Introduction: Navigating the Global Market for insulated bike water bottles

In an increasingly competitive marketplace, sourcing insulated bike water bottles that meet both performance and environmental standards poses a significant challenge for international B2B buyers. As cycling continues to gain popularity across diverse regions—especially in Africa, South America, the Middle East, and Europe—demand for high-quality, insulated bottles has surged. This guide aims to equip buyers with the insights necessary to navigate this complex landscape, focusing on the various types of insulated bottles available, their applications, and the key factors to consider when selecting suppliers.

Within this comprehensive resource, we will explore the latest innovations in insulated bottle technology, from double-wall vacuum insulation to BPA-free materials. We will also delve into the intricacies of supplier vetting, ensuring that buyers can confidently assess quality, pricing, and sustainability practices. Additionally, we will provide actionable insights into cost considerations and market trends, empowering buyers to make informed purchasing decisions.

By addressing the unique needs of B2B buyers across different continents, this guide will serve as a vital tool in sourcing insulated bike water bottles that not only enhance the cycling experience but also align with global sustainability goals. Whether you are a retailer, distributor, or procurement professional, our objective is to help you navigate the global market effectively, ensuring that your product offerings meet the demands of today’s eco-conscious consumers.

Навигация по статье

- Top 7 Insulated Bike Water Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for insulated bike water bottles

- Understanding insulated bike water bottles Types and Variations

- Key Industrial Applications of insulated bike water bottles

- 3 Common User Pain Points for ‘insulated bike water bottles’ & Their Solutions

- Strategic Material Selection Guide for insulated bike water bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for insulated bike water bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘insulated bike water bottles’

- Comprehensive Cost and Pricing Analysis for insulated bike water bottles Sourcing

- Alternatives Analysis: Comparing insulated bike water bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for insulated bike water bottles

- Navigating Market Dynamics and Sourcing Trends in the insulated bike water bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of insulated bike water bottles

- Важный отказ от ответственности и условия использования

- Strategic Sourcing Conclusion and Outlook for insulated bike water bottles

Understanding insulated bike water bottles Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Double-Walled Stainless Steel | Excellent thermal insulation, durable, and often BPA-free | High-end cycling brands, sports retailers | Плюсы: Superior insulation, long-lasting; Конс: Higher price point. |

| Plastic Insulated Bottles | Lightweight, often with foam insulation, versatile designs | Budget-friendly options for mass markets | Плюсы: Affordable, lightweight; Конс: Less durable than metal. |

| Vacuum-Sealed Bottles | Advanced insulation technology, often with ergonomic designs | Premium cycling brands, specialty shops | Плюсы: Keeps drinks cold for extended periods; Конс: Can be heavier. |

| Collapsible Insulated Bottles | Space-saving design, flexible materials | Outdoor retailers, travel gear suppliers | Плюсы: Easy to store, lightweight; Конс: May not maintain temperature as long. |

| Настраиваемые бутылки | Ability to personalize with branding or unique designs | Corporate gifting, promotional items | Плюсы: Enhances brand visibility; Конс: May have longer lead times. |

What are the characteristics and suitability of double-walled stainless steel insulated bottles?

Double-walled stainless steel insulated bottles are renowned for their exceptional thermal performance and durability. These bottles typically feature a vacuum-sealed design that keeps beverages cold for hours, making them ideal for long cycling trips or hot climates. They are well-suited for B2B applications in high-end cycling brands and sports retailers, where quality and performance are paramount. Buyers should consider the higher price point associated with these bottles, as well as their resistance to wear and tear, which can justify the investment for long-term use.

How do plastic insulated bottles compare in the market?

Plastic insulated bottles are a popular choice for businesses aiming to offer budget-friendly options. They are lightweight and often feature foam insulation, making them versatile for various cycling activities. These bottles are particularly suitable for mass-market applications, appealing to casual cyclists and outdoor enthusiasts. While they provide a more affordable alternative, buyers should be aware that they may not offer the same durability or thermal retention as their stainless steel counterparts. This trade-off is essential to consider when targeting different market segments.

What advantages do vacuum-sealed bottles offer to B2B buyers?

Vacuum-sealed insulated bottles leverage advanced insulation technology to maintain beverage temperatures for extended periods. Their ergonomic designs cater to serious cyclists and outdoor adventurers, making them a favored choice among premium cycling brands and specialty shops. B2B buyers should note the potential for higher weight compared to other options, which may affect portability. However, the superior temperature retention can enhance customer satisfaction and loyalty, making these bottles a worthwhile investment for businesses focusing on quality.

Why are collapsible insulated bottles gaining popularity?

Collapsible insulated bottles are increasingly popular due to their space-saving designs and lightweight materials, making them ideal for travel and outdoor activities. These bottles are particularly appealing to outdoor retailers and suppliers of travel gear, as they can be easily stored when not in use. While they offer significant convenience, buyers should consider that their insulation capabilities may not match those of more rigid options. This is an important factor for businesses targeting consumers who prioritize lightweight solutions over extended temperature retention.

How can customizable bottles enhance brand visibility?

Customizable insulated bottles allow businesses to personalize their products with branding or unique designs, making them an effective promotional tool. They are particularly useful for corporate gifting and marketing campaigns, helping to enhance brand visibility among target audiences. However, buyers should be prepared for potentially longer lead times associated with customization processes. This aspect is crucial for businesses that need to plan ahead for promotional events or product launches, ensuring they align with marketing strategies effectively.

Key Industrial Applications of insulated bike water bottles

| Промышленность/сектор | Specific Application of Insulated Bike Water Bottles | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Отдых на природе | Hydration solutions for cycling tours and events | Enhanced customer experience through effective hydration solutions | Durable materials, temperature retention capabilities, and compliance with health standards |

| Корпоративное здоровье | Employee wellness programs promoting cycling | Improved employee health and productivity | Custom branding options, bulk purchasing discounts, and ergonomic design |

| Logistics and Delivery | Transportation of beverages during bike deliveries | Maintaining beverage temperature for customer satisfaction | Lightweight design, compatibility with delivery systems, and ease of cleaning |

| Спорт и фитнес | Training and competition hydration for athletes | Optimal hydration management for peak performance | High flow rate, BPA-free materials, and ease of use while cycling |

| Eco-Friendly Initiatives | Sustainable hydration solutions for eco-conscious consumers | Reduced plastic waste and enhanced brand reputation | Recyclable materials, carbon-neutral production, and innovative designs |

How Are Insulated Bike Water Bottles Used in Outdoor Recreation?

In the outdoor recreation industry, insulated bike water bottles are essential for cycling tours and events. They provide participants with reliable hydration options, keeping drinks cool during long rides in hot conditions. This enhances the overall customer experience, leading to higher satisfaction and repeat business. Buyers in this sector should prioritize durability and temperature retention capabilities, ensuring that the bottles can withstand rugged outdoor environments while complying with health standards.

What Role Do Insulated Bike Water Bottles Play in Corporate Wellness Programs?

Corporate wellness programs increasingly promote cycling as a healthy commuting option. Insulated bike water bottles serve as effective tools in these initiatives, encouraging employees to stay hydrated while cycling to work. This not only supports employee health but also boosts productivity and morale. For B2B buyers in this sector, custom branding options and bulk purchasing discounts can enhance the appeal, while ergonomic designs ensure comfort during use.

How Are Insulated Bike Water Bottles Utilized in Logistics and Delivery?

In the logistics and delivery industry, insulated bike water bottles are used to transport beverages during bike deliveries. Maintaining the temperature of drinks is crucial for customer satisfaction, particularly in hot climates. Sourcing considerations for businesses in this field include lightweight designs that do not impede delivery speed, compatibility with existing delivery systems, and ease of cleaning to ensure hygiene standards are met.

Why Are Insulated Bike Water Bottles Important for Athletes in Sports and Fitness?

In the sports and fitness sector, insulated bike water bottles are vital for athletes during training and competition. They help manage hydration effectively, ensuring athletes can perform at their best. High flow rates and BPA-free materials are critical requirements for buyers in this industry, as they need bottles that are easy to use while cycling and safe for health. The ability to maintain beverage temperatures also contributes to optimal performance.

How Do Insulated Bike Water Bottles Support Eco-Friendly Initiatives?

Eco-friendly initiatives benefit significantly from the use of insulated bike water bottles, which provide sustainable hydration solutions for environmentally conscious consumers. These bottles help reduce reliance on single-use plastics, aligning with the growing demand for sustainable products. Buyers should look for options made from recyclable materials, carbon-neutral production processes, and innovative designs that appeal to eco-minded consumers, enhancing brand reputation in the process.

3 Common User Pain Points for ‘insulated bike water bottles’ & Their Solutions

Scenario 1: Insufficient Insulation Performance in Hot Climates

Проблема: B2B buyers in regions with extreme heat, such as parts of Africa and the Middle East, often encounter insulated bike water bottles that fail to maintain the desired temperature for long durations. When cycling under a scorching sun, riders expect their beverages to remain cool, but inadequate insulation can lead to lukewarm drinks, negatively impacting hydration and overall performance. This is particularly concerning for businesses that provide cycling equipment for events or outdoor adventures, as customer satisfaction is paramount.

Решение: To combat this issue, buyers should prioritize sourcing insulated bottles with advanced double-wall vacuum insulation technology. When evaluating products, look for specifications that detail insulation performance, such as the duration the bottle can keep liquids cold (ideally over 12 hours). Additionally, consider bottles that are constructed from materials like stainless steel, which are known for their superior thermal retention. Engaging with suppliers who provide detailed testing results and user reviews can also help ensure that the products meet high-performance standards.

Scenario 2: Difficulty in Cleaning and Maintenance

Проблема: B2B buyers frequently face challenges with the cleaning and maintenance of insulated bike water bottles, particularly those with complex designs or non-removable parts. Over time, residues can build up, leading to unpleasant odors and tastes, which not only affects user experience but also tarnishes the reputation of the business providing these bottles. In regions where water quality may vary, this issue can be exacerbated, making it even more critical to have bottles that are easy to clean.

Решение: To address this pain point, opt for insulated bike water bottles that feature wide openings and disassemblable components. This design choice allows for thorough cleaning and prevents mold and residue buildup. When sourcing products, inquire about the ease of disassembly and whether the materials are dishwasher safe. Additionally, consider bottles made from BPA-free plastics or food-grade stainless steel, which are less likely to retain odors or flavors. Providing training to staff on proper cleaning techniques can further enhance the longevity and hygiene of these products.

Scenario 3: Compatibility Issues with Bike Cages

Проблема: Another common challenge faced by B2B buyers is the compatibility of insulated bike water bottles with various bike frames and cages. Bottles that do not fit securely can rattle, fall out, or be difficult to retrieve during rides, leading to rider frustration and potential loss of the product. This issue is particularly relevant for businesses that sell or rent bikes, as they need to ensure a seamless user experience for their customers.

Решение: When selecting insulated bike water bottles, focus on designs that are universally compatible with standard bike cages. Look for bottles with a streamlined shape that can accommodate different cage styles while also offering a snug fit. Additionally, consider bottles that feature a silicone grip or textured exterior, which can help prevent slipping and rattling during rides. Engaging in direct discussions with manufacturers about the compatibility of their products can provide valuable insights and ensure that the bottles meet the specific needs of your clientele. Providing guidance to customers on how to securely fit the bottles in their cages can also enhance their overall experience.

Strategic Material Selection Guide for insulated bike water bottles

What are the Key Materials Used in Insulated Bike Water Bottles?

When selecting materials for insulated bike water bottles, several common options stand out due to their unique properties and performance characteristics. Understanding these materials is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Stainless Steel Perform in Insulated Bike Water Bottles?

Stainless steel is a popular choice for insulated bike water bottles due to its excellent thermal insulation properties and durability. The double-wall vacuum insulation technology commonly used in stainless steel bottles can keep beverages cold for over 12 hours. Stainless steel is also highly resistant to corrosion and does not retain flavors, ensuring a clean taste for the user.

Плюсы: Stainless steel bottles are robust and can withstand rough handling, making them suitable for outdoor activities. They are also recyclable, aligning with increasing sustainability demands.

Конс: The manufacturing process for stainless steel can be complex and costly, which may affect the final product price. Additionally, they can be heavier than other materials, which might not appeal to all cyclists.

Влияние на применение: Stainless steel is compatible with various beverages, including acidic drinks, without risk of leaching harmful chemicals. However, buyers should ensure compliance with international food safety standards such as LFGB (Germany) or FDA (USA).

What Role Does BPA-Free Plastic Play in Insulated Bike Water Bottles?

BPA-free plastic is another common material used in insulated bike water bottles, particularly for those targeting budget-conscious consumers. These bottles often feature double-walled construction with foam insulation, providing adequate temperature retention.

Плюсы: BPA-free plastic is lightweight and generally less expensive than stainless steel, making it an attractive option for high-volume production. The manufacturing process is straightforward, allowing for diverse designs and colors.

Конс: While durable, plastic bottles can be more susceptible to wear and tear over time, leading to potential leaks. They may also retain odors and flavors from previous contents, which can be a significant drawback for consumers.

Влияние на применение: These bottles are suitable for a wide range of beverages but may not be ideal for hot liquids due to potential deformation. Compliance with ASTM standards for food safety is essential, especially in regions with strict regulations.

How Do Aluminum Bottles Compare in Insulated Bike Water Bottles?

Aluminum is a lightweight alternative that offers good thermal insulation when paired with an inner lining. Many aluminum bottles are designed with a double-wall construction, which helps maintain beverage temperature effectively.

Плюсы: Aluminum bottles are lightweight and often feature attractive designs, appealing to a younger demographic. They are generally more affordable than stainless steel.

Конс: Aluminum can be prone to dents and scratches, impacting durability. Additionally, the inner lining is crucial to prevent leaching, which can complicate manufacturing and compliance with safety standards.

Влияние на применение: Aluminum bottles are suitable for cold beverages but may not be ideal for hot drinks unless specifically designed with appropriate linings. Buyers should consider compliance with international standards such as JIS for safety.

What About Composite Materials in Insulated Bike Water Bottles?

Composite materials, combining plastic with insulating foams or other materials, are increasingly being used in insulated bike water bottles. These materials aim to leverage the benefits of both plastic and insulation technology.

Плюсы: Composite bottles can be designed for optimal weight-to-insulation ratios, making them competitive in performance. They can also be produced in various shapes and sizes, catering to different consumer preferences.

Конс: The complexity of manufacturing composite materials can lead to higher costs. Additionally, the performance can vary significantly based on the specific materials used, making quality control essential.

Влияние на применение: Composite materials can be suitable for a range of beverages, but buyers must ensure that they meet relevant safety standards, particularly in regions with stringent regulations.

Сводная таблица свойств материалов

| Материал | Typical Use Case for insulated bike water bottles | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Нержавеющая сталь | High-performance insulated bottles | Отличная прочность и изоляция | Повышенная сложность производства | Высокий |

| Пластик без содержания бисфенола | Budget-friendly options | Легкий и экономичный | Prone to wear and odor retention | Низкий |

| Алюминий | Lightweight, stylish designs | Attractive and affordable | Susceptible to dents and scratches | Средний |

| Composite | Versatile designs with insulation | Optimal weight-to-insulation ratio | Higher manufacturing costs | Средний |

This strategic material selection guide provides valuable insights for B2B buyers in the insulated bike water bottle market, helping them make informed decisions that align with their business needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for insulated bike water bottles

What Are the Main Stages in the Manufacturing Process of Insulated Bike Water Bottles?

The manufacturing process of insulated bike water bottles involves several key stages, each critical to ensuring the final product meets quality and performance standards. The main stages are material preparation, forming, assembly, and finishing.

How is Material Prepared for Insulated Bike Water Bottles?

Material preparation begins with the selection of high-quality materials such as stainless steel or BPA-free plastics. For insulated bottles, double-wall construction is often utilized, requiring the inner and outer layers to be formed from different materials to optimize insulation properties. This stage also includes the preparation of insulation materials, such as foam or vacuum chambers, which enhance thermal retention. Suppliers must ensure that all materials comply with international safety and health standards, such as FDA regulations for food contact materials.

What Techniques Are Used in the Forming Stage?

In the forming stage, various techniques are employed to shape the materials into the desired bottle form. Processes like blow molding, injection molding, or deep drawing are commonly used for plastic bottles, while stainless steel bottles may undergo stamping and welding. Advanced techniques like hydroforming can also be used for creating seamless designs that improve durability and aesthetics. This stage is crucial as it directly affects the bottle’s performance, including its strength, weight, and insulation effectiveness.

How is Assembly Conducted for Insulated Bike Water Bottles?

Once the individual components are formed, they proceed to the assembly stage. This involves fitting together the inner and outer layers, installing seals, and attaching lids or nozzles. For insulated bottles, ensuring airtight seals is vital to maintain temperature and prevent leakage. Automated assembly lines are often used to enhance efficiency, but manual assembly may be employed for specialized or custom designs. Attention to detail in this stage is essential to ensure that all components fit perfectly and function as intended.

What Finishing Techniques Are Commonly Used?

The finishing stage includes surface treatments, labeling, and packaging. Common surface treatments may involve polishing, coating, or applying finishes that enhance grip and aesthetics. The labeling process must comply with international regulations, including ingredient disclosure and recycling symbols. Finally, bottles are packaged securely to prevent damage during transportation. Proper finishing not only enhances the product’s appearance but also contributes to its durability and usability.

What Are the Key Quality Assurance Measures in Manufacturing Insulated Bike Water Bottles?

Quality assurance (QA) is a critical component of the manufacturing process to ensure that insulated bike water bottles meet both international and industry-specific standards. Implementing robust QA measures helps mitigate risks and ensures product reliability.

Which International Standards Are Relevant for Insulated Bike Water Bottles?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with this standard demonstrates a commitment to quality and customer satisfaction. Additionally, specific certifications such as CE for safety compliance and API for performance standards may be relevant depending on the target market. For example, European buyers may prioritize CE marking as a sign of safety and compliance with EU regulations.

What Are the Common Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and address issues early. These include:

- Входящий контроль качества (IQC): Inspection of raw materials upon delivery to ensure they meet specifications.

- Внутрипроцессный контроль качества (IPQC): Monitoring during manufacturing to catch defects as they occur.

- Окончательный контроль качества (ОКК): Comprehensive testing of the finished product before packaging, including leak tests and thermal performance evaluations.

These checkpoints are essential for maintaining consistent quality and performance across product batches.

What Testing Methods Are Commonly Employed?

Common testing methods for insulated bike water bottles include thermal performance tests to measure insulation effectiveness, leak tests to ensure seals are intact, and durability tests to assess resistance to impact and wear. Manufacturers may also conduct chemical analysis to verify that materials are free from harmful substances like BPA or phthalates. These tests help ensure that the final product is safe and reliable for consumer use.

Как покупатели B2B могут проверять контроль качества поставщиков?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some effective methods:

What Auditing Practices Should B2B Buyers Consider?

Conducting supplier audits is a crucial step in assessing quality control practices. Buyers should request access to the supplier’s quality management system documentation, including ISO certifications and internal audit reports. Regular audits can help ensure that suppliers adhere to established standards and maintain consistent quality.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality assurance processes. These services can conduct inspections at various stages of production, ensuring that the products meet the required specifications before shipment. This is particularly important for buyers in regions with strict regulatory requirements.

What Are the Nuances for International B2B Buyers?

International buyers, especially those from Africa, South America, the Middle East, and Europe, must navigate additional complexities, such as varying regulatory environments and cultural expectations. Understanding local regulations regarding product safety and environmental compliance is essential. Buyers should also consider the logistics of shipping and customs, which can affect product quality during transit. Building strong relationships with suppliers and maintaining open lines of communication can help mitigate these challenges.

In conclusion, understanding the manufacturing processes and quality assurance measures for insulated bike water bottles is essential for B2B buyers. By focusing on key stages such as material preparation, forming, assembly, and finishing, as well as implementing rigorous quality control measures, manufacturers can ensure they deliver high-quality products that meet the demands of the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘insulated bike water bottles’

In the competitive landscape of cycling accessories, sourcing insulated bike water bottles requires a strategic approach. This guide offers a step-by-step checklist to help B2B buyers make informed decisions, ensuring they choose products that meet both performance and market demands.

Шаг 1: Определите технические характеристики

Begin by outlining the specific technical requirements for the insulated bike water bottles you intend to source. Consider factors such as capacity, insulation type (e.g., double-wall vacuum), material (stainless steel vs. plastic), and nozzle design.

– Вместимость: Common sizes range from 500ml to 750ml, catering to various cycling needs.

– Изоляция: Opt for bottles that can maintain temperature for extended periods, especially in hotter climates.

Шаг 2: Identify Your Target Market Needs

Understanding the preferences of your target demographic is crucial. Conduct market research to determine the specific features that appeal to your customers in regions like Africa, South America, the Middle East, and Europe.

– Consumer Trends: Look for features like eco-friendliness, ease of cleaning, and customization options.

– Культурные предпочтения: Different regions may prioritize durability or aesthetics; tailor your offerings accordingly.

Шаг 3: Оцените потенциальных поставщиков

Before committing to a supplier, thorough vetting is essential. Request detailed company profiles, product samples, and references from other businesses in your industry.

– Certifications: Ensure suppliers hold relevant certifications (e.g., BPA-free, food-grade materials) that guarantee product safety and compliance.

– Production Capacity: Assess whether the supplier can meet your volume requirements without compromising quality.

Шаг 4: Analyze Pricing Structures

Price sensitivity varies across markets, so it’s important to compare pricing models among potential suppliers. Consider not only the base price but also shipping costs, tariffs, and minimum order quantities.

– Bulk Discounts: Inquire about pricing flexibility for larger orders, which can significantly affect your bottom line.

– Long-term Contracts: Explore options for long-term agreements that may secure better rates.

Шаг 5: Request Product Samples

Always request samples before finalizing your order. Testing the product can help verify that it meets your quality standards and technical specifications.

– Performance Testing: Evaluate insulation effectiveness, nozzle functionality, and overall durability.

– User Feedback: Consider obtaining feedback from potential end-users to gauge market acceptance.

Шаг 6: Review Logistics and Shipping Options

Logistics play a crucial role in the timely delivery of your products. Discuss shipping methods and timelines with your suppliers to ensure they align with your operational needs.

– Shipping Partners: Inquire about the suppliers’ logistics partners to ensure reliability.

– Customs and Duties: Understand the potential customs implications for your target markets, especially when importing.

Шаг 7: Assess After-Sales Support

Finally, consider the level of after-sales support the supplier offers. This includes warranty terms, return policies, and customer service responsiveness.

– Warranty and Returns: Ensure there are clear policies for defective products or returns.

– Customer Service: A responsive support team can facilitate smoother transactions and enhance your relationship with the supplier.

Following this checklist will empower B2B buyers to make informed decisions when sourcing insulated bike water bottles, ensuring that they meet both quality standards and market demands.

Comprehensive Cost and Pricing Analysis for insulated bike water bottles Sourcing

What Are the Key Cost Components in Sourcing Insulated Bike Water Bottles?

When sourcing insulated bike water bottles, it’s crucial to understand the primary cost components that contribute to the overall pricing. The main elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Материалы: The choice of materials significantly affects cost. High-quality stainless steel and BPA-free plastics are common, with stainless steel typically incurring higher costs due to durability and insulation properties. Additionally, eco-friendly materials may have a premium price but can attract environmentally conscious consumers.

-

Труд: Labor costs will vary depending on the manufacturing location. Countries with lower labor costs can provide competitive pricing but may impact quality. In contrast, regions with higher labor standards, such as parts of Europe, might offer better craftsmanship but at a higher price.

-

Производственные накладные расходы: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient production processes can help reduce overhead, contributing to lower prices.

-

Инструментальная оснастка: The initial investment in molds and machinery for production can be significant. For custom designs or specialized features, these costs can rise sharply, affecting unit pricing.

-

Контроль качества: Implementing stringent QC processes is essential to ensure product reliability and safety. However, these processes can add to production costs, especially if third-party inspections are involved.

-

Логистика: Shipping costs, including customs duties and tariffs, vary significantly based on the destination. International buyers must consider these expenses when evaluating total costs.

-

Маржа: Suppliers typically factor in a profit margin, which can vary based on market demand, competition, and product uniqueness.

How Do Price Influencers Affect Insulated Bike Water Bottle Costs?

Several factors influence pricing beyond the basic cost structure. Understanding these can aid buyers in making informed purchasing decisions.

-

Объем/МОК: Larger order quantities often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to maximize cost efficiency.

-

Технические характеристики и персонализация: Custom features, such as unique designs or specialized materials, can increase costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Качество и сертификация: Products that meet specific quality standards or certifications (e.g., ISO, FDA) may command higher prices. However, these certifications can enhance marketability and customer trust.

-

Факторы поставщика: The reputation and reliability of the supplier play a crucial role. Established suppliers may charge more but offer better quality assurance and service.

-

Инкотермс: Understanding Incoterms is vital for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, impacting the total cost of ownership.

What Are the Best Practices for Buyers in the International Market?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should adopt strategic approaches to enhance their sourcing experience.

-

Переговоры: Always engage in negotiations with suppliers to explore flexible pricing options, especially for bulk orders. Building a relationship with suppliers can lead to better terms over time.

-

Экономическая эффективность: Analyze the total cost of ownership, which includes not just the purchase price but also shipping, handling, and potential tariffs. This holistic view helps identify the most cost-effective sourcing options.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, European suppliers might offer higher quality but at a premium price, while South American suppliers could provide cost-effective options with varying quality.

-

Исследование рынка: Conduct thorough market research to understand the competitive landscape and identify potential suppliers that align with your quality and pricing expectations.

-

Trial Orders: Consider placing trial orders to assess product quality and supplier reliability before committing to larger volumes. This approach minimizes risks associated with quality discrepancies.

Заключение

Understanding the cost structure and pricing influencers in the insulated bike water bottle market is essential for international B2B buyers. By leveraging insights on cost components, negotiation strategies, and market nuances, buyers can make informed decisions that align with their business goals. Always remember that prices can vary significantly based on specific requirements, so it is crucial to engage in detailed discussions with suppliers to achieve the best possible outcomes.

Alternatives Analysis: Comparing insulated bike water bottles With Other Solutions

Введение в альтернативные решения для гидратации

In the competitive market of cycling accessories, insulated bike water bottles have established themselves as essential for maintaining optimal hydration and beverage temperature during rides. However, there are alternative solutions that also address the need for hydration on-the-go. This analysis compares insulated bike water bottles with hydration packs and traditional non-insulated water bottles, providing insights into their respective advantages and limitations for B2B buyers.

Сравнительная таблица

| Сравнительный аспект | Insulated Bike Water Bottles | Hydration Packs | Non-Insulated Water Bottles |

|---|---|---|---|

| Производительность | Excellent thermal insulation; keeps liquids cold for hours. | Good for hands-free hydration; limited insulation. | Basic functionality; no temperature retention. |

| Стоимость | Moderate ($12 – $100) | Higher ($30 – $150) | Low ($5 – $20) |

| Простота реализации | Easy to use; fits in standard bike cages. | Requires proper fitting and adjustment. | Extremely easy; just fill and go. |

| Техническое обслуживание | Requires regular cleaning; some may have complex parts. | Can be more complex to clean and maintain. | Minimal maintenance; just rinse. |

| Лучший пример использования | Long rides in hot conditions; cycling enthusiasts. | Trail and mountain biking where hands-free access is beneficial. | Casual riders or short trips where temperature is not a concern. |

Подробный анализ альтернатив

Hydration Packs

Hydration packs offer a unique solution for cyclists who prefer hands-free hydration. These backpacks come with a bladder that holds water and a tube for sipping, allowing riders to drink without stopping. The main advantage is convenience, particularly during rugged terrain or long-distance rides where accessing a water bottle may be cumbersome. However, hydration packs tend to be more expensive and can be cumbersome to clean, as they require thorough drying to prevent mold growth. Additionally, they may not provide the same level of temperature control as insulated bottles, making them less suitable for hot weather rides.

Non-Insulated Water Bottles

Non-insulated water bottles are the most cost-effective solution for hydration on the go. They are lightweight, easy to use, and require minimal maintenance, making them ideal for casual cyclists or short trips. However, they do not offer temperature retention, meaning that beverages can become uncomfortably warm in hot weather. For B2B buyers targeting budget-conscious consumers or those who may not ride extensively, non-insulated bottles present a viable alternative. Yet, the lack of insulation may lead to less satisfaction during long rides in high temperatures.

Заключение: Выбор правильного решения для гидратации

When selecting the best hydration solution, B2B buyers should consider the specific needs of their target market. Insulated bike water bottles excel in performance and temperature retention, making them ideal for serious cyclists and those riding in hot climates. On the other hand, hydration packs may appeal to adventure riders seeking convenience, while non-insulated bottles serve as a budget-friendly option for casual cyclists. Ultimately, understanding the unique preferences and riding conditions of potential customers will guide the decision-making process in choosing the most appropriate hydration solution.

Essential Technical Properties and Trade Terminology for insulated bike water bottles

What Are the Key Technical Properties of Insulated Bike Water Bottles?

When considering insulated bike water bottles for B2B procurement, understanding specific technical properties is crucial for making informed decisions. Here are some essential specifications:

-

Класс материала

The material used in the construction of insulated water bottles significantly impacts durability, thermal efficiency, and safety. Common materials include stainless steel, which offers excellent insulation and corrosion resistance, and BPA-free plastics, which are lighter but may not provide the same insulation properties. For B2B buyers, selecting a bottle made from high-grade materials ensures longevity and compliance with safety regulations, reducing the risk of product returns or customer complaints. -

Insulation Type

Insulated bottles typically feature either double-wall vacuum insulation or foam insulation. Double-wall vacuum insulation is more effective, maintaining beverage temperature for extended periods—often up to 12 hours for cold drinks. This property is particularly appealing to cycling enthusiasts who ride in varying climates. For B2B buyers, understanding insulation types can help in selecting products that meet customer expectations for performance and reliability. -

Capacity and Dimensions

Common capacities for insulated bike water bottles range from 15 to 24 ounces (450-700 ml). The dimensions of the bottle also affect its compatibility with bike cages. Buyers should consider these specifications to ensure that the bottles fit standard bike mounts and cater to user preferences for hydration needs during cycling. -

Flow Rate

The flow rate refers to how quickly water can be consumed from the bottle. Bottles with high-flow sport nozzles provide a more efficient drinking experience, which is essential during intense physical activity. This feature is particularly important for B2B buyers targeting competitive cyclists or long-distance riders who prioritize quick hydration. -

Вес

The weight of the bottle plays a vital role in cycling, where every ounce counts. Lightweight materials and designs contribute to an overall better riding experience. B2B buyers should assess the weight specifications to align with market demands, particularly in regions where cyclists favor lightweight gear for performance. -

Возможность вторичной переработки

As sustainability becomes increasingly important, the recyclability of materials used in water bottles is a significant selling point. Products that are 100% recyclable and made from eco-friendly materials cater to environmentally conscious consumers. B2B buyers should prioritize sustainable options to enhance brand reputation and appeal to a broader customer base.

What Are Common Trade Terms in the Insulated Bike Water Bottle Industry?

Familiarity with industry jargon can streamline communication and negotiations in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that may be marketed by another manufacturer. In the context of insulated bike water bottles, understanding OEM relationships can help buyers identify potential suppliers and assess product quality and customization options. -

MOQ (минимальное количество заказа)

MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, being aware of MOQ can inform purchasing decisions and inventory management, ensuring that orders align with market demand and cash flow considerations. -

RFQ (запрос котировок)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. Utilizing RFQs allows businesses to compare offers from multiple vendors, facilitating better negotiation outcomes and ensuring competitive pricing. -

Инкотермс (международные коммерческие термины)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms is essential for B2B transactions, as they dictate who bears the risk and cost at various stages of the shipping process. This knowledge helps buyers manage logistics and avoid unexpected expenses. -

Время выполнения

Lead time is the time taken from placing an order to its delivery. For B2B buyers, knowing the lead time is crucial for inventory planning and ensuring timely product availability, especially in fast-moving markets. -

Таможенные пошлины

These are tariffs imposed by governments on imported goods. Understanding customs duties is vital for international buyers to accurately calculate total costs and ensure compliance with trade regulations.

By grasping these technical properties and trade terms, B2B buyers can make more strategic decisions when sourcing insulated bike water bottles, ultimately enhancing their product offerings and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the insulated bike water bottles Sector

What Are the Current Market Dynamics and Key Trends in the Insulated Bike Water Bottles Sector?

The global market for insulated bike water bottles is currently experiencing robust growth, driven by rising health consciousness and an increasing number of outdoor activities. As consumers prioritize hydration while engaging in cycling, the demand for high-performance insulated bottles has surged. Particularly in regions like Africa, South America, the Middle East, and Europe, trends indicate a shift towards premium products that offer enhanced insulation capabilities and innovative features. For instance, bottles with double-wall vacuum insulation can keep beverages cold for over 12 hours, a critical selling point in hotter climates.

Emerging B2B tech trends are reshaping sourcing strategies. Digital platforms and e-commerce have revolutionized how businesses interact with suppliers, facilitating easier access to a wider range of products and manufacturers. International buyers can leverage data analytics to forecast demand and optimize inventory, ensuring they remain competitive. Additionally, customization options are gaining traction, allowing businesses to cater to specific consumer preferences, such as branding opportunities and personalized designs.

How Is Sustainability Influencing the Sourcing of Insulated Bike Water Bottles?

Sustainability is becoming a cornerstone of sourcing practices in the insulated bike water bottle market. With increasing scrutiny on environmental impact, B2B buyers are prioritizing suppliers that adhere to ethical and sustainable practices. This includes sourcing materials that are recyclable and free from harmful chemicals, such as BPA and phthalates, which are commonly found in plastic products.

Moreover, certifications such as ISO 14001 for environmental management and eco-labels for sustainable materials are gaining importance. Buyers are increasingly seeking products that not only perform well but also contribute to reducing environmental footprints. Brands that focus on sustainable production methods—such as using recycled stainless steel or biodegradable components—are more likely to resonate with environmentally conscious consumers. This shift not only enhances brand reputation but also aligns with the growing consumer preference for products that support a sustainable future.

What Is the Historical Context of Insulated Bike Water Bottles in the B2B Landscape?

The insulated bike water bottle market has evolved significantly over the past few decades. Initially dominated by simple plastic designs, the introduction of insulated technology marked a turning point. In the 1990s, companies began exploring double-walled designs that improved thermal retention, catering to the needs of serious cyclists who required reliable hydration solutions.

As cycling grew in popularity, particularly in urban areas and for recreational use, the market expanded to include a variety of materials and designs. Innovations such as stainless steel and BPA-free plastics gained traction, driven by consumer demand for durability and safety. Today, the sector is characterized by a diverse range of products that combine functionality, style, and sustainability, reflecting broader trends in consumer preferences and environmental consciousness. This evolution underscores the importance for B2B buyers to stay informed about advancements and shifts in the market to make well-informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of insulated bike water bottles

-

How do I choose the right insulated bike water bottle for my market?

When selecting insulated bike water bottles for your market, consider factors such as climate, target consumer preferences, and material durability. For regions with high temperatures, look for bottles that offer superior insulation (12+ hours cold retention). Investigate materials like stainless steel and BPA-free plastics that are compliant with safety regulations in your target market. Additionally, consider customization options to appeal to local tastes, such as color variations or branding opportunities, to enhance marketability. -

What are the key features to look for in insulated bike water bottles?

Key features to consider include insulation efficiency, material quality, ease of use, and cleaning convenience. Double-wall vacuum insulation ensures optimal temperature retention, while food-grade materials prevent taste transfer. Look for bottles with high-flow nozzles that facilitate easy drinking during rides. Additionally, features like a silicone grip can enhance usability in rugged conditions. Lastly, ensure the bottles are easy to disassemble for thorough cleaning, which is crucial for maintaining hygiene. -

What is the typical minimum order quantity (MOQ) for insulated bike water bottles?

The MOQ for insulated bike water bottles can vary significantly by supplier and customization requirements. Generally, it ranges from 500 to 1,000 units for standard models. However, for customized bottles, MOQs may increase to 2,000 units or more. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your business goals and market demand. -

How do I vet suppliers of insulated bike water bottles?

Vetting suppliers involves assessing their manufacturing capabilities, quality control processes, and compliance with international standards. Request samples to evaluate product quality and ensure they meet your specifications. Check for certifications, such as ISO or FDA compliance, which indicate adherence to safety and quality standards. Additionally, research supplier reviews and testimonials from other B2B buyers to gauge reliability and responsiveness before entering a partnership. -

What are common payment terms for purchasing insulated bike water bottles?

Payment terms can vary by supplier but typically include options like a 30% deposit upon order confirmation with the balance due before shipping. Some suppliers may offer net 30 or net 60 terms, allowing you to pay after receiving the goods. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card) and ensure they align with your financial processes. Establishing clear terms upfront can prevent misunderstandings and facilitate smoother transactions. -

How can I customize insulated bike water bottles for my brand?

Customization options may include color selection, logo printing, and unique packaging. Many suppliers offer services such as screen printing or laser engraving for logos, while others may provide color-matching options to align with your brand identity. Discuss your customization needs early in the sourcing process to ensure suppliers can accommodate your requests. Additionally, verify the costs associated with customization to factor them into your pricing strategy. -

What quality assurance processes should be in place for insulated bike water bottles?

Quality assurance processes should include pre-production samples, in-line inspections, and final product testing. Request detailed documentation on the supplier’s quality control procedures, including material sourcing and testing for insulation performance. Conducting regular audits or third-party inspections can further ensure compliance with your quality standards. Establishing a clear quality agreement with your supplier will help mitigate risks associated with product defects. -

What logistics considerations should I keep in mind when importing insulated bike water bottles?

Logistics considerations include shipping methods, customs regulations, and lead times. Determine whether air freight or sea freight is more cost-effective based on your urgency and budget. Familiarize yourself with import tariffs and regulations in your destination country, as these can impact overall costs. Additionally, communicate with your supplier about lead times and production schedules to ensure timely delivery, especially if you’re planning to launch a product during peak seasons.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимый и тщательный due diligence. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.

Top 7 Insulated Bike Water Bottles Manufacturers & Suppliers List

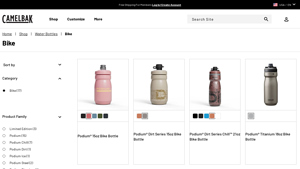

1. CamelBak – Podium® Bike Bottles

Домен: camelbak.com

Зарегистрирован: 1996 (29 лет)

Введение: [{‘name’: ‘Podium® 15oz Bike Bottle’, ‘price’: ‘$12.00’}, {‘name’: ‘Podium® Dirt Series 15oz Bike Bottle’, ‘price’: ‘$15.00’}, {‘name’: ‘Podium® Dirt Series Chill™ 21oz Bike Bottle’, ‘price’: ‘$19.00 – $21.00’}, {‘name’: ‘Podium® Titanium 18oz Bike Bottle’, ‘price’: ‘$100.00’}, {‘name’: ‘Podium® Steel 22oz Bike Bottle’, ‘price’: ‘$44.00’}, {‘name’: ‘Podium® Chill™ 21oz Bike Bottle’, ‘price’: ‘$16….

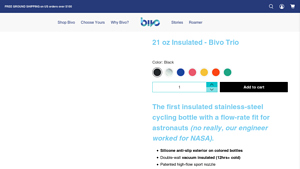

2. Bivo – Insulated Cycling Bottle

Домен: drinkbivo.com

Зарегистрирован: 2019 (6 лет)

Введение: {“product_name”: “Bivo Insulated Cycling Bottle – Stainless Steel – 21 oz”, “price”: “$49”, “colors”: [“Black”, “Raw”, “True Blue”, “Strawberry”, “Sun”, “Tomato”, “Turquoise”], “capacity”: “21 oz (621 ml)”, “weight”: “270 g”, “dimensions”: {“height”: “10.23” (260 mm)”, “diameter”: “3” (77 mm)}, “features”: [“First insulated stainless-steel cycling bottle with a flow-rate fit for astronauts”, “Sili…

3. Camelbak – Podium Insulated Cycling Bottle

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Camelbak Podium insulated cycling bottle; features include: quick flow nozzle, dishwasher safe, easy to clean, durable, available in many colors and sizes. There are different models: regular Podium, Podium insulated, and Podium chill (which has better insulation but is larger for the same capacity).

4. Escape Collective – Bivo Trio & CamelBak Podium Bottles

Домен: escapecollective.com

Зарегистрирован: 2017 (8 лет)

Введение: Bivo Trio: 500 mL (17 oz) and 620 mL (21 oz) sizes, available in 3 colors (Mini) and 5 colors (larger). Price: US$39-49. CamelBak Podium insulated stainless steel: 530 mL (18 oz) and 650 mL (22 oz) sizes, available in 6 colors. Price: US$35-40. CamelBak Podium insulated titanium: 530 mL (18 oz) size, raw brushed finish. Price: US$100. Performance: Bivo Trio and CamelBak Podium Ti reached 3°C (37°F…

5. Bicycling – Best Insulated Water Bottles

Домен: bicycling.com

Зарегистрирован: 1999 (26 лет)

Введение: Best Stainless Insulated: CamelBak Podium Steel (non-chilled, 3 hours)\nBest Plastic Insulated: Specialized Purist Insulated (pre-chilled, 90 mins)\nBest Riding Stainless Insulated: Bivo Insulated Trio\nBest Riding Plastic Insulated: Elite IceFly 500mL and RockBros Insulated\nTested 5 metal-insulated, 7 plastic-insulated, and 3 non-insulated bottles.\nInsulated Bottle Types: Plastic and Metal.\nSt…

6. Camelbak – Insulated Cycling Water Bottles

Домен: performancebike.com

Зарегистрирован: 1996 (29 лет)

Введение: Cycling Water Bottles available from top brands including Camelbak, Cannondale, Specialized, and more. Features include insulated options, various sizes (ranging from 18.5oz to 36oz), and styles such as screw top and squeeze bidons. Prices range from $5.30 to $44.00. Notable products include Camelbak Podium Chill Insulated Water Bottle, Cannondale Gripper Logo Water Bottle, and Specialized Purist …

7. Bicycle Warehouse – Bike Water Bottles

Домен: bicyclewarehouse.com

Зарегистрирован: 1998 (27 лет)

Введение: This company, Bicycle Warehouse – Bike Water Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for insulated bike water bottles

In the rapidly evolving market for insulated bike water bottles, strategic sourcing emerges as a crucial component for international B2B buyers. The diverse range of products available—from budget-friendly options to high-end models—underscores the importance of understanding customer needs and market trends. Buyers should prioritize suppliers who offer innovative features such as double-wall insulation, eco-friendly materials, and high-flow nozzles, as these attributes significantly enhance the user experience and drive sales.

Furthermore, the increasing demand for sustainable products presents an opportunity to align sourcing strategies with environmental responsibility. This is particularly relevant in regions like Africa, South America, the Middle East, and Europe, where consumer awareness and preference for sustainable goods are on the rise. By fostering relationships with manufacturers who prioritize sustainable practices, businesses can not only meet market demands but also enhance their brand reputation.

Looking ahead, B2B buyers are encouraged to conduct thorough market analyses and leverage data-driven insights to make informed sourcing decisions. Embrace the potential of insulated bike water bottles as a key product category that can drive growth and customer satisfaction. Now is the time to invest in strategic partnerships that will position your business advantageously in a competitive landscape.