses can leverage these products to reinforce their brand identity and meet their marketing objectives in a competitive landscape.

Article Navigation

- Introduction: Navigating the Global Market for water bottle bulk custom

- Top 10 Water Bottle Bulk Custom Manufacturers & Suppliers List

- Understanding water bottle bulk custom Types and Variations

- Key Industrial Applications of water bottle bulk custom

- 3 Common User Pain Points for ‘water bottle bulk custom’ & Their Solutions

- Strategic Material Selection Guide for water bottle bulk custom

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle bulk custom

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle bulk custom’

- Comprehensive Cost and Pricing Analysis for water bottle bulk custom Sourcing

- Alternatives Analysis: Comparing water bottle bulk custom With Other Solutions

- Essential Technical Properties and Trade Terminology for water bottle bulk custom

- Navigating Market Dynamics and Sourcing Trends in the water bottle bulk custom Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle bulk custom

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for water bottle bulk custom

Top 10 Water Bottle Bulk Custom Manufacturers & Suppliers List

1. VistaPrint – Custom Water Bottles

2. Drink Branders – Custom Printed Water Bottles

Domain: drinkbranders.com

Registered: 2013 (12 years)

Introduction: Custom printed water bottles available in bulk from various brands including Nalgene, Yeti, H2go, and more. All bottles are BPA free and come in a variety of materials such as stainless steel, plastic, glass, and aluminum. Imprint methods include screen print, full color, laser etching, and more. Production times range from 24 hours to 10 days. Options for insulation types include vacuum insulatio…

3. Pens – Custom Water Bottles

Domain: pens.com

Registered: 1995 (30 years)

Introduction: Custom water bottles available in various materials including plastic, stainless steel, aluminum, glass, and insulated options. Prices range from $0.67 to $69.99. Capacity options include 6 to 10 oz, 10 to 15 oz, 15 to 20 oz, 20 to 25 oz, 25 to 40 oz, and 40+ oz. Available colors include beige, black, blue, brown, clear, dark blue, gray, green, light blue, light green, orange, pink, purple, red, r…

4. Gatorade – Custom Water Bottle

5. 4imprint – Custom Water Bottles

Domain: 4imprint.com

Registered: 1998 (27 years)

Introduction: Custom water bottles available in bulk for company events, trade shows, and wellness programs. Materials include aluminum, stainless steel, glass, and plastic. Options for insulated bottles. Various colors and capacities ranging from 8 oz to 37 oz and above. Filters available for price range, production time, imprint colors, and materials.

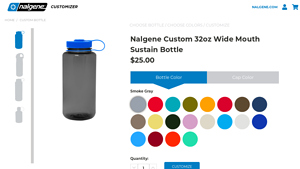

6. Nalgene – Customizable Bottles

Domain: custom.nalgene.com

Registered: 1997 (28 years)

Introduction: Customizable bottles from Nalgene, allowing users to choose bottle type, colors, and personalize their product.

7. Totally Promotional – Custom Water Bottles

Domain: totallypromotional.com

Registered: 2008 (17 years)

Introduction: Custom Water Bottles available in bulk with logo customization. Options include plastic, metal, glass, BPA-free, sustainable, shaker bottles, and drink pouches.

8. Rush Imprint – Custom Water Bottles

Domain: rushimprint.com

Registered: 2002 (23 years)

Introduction: Custom water bottles available in bulk, including plastic and metal options. Products include: 20 Oz. Frosted Fitness Bottles (from $1.46), The Sport Pint – 16 Oz. Water Bottle (from $1.01), Mini Mountain – 22 oz. Tritan Bottles (from $1.82), Mood 20 oz. Cycle Bottles (from $2.48), 24 oz. Slim Fit UpCycle RPET Bottle (from $2.46), 32 oz. Sports Bottles (from $1.24), 16 Oz. Polysure Inspire Bottles…

Understanding water bottle bulk custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Water Bottles | Durable, insulated, often with sleek designs | Corporate gifts, outdoor events | Pros: High durability, premium feel. Cons: Heavier and often pricier than plastic. |

| Plastic Water Bottles | Lightweight, versatile, available in various colors | Sports events, giveaways, promotions | Pros: Cost-effective, customizable. Cons: Less durable than metal or glass. |

| Glass Water Bottles | Eco-friendly, often aesthetically pleasing | Health-conscious brands, upscale events | Pros: Non-toxic, premium appearance. Cons: Fragile, heavier than plastic. |

| Insulated Water Bottles | Keeps beverages hot or cold for extended periods | Outdoor activities, corporate branding | Pros: Excellent thermal retention. Cons: Typically more expensive and bulkier. |

| Collapsible Water Bottles | Space-saving design, easy to carry | Travel promotions, eco-friendly initiatives | Pros: Lightweight, portable. Cons: May not be as durable as rigid bottles. |

What Are the Key Characteristics of Metal Water Bottles for B2B Buyers?

Metal water bottles are recognized for their robustness and insulation properties, making them ideal for both hot and cold beverages. Typically made from stainless steel or aluminum, they can be customized with various finishes and colors. B2B buyers often use these bottles for corporate gifts or outdoor events, where a premium feel can enhance brand perception. While they offer durability and a high-quality aesthetic, their weight and higher price point may be a consideration for bulk purchases.

How Do Plastic Water Bottles Serve Diverse B2B Applications?

Plastic water bottles are among the most popular choices for businesses due to their lightweight nature and cost-effectiveness. Available in a wide array of colors and designs, they can be easily customized with logos or branding messages. These bottles are frequently used for sports events, promotional giveaways, and trade shows. However, while they are affordable and versatile, buyers should be aware of their lower durability compared to metal or glass options, which may affect long-term brand visibility.

Why Choose Glass Water Bottles for Upscale Branding?

Glass water bottles are an eco-friendly option that appeals to health-conscious consumers and businesses aiming for a premium image. Their non-toxic nature and ability to preserve beverage flavors make them a preferred choice for upscale events and health-focused brands. B2B buyers should consider their aesthetic appeal and branding potential, but also weigh the risks of fragility and higher shipping costs associated with glass products.

What Advantages Do Insulated Water Bottles Offer for Corporate Branding?

Insulated water bottles are designed to maintain beverage temperatures for extended periods, making them perfect for outdoor activities and corporate branding initiatives. These bottles often feature double-wall construction and can be made from metal or durable plastic. B2B buyers appreciate their functionality and the potential for high-quality branding. However, they tend to be bulkier and more expensive than non-insulated options, which may impact budget constraints for larger orders.

How Do Collapsible Water Bottles Fit Into Eco-Friendly Initiatives?

Collapsible water bottles are an innovative solution for businesses focused on sustainability and convenience. These bottles can be folded down when not in use, making them highly portable and ideal for travel promotions or eco-friendly initiatives. While they are lightweight and easy to carry, buyers should consider their durability compared to rigid bottles, as they may not withstand heavy use over time.

Key Industrial Applications of water bottle bulk custom

| Industry/Sector | Specific Application of water bottle bulk custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Gifting | Custom-branded water bottles for employee gifts | Enhances brand visibility and employee morale | Minimum order quantities, customization options, lead times |

| Event Marketing | Promotional giveaways at trade shows and conferences | Increases brand exposure and engagement | Design flexibility, material choices, bulk pricing |

| Health & Wellness | Reusable bottles for gyms and fitness centers | Promotes sustainability and healthy lifestyles | BPA-free materials, durability, and insulation options |

| Educational Institutions | School branding and fundraising initiatives | Fosters community and school spirit | Age-appropriate designs, safety standards, and pricing for bulk orders |

| Travel & Tourism | Custom bottles for travel agencies and tours | Enhances customer experience and brand loyalty | Lightweight materials, collapsible options, and branding capabilities |

How are Custom Water Bottles Used in Corporate Gifting?

In the corporate sector, custom-branded water bottles serve as effective employee gifts, enhancing company branding and morale. These bottles can be personalized with the company logo, making them a constant reminder of the brand for employees and clients alike. For international buyers, especially in regions like Africa and South America, sourcing considerations include understanding local preferences for materials (e.g., metal versus plastic) and ensuring that the products meet any regional safety standards. Additionally, buyers should pay attention to minimum order quantities and customization capabilities to align with their branding strategies.

What Role Do Custom Water Bottles Play in Event Marketing?

For event marketing, bulk custom water bottles are invaluable as promotional giveaways at trade shows and conferences. They not only serve a practical purpose but also significantly increase brand visibility among attendees. When sourcing for such applications, businesses should consider the design flexibility, as unique and eye-catching designs can enhance engagement. Furthermore, understanding bulk pricing structures can help companies stay within budget while maximizing their promotional impact.

How Can Custom Water Bottles Promote Health and Wellness?

In the health and wellness industry, reusable water bottles are commonly used in gyms and fitness centers to promote sustainability and encourage hydration among clients. By providing these custom bottles, businesses can foster a culture of health while simultaneously promoting their brand. Buyers in this sector should prioritize BPA-free materials and durability, as fitness enthusiasts often require robust products. Insulation options are also essential, especially in hotter climates found in regions like the Middle East, where maintaining beverage temperature can be crucial.

Why Are Custom Water Bottles Effective for Educational Institutions?

Educational institutions leverage custom water bottles for branding and fundraising initiatives, creating a sense of community and school spirit. These bottles can be sold at events or given as gifts to students and staff. For international buyers, it is important to consider age-appropriate designs that appeal to both children and adults. Additionally, ensuring that the products meet safety standards is critical, particularly when targeting younger demographics. Pricing for bulk orders is also a key factor, as schools often operate within tight budgets.

How Do Travel and Tourism Businesses Benefit from Custom Water Bottles?

In the travel and tourism sector, custom water bottles enhance customer experience and brand loyalty. Travel agencies can provide these bottles to clients as part of travel packages, promoting sustainability while ensuring that customers have access to hydration during their travels. When sourcing, businesses should consider lightweight materials for ease of transport, as well as collapsible options that are convenient for travelers. Effective branding capabilities are also vital, as these bottles serve as ongoing advertisements for the agency during trips.

3 Common User Pain Points for ‘water bottle bulk custom’ & Their Solutions

Scenario 1: Managing Minimum Order Quantities Can Be Challenging

The Problem: B2B buyers often face hurdles when dealing with minimum order quantities (MOQs). For example, a small business looking to promote a local event may only need 50 custom water bottles, but many suppliers set their MOQs at 100 or more. This can lead to wasted resources and increased costs, especially if the buyer is unable to utilize the excess bottles or if they can’t afford to invest in such large quantities. This situation not only strains budgets but can also complicate inventory management.

The Solution: To navigate this issue, buyers should actively seek suppliers that offer flexible MOQ options. Many companies now provide no-minimum or low-minimum order policies, especially for bulk custom orders. It’s crucial to communicate your specific needs upfront. Engage with sales representatives to explore any potential for exceptions or discounts on smaller orders. Additionally, consider partnering with local distributors or co-op purchasing groups, which can aggregate orders from multiple buyers to meet MOQ requirements. This collaborative approach can significantly reduce costs and make the procurement process more efficient.

Scenario 2: Ensuring Product Quality and Compliance with Standards

The Problem: Quality assurance is a paramount concern for B2B buyers, especially when sourcing custom water bottles for events or corporate giveaways. Buyers often worry about the materials used in production, such as BPA-free plastics or food-grade stainless steel, to ensure safety and compliance with health regulations. A lack of clear information from suppliers can lead to uncertainty, risking potential health violations and damaging brand reputation if subpar products are distributed.

The Solution: To mitigate these concerns, buyers should prioritize sourcing from reputable suppliers who provide detailed product specifications and certifications. Before placing an order, request samples to evaluate quality firsthand. Additionally, ask for documentation proving that materials comply with local and international safety standards. Establishing a checklist of required certifications—such as FDA approval for food-grade materials—can streamline the sourcing process. Regularly reviewing supplier performance and maintaining open lines of communication can also ensure ongoing compliance and quality assurance.

Scenario 3: Overcoming Design and Customization Limitations

The Problem: Customization is a key factor for B2B buyers looking to create unique branding opportunities through water bottles. However, many suppliers have limited design options, which can stifle creativity and lead to dissatisfaction with the final product. Buyers may find that the color choices, imprint methods, or bottle shapes do not align with their branding requirements, leading to frustration and delays in their marketing efforts.

The Solution: To address these limitations, buyers should conduct thorough research on suppliers that specialize in a wide range of customizable options. Look for companies that offer multiple imprint methods (like screen printing, laser engraving, or digital printing) and various material choices (such as glass, metal, or recycled plastic). It’s beneficial to utilize design tools that some suppliers provide, allowing buyers to visualize their branding on the products. Additionally, establishing a clear design brief before engaging with suppliers can help ensure alignment on expectations. Collaborating with a marketing professional or designer to create eye-catching designs can also enhance the overall appeal of the final product, ensuring that it effectively represents the brand.

Strategic Material Selection Guide for water bottle bulk custom

When selecting materials for custom bulk water bottles, B2B buyers must consider various factors, including performance, cost, and compliance with international standards. Below, we analyze four common materials used in the production of water bottles, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Metal Water Bottles?

Metal water bottles, often made from stainless steel or aluminum, are known for their durability and corrosion resistance. They can withstand high temperatures and pressures, making them suitable for both hot and cold beverages. Stainless steel, in particular, offers excellent resistance to rust and staining, while aluminum is lightweight and provides good thermal conductivity.

Pros: Metal bottles are highly durable, reusable, and often insulated, keeping beverages at the desired temperature for extended periods. They also have a premium feel, enhancing brand perception.

Cons: The manufacturing process can be more complex and costly compared to plastic options. Additionally, metal bottles may dent or scratch, affecting their aesthetic appeal.

Impact on Application: Metal bottles are ideal for outdoor activities and premium branding. However, they may not be suitable for acidic beverages, which can react with certain metals.

Considerations for International Buyers: Compliance with food safety standards such as ASTM or FDA is crucial. Buyers in regions like Africa and South America should also consider the availability of recycling facilities for metal products.

How Do Plastic Water Bottles Compare in Performance?

Plastic water bottles are typically made from materials like PET, HDPE, or Tritan. They are lightweight, flexible, and resistant to shattering, making them a popular choice for promotional items and casual use.

Pros: Plastic bottles are cost-effective and can be produced in various shapes and colors. They are also less likely to break compared to glass or metal.

Cons: While many plastics are BPA-free, concerns about chemical leaching persist, especially with prolonged exposure to heat. Additionally, they may not be as durable as metal options.

Impact on Application: Plastic bottles are suitable for a wide range of beverages, including water, juices, and sports drinks. However, their longevity and environmental impact are often questioned.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding plastic use and recycling. In regions like Europe, there is a strong push towards sustainable materials, making recycled plastics a favorable option.

What Are the Advantages of Glass Water Bottles?

Glass water bottles are favored for their aesthetic appeal and purity of taste. They do not retain flavors or odors, ensuring that beverages taste as intended.

Pros: Glass is non-reactive and can be easily recycled, making it an environmentally friendly option. It also offers a premium look and feel, which can enhance brand image.

Cons: Glass bottles are heavy and fragile, making them less suitable for outdoor activities. They can also be more expensive due to higher manufacturing and shipping costs.

Impact on Application: Glass bottles are ideal for beverages that require a clean taste, such as water and juices. They are not suitable for high-impact environments due to their fragility.

Considerations for International Buyers: Compliance with safety standards is critical, especially in regions with stringent regulations. Buyers should also consider the logistics of shipping glass products, which may require additional protective packaging.

Why Choose Collapsible Water Bottles?

Collapsible water bottles, often made from silicone or flexible plastics, are designed for convenience and portability. They can be easily folded or rolled up when not in use.

Pros: These bottles are lightweight and space-saving, making them ideal for travel. They are often made from food-grade silicone, which is safe and durable.

Cons: Collapsible bottles may not be as sturdy as rigid options and can be prone to wear and tear over time. They may also have limitations in terms of temperature resistance.

Impact on Application: Collapsible bottles are perfect for hiking, camping, and travel, where space is a premium. However, they may not be suitable for hot liquids.

Considerations for International Buyers: Buyers should verify the quality of materials used to ensure compliance with safety standards. In regions like the Middle East, where temperatures can be extreme, ensuring the material’s heat resistance is essential.

Summary Table of Material Selection for Custom Water Bottles

| Material | Typical Use Case for water bottle bulk custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal | Outdoor activities, premium branding | Durable and insulated | Higher manufacturing complexity and cost | High |

| Plastic | Promotional items, casual use | Cost-effective and lightweight | Potential chemical leaching | Low |

| Glass | High-end beverages, aesthetic appeal | Non-reactive and recyclable | Heavy and fragile | Medium |

| Collapsible | Travel and outdoor convenience | Space-saving and portable | Less sturdy and limited temperature range | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to source custom water bottles, ensuring they make informed decisions that align with their brand values and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle bulk custom

What Are the Key Stages in the Manufacturing Process of Custom Water Bottles?

The manufacturing of custom water bottles involves several critical stages designed to ensure both quality and efficiency. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Commonly Used?

The first stage involves selecting the right materials, which can include metal (such as stainless steel or aluminum), plastic (like BPA-free polypropylene or Tritan), and glass. Each material offers distinct advantages in terms of durability, weight, and thermal insulation. For instance, stainless steel is often preferred for its longevity and insulation properties, while BPA-free plastics are popular for their lightweight and cost-effective nature. Suppliers typically source these materials from reputable manufacturers, ensuring compliance with international safety standards.

2. Forming: How Are Water Bottles Shaped?

The forming process varies based on the material chosen. For plastic bottles, techniques such as blow molding or injection molding are common. Blow molding involves inflating heated plastic into a mold, while injection molding allows for more complex shapes but requires significant upfront costs. Metal bottles may undergo processes like deep drawing or spinning, where sheets of metal are shaped into bottles through mechanical force. Each technique must be precisely controlled to ensure uniformity and strength.

3. Assembly: What Steps Are Involved in Putting It All Together?

Once the individual components are formed, the assembly stage begins. This may include attaching lids, straws, or insulation layers. For insulated bottles, a double-walled construction is often employed, which requires meticulous alignment and sealing to prevent thermal leakage. Automated assembly lines are increasingly used to enhance efficiency, but manual assembly may be applied for more intricate designs or customizations.

4. Finishing: How Is the Final Product Enhanced?

Finishing processes add the final touches to the water bottles. This can involve painting, coating, or printing logos and branding elements. Techniques like screen printing, digital inkjet, and laser engraving are commonly used for customization. This stage not only enhances the aesthetic appeal but also adds protective layers that can increase durability. Quality control measures must be in place to ensure that the branding is applied correctly and that the finish is consistent across batches.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for custom water bottles, ensuring that products meet both international standards and customer specifications.

1. What Are the Relevant International Standards for Custom Water Bottles?

B2B buyers should be aware of international quality standards such as ISO 9001, which focuses on quality management systems, and industry-specific certifications like CE marking for safety compliance in Europe. For food and beverage containers, compliance with FDA regulations in the U.S. or equivalent standards in other countries is crucial. Understanding these standards can help buyers assess the credibility of suppliers.

2. What QC Checkpoints Should Be Considered?

Quality control checkpoints are essential throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This occurs at the beginning of the manufacturing process, where materials are inspected for compliance with specifications.

- In-Process Quality Control (IPQC): Conducted during various stages of manufacturing, this ensures that processes are being followed correctly and that any deviations are addressed immediately.

- Final Quality Control (FQC): This is the last step before products are shipped, involving comprehensive testing and inspection of the final products for defects or inconsistencies.

3. What Common Testing Methods Are Used?

Common testing methods for water bottles include:

- Leak Testing: Ensuring that bottles do not leak under various conditions.

- Drop Testing: Assessing durability by dropping bottles from specified heights.

- Thermal Insulation Testing: Evaluating the effectiveness of insulation in keeping liquids hot or cold.

- Chemical Testing: Checking for harmful substances, especially in plastic bottles.

These tests help guarantee that the products are safe for consumer use and meet the desired quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control measures of a supplier is essential for B2B buyers, particularly when sourcing from different regions.

1. What Audits and Reports Should Buyers Request?

Buyers should request quality audits from suppliers, which can provide insights into their quality management practices. This includes reviewing documentation such as quality assurance reports, compliance certifications, and production logs. Regular audits by third-party organizations can also provide an unbiased assessment of a supplier’s practices.

2. How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can significantly bolster buyer confidence. These independent organizations can conduct audits and inspections at various stages of production, ensuring compliance with industry standards and specifications. This is particularly important for international buyers who may not have the ability to conduct on-site evaluations.

3. What Are the QC Nuances for International Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific regulations that may affect imports. For example, certain countries may have stricter regulations on materials used in food containers. Buyers should familiarize themselves with local laws and ensure that their suppliers are compliant with these regulations. Additionally, understanding the cultural and logistical challenges of sourcing from different regions can aid in mitigating risks associated with quality assurance.

Conclusion: Why Is Understanding Manufacturing Processes and Quality Assurance Crucial for B2B Buyers?

A deep understanding of the manufacturing processes and quality assurance measures for custom water bottles is essential for B2B buyers. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet both regulatory standards and customer expectations. By focusing on material selection, manufacturing techniques, and rigorous quality control, buyers can significantly reduce risks and enhance their brand reputation in the competitive market of custom water bottles.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle bulk custom’

Introduction

When sourcing custom water bottles in bulk, it’s essential for B2B buyers to navigate the process methodically to ensure they meet their branding and functional needs. This checklist will guide you through the crucial steps to procure high-quality custom water bottles, tailored to your specifications, while also considering cost-effectiveness and supplier reliability.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your custom water bottles. This includes the material (e.g., plastic, metal, glass), capacity (e.g., 16 oz, 32 oz), and design features (e.g., insulated, collapsible). Clearly defined specifications help streamline the sourcing process and ensure that you receive products that align with your branding and usage needs.

- Material Considerations: Choose materials that reflect your brand values, such as BPA-free plastics or recycled materials.

- Design Features: Consider user-friendly features like lids, spouts, and carrying options.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in custom water bottles. Utilize online platforms, industry directories, and trade shows to compile a list of potential partners. A well-researched supplier base is crucial for securing quality products and competitive pricing.

- Supplier Reviews: Look for reviews and testimonials from other businesses to gauge reliability.

- Industry Experience: Prioritize suppliers with a proven track record in your industry or region.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with industry standards. This includes checking for safety certifications, quality management systems (like ISO), and environmental compliance (such as BPA-free claims).

- Importance of Certifications: Certifications can serve as a quality assurance indicator, ensuring that products meet specific safety and environmental standards.

- Documentation Request: Don’t hesitate to request documentation to confirm compliance.

Step 4: Request Samples

Always request samples before placing a bulk order. This step allows you to assess the quality, design, and functionality of the water bottles firsthand. A sample can reveal potential issues that may not be apparent in product descriptions.

- Sample Evaluation: Test for durability, ease of use, and aesthetic appeal.

- Feedback Loop: Gather feedback from team members or potential customers to inform your final decision.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Look beyond just the unit price; consider factors such as minimum order quantities, shipping costs, and lead times.

- Total Cost of Ownership: Analyze the total cost, including delivery and any potential customs fees, especially if sourcing from international suppliers.

- Negotiation Opportunities: Be prepared to negotiate terms for better pricing or additional services.

Step 6: Confirm Production and Delivery Timelines

After selecting a supplier, confirm production timelines and delivery schedules. Understanding the timeline is critical to ensure that your custom water bottles arrive when needed for your marketing campaigns or events.

- Production Capacity: Inquire about the supplier’s production capacity to handle your order size within your required timeframe.

- Contingency Plans: Discuss potential delays and how they will be communicated.

Step 7: Establish a Quality Assurance Process

Finally, set up a quality assurance process to monitor the production of your custom water bottles. This can include regular updates from the supplier, on-site inspections, or third-party quality checks.

- Quality Control Measures: Outline specific quality metrics that need to be met before final acceptance.

- Continuous Improvement: Use feedback from this order to improve future sourcing processes.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing custom water bottles in bulk, ensuring a successful procurement that meets both their brand and customer needs.

Comprehensive Cost and Pricing Analysis for water bottle bulk custom Sourcing

When sourcing custom water bottles in bulk, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. This guide breaks down the cost components, price influencers, and provides actionable tips for negotiating and maximizing value.

What Are the Key Cost Components in Custom Water Bottle Sourcing?

The cost of custom water bottles comprises several critical components:

-

Materials: The choice of materials—plastic, metal, glass, or recycled options—significantly influences the cost. For instance, stainless steel bottles may be more expensive due to their durability and insulation properties, while BPA-free plastics can offer a cost-effective alternative.

-

Labor: Labor costs vary by region and can impact the overall price. Countries with lower labor costs might offer competitive pricing but may compromise on quality or production speed.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Buyers should inquire about the supplier’s overhead to gauge potential pricing flexibility.

-

Tooling: Customization often requires specific molds or designs, incurring additional tooling costs. Understanding these upfront costs can help in budget planning.

-

Quality Control (QC): Ensuring product quality through inspections and testing adds to the cost. Suppliers with stringent QC processes may charge higher prices but can reduce returns and dissatisfaction.

-

Logistics: Shipping costs, including freight and insurance, play a significant role, especially for international shipments. Incoterms (International Commercial Terms) will dictate who bears these costs and responsibilities.

-

Margin: Suppliers typically include a profit margin in their pricing, which can range from 10% to 30%. This margin can vary based on the supplier’s market position and product demand.

How Do Price Influencers Impact Custom Water Bottle Costs?

Several factors can influence the final pricing of custom water bottles:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer tiered pricing based on quantity, incentivizing bulk purchases.

-

Specifications and Customization: Custom designs, colors, and features (like insulation or collapsibility) can increase costs. Be clear about desired specifications to avoid unexpected charges.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like BPA-free or eco-friendly labels) can raise costs but may be essential for compliance in certain markets.

-

Supplier Factors: Reputation, location, and production capabilities of the supplier can impact pricing. Established suppliers may charge a premium for reliability and quality assurance.

-

Incoterms: Understanding shipping terms can help in negotiating total costs. For example, FOB (Free on Board) means the buyer assumes risk and costs once the goods are on board, while CIF (Cost, Insurance, and Freight) includes shipping in the price.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

To maximize value when sourcing custom water bottles, consider the following strategies:

-

Negotiate: Don’t hesitate to negotiate prices, especially when placing large orders. Discuss potential discounts for higher volumes or long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial costs to consider long-term expenses, such as shipping, storage, and potential returns. A lower purchase price may not always equate to overall savings.

-

Understand Pricing Nuances: Be aware of regional pricing differences. Suppliers in certain countries may have different cost structures, affecting both pricing and lead times.

-

Research and Compare Suppliers: Seek multiple quotes and assess suppliers based on quality, delivery times, and customer service. This due diligence can reveal the best value options.

-

Consider Local Suppliers: Depending on the destination market, sourcing from local suppliers can reduce logistics costs and lead times, making it a viable alternative.

Disclaimer on Indicative Prices

Prices for custom water bottles can vary widely based on the factors discussed above. The figures provided in various suppliers’ catalogs should be viewed as indicative, with final quotes subject to negotiation and specific order details. Always confirm current pricing and terms before proceeding with an order.

Alternatives Analysis: Comparing water bottle bulk custom With Other Solutions

Understanding Alternative Solutions to Bulk Custom Water Bottles

In the competitive landscape of promotional products, businesses often seek alternatives to bulk custom water bottles to meet their branding and operational needs. While custom water bottles provide excellent promotional opportunities and user engagement, other solutions may offer distinct advantages depending on specific requirements such as budget, sustainability, and audience appeal.

Comparison Table of Water Bottle Bulk Custom Against Alternatives

| Comparison Aspect | Water Bottle Bulk Custom | Reusable Drinkware (e.g., Tumblers) | Single-Use Bottles |

|---|---|---|---|

| Performance | High branding visibility; durable | Good thermal retention; versatile use | Convenient for events; no cleaning required |

| Cost | Moderate to high (bulk pricing) | Moderate (varies by material) | Low (typically inexpensive) |

| Ease of Implementation | Requires design and production planning | Quick sourcing; less customization | Ready-to-use; minimal setup |

| Maintenance | Requires cleaning and care | Dishwasher safe options available | No maintenance (disposable) |

| Best Use Case | Corporate giveaways, events, and trade shows | Daily use, gifts, and corporate gifting | Events, festivals, and short-term promotions |

What Are the Pros and Cons of Reusable Drinkware?

Reusable drinkware, such as tumblers or travel mugs, serves as an effective alternative to bulk custom water bottles. These products often come with excellent thermal insulation properties, making them ideal for hot or cold beverages. They also promote sustainability by reducing single-use plastic waste, appealing to environmentally conscious consumers. However, the initial investment can be high, and the options for customization may be limited compared to bulk custom water bottles, which can be tailored to specific branding needs.

How Do Single-Use Bottles Compare to Custom Water Bottles?

Single-use bottles are a straightforward solution for events, offering convenience and ease of distribution. They require no maintenance, making them ideal for large gatherings where cleanup might be challenging. However, their environmental impact is significant, and they lack the branding longevity that custom water bottles provide. Single-use options are typically less expensive but do not offer the same promotional value or user engagement over time, making them less suitable for businesses looking to build brand loyalty.

Conclusion: Which Solution Is Right for Your Business?

When evaluating alternatives to bulk custom water bottles, B2B buyers should consider their specific goals, target audience, and budget. If branding and long-term engagement are priorities, bulk custom water bottles remain a strong choice. However, if immediate convenience and cost-effectiveness are essential, exploring reusable drinkware or single-use bottles might be beneficial. Ultimately, the right solution will align with your company’s values, marketing strategies, and the preferences of your audience, ensuring a successful promotional campaign.

Essential Technical Properties and Trade Terminology for water bottle bulk custom

When engaging in the bulk custom water bottle market, understanding the essential technical properties and trade terminology can significantly enhance decision-making. Here’s a breakdown of key specifications and terms relevant to international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Technical Properties of Custom Water Bottles?

-

Material Composition

The choice of material directly impacts durability, safety, and usability. Common materials include BPA-free plastics, stainless steel, and glass. For example, stainless steel is known for its insulation properties and longevity, making it a preferred choice for premium products. Understanding material properties is crucial for compliance with health regulations and customer preferences. -

Capacity

Water bottles come in various sizes, typically ranging from 12 oz to 40 oz. The capacity influences user experience, catering to different market segments such as sports, corporate gifts, or outdoor activities. Offering a range of sizes can help meet diverse consumer needs, enhancing customer satisfaction and brand loyalty. -

Insulation Type

Insulated bottles maintain beverage temperatures, appealing to consumers who prioritize functionality. Double-wall vacuum insulation is a common feature in high-end products, keeping drinks hot or cold for extended periods. This property is vital for differentiating products in a competitive marketplace. -

Custom Imprint Methods

The method of branding, such as screen printing, pad printing, or laser engraving, affects both aesthetics and durability of the logo or design. Selecting the right imprint method ensures that branding is not only visually appealing but also long-lasting, reinforcing brand identity. -

Design Features

Features such as flip-top lids, straws, or collapsibility can significantly impact user convenience. Incorporating ergonomic designs or additional functionalities can enhance the product’s appeal, making it more attractive to potential buyers. -

Minimum Order Quantity (MOQ)

MOQs can vary significantly between suppliers. Understanding these quantities is essential for inventory planning and cost management. Lower MOQs may be favorable for smaller businesses or startups looking to test the market without substantial upfront investment.

What Are Common Trade Terms in the Water Bottle Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the context of custom water bottles, this means a buyer can have bottles produced under their brand without having to handle manufacturing directly. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is a crucial factor for B2B buyers as it affects purchasing decisions, especially for new businesses or those with limited budgets. Understanding MOQ helps in planning inventory and cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For bulk custom water bottles, an RFQ allows buyers to compare prices and conditions from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers in shipping agreements. They clarify who is responsible for shipping costs, insurance, and risks, making them essential for smooth cross-border transactions. -

BPA (Bisphenol A)

BPA is a chemical used in some plastics that can pose health risks. Products labeled as BPA-free are increasingly in demand, particularly among health-conscious consumers. Understanding this term helps buyers select safer products that comply with health regulations. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. This is a critical consideration for businesses needing timely delivery to meet customer demand. Knowing lead times helps in effective planning and inventory management.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and better navigate the complexities of the custom water bottle market.

Navigating Market Dynamics and Sourcing Trends in the water bottle bulk custom Sector

What Are the Key Market Dynamics and Trends Shaping the Bulk Custom Water Bottle Sector?

The bulk custom water bottle market is experiencing significant growth, driven by rising health consciousness and the increasing demand for sustainable products. Global buyers, especially in regions like Africa, South America, the Middle East, and Europe, are seeking customized solutions that not only meet functional needs but also align with their branding and environmental commitments. Notably, the proliferation of e-commerce platforms has simplified sourcing, enabling businesses to easily compare products and suppliers across borders.

Emerging technologies, such as 3D printing and digital printing, are revolutionizing customization capabilities, allowing for rapid prototyping and unique designs. Additionally, data analytics is playing a crucial role in understanding consumer preferences, enabling suppliers to tailor their offerings more effectively. As a result, international buyers can leverage these technologies to enhance their product offerings and streamline their supply chains.

Moreover, the market is witnessing a shift towards personalization, with businesses opting for bespoke designs that reflect their brand identity. This trend is particularly prominent in promotional events and corporate gifting, where customized water bottles serve as effective marketing tools. In essence, the dynamics of this market are characterized by an increasing emphasis on customization, technological advancements, and a growing preference for sustainable products.

How Is Sustainability Influencing Sourcing Decisions in the Bulk Custom Water Bottle Market?

Sustainability is no longer a buzzword; it has become a critical factor influencing sourcing decisions in the bulk custom water bottle sector. The environmental impact of single-use plastics has prompted businesses to seek alternatives that are both eco-friendly and socially responsible. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials, BPA-free plastics, and biodegradable options.

Furthermore, ethical sourcing is gaining traction, with buyers demanding transparency in their supply chains. Companies that can provide certifications, such as Fair Trade or Global Organic Textile Standard (GOTS), are often favored. These certifications not only assure buyers of ethical production practices but also enhance brand reputation in a market that values corporate social responsibility.

The use of ‘green’ materials, such as recycled stainless steel or eco-friendly plastics, is becoming a key differentiator for suppliers. As the demand for sustainable products continues to rise, businesses that adopt eco-conscious practices are likely to gain a competitive edge. In this context, buyers must consider not only the quality and cost of the products but also the environmental footprint and ethical implications of their sourcing decisions.

What Is the Historical Context of the Bulk Custom Water Bottle Industry?

The bulk custom water bottle industry has evolved significantly over the past few decades. Initially dominated by basic plastic designs, the market has transformed with advancements in materials and manufacturing techniques. The introduction of stainless steel and glass bottles addressed concerns over plastic waste and health risks associated with certain plastics.

In the early 2000s, the trend towards personalization began to take off, driven by the rise of promotional products as effective marketing tools. Businesses recognized the potential of customized water bottles to enhance brand visibility and customer loyalty. As health and wellness trends gained momentum, the industry adapted by offering a variety of styles, sizes, and functionalities, including insulated and collapsible options.

Today, the market is not only focused on aesthetics and functionality but also on sustainability and ethical sourcing. This evolution reflects broader societal shifts towards environmental responsibility and health consciousness, making the bulk custom water bottle sector a dynamic and competitive arena for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle bulk custom

-

How do I ensure the quality of custom water bottles when sourcing from international suppliers?

To ensure quality, start by requesting samples from potential suppliers. Evaluate these samples for material quality, durability, and functionality. It’s also advisable to check the supplier’s certifications, such as ISO, to confirm they adhere to international standards. Conducting a factory audit or using third-party inspection services can further verify that the production processes meet your expectations. Additionally, reviews and testimonials from previous clients can provide insights into the supplier’s reliability and product quality. -

What is the best material for custom water bottles in bulk orders?

The best material depends on your target market and intended use. Stainless steel offers durability and insulation, making it ideal for outdoor and fitness promotions. Plastic is lightweight and cost-effective, suitable for events and giveaways. Glass provides a premium feel but is more fragile. Consider the market preferences in regions like Africa and South America, where practicality may outweigh aesthetics. Ensure that all materials are BPA-free and comply with safety regulations in your target markets. -

What are the minimum order quantities (MOQ) for bulk custom water bottles?

Minimum order quantities vary significantly by supplier and the type of bottle. Generally, MOQs can range from as few as 12 units to several hundred, depending on the customization options and material. It’s crucial to discuss MOQs upfront with potential suppliers and factor in your budget and storage capabilities. Some suppliers may offer flexibility on MOQs for first-time orders or promotional events, so don’t hesitate to negotiate. -

What customization options are available for bulk water bottles?

Customization options typically include screen printing, laser engraving, and full-color digital printing. You can customize size, color, and shape, and many suppliers offer options for adding logos, slogans, or unique designs. Consider functionality as well, such as adding features like carabiners, straws, or collapsible designs. Ensure your design aligns with your brand identity and resonates with your target audience. -

What payment terms should I expect when ordering custom water bottles internationally?

Payment terms can vary widely among suppliers. Common arrangements include a deposit (often 30-50%) upfront and the balance upon delivery. Some suppliers might offer payment via letters of credit, PayPal, or bank transfers. It’s crucial to clarify these terms before placing an order to avoid misunderstandings. Assess the supplier’s reputation and trustworthiness when considering payment options, especially for larger orders. -

How can I vet suppliers for custom water bottles in international markets?

Begin by researching suppliers through platforms like Alibaba or trade directories. Check for reviews and ratings from previous buyers. Request references and contact past clients to discuss their experiences. Verify the supplier’s business licenses and certifications to ensure legitimacy. Engaging in direct communication can also help gauge their responsiveness and professionalism. If feasible, visiting the factory can provide firsthand insights into their operations. -

What are the logistics considerations for shipping custom water bottles internationally?

Considerations include shipping methods (air vs. sea), transit times, and customs regulations in your destination country. Air freight is faster but costlier, while sea freight is economical for larger shipments. Understand the import duties and taxes applicable in your country, as these can impact overall costs. Collaborating with a logistics partner experienced in international trade can streamline the process and ensure compliance with all regulations. -

What are common quality assurance practices for custom water bottles?

Implementing a quality assurance (QA) process is essential for maintaining product standards. This includes pre-production meetings to clarify specifications, in-line inspections during manufacturing, and final inspections before shipping. Establish clear quality criteria and communicate them with your supplier. Consider third-party QA services for unbiased assessments. Regularly reviewing the supplier’s quality performance and addressing any issues promptly can help maintain a strong business relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for water bottle bulk custom

What Are the Key Takeaways for Strategic Sourcing of Custom Water Bottles?

In conclusion, strategic sourcing for bulk custom water bottles offers significant advantages for international B2B buyers. By prioritizing quality, selecting the right materials—such as BPA-free plastic or insulated stainless steel—and leveraging customization options, businesses can effectively enhance their brand visibility. The diverse range of products available, including collapsible and insulated options, ensures that companies can meet the varied needs of their customers while promoting sustainability.

How Can Businesses Leverage Strategic Sourcing for Competitive Advantage?

Investing in strategic sourcing not only optimizes procurement costs but also fosters stronger supplier relationships, facilitating more favorable terms and quicker turnaround times. For buyers in Africa, South America, the Middle East, and Europe, this approach can lead to more resilient supply chains, especially in a rapidly changing global market.

What Is the Future Outlook for Custom Water Bottles in B2B Markets?

As consumer preferences increasingly shift towards eco-friendly and reusable products, the demand for custom water bottles is set to rise. Businesses that act now to integrate these products into their offerings will position themselves as leaders in sustainability and innovation. Don’t miss the opportunity to enhance your brand while catering to a growing market—begin your strategic sourcing journey today!