Introduction: Navigating the Global Market for cooler beer bottle

In the competitive landscape of beverage services, sourcing the right cooler beer bottle can significantly influence customer satisfaction and operational efficiency. With diverse international markets, including Africa, South America, the Middle East, and Europe, businesses face the challenge of identifying products that meet local preferences and climate conditions while ensuring quality and cost-effectiveness. This comprehensive guide delves into the various types of cooler beer bottles available, their applications across different venues, and essential factors for supplier vetting.

By exploring innovative designs such as insulated stainless steel and versatile neoprene options, buyers can make informed choices that cater to both aesthetic and functional needs. The guide also provides insights into pricing structures, helping businesses align their budgets with market expectations. Additionally, it addresses logistical considerations, ensuring that B2B buyers from regions like Vietnam and Germany can navigate import regulations and shipping complexities with ease.

Ultimately, this resource empowers international B2B buyers to enhance their beverage offerings, ensuring that every bottle served is not just cold but also leaves a lasting impression on their customers. With a focus on actionable insights and best practices, this guide is your essential tool for making strategic sourcing decisions in the cooler beer bottle market.

Навигация по статье

- Top 8 Cooler Beer Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cooler beer bottle

- Understanding cooler beer bottle Types and Variations

- Key Industrial Applications of cooler beer bottle

- 3 Common User Pain Points for ‘cooler beer bottle’ & Their Solutions

- Strategic Material Selection Guide for cooler beer bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for cooler beer bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cooler beer bottle’

- Comprehensive Cost and Pricing Analysis for cooler beer bottle Sourcing

- Alternatives Analysis: Comparing cooler beer bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for cooler beer bottle

- Navigating Market Dynamics and Sourcing Trends in the cooler beer bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cooler beer bottle

- Важный отказ от ответственности и условия использования

- Strategic Sourcing Conclusion and Outlook for cooler beer bottle

Understanding cooler beer bottle Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Insulated Stainless Steel | Triple insulation, durable, non-slip base | Bars, restaurants, outdoor events | Плюсы: Excellent temperature retention; Конс: Более высокая стоимость. |

| Foam & Neoprene Sleeves | Lightweight, portable, customizable designs | Retail promotions, events, giveaways | Плюсы: Cost-effective; Конс: Limited insulation capacity. |

| Commercial Bottle Coolers | Refrigeration capabilities, multiple sizes, accessible design | Bars, restaurants, retail outlets | Плюсы: Quick access to cold beverages; Конс: Requires power. |

| Growlers & Jugs | Large capacity, designed for beer transport | Breweries, craft beer retailers | Плюсы: Keeps beer fresh; Конс: Bulky for transport. |

| Specialty Koozies | Fun designs, promotional branding opportunities | Marketing events, parties | Плюсы: Attractive for branding; Конс: Less functional. |

What Are Insulated Stainless Steel Coolers and Their B2B Benefits?

Insulated stainless steel coolers are designed for maximum temperature retention, utilizing triple insulation technology to keep beverages cold for extended periods. Ideal for bars and restaurants, these coolers are durable and portable, making them suitable for outdoor events. When considering a purchase, businesses should weigh the higher upfront cost against the long-term benefits of enhanced customer satisfaction through cold beverages.

How Do Foam and Neoprene Sleeves Serve B2B Needs?

Foam and neoprene sleeves are lightweight and highly portable, making them an excellent choice for retail promotions, events, and giveaways. Their customizable designs allow businesses to enhance brand visibility. However, while they are cost-effective, their insulation capacity is limited compared to metal options, which may not be suitable for all environments.

Why Choose Commercial Bottle Coolers for Your Business?

Commercial bottle coolers are essential for bars and restaurants, providing refrigeration capabilities and quick access to cold beverages. Available in various sizes, these coolers can accommodate different bottle types and volumes. While they ensure efficiency in service, buyers must consider the need for a power source and the space they will occupy in their establishments.

What Are Growlers and Jugs, and How Do They Benefit Breweries?

Growlers and jugs are designed for transporting larger volumes of beer, making them ideal for breweries and craft beer retailers. They help maintain the freshness of the beer, appealing to customers looking for quality. However, their bulkiness can be a drawback for transport, so businesses should assess their logistics before investing.

How Do Specialty Koozies Enhance Branding Opportunities?

Specialty koozies are not only functional but also serve as effective promotional tools. With vibrant designs, they can be customized for marketing events or parties, enhancing brand visibility. However, they may sacrifice some insulation effectiveness, making them less suitable for environments where keeping drinks cold is a priority.

Key Industrial Applications of cooler beer bottle

| Промышленность/сектор | Specific Application of cooler beer bottle | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Гостеприимство | Use in bars and restaurants to keep beer bottles cold | Enhances customer experience, leading to increased sales | Durability, energy efficiency, and size to fit bar layouts |

| Events & Catering | Portable coolers for outdoor events and festivals | Provides a convenient solution for serving chilled beverages | Portability, insulation effectiveness, and branding options |

| Розничная торговля | Merchandising in convenience stores and supermarkets | Attracts customers and promotes sales of chilled beverages | Size, display features, and compliance with local regulations |

| Food & Beverage Production | Internal use in breweries for storage and distribution | Maintains product quality and extends shelf life | Temperature control, capacity, and material quality |

| Tourism & Recreation | Coolers for beach resorts and outdoor recreational facilities | Enhances guest satisfaction and encourages repeat visits | Lightweight design, insulation performance, and aesthetic appeal |

How Are Cooler Beer Bottles Utilized in the Hospitality Sector?

In the hospitality industry, cooler beer bottles are essential for bars and restaurants to maintain optimal serving temperatures for beverages. These coolers allow establishments to enhance customer experiences by ensuring that drinks are always served cold. For international B2B buyers, considerations such as durability, energy efficiency, and the cooler’s size to fit specific bar layouts are crucial. Investing in high-quality coolers can lead to increased sales and customer satisfaction, particularly in regions with hot climates, where cold beverages are in high demand.

What Role Do Cooler Beer Bottles Play in Events and Catering?

Portable cooler beer bottles are widely used in events and catering services, particularly for outdoor festivals and gatherings. They provide a practical solution for serving chilled beverages away from traditional refrigeration units. Buyers in this sector should focus on the coolers’ portability, insulation effectiveness, and branding options to maximize their visibility at events. This application not only ensures that guests enjoy their drinks at the right temperature but also enhances the overall experience, encouraging positive feedback and repeat business.

How Do Retailers Benefit from Cooler Beer Bottles?

Retailers, particularly convenience stores and supermarkets, utilize cooler beer bottles to attract customers and promote chilled beverage sales. These coolers can be strategically placed near checkout areas or in high-traffic sections to increase visibility. When sourcing these coolers, businesses should consider size, display features, and compliance with local regulations regarding beverage storage. Effective merchandising through cooler beer bottles can significantly impact sales, especially in regions where consumers prefer ready-to-drink options.

In What Ways Are Cooler Beer Bottles Essential for Food & Beverage Production?

In the food and beverage production sector, cooler beer bottles are crucial for breweries to store and distribute their products. These coolers help maintain product quality by ensuring that beverages remain at the correct temperature throughout the supply chain. Buyers should prioritize temperature control, capacity, and material quality when selecting coolers for production facilities. Implementing efficient cooling solutions not only extends the shelf life of beverages but also supports compliance with safety and quality standards.

How Do Cooler Beer Bottles Enhance Tourism and Recreation Experiences?

In the tourism and recreation industry, cooler beer bottles are utilized by beach resorts and outdoor recreational facilities to enhance guest satisfaction. They provide a convenient way to keep beverages cold during hot weather, encouraging guests to spend more time enjoying the amenities. For international buyers, lightweight design, insulation performance, and aesthetic appeal are key factors in sourcing decisions. By offering chilled drinks in a visually appealing manner, businesses can foster customer loyalty and encourage repeat visits, particularly in tourist-heavy locations.

3 Common User Pain Points for ‘cooler beer bottle’ & Their Solutions

Scenario 1: Struggling with Temperature Maintenance During Distribution

Проблема: B2B buyers, especially those in the beverage distribution sector, often face challenges in maintaining optimal temperatures for cooler beer bottles during transport. Fluctuating temperatures can lead to warm beer, compromising quality and customer satisfaction. This is particularly critical in regions with extreme climates, such as parts of Africa and South America, where high ambient temperatures can significantly affect product integrity during lengthy delivery times.

Решение: To mitigate temperature control issues, buyers should invest in insulated transport solutions specifically designed for beverage distribution. This could include using specialized refrigerated trucks or insulated containers that maintain low temperatures throughout the delivery process. Additionally, sourcing triple-insulated beer bottle coolers can further enhance temperature retention once the product reaches retail locations. Buyers should ensure that the coolers used are compatible with their specific bottle sizes and materials to maximize efficiency. Regular training sessions for staff on proper loading and unloading techniques can also help maintain product integrity, ensuring that beers remain chilled from warehouse to consumer.

Scenario 2: Limited Space for Cooler Storage in Retail Outlets

Проблема: Retailers often struggle with limited space for displaying and storing cooler beer bottles. This issue is exacerbated in busy urban environments or smaller establishments where every square foot counts. An inefficient use of space can lead to lost sales opportunities as customers may find it difficult to access the products they want or may overlook available options entirely.

Решение: B2B buyers should consider sourcing compact and multifunctional cooler units that optimize space without sacrificing capacity. For instance, vertical bottle coolers can be more space-efficient than traditional horizontal units while still providing ample storage for a variety of beer brands. Additionally, implementing a well-organized inventory system within these coolers can enhance product visibility and accessibility. Utilizing modular shelving systems allows retailers to adjust their display according to product demand, making the most of limited space. Regularly updating the inventory based on sales data can help ensure that popular items are always readily available, keeping customer satisfaction high.

Scenario 3: Consumer Demand for Eco-Friendly Options

Проблема: There is an increasing demand for eco-friendly products among consumers, including those purchasing cooler beer bottles. B2B buyers are often challenged to align their product offerings with this trend while also ensuring cost-effectiveness. Failing to meet this demand can lead to a loss of competitive edge and customer loyalty, particularly in environmentally conscious markets in Europe and parts of the Middle East.

Решение: To address this challenge, buyers should prioritize sourcing sustainable cooler beer bottles made from recyclable or biodegradable materials. Engaging with manufacturers that emphasize environmentally friendly production processes can also enhance brand reputation. Additionally, promoting these eco-friendly options through marketing efforts can attract environmentally conscious consumers. Buyers can also explore partnerships with local breweries that emphasize sustainability, which can further enhance their product offering. Educating staff about the benefits of these eco-friendly products can help them effectively communicate value to consumers, reinforcing the brand’s commitment to sustainability while driving sales.

Strategic Material Selection Guide for cooler beer bottle

What Are the Key Properties of Common Materials Used in Cooler Beer Bottles?

When selecting materials for cooler beer bottles, several factors such as thermal efficiency, durability, and cost-effectiveness come into play. Below, we analyze four common materials used in the manufacturing of cooler beer bottles: stainless steel, aluminum, plastic, and neoprene.

Stainless Steel: The Premium Choice for Durability and Insulation

Stainless steel is renowned for its excellent thermal insulation properties, making it a top choice for cooler beer bottles. It typically has a high temperature rating, is resistant to corrosion, and can withstand significant pressure without deforming. The durability of stainless steel ensures that the bottles can endure rough handling, which is particularly beneficial for businesses in the beverage industry.

Плюсы: Stainless steel bottles offer high durability, resistance to rust, and superior insulation, keeping beverages cold for extended periods. They are also aesthetically pleasing and can be easily customized with branding.

Конс: The initial manufacturing costs are higher compared to other materials, and the complexity of production can lead to longer lead times. Additionally, stainless steel can be heavier than other options.

Влияние на применение: Stainless steel is compatible with a wide range of beverages, including carbonated drinks, due to its non-reactive nature. This makes it suitable for international markets where diverse beverage types are sold.

Соображения для международных покупателей: Compliance with food safety standards such as FDA or EU regulations is crucial. Buyers should also consider local preferences for aesthetics and branding.

Aluminum: Lightweight and Cost-Effective

Aluminum is another popular material for cooler beer bottles. It has a lower density than stainless steel, making it lightweight and easy to transport. Aluminum bottles can be treated to enhance their corrosion resistance and are often used for single-use applications.

Плюсы: The lightweight nature of aluminum reduces shipping costs, and its lower manufacturing costs make it an attractive option for budget-conscious businesses. Aluminum also offers good thermal performance when insulated.

Конс: While aluminum is durable, it is more susceptible to dents and scratches than stainless steel. Additionally, it may not provide the same level of insulation unless paired with additional insulating materials.

Влияние на применение: Aluminum is suitable for carbonated beverages but may require a liner to prevent reactions with certain acidic drinks. This is particularly relevant for international markets with diverse beverage offerings.

Соображения для международных покупателей: Buyers should ensure compliance with local recycling regulations, as aluminum is highly recyclable. Understanding local market preferences for sustainability can also influence purchasing decisions.

Plastic: Versatile and Economical

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are frequently used in cooler beer bottles. These materials are lightweight and can be molded into various shapes, making them versatile for different designs.

Плюсы: Plastic bottles are generally less expensive to produce and can be manufactured quickly. They are also resistant to breakage, making them suitable for outdoor events.

Конс: Plastic has lower thermal insulation properties compared to metal options and can degrade over time, especially when exposed to UV light. Additionally, some plastics may not be suitable for long-term storage of carbonated beverages.

Влияние на применение: Plastic is ideal for casual settings and events where breakage is a concern. However, it may not be the best choice for premium products that require longer shelf life and better insulation.

Соображения для международных покупателей: Buyers should be aware of regulations regarding food-grade plastics and recycling standards in their respective countries. There may also be consumer preferences leaning towards more sustainable materials.

Neoprene: The Flexible Insulator

Neoprene is commonly used for cooler sleeves rather than the bottles themselves. It offers excellent insulation and flexibility, making it easy to transport and store.

Плюсы: Neoprene provides good insulation, is lightweight, and can be easily customized for branding. It is also durable and resistant to water and UV light.

Конс: Neoprene is not as durable as metal or high-quality plastics and may wear out over time. It is also less suitable for long-term storage of beverages.

Влияние на применение: Neoprene is ideal for casual and outdoor settings, where portability is essential. It can effectively keep beverages cool for short periods.

Соображения для международных покупателей: Buyers should consider local preferences for promotional items, as customized neoprene sleeves can serve as effective marketing tools.

Summary Table of Material Selection for Cooler Beer Bottles

| Материал | Typical Use Case for cooler beer bottle | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Нержавеющая сталь | Premium beer bottles for long-term use | Excellent insulation and durability | Более высокая стоимость производства | Высокий |

| Алюминий | Lightweight, single-use bottles | Экономичный и легкий | Susceptible to dents and scratches | Средний |

| Пластик | Casual settings and outdoor events | Economical and versatile | Lower thermal insulation | Низкий |

| Neoprene | Cooler sleeves for portability | Good insulation and customization | Less durable over time | Средний |

This guide provides a comprehensive overview of the materials suitable for cooler beer bottles, aiding international B2B buyers in making informed decisions based on their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cooler beer bottle

What Are the Key Stages in the Manufacturing Process of Cooler Beer Bottles?

The manufacturing process for cooler beer bottles involves several critical stages that ensure the final product is both functional and of high quality. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

The primary materials used in the production of cooler beer bottles typically include stainless steel, aluminum, and high-grade plastics. Stainless steel is favored for its durability and insulation properties, while aluminum is lightweight and often used in combination with insulated layers.

In the material preparation stage, suppliers conduct a thorough inspection of raw materials to ensure they meet industry specifications. This might include checking for corrosion resistance and thermal conductivity. Additionally, suppliers may treat the materials to enhance their properties, such as applying anti-corrosion coatings to steel or anodizing aluminum for added durability.

How Are Cooler Beer Bottles Formed?

The forming stage involves shaping the prepared materials into the desired bottle design. This process can vary depending on the material used. For stainless steel, techniques like deep drawing and hydroforming are commonly employed. These methods allow for the creation of seamless, robust structures that enhance insulation and aesthetic appeal.

For plastic components, injection molding is often utilized. This method allows for intricate designs and is particularly useful for creating bottle caps and insulating sleeves. The choice of technique will depend on the final product specifications and the intended market.

What Are the Assembly and Finishing Processes for Cooler Beer Bottles?

After the components are formed, the next stage is assembly. This may include fitting the insulating layers, attaching caps, and integrating any additional features like handles or non-slip bases. Automated assembly lines are often used to improve efficiency and maintain consistency.

The finishing stage involves several critical processes, including surface treatment, polishing, and quality checks. Surface treatments may include powder coating or painting to enhance aesthetics and provide additional protection against wear and tear. Polishing ensures that the bottles are free from scratches and blemishes, which is particularly important for products marketed as premium.

What Quality Control Measures Are Essential for Cooler Beer Bottles?

Quality assurance is a vital aspect of the manufacturing process, ensuring that cooler beer bottles meet international standards and customer expectations. Manufacturers typically adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates a commitment to quality and continuous improvement.

Каковы ключевые контрольные точки контроля качества?

-

Входящий контроль качества (IQC): This initial checkpoint involves inspecting raw materials upon arrival to verify their quality and compliance with specifications. This step is crucial to prevent defects from entering the production line.

-

Внутрипроцессный контроль качества (IPQC): During the manufacturing process, regular checks are conducted to monitor the production parameters and ensure that all components are being assembled correctly. This may include measuring dimensions, checking weld quality, and ensuring proper insulation.

-

Окончательный контроль качества (ОКК): Once the cooler beer bottles are fully assembled, FQC involves comprehensive testing of the finished products. This may include thermal insulation tests, pressure tests, and visual inspections to ensure that each bottle meets quality standards.

How Do International Standards Impact Quality Control for Cooler Beer Bottles?

B2B buyers must be aware of various international certifications that can impact their purchasing decisions. In addition to ISO 9001, other relevant certifications may include CE marking for products sold in the European market, which ensures compliance with health and safety standards. API standards may also apply if the products are intended for specific industrial applications.

Какие методы тестирования обычно используются в обеспечении качества?

Several testing methods are commonly employed to assess the quality of cooler beer bottles:

-

Thermal Conductivity Tests: These tests measure how well the bottles maintain temperature under various conditions. This is crucial for ensuring that the product performs as advertised.

-

Испытания на падение: To assess durability, bottles may be subjected to drop tests from specified heights to evaluate their ability to withstand impact without damage.

-

Leak Tests: These tests ensure that the bottles are airtight and will not leak, which is essential for maintaining the integrity of the beverage inside.

Как покупатели B2B могут проверять процессы контроля качества поставщиков?

B2B buyers can take several steps to ensure that their suppliers adhere to rigorous quality control processes:

-

Проведение аудиторских проверок: Regular audits of suppliers can help verify compliance with quality standards. This may involve onsite visits to assess manufacturing practices and quality control measures.

-

Request Documentation: Buyers should ask for quality control reports, test results, and certifications to evaluate the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality.

What Are the Unique QC Considerations for International B2B Buyers?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is crucial. Different regions may have varying standards for materials and safety, which can impact product acceptance.

Furthermore, language barriers and cultural differences can influence communication regarding quality standards. Therefore, it is advisable for buyers to establish clear, documented agreements with suppliers that outline quality expectations and compliance measures.

Conclusion: The Importance of Quality Assurance in Cooler Beer Bottle Manufacturing

In the competitive landscape of cooler beer bottle manufacturing, quality assurance is paramount. By understanding the manufacturing processes and the associated quality control measures, B2B buyers can make informed decisions that align with their business needs and consumer expectations. Prioritizing suppliers who adhere to international standards and demonstrate robust quality control practices will ultimately lead to better product performance and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cooler beer bottle’

This guide is designed to assist B2B buyers in the international market, particularly those from Africa, South America, the Middle East, and Europe, in sourcing cooler beer bottles effectively. By following this checklist, you can ensure that you select the right products and suppliers to meet your business needs.

Шаг 1: Определите технические характеристики

Establishing clear technical specifications is essential before initiating your sourcing process. Consider factors such as the material (e.g., stainless steel, insulated foam), capacity (number of bottles), and specific design features (e.g., portability, non-slip base). Documenting these specifications will help streamline your search and ensure that potential suppliers understand your requirements.

Шаг 2: Исследование тенденций рынка и предпочтений потребителей

Understanding current market trends and consumer preferences in your target regions is crucial. Investigate which types of cooler beer bottles are popular, including sizes, materials, and functionalities. This information will not only guide your sourcing decisions but also enable you to offer products that resonate with your customer base.

Шаг 3: Оцените потенциальных поставщиков

Before committing to any supplier, thorough evaluation is vital. Request company profiles, product catalogs, and references from buyers in similar industries or regions. Pay attention to factors such as:

– Experience: Look for suppliers with a proven track record in producing cooler beer bottles.

– Product Quality: Ask for samples to assess the quality of materials and construction.

Шаг 4: Verify Supplier Certifications and Compliance

Ensure that potential suppliers meet all necessary certifications and compliance standards relevant to your market. This may include safety certifications, environmental compliance, and quality assurance standards. Verifying these credentials helps mitigate risks associated with product liability and ensures that you are sourcing from reputable manufacturers.

Шаг 5: Request Quotes and Compare Pricing

Once you have narrowed down your list of potential suppliers, request detailed quotes for your specified products. Compare pricing structures, including bulk discounts and shipping costs. Consider not only the price but also the value offered, such as warranty terms and after-sales support. This will help you make an informed decision while staying within your budget.

Шаг 6: Assess Shipping and Delivery Options

Evaluate the shipping and delivery options provided by your selected suppliers. Understand lead times, shipping methods, and costs to avoid delays that could impact your operations. Ensure that the supplier can accommodate your delivery schedule and that they have reliable logistics in place.

Шаг 7: Разработать план коммуникации

Effective communication is key to a successful sourcing partnership. Establish a clear communication plan with your supplier to discuss order updates, quality issues, and any other concerns. Regular check-ins can help address potential problems early and maintain a strong working relationship.

By following these steps, you can navigate the sourcing process for cooler beer bottles with confidence, ensuring that you select products that meet your business’s needs while building successful partnerships with suppliers.

Comprehensive Cost and Pricing Analysis for cooler beer bottle Sourcing

What Are the Key Cost Components for Sourcing Cooler Beer Bottles?

When sourcing cooler beer bottles, it’s essential to understand the various cost components that contribute to the overall price. The primary cost elements include:

-

Материалы: The choice of materials significantly affects pricing. Stainless steel, for instance, offers durability and insulation but is more expensive than foam or neoprene. Buyers should consider the long-term benefits of investing in higher-quality materials, which can enhance customer satisfaction and brand reputation.

-

Труд: Manufacturing labor costs vary by region. Countries with lower labor costs might offer competitive pricing but could compromise on quality. Understanding the local labor market in supplier countries can help buyers assess potential cost savings.

-

Производственные накладные расходы: This includes costs associated with factory operations, such as utilities and equipment maintenance. Buyers should inquire about the supplier’s operational efficiency, as this can impact the final price.

-

Инструментальная оснастка: Initial costs related to custom molds and production setups can be significant, especially for bespoke designs. Buyers should factor these costs into their budget, particularly if they require unique specifications.

-

Контроль качества (QC): Implementing robust QC processes ensures that products meet required standards. However, this incurs additional costs. Buyers should balance the need for quality assurance with their budget constraints.

-

Логистика: Shipping costs can vary dramatically based on distance, shipping method, and freight terms. Understanding the logistics landscape can help in negotiating better shipping rates.

-

Маржа: Suppliers typically mark up their costs to ensure profitability. Buyers should be aware of standard margins in the industry to gauge whether a quoted price is reasonable.

How Do Price Influencers Affect Cooler Beer Bottle Costs?

Several factors influence the pricing of cooler beer bottles, making it crucial for buyers to conduct thorough research:

-

Объем и минимальное количество заказа (MOQ): Suppliers often provide discounts for larger orders. Negotiating for favorable terms based on anticipated volume can significantly reduce costs.

-

Технические характеристики и персонализация: Custom designs and specifications usually come at a premium. Buyers should clearly define their needs and assess whether customization is necessary or if standard options suffice.

-

Сертификация материалов и качества: Higher-quality materials and certifications (e.g., ISO, FDA) can elevate costs. Buyers should evaluate whether these certifications are essential for their market or if they can opt for lower-cost alternatives.

-

Факторы поставщика: The reliability, reputation, and financial stability of suppliers can impact pricing. Engaging with established suppliers may lead to better pricing structures and consistent quality.

-

Инкотермс: Understanding shipping terms can affect overall costs. Buyers should be clear about who is responsible for shipping costs, insurance, and customs duties to avoid unexpected expenses.

What Tips Can Help Buyers Optimize Costs When Sourcing Cooler Beer Bottles?

To maximize cost efficiency and ensure a favorable sourcing experience, buyers should consider the following strategies:

-

Negotiation Techniques: Develop strong negotiation skills to secure better pricing. Building a rapport with suppliers can lead to more favorable terms and potential discounts.

-

Общая стоимость владения (TCO): Evaluate the TCO rather than just the upfront price. Factors like durability, maintenance, and potential for reusability can provide long-term savings.

-

Нюансы ценообразования для международных покупателей: Be aware of currency fluctuations, tariffs, and import duties, especially when sourcing from different regions. This knowledge can help in budgeting and forecasting costs more accurately.

-

Исследование рынка: Conduct thorough research to understand the competitive landscape and prevailing prices. This information can empower buyers in negotiations and sourcing strategies.

In summary, understanding the comprehensive cost structure and pricing influences is vital for international B2B buyers sourcing cooler beer bottles. By leveraging these insights and strategies, buyers can make informed decisions that enhance their procurement processes and overall profitability.

Alternatives Analysis: Comparing cooler beer bottle With Other Solutions

Exploring Alternatives to Cooler Beer Bottles: A Comparative Analysis

When considering solutions for keeping beverages chilled, it’s essential to explore various options available in the market. Cooler beer bottles have gained popularity for their convenience and effectiveness, but alternative methods and technologies also exist. This section will evaluate these alternatives based on performance, cost, ease of implementation, maintenance, and best use cases, providing B2B buyers with actionable insights for informed decision-making.

| Сравнительный аспект | Cooler Beer Bottle | Insulated Can Coolers | Commercial Bottle Coolers |

|---|---|---|---|

| Производительность | Excellent insulation; keeps beer cold for hours | Good insulation; varies by design | Highly efficient cooling for large quantities |

| Стоимость | Moderate price point (e.g., $20-$40) | Ranges from $5 to $30 depending on material | Higher initial investment (starting at $800) |

| Простота реализации | Portable and easy to use; suitable for individuals | Simple to use; best for casual settings | Requires installation and space; best for commercial use |

| Техническое обслуживание | Minimal; occasional cleaning | Minimal; generally hand wash | Regular cleaning and maintenance needed |

| Лучший пример использования | Personal use during outings or events | Ideal for picnics, camping, and casual gatherings | Bars, restaurants, and events needing quick access to chilled beverages |

Insulated Can Coolers: A Flexible Option

Insulated can coolers, such as those produced by companies like BrüMate, are designed for casual settings. They provide good insulation for various can sizes and are portable, making them ideal for picnics and outdoor gatherings. The primary advantage is their affordability and ease of use, with prices typically ranging from $5 to $30. However, they are limited to single servings and may not be as effective in high-demand commercial environments where multiple beverages need to be chilled simultaneously.

Commercial Bottle Coolers: Efficient for High Volume Needs

For businesses that serve large quantities of beverages, commercial bottle coolers are an excellent alternative. These refrigerators can hold dozens of bottles and keep them at optimal temperatures, making them essential for bars and restaurants. While they require a higher initial investment, often starting at around $800, their ability to handle high-volume demands efficiently makes them a worthwhile investment for establishments focused on quick service. However, they do require regular maintenance and cleaning, which can add to operational costs.

Conclusion: Selecting the Right Solution for Your Business Needs

Choosing the right solution for keeping beverages chilled depends largely on the specific needs of your business. Cooler beer bottles offer portability and convenience for personal use, while insulated can coolers are great for casual settings. On the other hand, commercial bottle coolers are ideal for businesses that prioritize efficiency and quick service. By assessing the performance, cost, ease of implementation, and maintenance of each option, B2B buyers can make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for cooler beer bottle

What Are the Key Technical Properties of a Cooler Beer Bottle?

When sourcing cooler beer bottles for commercial use, understanding the technical specifications is crucial. Here are several key properties to consider:

-

Класс материала: Most cooler beer bottles are made from high-quality stainless steel or durable plastics. Stainless steel offers superior insulation, ensuring beverages remain cold longer, while also being resistant to corrosion. The choice of material affects not only the product’s durability but also its thermal performance. For B2B buyers, opting for higher-grade materials can lead to increased customer satisfaction and reduced replacement costs.

-

Технология изоляции: Insulation can vary significantly, with options like double or triple wall vacuum insulation. This technology is vital for maintaining the desired temperature of beverages over extended periods. For businesses, selecting products with superior insulation can enhance customer experience, particularly in outdoor or event settings, where maintaining cold temperatures is essential.

-

Вместимость: Cooler beer bottles typically come in various sizes, often ranging from 12 oz to 25 oz. Understanding the capacity needed for your target market is essential for inventory management. Larger capacities may appeal to high-volume consumers, while smaller sizes may be more suited for casual users. This consideration can help tailor product offerings to meet diverse customer preferences.

-

Вес и портативность: The weight of the cooler bottle can impact its ease of transport and consumer preference. Lighter options may be more appealing for outdoor activities, while heavier, more robust designs may be favored for durability in commercial settings. For B2B buyers, balancing portability with durability is key to ensuring the product meets end-user expectations.

-

Особенности конструкции: Additional features such as non-slip bases, easy-clean surfaces, and ergonomic designs can enhance user experience. These attributes can differentiate your product in a competitive market. Buyers should consider these features when evaluating products to ensure they align with consumer needs and preferences.

-

Thermal Performance Ratings: Some manufacturers provide ratings for how long a cooler bottle can keep beverages cold. This rating can be a deciding factor for businesses looking to provide quality products. A higher thermal performance rating can justify a premium price and attract discerning customers.

What Are Common Trade Terms in the Cooler Beer Bottle Industry?

Familiarity with industry jargon can streamline communication and negotiations. Here are essential terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products that are then rebranded by another company. For B2B buyers, partnering with an OEM can provide access to high-quality products without the need for in-house manufacturing.

-

MOQ (минимальное количество заказа): This is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for inventory planning and can affect cash flow. Buyers should negotiate MOQs to align with their sales forecasts.

-

RFQ (запрос котировок): An RFQ is a formal process where buyers request pricing and terms from suppliers. This can help in comparing offers and making informed purchasing decisions. Buyers should include detailed specifications to receive accurate quotes.

-

Инкотермс (международные коммерческие термины): These are standardized terms used in international trade to define responsibilities regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers engaged in cross-border transactions, as they clarify the obligations of both parties involved.

-

Время выполнения: This refers to the time from placing an order to receiving the goods. Understanding lead time is essential for managing inventory and ensuring that products are available when needed.

-

Стандарты сертификации: Many cooler beer bottles may need to meet specific industry standards or certifications, such as FDA approval for food safety. Awareness of these standards can help buyers ensure compliance and enhance product credibility in the market.

Understanding these technical properties and trade terms can empower B2B buyers to make informed purchasing decisions, optimize product offerings, and ultimately enhance customer satisfaction in their markets.

Navigating Market Dynamics and Sourcing Trends in the cooler beer bottle Sector

What Are the Current Market Dynamics and Key Trends in the Cooler Beer Bottle Sector?

The cooler beer bottle market is witnessing significant growth, driven by rising consumer preferences for outdoor activities and the increasing popularity of craft beers. As more individuals seek convenience in enjoying their beverages on-the-go, innovations in cooler technology are becoming paramount. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly interested in sourcing high-quality, insulated coolers that enhance the consumer experience.

Emerging technologies such as smart insulation and lightweight materials are reshaping the product offerings. For instance, advanced materials like triple-insulated stainless steel provide superior temperature retention, ensuring beverages remain cold for extended periods. Moreover, customization options are becoming a key trend, allowing businesses to tailor products to specific market demands. Buyers are also gravitating toward versatile products that accommodate various bottle sizes and types, from standard beer bottles to larger craft brews.

Market dynamics are further influenced by changing consumer behavior, where eco-consciousness plays a crucial role. B2B buyers are now prioritizing suppliers who can demonstrate sustainable practices and materials in their products. This shift not only addresses the growing environmental concerns but also aligns with the marketing strategies of brands looking to connect with a more conscious consumer base.

How Does Sustainability Impact the Sourcing of Cooler Beer Bottles?

Sustainability is no longer a buzzword; it has become a critical factor influencing purchasing decisions in the cooler beer bottle sector. The environmental impact of production processes, particularly in terms of resource consumption and waste generation, is under scrutiny. B2B buyers are increasingly looking for manufacturers that adhere to sustainable practices, such as using recyclable materials and minimizing carbon footprints.

Ethical sourcing is also gaining traction, as businesses recognize the importance of transparency in their supply chains. Suppliers that can provide certifications for sustainability—such as ISO 14001 or materials sourced from renewable resources—are more likely to attract discerning B2B clients. Additionally, the use of biodegradable or eco-friendly materials in cooler production not only reduces environmental impact but also enhances brand loyalty among consumers who prioritize sustainability.

Investing in greener alternatives not only meets regulatory requirements but can also lead to cost savings in the long term. As energy-efficient manufacturing processes and sustainable sourcing practices become commonplace, companies can expect to see a positive return on investment while contributing to global sustainability goals.

What Is the Brief Evolution of the Cooler Beer Bottle Market?

The cooler beer bottle market has evolved significantly over the past few decades. Initially dominated by basic foam sleeves designed to keep drinks cool, the sector has transformed with advancements in materials and technology. The introduction of insulated stainless steel and innovative designs has allowed manufacturers to cater to a more diverse range of consumer preferences.

In recent years, the growth of the craft beer movement has further fueled demand for specialized coolers that enhance the enjoyment of artisanal brews. This has led to increased competition among manufacturers to develop unique, high-quality products that stand out in a crowded marketplace. As the market continues to expand globally, especially in emerging regions, the focus on sustainability and ethical sourcing is likely to shape its future trajectory.

Frequently Asked Questions (FAQs) for B2B Buyers of cooler beer bottle

-

How do I choose the right cooler beer bottle for my business?

When selecting a cooler beer bottle for your business, consider factors such as insulation efficiency, size compatibility, and material durability. Look for products that provide triple insulation, typically found in stainless steel options, which help maintain cold temperatures for extended periods. Additionally, assess your target market’s preferences; for instance, slim coolers may appeal more in certain regions. Finally, ensure that the cooler fits standard bottle sizes to maximize versatility. -

What is the best type of cooler beer bottle for outdoor events?

The best cooler beer bottles for outdoor events are typically made from durable, insulated materials such as stainless steel or high-quality plastics. Look for designs that offer features like a non-slip base and easy portability. A model like the BrüMate Hopsulator Bott’l, which is specifically designed for standard beer bottles, can keep drinks cold while being easy to transport, making it ideal for picnics, festivals, or sports events. -

What should I consider when vetting suppliers for cooler beer bottles?

When vetting suppliers, check their reputation through customer reviews and industry certifications. Evaluate their production capabilities, quality assurance processes, and adherence to international safety standards. Request samples to assess product quality firsthand. Additionally, ensure they can meet your desired customization options, such as branding or specific designs, and inquire about their logistics capabilities to ensure timely delivery to your location. -

What are the typical minimum order quantities (MOQ) for cooler beer bottles?

Minimum order quantities for cooler beer bottles can vary widely depending on the supplier and the type of product. Generally, MOQs range from 100 to 1,000 units for custom designs, while stock items may have lower MOQs. Always clarify with potential suppliers about their MOQ requirements and whether they offer discounts for bulk orders, which could impact your purchasing strategy and cash flow. -

How can I customize cooler beer bottles for my brand?

Customization options for cooler beer bottles often include printing your logo, selecting specific colors, or even altering the bottle shape. Discuss your ideas with the supplier during the initial consultation to explore available options. Many suppliers offer mock-up designs to visualize your branding on the product before committing to a larger order. Ensure that the supplier can accommodate your design requirements within your timeline and budget. -

What payment terms should I negotiate with my supplier?

When negotiating payment terms, consider options like a deposit followed by the balance upon delivery, which is common in B2B transactions. Some suppliers may offer trade credit, allowing you to pay after receiving the goods. Always clarify payment methods accepted (e.g., bank transfer, credit card) and ensure they align with your financial processes. Establishing favorable terms can improve cash flow and reduce financial risk. -

What quality assurance measures should I expect from my supplier?

Expect your supplier to have a robust quality assurance process in place, which may include pre-production samples, in-process inspections, and final quality checks before shipment. Request documentation of their quality control protocols and any relevant certifications, such as ISO standards. It’s also wise to inquire about their return policy and how they handle defective products to mitigate risks associated with quality issues. -

What logistics considerations are important for importing cooler beer bottles?

When importing cooler beer bottles, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner who can handle freight forwarding and customs clearance efficiently. Understand the estimated delivery times and ensure that your supplier can provide the necessary shipping documents. Additionally, factor in storage needs upon arrival, especially if you expect high inventory turnover or seasonal demand spikes.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимый и тщательный due diligence. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.

Top 8 Cooler Beer Bottle Manufacturers & Suppliers List

1. RTIC – Bottle Chiller

Домен: rticoutdoors.com

Зарегистрирован: 2016 (9 лет)

Введение: This company, RTIC – Bottle Chiller, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Beverage-Air – Bottle Coolers

Домен: beverage-air.com

Зарегистрирован: 1996 (29 лет)

Введение: Bottle Coolers include various models such as DW49HC-B, DW49HC-B-29, DW49HC-S, DW49HC-S-29, DW64HC-B, DW64HC-B-29, DW64HC-S, DW64HC-S-29, DW79HC-B, DW79HC-B-29, DW79HC-S, DW79HC-S-29, DW94HC-B, DW94HC-B-29, DW94HC-S, DW94HC-S-29, SF34HC-B, and SF34HC-S. Key features include:

– Exterior options: black painted steel or stainless steel

– Interior: galvanized steel

– Full electronic control

– Easy…

3. BrüMate – Insulated Can Coolers

Домен: brumate.com

Зарегистрирован: 2017 (8 лет)

Введение: BrüMate offers a variety of insulated can coolers designed to keep beverages cold. Key products include: 1. Hopsulator Slim – for 12oz slim cans. 2. Hopsulator Duo – for 12oz standard cans. 3. Hopsulator Bott’l – for 12oz bottles. 4. Juggernaut – for 24/25oz cans. The coolers are made from stainless steel, providing insulation and preventing condensation. They are designed for various sizes of can…

4. Bar Products – Coolers

Домен: barproducts.com

Зарегистрирован: 1997 (28 лет)

Введение: This company, Bar Products – Coolers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Avantco – Equipment Unity

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: 1. Avantco – Users appreciate the unity in equipment and suggest local sourcing for cost-effectiveness.

2. Pepsi/Coke coolers – Some users recommend the free coolers provided by these brands due to their reliability and maintenance support.

3. True – Considered the best but also the most expensive; some users have had long-lasting experiences with True products.

4. Beverage Air – Users report simi…

6. Equippers – Bottle Coolers

Домен: equippers.com

Зарегистрирован: 1999 (26 лет)

Введение: This company, Equippers – Bottle Coolers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Avantco – Bottle Coolers

Домен: avantcorefrigeration.com

Зарегистрирован: 2009 (16 лет)

Введение: This company, Avantco – Bottle Coolers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

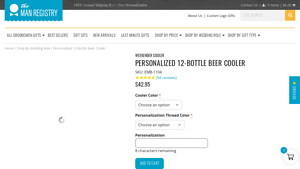

8. The Man Registry – Personalized Craft Beer Cooler

Домен: themanregistry.com

Зарегистрирован: 2004 (21 год)

Введение: Product Name: Personalized Craft Beer 12-Pack Bottle Cooler

SKU: EMB-1104

Price: $42.95

Color Options: Black, Green, Navy Blue

Personalization: Free personalization with recipient’s name or initials in 19 thread colors

Capacity: Holds up to 12 bottles or 18 cans

Dimensions: 11.5” x 7.5” x 10” H

Strap: 50” adjustable shoulder strap

Features: Padded handles, front slip pocket, attached bottle opener…

Strategic Sourcing Conclusion and Outlook for cooler beer bottle

How Can Strategic Sourcing Enhance Your Cooler Beer Bottle Procurement?

In the evolving landscape of beverage packaging, strategic sourcing plays a pivotal role in optimizing supply chain efficiencies and ensuring product quality. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of cooler beer bottle offerings—from insulated designs to commercial refrigeration solutions—can lead to significant competitive advantages.

Investing in high-quality cooler bottles not only enhances the customer experience by keeping beverages at optimal temperatures but also aligns with sustainability trends through the use of durable materials like stainless steel. Buyers should prioritize partnerships with reputable suppliers who can deliver both innovative designs and reliable service, enabling them to meet diverse market demands.

As the global market continues to expand, staying ahead of consumer preferences and sustainability initiatives will be crucial. We encourage international buyers to leverage strategic sourcing to explore new product developments and supplier relationships. Together, let’s raise the bar on beverage enjoyment and ensure that every sip is as refreshing as the first.