Introduction: Navigating the Global Market for can you wash bottles in dishwasher

In today’s fast-paced global market, the question of whether you can wash bottles in a dishwasher has become increasingly pertinent for businesses involved in the manufacturing and distribution of consumer goods. For international B2B buyers, particularly those sourcing products from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of dishwasher safety and cleaning efficiency is crucial. This comprehensive guide delves into the various types of bottles, their dishwasher compatibility, and the best practices for ensuring thorough sanitation, all while considering the unique needs of diverse markets.

This guide will cover essential aspects such as identifying dishwasher-safe materials, the importance of proper disassembly, and the selection of suitable detergents. Additionally, we will explore supplier vetting processes, cost implications, and how to navigate regional regulations that may affect bottle cleaning practices. By empowering buyers with actionable insights and industry best practices, this guide facilitates informed purchasing decisions, helping businesses ensure product quality and safety in a competitive landscape. Whether you’re a distributor in Saudi Arabia or a manufacturer in Vietnam, this resource is designed to enhance your understanding and streamline your operations, ultimately leading to better customer satisfaction and brand loyalty.

Навигация по статье

- Top 6 Can You Wash Bottles In Dishwasher Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for can you wash bottles in dishwasher

- Understanding can you wash bottles in dishwasher Types and Variations

- Key Industrial Applications of can you wash bottles in dishwasher

- 3 Common User Pain Points for ‘can you wash bottles in dishwasher’ & Their Solutions

- Strategic Material Selection Guide for can you wash bottles in dishwasher

- In-depth Look: Manufacturing Processes and Quality Assurance for can you wash bottles in dishwasher

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you wash bottles in dishwasher’

- Comprehensive Cost and Pricing Analysis for can you wash bottles in dishwasher Sourcing

- Alternatives Analysis: Comparing can you wash bottles in dishwasher With Other Solutions

- Essential Technical Properties and Trade Terminology for can you wash bottles in dishwasher

- Navigating Market Dynamics and Sourcing Trends in the can you wash bottles in dishwasher Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of can you wash bottles in dishwasher

- Важный отказ от ответственности и условия использования

- Strategic Sourcing Conclusion and Outlook for can you wash bottles in dishwasher

Understanding can you wash bottles in dishwasher Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Baby Bottles | Typically made from plastic or glass; often have small parts like nipples and caps. | Baby product manufacturers and retailers | Плюсы: Convenient cleaning; Конс: Must ensure all components are dishwasher safe. |

| Reusable Water Bottles | Available in various materials (stainless steel, plastic); often designed for durability. | Outdoor and fitness brands | Плюсы: Eco-friendly; Конс: Some materials may warp or degrade. |

| Medical Bottles | Designed for sterile environments; often made of specialized plastics. | Healthcare and pharmaceutical sectors | Плюсы: Ensures cleanliness; Конс: High temperatures may damage some materials. |

| Food Storage Containers | Made from glass or BPA-free plastics; often stackable and modular. | Food service and catering businesses | Плюсы: Helps maintain hygiene; Конс: Not all are dishwasher safe. |

| Infant Feeding Bottles | Similar to baby bottles but often come with specialized designs for feeding. | Pediatric health suppliers | Плюсы: Essential for sanitization; Конс: Requires careful handling to prevent damage. |

What Are the Key Characteristics of Baby Bottles Suitable for Dishwasher Cleaning?

Baby bottles are primarily constructed from materials like BPA-free plastic or glass, designed to withstand repeated cleaning cycles. They often feature small components such as nipples and caps that require disassembly before washing. For B2B buyers, understanding the dishwasher safety of these products is crucial, as not all baby bottles are created equal. Retailers and manufacturers must ensure they provide clear guidelines for consumers about which products are dishwasher safe to avoid customer dissatisfaction and potential returns.

How Do Reusable Water Bottles Vary in Dishwasher Compatibility?

Reusable water bottles come in various materials, including stainless steel, plastic, and silicone. The dishwasher compatibility largely depends on the specific material used. For B2B applications, companies in the outdoor and fitness sectors should prioritize sourcing bottles that are both durable and dishwasher safe, as this enhances customer satisfaction and brand loyalty. It’s essential to educate consumers about proper cleaning practices to extend the lifespan of these products.

What Should Healthcare Suppliers Consider When Using Medical Bottles in Dishwashers?

Medical bottles are often made from specialized plastics that can withstand high temperatures, ensuring sterility. However, B2B buyers in the healthcare and pharmaceutical sectors must be cautious, as not all medical-grade materials are dishwasher safe. They should opt for products that clearly state compatibility with dishwashers, ensuring they maintain hygiene standards without compromising the integrity of the bottles. This knowledge is vital for compliance with health regulations.

Why Are Food Storage Containers Important for Catering Businesses?

Food storage containers are designed for both durability and hygiene, often made from glass or BPA-free plastic. In the food service and catering industries, these containers must be easy to clean to prevent cross-contamination. B2B buyers should focus on sourcing containers that are explicitly labeled as dishwasher safe, as this will streamline operations and enhance food safety protocols. Understanding the limitations of certain materials is also crucial for maintaining product longevity.

How Do Infant Feeding Bottles Differ from Standard Baby Bottles?

Infant feeding bottles are similar to standard baby bottles but often include specialized features that cater to newborn needs. These bottles are typically designed for easy cleaning and may include additional components like anti-colic valves. For B2B buyers in pediatric health supply, it’s essential to ensure that these bottles can withstand dishwasher cleaning without degrading. Providing clear usage instructions can help avoid misuse and enhance the customer experience.

Key Industrial Applications of can you wash bottles in dishwasher

| Промышленность/сектор | Specific Application of can you wash bottles in dishwasher | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Еда и напитки | Sanitizing beverage bottles for production | Ensures hygiene compliance and extends product shelf life | Compatibility with high-temperature washing; material durability |

| Healthcare | Cleaning medical bottles and containers | Maintains sterile conditions, reducing infection risks | Regulatory compliance; materials that withstand repeated cycles |

| Childcare and Parenting | Washing baby bottles and feeding accessories | Saves time and labor, ensuring safe feeding practices | Safety certifications; compatibility with baby-friendly detergents |

| Cosmetics and Personal Care | Cleaning product containers and applicators | Enhances product integrity and consumer safety | Material compatibility with cleaning agents; eco-friendly options |

| Industrial Manufacturing | Cleaning reusable containers and tools | Reduces contamination risks and improves operational efficiency | Robustness of materials; ability to withstand harsh detergents |

How Does the Food and Beverage Industry Utilize Dishwasher-Safe Bottle Washing?

In the food and beverage sector, the ability to wash bottles in dishwashers is critical for maintaining hygiene standards. Production facilities often use high-temperature dishwashers to sanitize beverage bottles, ensuring they are free from contaminants before filling. This process not only complies with health regulations but also extends the shelf life of products by preventing microbial growth. B2B buyers must consider the compatibility of their bottles with dishwashing processes, focusing on materials that can withstand high temperatures without warping or degrading.

What Role Does Dishwasher-Safe Bottle Washing Play in Healthcare?

In healthcare settings, the cleaning of medical bottles and containers is paramount. Dishwashers are employed to maintain sterile conditions, which is essential for patient safety and infection control. The use of dishwashers allows for efficient cleaning, reducing labor costs and ensuring thorough sanitization. Buyers in this sector should prioritize equipment that meets regulatory standards and materials that can endure repeated high-temperature washing cycles, ensuring longevity and safety in their applications.

How Do Childcare Facilities Benefit from Dishwasher-Safe Bottle Washing?

Childcare facilities benefit significantly from the convenience of washing baby bottles and feeding accessories in dishwashers. This method saves time for busy caregivers while ensuring that feeding equipment is sanitized properly. The focus on safety is paramount, as any leftover residues can pose health risks to infants. Buyers should look for dishwasher-safe products that carry safety certifications and are compatible with mild detergents designed for children’s items, ensuring a safe feeding environment.

Why is Dishwasher Cleaning Important in Cosmetics and Personal Care?

In the cosmetics and personal care industry, the cleaning of product containers and applicators is vital for maintaining product integrity and consumer safety. Dishwashers provide an effective means to sanitize these items, preventing contamination that could affect product quality. B2B buyers must ensure that their containers are made from materials compatible with dishwasher cleaning and that they can withstand various detergents, including eco-friendly options, to align with consumer preferences for sustainability.

How Does Industrial Manufacturing Leverage Dishwasher-Safe Bottle Washing?

Industrial manufacturing relies on the ability to clean reusable containers and tools efficiently. The use of dishwashers in this context reduces contamination risks associated with product handling, thereby enhancing operational efficiency. Buyers in this sector should focus on sourcing robust materials capable of withstanding harsh detergents and high-temperature washing cycles. This consideration is crucial for maintaining the integrity of both the containers and the manufacturing process.

3 Common User Pain Points for ‘can you wash bottles in dishwasher’ & Their Solutions

Scenario 1: Ensuring Dishwasher Compatibility of Bottles

Проблема: One of the primary concerns for B2B buyers, especially those in manufacturing or retailing baby products, is the compatibility of bottles with dishwashers. Many businesses face challenges when their customers unknowingly purchase bottles that cannot withstand the high temperatures and harsh detergents used in dishwashers. This can lead to product damage, customer dissatisfaction, and increased return rates. Additionally, the lack of clear labeling on products regarding dishwasher safety can complicate purchasing decisions and lead to compliance issues with safety standards.

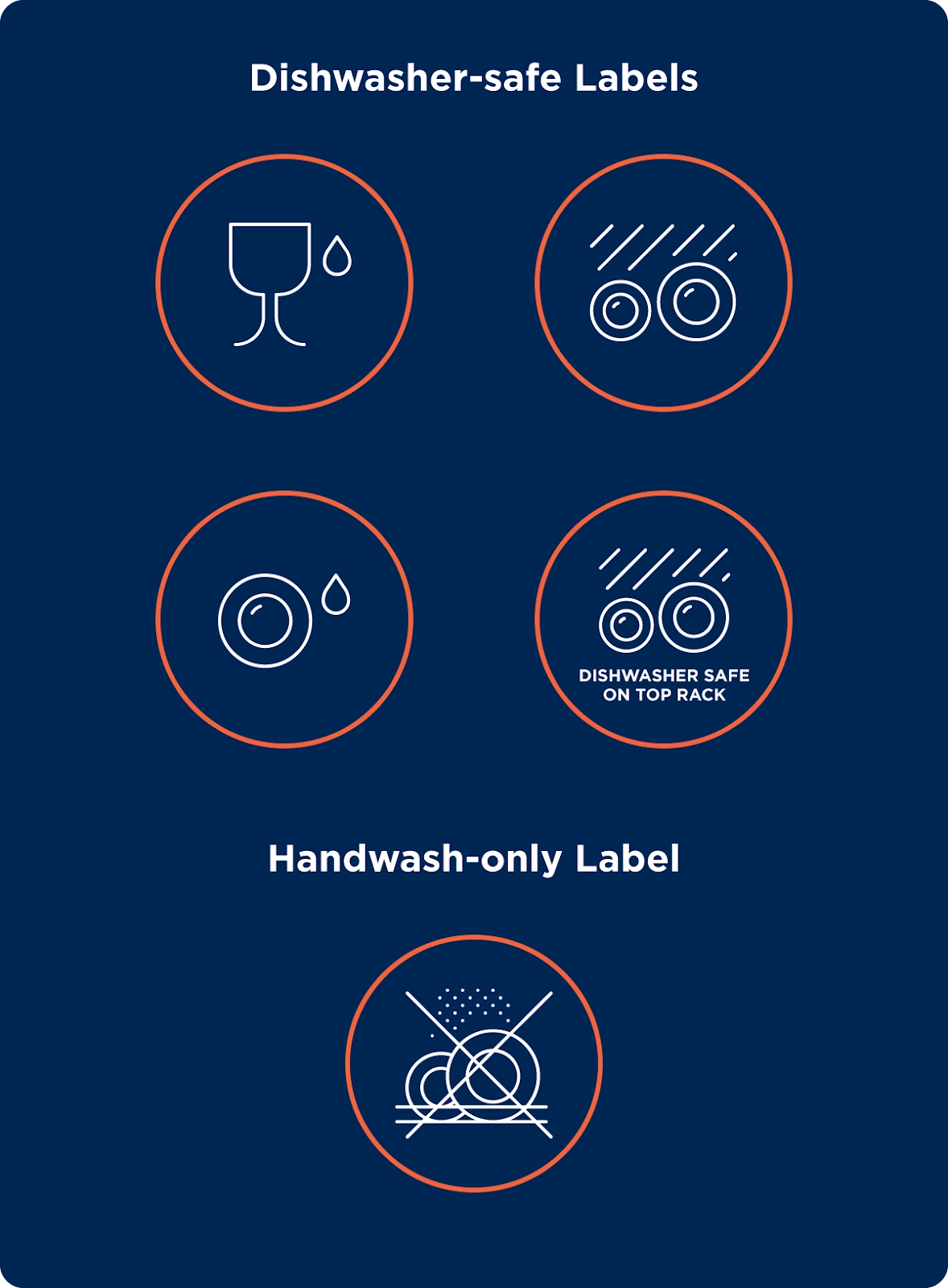

Решение: To mitigate these challenges, B2B buyers should prioritize sourcing bottles that are explicitly labeled as “dishwasher safe.” This includes ensuring that the manufacturing process incorporates materials that can withstand high temperatures without warping or degrading. Buyers should also collaborate with suppliers to provide clear and accessible information on the dishwasher safety of their products. Implementing a quality assurance process that includes testing products in dishwashers can also help confirm their durability. By providing comprehensive guidelines for consumers, including symbols indicating dishwasher compatibility and detailed care instructions, businesses can enhance customer satisfaction and reduce product returns.

Scenario 2: Effective Cleaning and Sanitization of Bottles

Проблема: In the fast-paced world of B2B transactions, particularly in the baby products sector, ensuring the effective cleaning and sanitization of bottles can be a significant pain point. Companies may struggle with the challenge of educating their customers about the proper cleaning techniques to maximize hygiene and safety. There is also the risk of bacteria growth if bottles are not cleaned thoroughly, which can lead to health concerns and liability issues for businesses. This situation is exacerbated by the diversity of bottle designs and materials, which may require different cleaning approaches.

Решение: To address this issue, B2B buyers should invest in partnerships with educational content providers to create informative resources about the proper cleaning and sanitization of bottles in dishwashers. These resources could include detailed guides on pre-rinsing, disassembly of components, and appropriate placement in the dishwasher. Additionally, businesses should offer training sessions or workshops for retailers, equipping them with the knowledge to better inform customers. By highlighting the importance of using gentle, baby-safe detergents and recommending specific dishwasher settings, companies can foster trust and loyalty among their customers while ensuring a higher standard of hygiene.

Scenario 3: Addressing Concerns About Residue and Cleaning Efficacy

Проблема: Another common pain point for B2B buyers is the concern over residue left on bottles after washing them in a dishwasher. This issue is particularly relevant for businesses that deal in high-quality baby products, where the presence of residues can pose health risks and lead to negative consumer reviews. The variability in water hardness and detergent effectiveness can affect the cleaning process, resulting in cloudy or poorly cleaned bottles. This not only undermines customer confidence but can also lead to increased customer service inquiries and complaints.

Решение: B2B buyers can proactively tackle this issue by selecting high-quality detergents that are specifically formulated for baby items and known to perform well in various water conditions. Partnering with detergent manufacturers to offer bundled products can also enhance customer experience. Additionally, businesses should create educational materials that advise customers on how to check for residual cleaning agents and what to do if they encounter issues. Encouraging customers to run a rinse cycle before the actual wash can also help minimize residue. By addressing these concerns through well-informed product choices and customer education, companies can enhance product satisfaction and loyalty.

Strategic Material Selection Guide for can you wash bottles in dishwasher

What Materials Are Commonly Used for Bottles That Can Be Washed in Dishwashers?

When selecting materials for bottles intended for dishwasher use, it’s essential to consider their properties, advantages, disadvantages, and compliance with international standards. Below are analyses of four common materials used for manufacturing bottles that are dishwasher safe.

1. Polypropylene (PP)

Ключевые свойства:

Polypropylene is known for its high melting point (around 160°C) and excellent chemical resistance. It is lightweight and has a low moisture absorption rate, making it suitable for repeated use in dishwashers.

Плюсы и минусы:

Pros include its durability and resistance to fatigue, which makes it ideal for long-term use. Additionally, it is relatively inexpensive, making it a cost-effective choice for manufacturers. However, it can become brittle over time, especially when exposed to UV light, which may limit its lifespan.

Влияние на применение:

Polypropylene is compatible with a wide range of media, including water and various food substances, making it suitable for baby bottles and other food containers.

International Considerations:

For buyers in regions like Africa and South America, ensuring compliance with local food safety standards is crucial. Standards such as ASTM F963 or EU regulations on food contact materials should be considered.

2. Polyethylene Terephthalate (PET)

Ключевые свойства:

PET has a high resistance to impact and is stable at high temperatures, making it suitable for dishwasher use. It has a melting point of around 250°C and is known for its clarity and strength.

Плюсы и минусы:

The primary advantage of PET is its excellent barrier properties against moisture and gases, which helps in preserving the contents. However, it is more expensive than polypropylene and may not be as durable under repeated dishwasher cycles, leading to potential wear over time.

Влияние на применение:

PET is commonly used for beverage bottles and food containers, making it suitable for applications where clarity and safety are paramount.

International Considerations:

B2B buyers should verify compliance with international standards such as FDA regulations in the U.S. and similar standards in Europe and the Middle East. The recyclability of PET is also an important consideration in sustainability-focused markets.

3. Tritan™ Copolyester

Ключевые свойства:

Tritan™ is a BPA-free copolyester known for its high clarity and toughness. It has a high heat resistance (up to 100°C) and does not retain odors or flavors.

Плюсы и минусы:

The main advantage of Tritan™ is its durability and resistance to shattering, making it an excellent choice for children’s products. However, it is generally more expensive than other plastics, which may affect pricing strategies for manufacturers.

Влияние на применение:

Tritan™ is suitable for a variety of applications, including baby bottles and sports bottles, due to its safe and robust nature.

International Considerations:

Buyers should ensure compliance with regulations such as those set by the European Food Safety Authority (EFSA) and the U.S. FDA. Tritan™ is often marketed as a safer alternative to traditional plastics, which can be a selling point in regions with heightened health concerns.

4. Stainless Steel

Ключевые свойства:

Stainless steel is highly durable and resistant to corrosion, withstanding high temperatures without degrading. It is non-reactive, making it ideal for food and beverage containers.

Плюсы и минусы:

The key advantage of stainless steel is its longevity and resistance to wear and tear. However, it is heavier than plastic alternatives and typically comes at a higher cost, which may deter some buyers.

Влияние на применение:

Stainless steel is ideal for insulated bottles and containers that require temperature retention, making it suitable for both hot and cold beverages.

International Considerations:

For international buyers, compliance with standards such as ISO 22000 for food safety management systems is vital. Additionally, the preference for sustainable materials may drive demand for stainless steel in markets focused on reducing plastic use.

Summary Table

| Материал | Typical Use Case for can you wash bottles in dishwasher | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Polypropylene (PP) | Baby bottles, food containers | Durable and cost-effective | Can become brittle over time | Низкий |

| Полиэтилентерефталат (ПЭТ) | Beverage bottles, food containers | Excellent moisture barrier | More expensive, less durable | Мед |

| Tritan™ Copolyester | Baby bottles, sports bottles | BPA-free, shatter-resistant | Higher cost | Высокий |

| Нержавеющая сталь | Insulated bottles, food containers | Long-lasting and corrosion-resistant | Heavier and more expensive | Высокий |

This strategic material selection guide provides B2B buyers with essential insights into the materials commonly used for bottles that can be washed in dishwashers, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for can you wash bottles in dishwasher

What Are the Key Stages in the Manufacturing Process of Dishwasher-Safe Bottles?

Understanding the manufacturing process of bottles designed to withstand dishwasher cleaning is crucial for B2B buyers. The typical process includes several main stages: material preparation, forming, assembly, and finishing.

-

Подготовка материалов

The first step involves selecting suitable materials that are both durable and dishwasher-safe. Common materials include BPA-free plastics, silicone, and glass. Each material undergoes rigorous testing to ensure it can endure high temperatures and strong detergents without degrading. Manufacturers often source these materials from certified suppliers who adhere to international safety standards. -

Формирование

In this stage, the prepared materials are shaped into bottle forms using various techniques such as injection molding, blow molding, or extrusion. Injection molding is commonly used for plastic bottles, as it allows for precise shapes and minimizes material waste. For glass bottles, blow molding is prevalent, ensuring uniform thickness and strength. During forming, quality assurance measures are implemented to check for defects, such as air bubbles or inconsistencies in thickness. -

Сборка

After forming, components such as caps, straws, and valves are assembled. This process may be automated or manual, depending on the complexity of the design. Quality checks at this stage focus on ensuring that all parts fit securely and function as intended, preventing leaks or malfunctions during use. -

Отделка

The final stage involves surface treatments and coatings that enhance the durability and aesthetic appeal of the bottles. This may include applying a non-slip grip, color finishes, or UV coatings to protect against sun exposure. Manufacturers conduct final inspections to ensure that the finishing process has not compromised the bottle’s integrity or dishwasher safety.

What Quality Assurance Standards Are Relevant for Dishwasher-Safe Bottles?

Quality assurance is paramount in the manufacturing of dishwasher-safe bottles, particularly for international B2B buyers. Key standards include:

-

ISO 9001

This internationally recognized standard sets criteria for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer consistently provides products that meet customer and regulatory requirements. Buyers should verify a supplier’s ISO certification to ensure reliability. -

CE Marking

For products sold within the European Economic Area, CE marking demonstrates compliance with safety, health, and environmental protection standards. Bottles that carry the CE mark have undergone rigorous testing and certification, making them more appealing to buyers in Europe. -

API Standards

The American Petroleum Institute (API) provides standards that may apply to specific materials used in bottle manufacturing, particularly those made from polymers. Compliance with API standards ensures that the materials used are safe and reliable.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated into every stage of the manufacturing process. Here are the primary checkpoints:

-

Входящий контроль качества (IQC)

This involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide certificates of analysis (CoA) to confirm that materials meet specified standards. IQC aims to prevent defective materials from entering the production process. -

Внутрипроцессный контроль качества (IPQC)

During the manufacturing process, regular inspections occur to monitor production parameters and product quality. Techniques such as statistical process control (SPC) are utilized to detect variations that could indicate potential issues. -

Окончательный контроль качества (ОКК)

After the manufacturing process, FQC ensures that the finished products meet all specified requirements. This includes visual inspections, dimensional checks, and functionality tests. Products that pass FQC are prepared for shipping, while those that fail are either reworked or discarded.

Как покупатели B2B могут проверять контроль качества поставщиков?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are actionable steps:

-

Conduct Supplier Audits

Regular audits of suppliers can help assess their manufacturing processes and QC measures. Buyers should prepare a checklist based on international standards and specific industry requirements to guide their evaluations. -

Request Quality Reports

Buyers should request detailed quality reports that outline the QC measures implemented throughout the manufacturing process. These reports should include information on the frequency of inspections, testing methods used, and the results of any quality assessments. -

Проверки третьих сторон

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control. These agencies often conduct comprehensive audits and testing to ensure compliance with relevant standards.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC and certification:

-

Regional Standards

Different regions may have varying regulatory requirements for dishwasher-safe products. Buyers should familiarize themselves with local regulations that may affect product compliance, such as food safety standards or environmental regulations. -

Import Regulations

When sourcing products internationally, it is essential to understand import regulations that may require specific certifications or testing before products can enter the market. Non-compliance can lead to delays or additional costs. -

Культурные соображения

Understanding cultural preferences and expectations regarding product safety and quality can influence purchasing decisions. Buyers should consider conducting market research to better align with local standards and consumer expectations.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing dishwasher-safe bottles. Prioritizing quality and compliance not only enhances product reliability but also builds trust with end-users in various global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you wash bottles in dishwasher’

Введение

This guide serves as a practical checklist for B2B buyers interested in sourcing bottles that are suitable for washing in dishwashers. Understanding the compatibility of bottles with dishwasher cleaning processes is essential for ensuring hygiene and longevity, particularly for markets in Africa, South America, the Middle East, and Europe. This checklist outlines the critical steps to take when evaluating and procuring these products.

Шаг 1: Assess Material Compatibility

Before sourcing bottles, confirm that the materials used are dishwasher safe. Look for labels indicating “dishwasher safe” or relevant symbols on the product. Materials like BPA-free plastic, glass, and stainless steel typically withstand dishwasher conditions, while others may warp or degrade.

- Tip: Consult the manufacturer’s specifications to ensure the material can endure high temperatures and detergent exposure.

Шаг 2: Evaluate Design Features

Focus on the design of the bottles, ensuring they can be easily disassembled for thorough cleaning. Features such as removable caps, valves, and straws enhance cleaning efficiency and hygiene.

- Tip: Bottles with fewer nooks and crannies are generally easier to clean, so prioritize straightforward designs.

Шаг 3: Проверьте сертификаты поставщиков

Ensure that potential suppliers hold relevant certifications, such as ISO or FDA approvals, indicating compliance with safety and quality standards. This verification is crucial for maintaining product integrity, especially for items intended for children or sensitive environments.

- Tip: Request documentation proving compliance with international standards, particularly if you are importing products across borders.

Шаг 4: Review Cleaning Recommendations

Investigate the recommended cleaning processes for the bottles, including ideal dishwasher settings and compatible detergents. Clear guidelines from the manufacturer can prevent misuse and ensure the longevity of the bottles.

- Tip: Look for suppliers who provide comprehensive cleaning instructions alongside their products, as this can enhance customer satisfaction and reduce returns.

Шаг 5: Check for Product Warranties

Inquire about warranties or guarantees related to the bottles’ performance in dishwashers. A solid warranty can provide peace of mind and assurance that the supplier stands behind the quality of their products.

- Tip: Understand the terms of the warranty, including coverage specifics for dishwasher-related damage.

Шаг 6: Conduct a Cost-Benefit Analysis

Analyze the cost implications of sourcing dishwasher-safe bottles versus their long-term benefits. Consider factors such as durability, ease of cleaning, and potential health compliance costs.

- Tip: Compare multiple suppliers to identify the best value for money while ensuring quality standards are met.

Шаг 7: Request Samples for Testing

Before finalizing your order, request samples to evaluate how the bottles perform in real-world dishwasher conditions. Testing for durability, cleaning efficiency, and overall functionality will help confirm that the products meet your requirements.

- Tip: Engage in a trial run with your specific dishwasher settings to ensure compatibility and effectiveness.

By following this checklist, B2B buyers can make informed decisions when sourcing dishwasher-safe bottles, ensuring they meet both operational needs and market expectations.

Comprehensive Cost and Pricing Analysis for can you wash bottles in dishwasher Sourcing

What Are the Key Cost Components for Sourcing Dishwasher-Safe Baby Bottles?

When analyzing the costs associated with sourcing bottles that can be washed in dishwashers, several key components come into play. The materials used in the production of these bottles significantly affect the overall cost. High-quality, dishwasher-safe plastics or glass may command a higher price, but they offer durability and safety, appealing to health-conscious consumers. Labor costs also vary by region; countries with lower labor costs may provide more competitive pricing, while those with higher wages may require negotiation to maintain profitability.

Manufacturing overhead includes expenses like energy consumption, factory rent, and equipment maintenance. It’s essential to consider these factors, especially in regions with fluctuating energy prices. Tooling costs for specialized molds to create unique bottle designs can be substantial, particularly for custom or branded products. Moreover, quality control (QC) processes are crucial for ensuring that the bottles meet safety standards. This may involve additional testing and inspection, contributing to higher costs.

Логистика also play a vital role in the cost structure. Transporting bottles from manufacturers to international markets involves freight charges, customs duties, and potential tariffs, which can vary significantly based on the Incoterms agreed upon during the transaction. Lastly, a reasonable margin must be added to ensure profitability for both suppliers and distributors.

How Do Price Influencers Impact the Sourcing of Dishwasher-Safe Bottles?

Several factors influence the pricing of dishwasher-safe baby bottles. Volume or Minimum Order Quantity (MOQ) is a significant determinant; larger orders typically lead to lower per-unit costs. Suppliers are often willing to offer discounts for bulk purchases, making it essential for buyers to assess their needs accurately.

Specifications and customization can also drive costs. Unique designs or features—such as BPA-free materials or ergonomic shapes—may increase the base price. Buyers should consider whether these features align with their target market’s demands and willingness to pay.

Сайт quality and certifications of the materials used are crucial for market acceptance, especially in regions with strict health regulations. Products that come with relevant certifications (e.g., FDA-approved, BPA-free) can command higher prices due to increased consumer trust.

Supplier factors play a role as well. Established suppliers with a proven track record may charge a premium for their reliability and quality assurance. Conversely, newer suppliers might offer lower prices to gain market entry, but buyers should weigh this against potential risks.

What Are the Best Buyer Tips for Negotiating Prices in the International Market?

When negotiating prices for dishwasher-safe bottles, international buyers should focus on cost-efficiency by evaluating the Total Cost of Ownership (TCO). This includes not only the purchase price but also shipping, handling, and potential warehousing costs. Understanding the complete cost structure allows buyers to make more informed decisions.

Buyers should also be mindful of pricing nuances in international markets. For instance, cultural perceptions regarding quality and safety may influence pricing strategies in regions like Africa or the Middle East. Tailoring negotiations to local preferences can yield better outcomes.

Establishing a good relationship with suppliers can lead to favorable terms and pricing. Regular communication and transparency about volume forecasts can incentivize suppliers to offer better pricing structures. Additionally, leveraging Инкотермс effectively can help in negotiating shipping costs and responsibilities, further enhancing overall cost management.

Оговорка об ориентировочных ценах

Pricing for dishwasher-safe baby bottles can vary widely based on the factors outlined above. Buyers are encouraged to conduct thorough market research and consult multiple suppliers to obtain accurate pricing tailored to their specific needs and regional considerations.

Alternatives Analysis: Comparing can you wash bottles in dishwasher With Other Solutions

Introduction to Alternative Cleaning Methods for Bottles

In the realm of bottle cleaning, particularly for baby bottles and water bottles, the dishwasher presents a popular solution for busy parents and professionals. However, several alternative methods exist, each with its own advantages and limitations. Understanding these alternatives is crucial for B2B buyers looking to optimize their cleaning processes, whether for manufacturing, distribution, or retail purposes. This analysis will compare the effectiveness of washing bottles in a dishwasher against handwashing and using specialized bottle sterilizers.

Сравнительная таблица

| Сравнительный аспект | Can You Wash Bottles In Dishwasher | Handwashing | Specialized Bottle Sterilizers |

|---|---|---|---|

| Производительность | High, but depends on the model and detergent used | Moderate, can be thorough if done correctly | Very high, effective sterilization |

| Стоимость | Moderate (initial investment in dishwasher, ongoing detergent costs) | Low (minimal costs for soap and water) | High (upfront cost of sterilizer) |

| Простота реализации | Easy, requires loading and selecting a cycle | Time-consuming, requires manual effort | Easy, just load and run the cycle |

| Техническое обслуживание | Moderate (regular cleaning of dishwasher needed) | Low (no maintenance, just washing) | Moderate (requires regular cleaning and upkeep) |

| Лучший пример использования | High-volume cleaning, convenience for busy users | Small batch cleaning, items that are not dishwasher safe | Sterilizing bottles for infants or immunocompromised individuals |

Подробный анализ альтернатив

Handwashing: What Are Its Pros and Cons?

Handwashing is a straightforward method that involves using warm, soapy water and a brush to clean bottles. The primary advantage is the low cost; it requires minimal investment in supplies, making it accessible to all. Additionally, handwashing allows for meticulous cleaning, ensuring that every nook and cranny is addressed. However, this method can be time-consuming and labor-intensive, particularly for businesses with high volumes of bottles to clean. Inconsistent cleaning quality can also arise if proper techniques are not followed.

Specialized Bottle Sterilizers: How Do They Compare?

Specialized bottle sterilizers are designed to provide thorough cleaning and sanitization, often using steam or UV light. They excel in performance, ensuring that bacteria and harmful pathogens are eradicated, making them ideal for infant care and sensitive uses. The ease of use is another significant advantage; users simply load the bottles and initiate the cycle. However, the initial investment can be high, and ongoing maintenance is required to keep these devices functioning effectively. For businesses, the cost may be justified in environments where hygiene is paramount.

Conclusion: How to Choose the Right Bottle Cleaning Solution?

Selecting the appropriate bottle cleaning method hinges on specific business needs and operational demands. For high-volume environments where convenience is essential, using a dishwasher can streamline processes and save time. Handwashing may be suitable for smaller operations or where cost is a concern, but it requires more labor. Meanwhile, specialized sterilizers are best for settings that require stringent hygiene standards, such as hospitals or nurseries. B2B buyers should assess their volume, budget, and hygiene requirements to determine the most effective solution for their needs.

Essential Technical Properties and Trade Terminology for can you wash bottles in dishwasher

What Are the Key Technical Properties to Consider When Washing Bottles in a Dishwasher?

When assessing the compatibility of bottles for dishwasher cleaning, several critical technical properties must be evaluated. These specifications ensure that the bottles maintain their integrity and functionality post-cleaning.

-

Класс материала

– The material from which a bottle is made significantly influences its dishwasher safety. Common materials include polycarbonate, polypropylene, and glass. For instance, polycarbonate is durable but may warp under high temperatures, while glass can withstand higher heat but is prone to breakage. Understanding material grades helps B2B buyers select products that can endure the rigors of dishwasher cleaning without compromising quality. -

Heat Resistance

– Bottles must be rated for high-temperature cleaning cycles, often reaching 65.6°C (150°F) or higher. Heat resistance is crucial for sanitizing bottles effectively. Buyers should look for products with clear specifications on heat tolerance to avoid purchasing items that may deform or degrade during the washing process. -

Dishwasher Compatibility

– Manufacturers often include dishwasher-safe labels or symbols that indicate compatibility. This property is vital for ensuring that the cleaning process does not damage the bottle. Buyers should prioritize products with explicit dishwasher-safe certifications to guarantee ease of cleaning and maintenance. -

Chemical Resistance

– The ability of a bottle to withstand various detergents and cleaning agents is essential. Some materials may react negatively with certain chemicals, leading to degradation or leaching of harmful substances. Understanding chemical resistance helps buyers select safe, long-lasting products that are suitable for repeated washing. -

Sealing Mechanism Integrity

– Bottles equipped with sealing mechanisms (e.g., lids with valves) should maintain their effectiveness after dishwasher cleaning. Ensuring that seals remain intact and functional is crucial for preventing leaks and maintaining hygiene. Buyers must assess the design and materials of seals to ensure they can withstand repeated exposure to hot water and detergents.

What Trade Terminology Should B2B Buyers Understand Regarding Dishwasher-Safe Bottles?

Understanding industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms relevant to the discussion of dishwasher-safe bottles.

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce products or components that are sold under another company’s brand name. B2B buyers should recognize OEM products for their reliability and adherence to specific quality standards, particularly regarding dishwasher safety. -

MOQ (минимальное количество заказа)

– MOQ represents the smallest quantity of products that a supplier is willing to sell. For buyers, understanding MOQ is crucial for budgeting and inventory management, especially when sourcing dishwasher-safe bottles in bulk. -

RFQ (запрос котировок)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process helps B2B buyers compare costs and ensure they obtain competitive pricing on dishwasher-safe bottles. -

Инкотермс (международные коммерческие термины)

– These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, insurance, and cost allocation, particularly when importing dishwasher-safe bottles from various regions. -

FDA Approval

– For products intended for food and beverage use, FDA approval indicates compliance with safety standards. B2B buyers should seek dishwasher-safe bottles that are FDA-approved to ensure they meet health and safety regulations.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing dishwasher-safe bottles, ensuring they select high-quality products that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the can you wash bottles in dishwasher Sector

What are the Global Drivers Influencing the Market for Washing Bottles in Dishwashers?

The demand for dishwasher-safe bottles is being driven by several global factors, including the increasing pace of urbanization and changing lifestyles. As more consumers, particularly busy parents and professionals, seek convenience and efficiency, the appeal of products that simplify cleaning routines grows. Additionally, technological advancements in dishwasher design, which now offer specialized cycles for cleaning baby bottles and other delicate items, are enhancing market growth. This presents a significant opportunity for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, where the adoption of modern kitchen appliances is on the rise.

Emerging trends such as smart dishwashing technology, which utilizes IoT for optimized cleaning cycles, are also reshaping the market landscape. Buyers should be aware of these innovations as they can influence product sourcing decisions. Moreover, sustainability is becoming a critical factor, with consumers increasingly opting for products that are not only functional but also environmentally friendly. This trend is prompting manufacturers to innovate in materials and design, thus creating a competitive edge for B2B buyers who prioritize sourcing from forward-thinking suppliers.

How is Sustainability and Ethical Sourcing Shaping the Bottle Washing Market?

Sustainability is no longer just a buzzword; it is a core component of product development and sourcing strategies. In the context of dishwasher-safe bottles, buyers are increasingly scrutinizing the environmental impact of materials used in manufacturing. Bottles made from recycled plastics or biodegradable materials are gaining traction, as they align with the growing consumer preference for eco-friendly products.

Ethical sourcing practices are also becoming paramount. Buyers should look for suppliers who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and labor practices are fair. Certifications such as ISO 14001 (Environmental Management) and materials labeled as BPA-free or recyclable can serve as indicators of a supplier’s commitment to sustainability. By prioritizing these factors, B2B buyers can not only meet regulatory requirements but also cater to a market segment that values social responsibility.

What is the Historical Context of Dishwasher-Safe Bottle Development?

The evolution of dishwasher-safe bottles has been closely tied to advancements in both material science and consumer behavior. Initially, many baby and water bottles were made from glass or less durable plastics that could not withstand the high temperatures of dishwashers. However, with the introduction of high-quality, heat-resistant plastics in the late 20th century, manufacturers began to produce bottles designed specifically for dishwasher use.

Over the past two decades, as awareness of hygiene and convenience has increased, the demand for dishwasher-safe options has surged. This shift has been particularly pronounced in urban areas where busy lifestyles make time-saving products essential. As a result, manufacturers have responded by innovating designs that not only ensure safety during washing but also enhance user experience through features such as easy disassembly and robust labeling on dishwasher compatibility. Understanding this historical context can help B2B buyers make informed decisions when sourcing products that meet current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of can you wash bottles in dishwasher

-

How do I determine if my bottles are dishwasher safe?

To ascertain if your bottles are dishwasher safe, always refer to the manufacturer’s guidelines. Look for specific labels or symbols indicating compatibility, such as a square with a glass and water droplets. If no clear instructions are available, it is advisable to opt for handwashing to avoid damage. Additionally, understanding the materials used in the bottles can help; for example, certain plastics may warp under high temperatures. Always err on the side of caution to maintain product integrity. -

What is the best cleaning method for baby bottles in a dishwasher?

The optimal cleaning method involves several steps. First, rinse the bottles with warm water to eliminate any residual formula or milk. Then, disassemble all components, including caps and nipples, and secure smaller parts in a mesh bag or basket to prevent loss. Place the bottles face down on the top rack and select a sanitizing cycle if available. This approach ensures thorough cleaning while protecting the bottles from potential damage due to heat exposure at the bottom of the dishwasher. -

What should I consider when sourcing bottles for international markets?

When sourcing bottles for international markets, consider factors such as compliance with local regulations, cultural preferences, and environmental standards. Research the materials used to ensure they meet safety and quality standards specific to each region, such as BPA-free plastics. Additionally, evaluate potential suppliers based on their certifications, production capabilities, and previous export experience. Understanding local market demands will also guide your product customization and marketing strategies. -

How can I vet suppliers for dishwasher-safe bottles?

To effectively vet suppliers, start by assessing their certifications and compliance with international safety standards. Request samples of their products and conduct quality assurance tests to ensure they meet your specifications. Look for reviews or testimonials from other businesses that have worked with the supplier. Additionally, consider their production capacity, lead times, and ability to provide customization options, as these factors will impact your supply chain efficiency. -

What are the typical minimum order quantities (MOQ) for bottle manufacturers?

Minimum order quantities vary widely among manufacturers, often ranging from 1,000 to 10,000 units, depending on the supplier’s capacity and the complexity of the product. Some suppliers may offer lower MOQs for custom designs or smaller businesses to foster partnerships. When negotiating MOQs, be clear about your requirements and explore potential flexibility based on your long-term partnership plans. Establishing a good relationship with suppliers can often lead to favorable terms. -

What payment terms should I expect when importing bottles?

Payment terms for importing bottles can vary, but typical arrangements include a deposit upfront (often 30-50%) with the balance due before shipment or upon receipt of goods. Some suppliers may offer payment through letters of credit or escrow services to enhance security. Always clarify payment conditions in advance and ensure they align with your financial capabilities and cash flow management. Negotiating favorable terms is crucial for maintaining a healthy business relationship. -

How do I ensure quality assurance (QA) for my bottle orders?

Implementing a robust quality assurance process involves several steps. First, establish clear quality standards and specifications with your supplier before production begins. Conduct random inspections during production, and consider hiring third-party inspection services to verify compliance. After delivery, perform thorough quality checks on your stock to identify any defects. Maintaining open communication with suppliers about QA expectations can foster a commitment to quality on both sides. -

What logistics considerations should I keep in mind when importing bottles?

When importing bottles, logistics considerations include selecting the right shipping method (air vs. sea), understanding customs regulations in your destination country, and calculating shipping costs accurately. Work with a reliable freight forwarder to navigate the complexities of international shipping, including documentation and clearance procedures. Additionally, consider lead times and potential delays in shipping, especially during peak seasons, to manage your inventory effectively and meet customer demand.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимый и тщательный due diligence. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.

Top 6 Can You Wash Bottles In Dishwasher Manufacturers & Suppliers List

1. Baby Brezza – 3 in 1 Bottle Washer, Sterilizer & Dryer

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Baby Brezza 3 in 1: washes, sterilizes, and dries bottles; considered pricey but worth it by users. Momcozy version: frequently used, currently on a 20% off sale; praised for its efficiency and convenience in cleaning baby bottles.

2. VEVOR – Dual Tap Draft Beer Dispenser

Домен: homebrewtalk.com

Зарегистрирован: 2004 (21 год)

Введение: VEVOR Beer Kegerator, Dual Tap Draft Beer Dispenser, Full Size Keg Refrigerator With Shelf, CO2 Tank(No Gas), Drip Tray & Rail, 23°F- 82.4°F Temperature Control, 162L, Silver – $664.99; Craft A Brew – Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead – $49.95; 3″ Tri Clamp Fermenters ball lock post Convert Lid with Gas Post Beer Post PRV, Fermentasaurus Pressure, Homebrew…

3. Dr. Brown’s – Baby Bottles

Домен: drbrownsbaby.com

Зарегистрирован: 2010 (15 лет)

Введение: Dr. Brown’s baby bottles can be hand-washed or cleaned in the dishwasher (top rack only). For first-time use, all parts should be washed and boiled in hot water for five minutes. For everyday cleaning, wash all parts in hot water and detergent. A small brush is included for cleaning holes in the insert and reservoir. The Dr. Brown’s Bottle Brush features a sponge and bristles for thorough cleaning…

4. BabyCenter – Washing Baby Bottles

Домен: babycenter.ca

Registered: 2000 (25 years)

Введение: The text discusses various opinions on washing baby bottles in a dishwasher. Key points include: 1. Some users recommend washing baby bottles by hand in hot soapy water and then sterilizing them, particularly for nipples and plastic parts. 2. Others find it easier to wash bottles in the dishwasher, suggesting using a dishwasher basket and placing bottles on the top shelf. 3. Opinions vary on the n…

5. What to Expect – Bottle Cleaning Tips

Домен: community.whattoexpect.com

Зарегистрирован: 1998 (27 лет)

Введение: This company, What to Expect – Bottle Cleaning Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Momcozy – KleanPal Pro Baby Bottle Washer and Sterilizer

Домен: momcozy.com

Зарегистрирован: 2017 (8 лет)

Введение: Momcozy KleanPal Pro Baby Bottle Washer and Sterilizer – $299.99 USD, Flash Sale Price: $269.99 USD. Features: Automatically washes, sterilizes, dries, and stores baby bottles, pump parts, and tableware. Modes include 19-minutes Rapid Wash, 29-minutes Normal Wash, and 60-minute Sterilize + Dry. Storage Mode keeps items sterile and dry for up to 72 hours.

Strategic Sourcing Conclusion and Outlook for can you wash bottles in dishwasher

As businesses increasingly prioritize efficiency and hygiene in their operations, understanding the nuances of washing bottles in dishwashers becomes essential. Key takeaways highlight the importance of verifying dishwasher compatibility, disassembling bottles for thorough cleaning, and using appropriate detergents to ensure safety and effectiveness. By adopting these best practices, organizations can enhance operational efficiency while meeting safety standards, thus reinforcing their commitment to quality.

Strategic sourcing plays a pivotal role in optimizing these processes. By collaborating with reliable suppliers who offer dishwasher-safe products, businesses can mitigate risks associated with non-compliance and enhance customer satisfaction. Moreover, sourcing high-quality cleaning agents designed for sensitive items ensures that hygiene standards are consistently met.

Looking ahead, international B2B buyers in regions such as Africa, South America, the Middle East, and Europe should seize the opportunity to streamline their supply chains. By investing in robust sourcing strategies that prioritize quality and efficiency, businesses can not only improve their operational outcomes but also position themselves as industry leaders. Engage with trusted suppliers today to elevate your hygiene practices and drive sustainable growth in your market.