Guide Contents

Market Trends: Double Wall Stainless Steel Bottle Manufacturer

The global fitness hydration market is undergoing a transformative shift, driven by rising health consciousness, sustainability demands, and the growing influence of branded lifestyle products. As consumers increasingly prioritize wellness and active lifestyles, the demand for high-performance, aesthetically appealing hydration solutions has surged. Within this landscape, double wall stainless steel bottle manufacturers are no longer just producers of functional containers—they are strategic partners in building brand identity and customer loyalty for fitness-oriented businesses.

At Wala Sports Bottles, part of Akey Fitness, we recognize that hydration is central to performance, recovery, and daily wellness. This insight has positioned insulated stainless steel bottles as essential accessories in gyms, yoga studios, outdoor adventures, and corporate wellness programs. The double wall vacuum insulation technology, which maintains beverage temperature for extended periods, has become a baseline expectation. However, the market is now differentiating on design, durability, customization, and sustainability—areas where strategic manufacturer partnerships deliver tangible competitive advantage.

Branded bottles are no longer mere giveaways; they are powerful marketing tools that extend brand presence beyond digital and physical storefronts. When a customer carries a custom-branded Wala bottle, they become an ambassador, reinforcing brand visibility with every use. This is particularly impactful in the fitness industry, where community and identity play a crucial role. Studios, gyms, and wellness influencers leverage branded bottles to strengthen member engagement, enhance perceived value, and differentiate their offerings in a crowded marketplace.

Moreover, sustainability is reshaping sourcing decisions. Consumers and B2B buyers alike favor reusable, eco-conscious products over single-use plastics. Stainless steel bottles align with ESG goals and support green certifications, making them a preferred choice for corporate gifting, event swag, and retail partnerships. As a factory-direct manufacturer, Wala Sports Bottles ensures full control over material sourcing, production ethics, and environmental impact—critical factors for modern procurement teams.

The table below highlights key market drivers influencing the demand for branded double wall stainless steel bottles.

| Trend | Impact on Market | Relevance to Branded Bottles |

|---|---|---|

| Health & Wellness Growth | Global fitness market projected to reach $1.2T by 2028 | Drives demand for performance hydration products |

| Sustainability Mandates | 74% of consumers prefer reusable over plastic bottles | Supports eco-friendly branding and CSR initiatives |

| Customization Demand | 68% of B2B buyers seek high personalization | Enables unique branding, logos, colors, and finishes |

| Корпоративные оздоровительные программы | 60% of Fortune 500 companies offer wellness perks | Creates bulk sourcing opportunities for branded fleets |

| Influencer & Studio Partnerships | Fitness influencers drive product adoption | Branded bottles enhance community engagement and loyalty |

As the line between fitness, lifestyle, and personal identity continues to blur, the role of the double wall stainless steel bottle evolves from utility to statement. For brands looking to build trust, visibility, and long-term engagement, investing in high-quality, custom-branded hydration solutions is not just strategic—it’s essential. At Wala Sports Bottles, we empower fitness brands to lead with purpose, performance, and style.

Winning Features: Insulated Stainless Steel Bottle

Wala Sports Bottles (Akey Fitness) prioritizes product innovation as the cornerstone of our factory-direct B2B sourcing strategy for insulated stainless steel bottles. We seek manufacturing partners who demonstrate deep technical expertise and a commitment to exceeding baseline industry standards, ensuring our end consumers receive unparalleled performance and safety. True innovation in this category transcends basic insulation; it lies in the precise engineering of the double-wall vacuum structure, the strategic selection of premium materials, and rigorous adherence to global safety certifications. Our specifications are non-negotiable, designed to deliver the reliability athletes and outdoor enthusiasts demand.

The heart of exceptional thermal performance is the double-wall vacuum insulation. We require manufacturers to utilize advanced laser welding and evacuation techniques to create a near-perfect vacuum between the inner and outer walls. This eliminates conductive and convective heat transfer, the primary mechanisms for temperature loss. Merely stating vacuum insulation is insufficient; we mandate verification of the vacuum integrity through helium leak testing during production. Superior vacuum quality directly enables our stringent performance targets: maintaining beverage temperatures below 4°C for a minimum of 24 hours and above 55°C for at least 12 hours, measured under controlled conditions starting with ice water or boiling water at 70°F ambient temperature. Compromised vacuum seals lead to rapid performance degradation, a risk we mitigate through our direct oversight of the manufacturing process.

Material science is equally critical. We exclusively specify food-grade stainless steel, with SS304 being the mandatory baseline for all interior and exterior surfaces contacting beverages. SS304 offers an optimal balance of corrosion resistance, durability, and cost-effectiveness for most applications. For premium lines targeting extreme environments or specific medical-grade requirements, we actively source partners capable of utilizing SS316, which provides superior resistance to pitting and crevice corrosion, particularly against salt and chlorides. All materials must be certified to meet or exceed FDA 21 CFR 174-178 and EU LFGB standards, verified through comprehensive batch testing documentation provided by the mill and re-confirmed by our independent lab audits. Surface finishes must be electrolytically polished to a minimum of 180 grit for optimal smoothness, preventing flavor retention and ensuring easy cleaning.

Compliance is not a checkbox but an integrated part of our innovation framework. Beyond material certifications, we require full traceability from raw material batch to finished product, including Certificates of Analysis for every production run. Our factory-direct model allows us to embed compliance verification directly into the production line, ensuring no step is outsourced or compromised. This commitment guarantees bottles free from BPA, phthalates, and other harmful substances, providing absolute safety and peace of mind.

The following table summarizes the core technical specifications we enforce through our strategic sourcing partnerships

| Feature | Specification Requirement | Verification Method |

|---|---|---|

| Технология изоляции | Double-wall vacuum with laser-welded seam | Helium leak testing records per batch |

| Thermal Performance | ≥24h cold retention (4°C), ≥12h hot retention (55°C) | ISO 14993:2008 compliant testing |

| Класс материала | SS304 (mandatory), SS316 (premium option) | Mill Certificates, Spectrographic analysis |

| Material Compliance | FDA 21 CFR 174-178, EU LFGB | Batch CoA, Third-party lab audit |

| Interior Finish | Electrolytically polished ≥180 grit | Visual inspection, Surface roughness test |

| Safety Standards | BPA-free, Phthalate-free | Independent lab testing per production run |

This rigorous focus on engineered innovation ensures Wala Sports Bottles consistently delivers products where peak thermal performance, uncompromised safety, and exceptional durability converge, directly from the factory floor to our valued retail partners.

Manufacturing Insight

At Wala Sports Bottles, part of Akey Fitness, we specialize in premium double wall stainless steel bottle manufacturing with a vertically integrated production process that ensures durability, thermal performance, and aesthetic excellence. Our advanced manufacturing workflow combines precision engineering with sustainable practices, enabling B2B partners to deliver high-performance insulated bottles that meet rigorous market demands.

The production journey begins with hydroforming, a high-pressure tube expansion technique that shapes seamless stainless steel into precise bottle contours. This method eliminates weak seams and ensures uniform wall thickness, enhancing both structural integrity and insulation efficiency. We use food-grade 304 stainless steel for all bottles, guaranteeing corrosion resistance and long-term safety for beverage storage.

Following hydroforming, the bottles proceed to laser welding. Our automated welding stations create airtight, clean seams between the inner and outer walls with micron-level accuracy. This critical step ensures the vacuum layer remains intact, directly impacting thermal retention. Each weld is visually and pressure-tested to maintain consistent quality across large production runs.

The next phase—vacuumizing—is where superior insulation is achieved. Bottles are placed in a vacuum chamber where air is extracted from the space between the double walls. A microscopic vacuum seal is then permanently sealed, enabling temperature retention for up to 24 hours for hot liquids and 48 hours for cold. This vacuum layer is validated through batch testing, with results documented for quality assurance and client transparency.

After insulation is secured, bottles move to surface finishing. We apply electrostatic powder coating for a durable, scratch-resistant exterior. This eco-friendly process uses minimal volatile organic compounds (VOCs) and allows for full-body color coverage in any Pantone-matched finish. The powder is cured in a temperature-controlled oven, creating a resilient, chip-proof surface ideal for high-use environments.

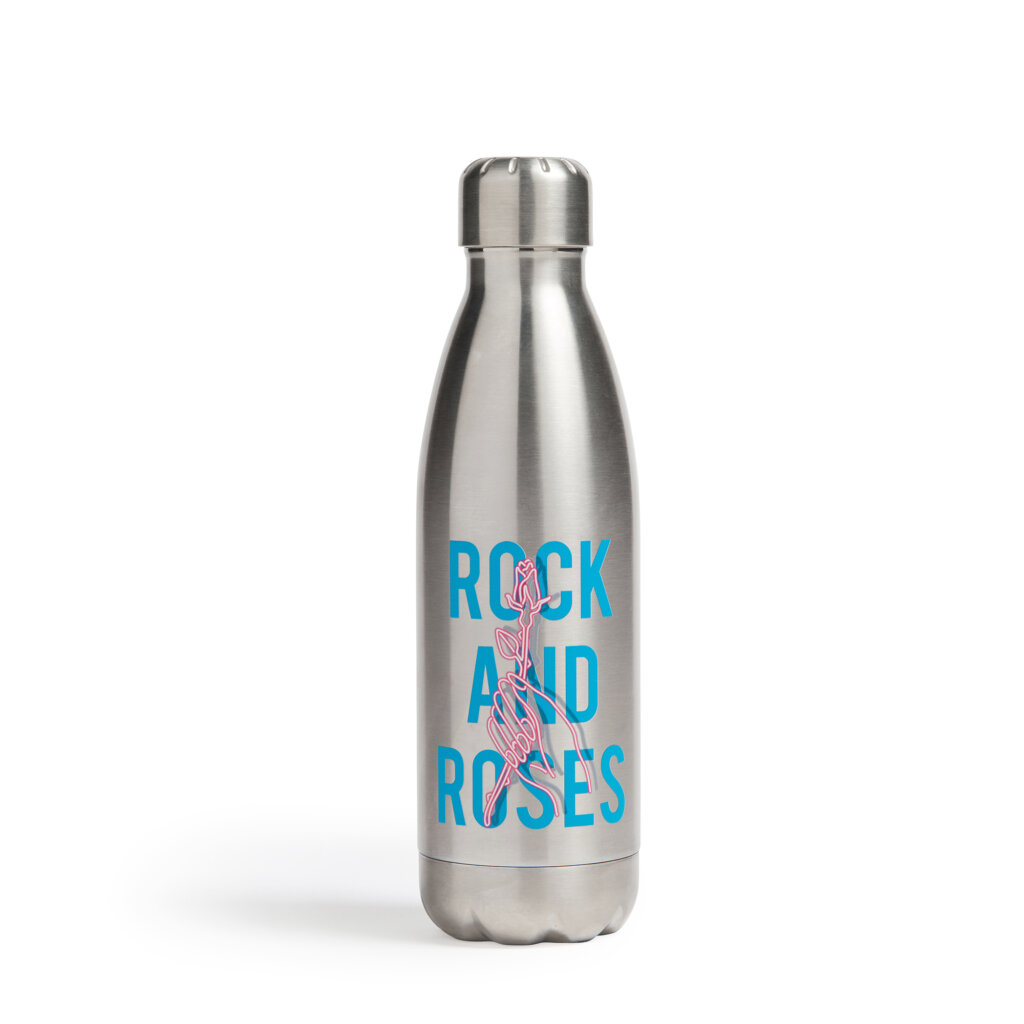

Customization is central to our offering. We support full-surface UV printing for intricate logos, patterns, and branding elements. Our UV-curable inks are non-toxic and fade-resistant, adhering strongly to curved surfaces without cracking. Clients can choose from matte, gloss, or textured finishes to align with brand identity. With digital color profiling, we ensure precise Pantone color matching across all production batches, maintaining brand consistency at scale.

Whether you’re launching a fitness line, corporate giveaway, or retail collection, our end-to-end manufacturing and customization capabilities empower B2B partners with speed, quality, and creative freedom.

| Feature | Specification |

|---|---|

| Материал | 304 Food-Grade Stainless Steel |

| Insulation Performance | 24h hot / 48h cold |

| Wall Construction | Double Wall, Vacuum-Insulated |

| Coating Type | Electrostatic Powder Coating |

| Color Options | Full Pantone Matching System (PMS) |

| Printing Method | UV Digital Printing |

| Finish Types | Matte, Gloss, Textured |

| Minimum Order Quantity (MOQ) | 500 units |

| Production Lead Time | 25–35 days after approval |

Factory Direct Advantage

Wala Sports Bottles (Akey Fitness) operates as a vertically integrated manufacturer, not a trading intermediary. This fundamental distinction shapes every aspect of the B2B partnership, delivering tangible strategic advantages for brands prioritizing control, efficiency, and long-term value in the insulated stainless steel bottle market. Sourcing directly from our dedicated production facility eliminates layers of markup and communication friction inherent in trading company models. Trading companies act as brokers, sourcing finished goods from multiple anonymous factories. While they offer apparent simplicity in initial contact, this model introduces significant hidden costs and operational vulnerabilities. Brands relinquish direct oversight of production standards, material traceability, and engineering capabilities, often discovering quality inconsistencies only after shipment. Crucially, trading companies cannot influence factory scheduling or troubleshoot production issues in real-time, leading to unpredictable delays that disrupt retail timelines. Their value proposition frequently hinges on aggregating volume from diverse clients, which inherently conflicts with a single brand’s urgent needs or unique specifications.

The operational contrast becomes starkly evident across three critical dimensions determining sourcing success. Trading companies inflate costs through multiple markup layers while adding minimal operational value beyond basic order coordination. Their lack of production ownership means lead times are dictated by third-party factory availability, not client urgency, with minimal recourse for acceleration. Furthermore, arbitrary minimum order quantities imposed by trading companies often exceed a brand’s actual market demand, forcing excessive inventory investment and limiting agility. Wala, as the originator of every bottle, provides transparent factory-direct pricing reflecting true production economics. Our integrated control over the entire process – from raw material sourcing through welding, insulation, finishing, and QC – enables responsive lead times and proactive issue resolution. We align MOQs with realistic brand growth trajectories, supporting market entry and scaling without penalizing flexibility. This direct partnership model fosters collaborative innovation, allowing brands to leverage our engineering expertise for customizations impossible through disconnected trading channels.

The following comparison quantifies the core operational differentiators between factory-direct sourcing with Wala and the trading company alternative

| Factor | Wala Sports Bottles (Factory Direct) | Trading Companies |

|---|---|---|

| Price | Transparent factory cost structure; 15-25% lower total landed cost due to eliminated markup layers | Multiple markups (broker + factory); hidden fees inflate final cost |

| Speed | 30-45 day standard lead time; responsive capacity allocation for urgent orders; direct production oversight enables proactive delay mitigation | 45-75+ day lead times; subject to third-party factory schedules; limited visibility or control over delays |

| MOQ | Flexible starting at 500 units; scalable tiers aligned with brand growth; no arbitrary inventory burdens | Typically 3,000+ units; inflexible minimums based on factory batches, not brand needs |

Choosing Wala means selecting partnership over transaction. We provide the stability of direct production control, the cost efficiency of vertical integration, and the agility to adapt to your market demands. Trading companies offer distance from the manufacturing reality – a risk that translates directly into higher costs, slower time-to-market, and constrained responsiveness in today’s competitive hydration category. Partner with the source for sustainable growth.

Start Your Custom Order

Partner with Wala – Your Trusted Manufacturer of Premium Double Wall Stainless Steel Bottles

For over two decades, Wala Sports Bottles, a brand under Akey Fitness, has been at the forefront of designing and manufacturing high-performance insulated stainless steel bottles. As a factory-direct supplier with deep roots in innovation, quality control, and sustainable production, we specialize in crafting double wall vacuum-insulated bottles that meet the evolving demands of global B2B partners. Our expertise spans from concept to delivery, ensuring every product reflects precision engineering, durability, and modern aesthetics.

With 20 years of experience in the drinkware industry, we’ve built a reputation for excellence by consistently delivering bottles that exceed expectations in thermal performance, material safety, and design versatility. Our state-of-the-art manufacturing facility in China operates under strict ISO-certified processes, enabling us to maintain tight tolerances, rapid turnaround times, and full compliance with international standards including FDA, LFGB, and REACH. Whether you’re a retailer, corporate gifting provider, or fitness brand, we offer scalable production solutions tailored to your volume and branding needs.

At Wala, we understand that differentiation is key in a competitive market. That’s why we provide comprehensive OEM and ODM services, allowing you to customize shape, size, color, lid type, and branding with ease. From matte finishes to powder coating, laser engraving to full-wrap printing, our design team works closely with partners to bring unique visions to life—without minimum order constraints holding you back.

What truly sets us apart is our commitment to partnership. We don’t just manufacture bottles—we build long-term relationships based on trust, transparency, and technical support. Our in-house R&D team continuously explores advancements in insulation technology, leak-proof sealing, and eco-friendly materials to keep your offerings ahead of the curve.

To experience the Wala difference firsthand, we invite qualified B2B partners to request a free sample and design consultation. See and feel the quality, test the insulation performance, and explore customization options—absolutely no cost, no obligation.

Whether you’re launching a new product line or upgrading your current supply chain, partnering with Wala means gaining a reliable, experienced, and innovative manufacturer dedicated to your success.

| Feature | Specification |

|---|---|

| Материал | 18/8 Food-Grade Stainless Steel (BPA-Free) |

| Технология изоляции | Double Wall Vacuum Insulation |

| Temperature Retention | 24h Hot / 48h Cold |

| Capacity Range | 350ml – 1000ml |

| Параметры настройки | Logo Printing, Color Matching, Lid Styles, Packaging |

| Certifications | FDA, LFGB, REACH, ISO 9001 |

| MOQ | Flexible (Sample Orders Welcome) |

| Время выполнения | 15–25 Days (After Confirmation) |

| Sample Availability | Free Sample & Design Support (For Qualified Partners) |

💰 OEM Cost Savings Calculator

Compare local distributor price vs. Wala direct factory price.