Introduction: Navigating the Global Market for bottle screen printing

In today’s competitive landscape, navigating the global market for bottle screen printing presents unique challenges for B2B buyers. As businesses aim to enhance brand visibility and product appeal, sourcing reliable printing solutions that align with quality expectations and budget constraints becomes paramount. This comprehensive guide delves into the multifaceted world of bottle screen printing, covering everything from the various types of printing techniques and their applications to essential supplier vetting processes and cost considerations.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—will find actionable insights tailored to their specific needs. The guide highlights critical factors such as material compatibility, design specifications, and production scalability, enabling informed purchasing decisions that can significantly impact brand success.

Moreover, by understanding the nuances of screen printing on both glass and plastic bottles, businesses can leverage this decorative method to create lasting impressions that differentiate their products in crowded marketplaces. Whether you’re a startup looking for small batch solutions or an established company aiming for large-scale production, this guide empowers you with the knowledge to select the right partners and optimize your bottle branding strategies effectively.

Навигация по статье

- Top 6 Bottle Screen Printing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle screen printing

- Understanding bottle screen printing Types and Variations

- Key Industrial Applications of bottle screen printing

- 3 Common User Pain Points for ‘bottle screen printing’ & Their Solutions

- Strategic Material Selection Guide for bottle screen printing

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle screen printing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle screen printing’

- Comprehensive Cost and Pricing Analysis for bottle screen printing Sourcing

- Alternatives Analysis: Comparing bottle screen printing With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle screen printing

- Navigating Market Dynamics and Sourcing Trends in the bottle screen printing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle screen printing

- Важный отказ от ответственности и условия использования

- Strategic Sourcing Conclusion and Outlook for bottle screen printing

Understanding bottle screen printing Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Glass Bottle Screen Printing | Direct ink application on glass, permanent and waterproof designs | Beverage, cosmetics, and food packaging | Плюсы: Durable, high-quality finish; Конс: Higher initial setup costs. |

| Plastic Bottle Screen Printing | Flexible materials suitable for various bottle shapes and sizes | Personal care products, chemicals, and beverages | Плюсы: Lightweight, cost-effective; Конс: May have lower durability compared to glass. |

| Silk Screen Printing | Uses a mesh screen for ink transfer, suitable for complex designs | Specialty products like CBD oils, cosmetics | Плюсы: High detail and color vibrancy; Конс: Limited to specific types of inks and substrates. |

| Multi-Color Printing | Capability to print multiple colors in one pass | High-end products requiring intricate branding | Плюсы: Eye-catching designs; Конс: Increased complexity and cost. |

| Frosted Glass Printing | Unique texture and appearance, often requires additional vessels | Premium beverage and cosmetic packaging | Плюсы: Distinctive look; Конс: Higher production requirements and costs. |

What are the Characteristics of Glass Bottle Screen Printing?

Glass bottle screen printing involves applying ink directly onto the glass surface, creating permanent and waterproof designs. This method is ideal for industries such as beverage and cosmetics, where a high-quality finish can enhance product appeal. Buyers should consider the initial setup costs, which can be higher than other printing methods, but the durability and aesthetic advantages often justify the investment.

How Does Plastic Bottle Screen Printing Differ?

Plastic bottle screen printing offers flexibility in terms of bottle shapes and sizes, making it suitable for a wide range of applications, including personal care products and chemicals. This method tends to be more cost-effective than glass printing, appealing to businesses looking to minimize expenses. However, buyers should note that plastic prints may not be as durable as glass, which could impact long-term branding effectiveness.

What are the Benefits of Silk Screen Printing?

Silk screen printing utilizes a mesh screen to transfer ink, allowing for intricate designs and vibrant colors. This technique is particularly popular for specialty products like CBD oils and cosmetics, where brand differentiation is crucial. While the quality of the print is a significant advantage, businesses should be aware of the limitations regarding ink types and substrate compatibility, which may affect design choices.

What Should Buyers Know About Multi-Color Printing?

Multi-color printing enables brands to create eye-catching designs that can significantly enhance shelf appeal. This method is particularly valuable for high-end products that require intricate branding. However, the complexity of the printing process can lead to increased costs and production time, making it essential for buyers to assess whether the investment aligns with their marketing strategy.

Why Consider Frosted Glass Printing?

Frosted glass printing provides a unique texture and appearance that can set a product apart in a competitive market. It is often used for premium beverages and cosmetic packaging, appealing to consumers looking for luxury items. However, buyers should consider the additional production requirements and costs associated with this method, as it typically requires more vessels to ensure quality outputs.

Key Industrial Applications of bottle screen printing

| Промышленность/сектор | Specific Application of bottle screen printing | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Beverage | Custom branding on beer, wine, and spirit bottles | Enhances brand visibility and consumer appeal | Ensure compatibility with bottle materials and design specifics |

| Cosmetics | Screen printing on makeup and skincare product containers | Creates a premium look and feel, enhancing product perception | Consider ink durability and safety for skin contact |

| Food & Beverage Packaging | Printing labels for sauces, oils, and condiments | Provides a waterproof, tear-resistant alternative to labels | Check for food-safe inks and compliance with local regulations |

| CBD and Health Products | Branding on CBD tincture and supplement bottles | Establishes brand identity in a competitive market | Verify compliance with regional health regulations |

| Home Fragrance | Printing on candle jars and diffuser bottles | Differentiates products on retail shelves | Assess printing techniques suitable for glass and ceramic |

How Is Bottle Screen Printing Applied in the Beverage Industry?

In the beverage sector, bottle screen printing is extensively used for custom branding on beer, wine, and spirit bottles. This method allows manufacturers to create eye-catching designs that enhance brand visibility and attract consumers in a crowded market. The direct application of ink on glass ensures durability and resistance to wear, making it a preferred choice over traditional labels. International buyers should consider the compatibility of their bottle materials with printing processes and ensure that designs meet local aesthetic standards.

What Role Does Bottle Screen Printing Play in Cosmetics Packaging?

In the cosmetics industry, screen printing is utilized to decorate makeup and skincare product containers. This application not only provides a premium appearance but also conveys brand messaging effectively. With the trend towards sustainable packaging, screen printing offers a permanent solution that avoids the use of paper labels, which can tear or stain. Buyers must ensure that the inks used are durable and safe for skin contact, adhering to international regulations for cosmetic products.

Why Is Bottle Screen Printing Important for Food & Beverage Packaging?

Bottle screen printing is crucial for food packaging, especially for sauces, oils, and condiments. This technique provides a waterproof and tear-resistant alternative to paper labels, ensuring that branding remains intact throughout the product’s lifecycle. The ability to print directly onto glass or plastic enhances the product’s shelf appeal, which is vital in competitive markets. Buyers should prioritize sourcing inks that are food-safe and compliant with local health regulations to maintain consumer safety.

How Does Bottle Screen Printing Benefit CBD and Health Products?

In the rapidly growing CBD and health products market, screen printing is vital for branding tincture and supplement bottles. This method allows for intricate designs that help establish a strong brand identity in a competitive landscape. Furthermore, the permanence of the print ensures that branding remains intact, which is essential for consumer trust. Buyers should focus on compliance with regional health regulations, as well as the durability of the inks used, to ensure product integrity.

What Advantages Does Bottle Screen Printing Offer for Home Fragrance Products?

Bottle screen printing is widely used in the home fragrance industry for decorating candle jars and diffuser bottles. This application differentiates products on retail shelves, making them visually appealing to consumers. The durability of screen-printed designs ensures longevity, which is particularly important for items that may be exposed to heat or moisture. Buyers should assess the suitability of printing techniques for various materials, such as glass or ceramic, to achieve the desired aesthetic and functional outcomes.

3 Common User Pain Points for ‘bottle screen printing’ & Their Solutions

Scenario 1: Navigating Minimum Order Quantities for Custom Designs

Проблема: Many B2B buyers, especially small businesses and startups, find themselves frustrated by the minimum order quantities (MOQs) imposed by bottle screen printing suppliers. These MOQs can often be prohibitive for companies that are just entering the market or testing new product lines. For instance, a small craft beverage producer may want to launch a limited edition bottle design, but the supplier’s MOQ of 500 units makes this financially unviable.

Решение: To navigate this challenge, buyers should look for printing companies that offer flexible printing options without strict minimums. Suppliers like Bottles and Print cater to small order needs, allowing buyers to produce as few as 10 bottles. When approaching potential suppliers, it’s essential to communicate your specific requirements clearly. Inquire about their policies on small runs and ask for samples of previous work. Additionally, consider collaborating with other small businesses to pool orders, thus meeting MOQ requirements while sharing costs. This cooperative approach can also foster community ties within the industry.

Scenario 2: Ensuring Color Accuracy and Quality Control

Проблема: Achieving precise color matching and consistent quality across batches is a significant concern for B2B buyers in bottle screen printing. When launching a product, a company needs to ensure that its branding is represented accurately, as any discrepancies can lead to consumer distrust and damage to brand reputation. For example, a cosmetic brand may require specific Pantone colors for their packaging, and any variations could undermine their marketing efforts.

Решение: To address color accuracy, buyers should work closely with their printing partner from the outset. Request a detailed color proof before the production run begins, using a Pantone color guide for reference. It’s advisable to provide the supplier with physical samples whenever possible, as this helps in achieving a more accurate match. Additionally, establishing a quality control process during production can help catch inconsistencies early. Consider scheduling regular check-ins with the printer and requesting updates on the production process to ensure that the output aligns with your expectations. This proactive communication helps in maintaining the integrity of the brand’s visual identity.

Scenario 3: Overcoming Design File Challenges for Effective Printing

Проблема: A common pain point for B2B buyers is the technical complexity involved in preparing design files for bottle screen printing. Many companies may lack in-house graphic design expertise, resulting in delays and potential errors in the printing process. For instance, a food product company may submit a bitmap image instead of a vector file, leading to poor-quality prints and additional costs for revisions.

Решение: To mitigate design file challenges, companies should invest time in understanding the requirements for print-ready files. Engage a professional graphic designer familiar with screen printing specifications to create the necessary artwork. Suppliers often provide guidelines or resources for preparing files, so take advantage of these offerings. Additionally, consider requesting a preflight check from the printer before the production stage to catch any issues early. Establishing a checklist that includes file format, color settings, and resolution can streamline the submission process and reduce the likelihood of costly mistakes, ensuring a smoother path from design to finished product.

Strategic Material Selection Guide for bottle screen printing

What Are the Key Materials for Bottle Screen Printing?

Bottle screen printing is a specialized process that requires careful consideration of the materials used for both the bottles and the inks. Below, we analyze four common materials—glass, plastic, metal, and ceramic—focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Glass Perform in Bottle Screen Printing?

Ключевые свойства: Glass is a non-porous material with excellent clarity and a smooth surface, making it ideal for high-quality printing. It can withstand high temperatures and is resistant to corrosion, ensuring that printed designs remain intact over time.

Плюсы и минусы: The durability of glass is one of its primary advantages; it is resistant to tearing and wrinkling, unlike paper labels. However, glass can be more expensive to produce and transport due to its weight and fragility. Additionally, the manufacturing process can be complex, requiring precise handling to avoid breakage.

Влияние на применение: Glass is compatible with a variety of inks, including metallics and custom colors. However, it requires careful handling during the printing process to avoid defects.

Соображения для международных покупателей: Buyers from regions like Africa and South America should consider local regulations regarding glass packaging, as well as the potential for breakage during shipping. Compliance with international standards such as ASTM can also be a factor in selecting glass as a material.

What Are the Advantages of Plastic in Bottle Screen Printing?

Ключевые свойства: Plastic bottles are lightweight, flexible, and resistant to impact. They can be produced in various forms, including PET and HDPE, which offer good chemical resistance and durability.

Плюсы и минусы: The primary advantage of plastic is its lower cost and ease of manufacturing. However, the print quality may not match that of glass, and plastics can be susceptible to scratching and fading over time. Additionally, environmental concerns regarding plastic waste are increasingly influencing buyer preferences.

Влияние на применение: Plastic is suitable for a wide range of products, from beverages to personal care items. However, the choice of ink must be compatible with the plastic type to ensure adhesion and durability.

Соображения для международных покупателей: Buyers in Europe, particularly in Germany, may face stricter regulations on plastic use, emphasizing the need for compliance with EU directives on packaging. Understanding local recycling policies is also crucial.

How Does Metal Compare for Bottle Screen Printing?

Ключевые свойства: Metal bottles, often made from aluminum or stainless steel, offer excellent durability and resistance to corrosion. They can withstand extreme temperatures and pressures, making them suitable for a variety of applications.

Плюсы и минусы: The key advantage of metal is its strength and longevity, which can enhance the shelf life of products. However, metal can be more expensive than glass or plastic, and the printing process may require specialized inks to adhere properly.

Влияние на применение: Metal is particularly well-suited for beverages and products requiring a robust container. However, the need for specialized inks can complicate the printing process.

Соображения для международных покупателей: Compliance with standards such as JIS in Japan or ASTM in the U.S. is essential for metal products. Buyers should also consider the environmental impact of metal production and recycling options available in their region.

What Role Does Ceramic Play in Bottle Screen Printing?

Ключевые свойства: Ceramic bottles are known for their aesthetic appeal and excellent resistance to chemical interactions. They can withstand high temperatures, making them suitable for products like sauces and oils.

Плюсы и минусы: The primary advantage of ceramic is its premium look and feel, which can enhance brand perception. However, ceramics are heavy and fragile, leading to higher shipping costs and breakage risks.

Влияние на применение: Ceramic is ideal for high-end products, but the printing process can be more complex and may require additional curing steps.

Соображения для международных покупателей: Buyers should be aware of the fragility of ceramic and the potential need for protective packaging during shipping. Compliance with local regulations regarding food safety and packaging materials is also critical.

Summary Table of Material Selection for Bottle Screen Printing

| Материал | Typical Use Case for bottle screen printing | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Стекло | Beverage bottles, cosmetics | High durability, premium appearance | Fragile, higher shipping costs | Высокий |

| Пластик | Personal care products, beverages | Lightweight, cost-effective | Lower print quality, environmental concerns | Средний |

| Metal | Energy drinks, premium beverages | Excellent durability, temperature resistance | Higher cost, specialized inks needed | Высокий |

| Ceramic | Sauces, oils, luxury items | Aesthetic appeal, chemical resistance | Heavy, fragile | Высокий |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their bottle screen printing processes. Understanding the properties and implications of each material can help in making informed decisions that align with product requirements and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for bottle screen printing

What Are the Main Stages in the Manufacturing Process of Bottle Screen Printing?

Bottle screen printing involves several key stages, each critical to ensuring a high-quality finished product. The primary stages include material preparation, printing, drying, curing, and finishing.

-

Подготовка материалов: The process begins with selecting appropriate glass or plastic bottles. Each type of material has its own specifications and requirements, which must be adhered to for successful printing. Bottles must be clean and free from contaminants, which can affect ink adhesion. This stage often includes a thorough inspection of the bottles for imperfections or inconsistencies.

-

Printing: Screen printing itself is a technique that involves transferring ink through a mesh screen, where a stencil blocks certain areas to create the desired design. This method is favored for its durability and vibrant colors. The inks used are typically UV-cured or ceramic, which provide excellent adhesion and resistance to wear and environmental factors. Each color in the design requires a separate screen, making this stage highly meticulous.

-

Drying and Curing: After printing, the bottles must be dried and cured to ensure the ink adheres properly. Drying can occur through various methods, including air drying or using heat lamps. Curing is often done with UV light or heat, depending on the ink type used. This step is crucial for achieving the desired durability and longevity of the print.

-

Отделка: The final stage involves quality checks and any necessary finishing touches, such as applying protective coatings or additional treatments to enhance the bottle’s appearance. This step may also include labeling or packaging the bottles for shipment.

What Key Techniques Are Used in Bottle Screen Printing?

Several techniques are employed in bottle screen printing to enhance quality and efficiency. These include:

-

Multi-Color Printing: This technique allows for complex designs by using multiple screens, each dedicated to a specific color. Precision registration is critical to ensure that colors align correctly.

-

High-Resolution Printing: Advanced printing technology enables high-resolution designs that capture intricate details. This is particularly important for brands looking to create a strong visual impact.

-

Custom Ink Formulations: Suppliers often offer custom ink colors and formulations to match brand specifications. This can include special effects like metallic finishes or matte coatings.

How Is Quality Assurance Maintained in Bottle Screen Printing?

Quality assurance in bottle screen printing is vital for ensuring consistency and meeting customer expectations. Key international standards and industry-specific certifications play a significant role in this process.

-

International Standards: Adherence to ISO 9001 is common in the bottle printing industry, focusing on quality management systems. This certification ensures that companies maintain high standards throughout their manufacturing processes.

-

Industry-Specific Standards: Depending on the market, additional certifications may be required. For instance, CE marking may be necessary for products sold in Europe, while API certification could be crucial for medical or pharmaceutical containers.

-

Контрольные точки контроля качества: Quality control involves several checkpoints throughout the manufacturing process:

– Входящий контроль качества (IQC): This initial stage involves inspecting raw materials and bottles before production begins.

– Внутрипроцессный контроль качества (IPQC): During production, ongoing checks are conducted to monitor the printing process and ensure that the output meets established standards.

– Окончательный контроль качества (ОКК): After printing and curing, a final inspection is performed to assess the overall quality and appearance of the finished product.

What Common Testing Methods Are Used to Ensure Quality in Bottle Screen Printing?

Common testing methods used in the quality assurance of screen-printed bottles include:

-

Adhesion Testing: This measures how well the ink adheres to the surface of the bottle. Tape tests or scratch tests can be used to evaluate adhesion strength.

-

Испытание на долговечность: Printed bottles are subjected to wear and tear assessments, including exposure to chemicals, UV light, and mechanical abrasion to simulate real-world conditions.

-

Visual Inspections: Trained quality control personnel perform visual inspections to check for color consistency, clarity of design, and any defects in the print.

Как покупатели B2B могут проверить практику контроля качества поставщиков?

For international B2B buyers, ensuring that suppliers adhere to robust quality control practices is essential. Here are some actionable steps:

-

Аудиты поставщиков: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes reviewing their quality management systems and compliance with international standards.

-

Requesting Quality Reports: Buyers should request and review quality assurance reports, including details about testing methods, results, and corrective actions taken for any identified issues.

-

Проверки третьих сторон: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. This is especially important for buyers in regions with varying quality standards.

Каковы нюансы контроля качества и сертификации для международных покупателей B2B?

International buyers must navigate several nuances related to quality control and certification, particularly when sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

-

Understanding Local Standards: Different regions may have unique quality standards and regulations. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Language Barriers: Communication can pose challenges when verifying quality control practices. Buyers should ensure that they can effectively communicate their requirements and understand the supplier’s quality documentation.

-

Cultural Differences: Cultural attitudes towards quality and customer service can vary significantly. Building strong relationships and clear communication with suppliers can help mitigate misunderstandings and ensure that quality expectations are met.

By understanding the manufacturing processes and quality assurance practices in bottle screen printing, B2B buyers can make informed decisions, ensuring that their products not only meet their branding needs but also adhere to the highest quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle screen printing’

To assist international B2B buyers in navigating the complexities of bottle screen printing, this guide provides a clear, actionable checklist. Each step is designed to ensure that you make informed decisions while sourcing your printing needs.

Шаг 1: Определите технические характеристики

Begin by outlining the specific requirements for your bottle printing project. This includes the type of bottles (glass or plastic), dimensions, shape (cylindrical or flat-sided), and surface characteristics. Knowing these details is crucial, as they dictate which printing processes and inks can be used effectively.

Шаг 2: Исследование потенциальных поставщиков

Conduct thorough research to identify suppliers that specialize in bottle screen printing. Look for companies with a proven track record in your industry. Evaluate their online presence, client testimonials, and case studies to gauge their reliability and quality of work.

- Tip: Consider reaching out to suppliers for references from clients in similar markets or regions to gain insights into their performance.

Шаг 3: Evaluate Production Capabilities

Assess the production capabilities of your shortlisted suppliers. Inquire about their minimum order quantities, lead times, and capacity for both small and large runs. This is particularly important if your business requires flexibility in order sizes or quick turnaround times.

- Tip: Suppliers with a history of handling diverse project sizes often have more robust quality control processes in place.

Шаг 4: Verify Quality Control Measures

Quality is paramount in bottle screen printing, as it directly impacts brand perception. Ensure that the suppliers you consider have stringent quality control measures in place. Ask about their processes for monitoring print consistency and accuracy, and whether they conduct pre-production proofs.

Шаг 5: Understand Ink and Material Options

Different suppliers may offer various ink types and application techniques. Familiarize yourself with the options available, such as UV inks, water-based inks, or metallic finishes. Consider how these choices align with your branding and product requirements.

- Tip: Discuss color matching services, especially if you have specific brand colors that need to be replicated accurately.

Шаг 6: Request Quotes and Compare Pricing

Once you have defined your project specifics and vetted potential suppliers, request detailed quotes. Compare pricing not only based on the cost per unit but also consider additional factors like setup fees, shipping costs, and any minimum order requirements.

- Tip: A lower price doesn’t always equate to better value; ensure that you are comparing similar service levels and product quality.

Шаг 7: Finalize Agreements and Terms

Before proceeding, carefully review the contract terms with your chosen supplier. Pay attention to aspects like payment terms, delivery schedules, and any penalties for delays or quality issues. Clear agreements help prevent misunderstandings and ensure a smoother collaboration.

By following this checklist, you can confidently navigate the sourcing process for bottle screen printing, ensuring that your products meet your branding needs while maintaining high quality and service standards.

Comprehensive Cost and Pricing Analysis for bottle screen printing Sourcing

What Are the Key Cost Components in Bottle Screen Printing?

When evaluating the costs associated with bottle screen printing, several critical components come into play. Understanding these can help international B2B buyers make informed decisions.

-

Материалы: The type of bottle material (glass or plastic) significantly impacts the cost. Glass bottles tend to be more expensive due to higher raw material costs and processing requirements. Additionally, the choice of inks (e.g., standard colors versus custom Pantone matches) can affect the overall material expense.

-

Труд: Labor costs are determined by the complexity of the design and the printing process. Skilled labor is essential for setup, operation, and quality control. High-quality craftsmanship can lead to higher labor costs but often results in superior print quality.

-

Производственные накладные расходы: This includes expenses related to equipment maintenance, utilities, and facility costs. Efficient production processes can help minimize overhead, but buyers should consider these costs when assessing overall pricing.

-

Инструментальная оснастка: Initial tooling costs for screens and stencils can be significant, especially for custom designs. While some suppliers may absorb these costs into the unit price, others may charge them upfront, affecting the initial order cost.

-

Контроль качества (QC): Ensuring that each printed bottle meets quality standards incurs additional costs. This may include inspections and testing, particularly for products that require certifications or adhere to specific industry regulations.

-

Логистика: Shipping costs can vary widely based on the supplier’s location, the shipping method chosen, and the Incoterms agreed upon. International buyers should factor in customs duties and potential tariffs when sourcing from abroad.

-

Маржа: Suppliers typically add a profit margin to their costs. Understanding the average market margins can help buyers negotiate better pricing.

How Do Price Influencers Affect Bottle Screen Printing Costs?

Several factors can influence the pricing of bottle screen printing, particularly for international buyers:

-

Объем и минимальное количество заказа (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. However, suppliers may impose MOQs, which can impact smaller businesses or those testing new products.

-

Технические характеристики и персонализация: Custom designs and specific requirements (e.g., unique shapes or colors) can increase costs. Buyers should communicate their needs clearly to receive accurate quotes.

-

Качество материалов и сертификаты: Higher quality materials or those that meet specific certifications (e.g., food-safe, eco-friendly) can lead to increased costs. Buyers should evaluate the importance of these factors in relation to their brand and target market.

-

Факторы поставщика: Supplier experience, reputation, and production capabilities can affect pricing. Established suppliers may charge more for their expertise and reliability but may also deliver superior quality and service.

-

Инкотермс: The agreed-upon Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs. Buyers should choose terms that align with their logistics capabilities and risk tolerance.

What Tips Can Help Buyers Negotiate Better Pricing?

-

Переговоры: Always be prepared to negotiate. Understanding market rates and your specific needs can provide leverage during discussions with suppliers.

-

Экономическая эффективность: Consider the total cost of ownership, not just the upfront price. Factors such as durability, shelf appeal, and the potential for returns due to quality issues should be included in your calculations.

-

Нюансы ценообразования для международных покупателей: Be aware of currency fluctuations, customs duties, and shipping delays when sourcing internationally. Building strong relationships with suppliers can lead to more favorable terms and pricing adjustments.

-

Exploring Multiple Suppliers: Don’t settle for the first quote. Engaging with multiple suppliers can provide insights into competitive pricing and service options.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to volume discounts and priority service, ultimately reducing costs.

Disclaimer

The prices and cost structures mentioned are indicative and can vary based on specific project requirements, market conditions, and supplier negotiations. Always consult with multiple suppliers for the most accurate quotes tailored to your needs.

Alternatives Analysis: Comparing bottle screen printing With Other Solutions

Understanding Alternatives to Bottle Screen Printing

When it comes to branding and packaging solutions for bottles, businesses often explore various printing methods to find the best fit for their products. Bottle screen printing is a popular choice, but several alternative solutions can also achieve similar branding goals. This section will compare bottle screen printing against other viable methods, helping B2B buyers make informed decisions.

Сравнительная таблица

| Сравнительный аспект | Bottle Screen Printing | Digital Printing | Paper Labeling |

|---|---|---|---|

| Производительность | High durability; waterproof and resistant to wear | Good quality but may fade over time | Moderate durability; susceptible to tearing and staining |

| Стоимость | Higher initial setup cost, but lower cost per unit for large runs | Lower setup cost; higher cost per unit for small runs | Generally low initial costs; variable based on quality |

| Простота реализации | Requires design preparation and specific bottle shapes | Flexible design changes; easy to implement | Simple to apply; requires no special equipment |

| Техническое обслуживание | Minimal once set up; long-lasting | Requires regular maintenance for printers | Low maintenance; easy to replace |

| Лучший пример использования | Ideal for high-end products needing permanence | Best for short runs and variable data | Suitable for cost-sensitive products with frequent design changes |

Подробный анализ альтернатив

Digital Printing

Digital printing involves applying designs directly onto bottles using inkjet technology. This method allows for high-quality, full-color images and is particularly effective for short runs or customized products. One of the main advantages of digital printing is its flexibility; businesses can easily change designs without significant setup costs. However, the durability of digital prints may not match that of screen-printed designs, as they can fade or wear off with time, especially if exposed to harsh conditions.

Paper Labeling

Paper labeling is a traditional method where printed paper labels are affixed to bottles. This approach is cost-effective, particularly for businesses that require frequent design changes or low-volume production. The initial investment is generally lower than screen printing, making it accessible for small businesses. However, paper labels have notable downsides, including susceptibility to damage from moisture, tearing, and staining. This method may not be ideal for products that require a premium look or durability.

Conclusion: How to Choose the Right Printing Solution

Selecting the right printing method for your bottles ultimately depends on your specific needs and product requirements. If your brand emphasizes high quality and durability, bottle screen printing may be the best choice, particularly for products in competitive markets where shelf appeal is critical. Alternatively, if you prioritize flexibility and lower initial costs, digital printing could be more suitable, especially for short production runs. Lastly, paper labeling might be the right fit for budget-conscious businesses or those needing frequent design changes. Assessing your product’s market positioning, volume needs, and budget constraints will guide you in making the optimal choice.

Essential Technical Properties and Trade Terminology for bottle screen printing

What Are the Key Technical Properties in Bottle Screen Printing?

Understanding the essential technical properties in bottle screen printing can significantly influence your production process and final product quality. Here are some critical specifications that every B2B buyer should be aware of:

1. Material Compatibility

The type of glass or plastic used for bottles directly affects the printing process. Glass is preferred for its durability and aesthetic appeal, especially in sectors like wine and spirits. Plastic, on the other hand, offers flexibility and is lightweight, making it suitable for a broader range of consumer goods. Ensuring that the printing inks and techniques are compatible with the chosen material is vital for achieving optimal results.

2. Surface Tolerance

Surface tolerance refers to the smoothness and evenness of the bottle’s surface. Bottles must have a smooth surface for effective ink adhesion. Irregular surfaces can lead to misprints or poor-quality finishes. This is especially important in high-volume production where consistency is key to maintaining brand integrity.

3. Ink Adhesion Quality

The quality of ink adhesion is crucial for the longevity of the printed design. Inks must bond effectively with the bottle surface to ensure resistance to abrasion, moisture, and UV exposure. This property is essential for maintaining the visual appeal of the product throughout its shelf life, making it a critical consideration for brands that prioritize quality.

4. Color Accuracy

Color accuracy is paramount in bottle screen printing, especially for brands that rely on specific color palettes for their identity. Using the Pantone Matching System (PMS) allows for consistent color reproduction across different batches. Variations can lead to consumer confusion and dilution of brand identity, so ensuring precise color matching is essential for B2B buyers.

5. Print Coverage Area

This specification defines the area of the bottle that will be printed. Understanding print coverage is important for cost estimation and design planning. Larger coverage areas may require more ink and time, impacting overall production costs. Buyers should be clear about their design requirements to optimize their budget.

What Are Common Trade Terms in Bottle Screen Printing?

Familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are some common terms used in bottle screen printing:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are then branded and sold by another company. Understanding the OEM process is vital for B2B buyers who want to ensure that the manufacturing aligns with their brand standards and quality expectations.

2. MOQ (минимальное количество заказа)

MOQ indicates the smallest number of units a supplier is willing to produce for an order. This term is crucial for budget planning, as higher MOQs can affect cash flow, especially for small businesses or startups. Buyers should negotiate MOQs that align with their production needs.

3. RFQ (запрос котировок)

An RFQ is a document that solicits price proposals from suppliers. It typically includes specifications about the printing process, materials, and quantities. Submitting a well-defined RFQ can lead to more accurate quotes and better supplier responses.

4. Инкотермс (международные коммерческие термины)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for B2B buyers to clarify shipping responsibilities, insurance, and risk management during transit.

5. Время выполнения

Lead time refers to the period from placing an order to delivery. In bottle screen printing, lead times can vary based on order size and complexity. Understanding lead time is critical for inventory management and ensuring timely product launches.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline their procurement processes, and enhance their product offerings in the competitive bottle screen printing market.

Navigating Market Dynamics and Sourcing Trends in the bottle screen printing Sector

What are the Key Trends Influencing the Global Bottle Screen Printing Market?

The bottle screen printing market is currently experiencing significant growth driven by a combination of consumer preferences, technological advancements, and sustainability concerns. As brands increasingly recognize the importance of distinctive packaging in a crowded marketplace, screen printing offers a robust solution with its ability to produce high-quality, permanent designs directly on glass and plastic surfaces. This trend is particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where local craftsmanship and unique branding are becoming focal points for market differentiation.

Emerging technologies in digital printing and automation are reshaping the landscape, allowing for faster production times and lower costs even for small runs. This flexibility is crucial for new businesses and entrepreneurs looking to enter the market without the burden of minimum order quantities. Additionally, customization options are expanding, with suppliers offering a variety of inks and finishes that cater to diverse branding needs.

Buyers should also be aware of the market dynamics that affect sourcing strategies. For instance, regional supply chain challenges, such as logistics and material availability, can impact lead times and pricing. Understanding these factors is essential for effective planning and procurement in the bottle screen printing sector.

How is Sustainability Shaping the Bottle Screen Printing Industry?

Sustainability is no longer just a buzzword; it has become a critical factor in the decision-making process for B2B buyers in the bottle screen printing sector. The environmental impact of packaging materials is under increasing scrutiny, prompting brands to seek out sustainable options. This includes using eco-friendly inks, recyclable materials, and energy-efficient printing processes.

Ethical sourcing is also gaining traction, with buyers increasingly prioritizing suppliers that adhere to sustainable practices and transparency in their supply chains. Certifications such as FSC (Forest Stewardship Council) for paper products and ISO certifications for environmental management systems are becoming prerequisites for many businesses. These certifications not only enhance brand reputation but also align with the growing consumer demand for responsible practices.

Moreover, adopting sustainable practices can lead to cost savings in the long run. By minimizing waste and optimizing resource use, businesses can improve their bottom line while contributing positively to the environment. B2B buyers should consider these factors when selecting suppliers for bottle screen printing to ensure they align with their own sustainability goals.

What is the Historical Context of Bottle Screen Printing?

The evolution of bottle screen printing can be traced back several decades, with significant advancements in printing technology and materials. Initially, the process was labor-intensive, relying heavily on manual techniques. However, as industrialization took hold in the mid-20th century, the introduction of automated screen printing machines revolutionized production capabilities. This shift not only increased efficiency but also improved the quality and consistency of printed designs.

Over time, the industry has embraced innovations such as UV-curable inks and digital printing, further enhancing the range of applications for bottle screen printing. Today, businesses can leverage these technological advancements to create intricate designs that appeal to a global audience. As the market continues to evolve, understanding this historical context can provide valuable insights for B2B buyers looking to capitalize on current trends and anticipate future developments in the bottle screen printing sector.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle screen printing

-

How do I choose the right bottle screen printing supplier for my business?

Selecting the right supplier involves evaluating their experience, capabilities, and quality assurance processes. Look for suppliers with a proven track record in your industry, particularly those who understand the nuances of screen printing on glass or plastic bottles. Request samples of their work to assess print quality and durability. Additionally, consider their communication style and responsiveness, as these factors are crucial for a successful partnership. Don’t hesitate to ask for references from other businesses that have worked with them. -

What are the minimum order quantities (MOQs) for bottle screen printing?

MOQs can vary widely between suppliers and depend on the complexity of your design and the materials used. Some suppliers may have no minimums for small runs, while others could require a minimum order of several hundred pieces. It’s essential to clarify this with your supplier upfront, especially if you are a startup or looking to test a new product. Understanding MOQs will help you plan your budget and inventory more effectively. -

What customization options are available for bottle screen printing?

Most suppliers offer a range of customization options, including ink colors, finishes, and printing techniques. You can choose from standard colors or request custom Pantone matches for your branding. Additionally, some suppliers provide options for special effects like metallic inks or textured finishes. Discuss your specific design needs with potential suppliers to ensure they can accommodate your requests and provide guidance on design feasibility. -

How can I ensure the quality of printed bottles?

To ensure quality, select a supplier with rigorous quality assurance protocols. This includes pre-production proofs, where you can review a sample before the full run. Request details on their inspection processes, including how they handle defects and misprints. It’s also beneficial to inquire about their experience with the materials you’re using, as this can impact the final product’s durability and appearance. Regular communication throughout the production process will also help address any issues promptly. -

What are common payment terms for bottle screen printing orders?

Payment terms can vary significantly among suppliers, but common practices include a deposit upfront with the balance due upon completion or delivery. Some suppliers might offer net 30 or net 60 terms for established clients. Always clarify payment terms during negotiations to avoid misunderstandings later. Additionally, consider discussing the possibility of discounts for early payment or bulk orders, which can help improve your cash flow. -

How do I handle shipping and logistics for international orders of printed bottles?

When ordering internationally, it’s crucial to discuss shipping options with your supplier. Ask about their shipping partners, estimated delivery times, and whether they provide tracking. Be aware of customs regulations and potential import duties in your country, as these can impact the total cost. Suppliers may offer drop shipping services, which can simplify logistics by shipping directly to your customers, reducing your handling time and costs. -

What types of bottles are suitable for screen printing?

Screen printing is typically best suited for glass and certain plastic bottles with smooth surfaces. Common applications include beverage bottles, cosmetic containers, and food jars. Ensure your bottles meet the supplier’s requirements, such as being cylindrical or flat-sided, as some shapes may not be suitable. Discuss any unique designs or materials with your supplier to confirm printability. -

How can I verify the reliability of a bottle screen printing supplier?

To assess a supplier’s reliability, conduct thorough research, including checking online reviews and testimonials. Request references from past clients, especially those in your industry, to gauge their experience. Additionally, consider visiting their production facility if possible, as this can provide valuable insights into their operations and quality control measures. Engaging in open communication about your expectations and their capabilities will also help establish a trustworthy partnership.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимый и тщательный due diligence. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.

Top 6 Bottle Screen Printing Manufacturers & Suppliers List

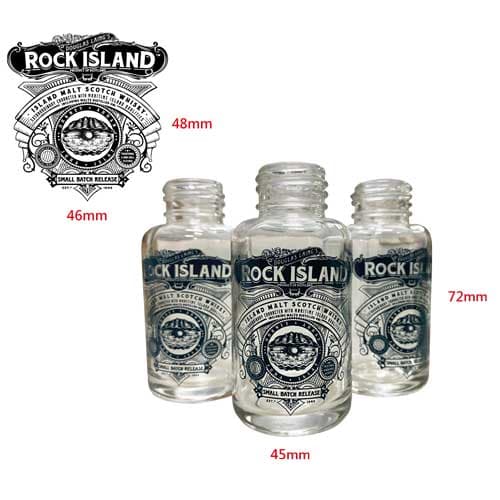

1. Norman’s Printery – Glass Bottle Printing

Домен: normansprintery.com

Зарегистрирован: 2010 (15 лет)

Введение: Norman’s Printery offers glass bottle and vessel printing services using screen printing technology. This method allows for direct printing on glass surfaces, providing a permanent, waterproof label alternative to paper labels. The service is suitable for a variety of glass containers, including candle jars, beverage bottles, makeup containers, CBD oil bottles, reed diffuser bottles, drinkware, pe…

2. Skincare Brand – Direct Bottle Printing Solutions

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Small business making skincare products; currently using labels on plastic bottles; interested in improving aesthetics by screen printing directly on plastic or glass bottles; exploring options for printing methods and suppliers; concerns about minimum order quantities for printing services.

3. Bergin Glass – Wine Bottle Screen Printing & Etching

Домен: berginglass.com

Registered: 2000 (25 years)

Введение: Wine Bottle Screen Printing and Etching services offered by Bergin Glass, emphasizing quality through craftsmanship and technology. Established in 1989, Bergin Glass is known for its commitment to excellence, customer service, and attention to detail. They provide custom labeling solutions that enhance brand visibility and improve sales for wineries.

4. Kaufman Container – Bottle Screen Printing Services

Домен: kaufmancontainer.com

Зарегистрирован: 2001 (24 года)

Введение: Kaufman Container offers bottle screen printing services as a custom solution for businesses. They provide expertise in packaging and customer service, with an in-house decorating facility capable of printing on various shapes and sizes of bottles, jars, tubes, and closures. The service includes screen printing on glass, plastic, and metal materials. Screen printing, also known as Silk Screen Prin…

5. Mission Screen Printing – Bottle Printing Solutions

Домен: missionscreenprinting.com

Зарегистрирован: 2009 (16 лет)

Введение: Bottle Printing – Container Printing

– Specialty screen printing shop offering top-quality container and bottle printing.

– Advantages of Bottle Printing:

– Direct printing withstands oils, alcohols, and dishwasher detergents better than labels.

– Increases product value with an upscale appearance.

– Printing methods: UV and solvent-based inks with multiple catalysts, hardeners, and modifiers …

6. OMSO – Automatic Screen Printing Machines

Домен: omso.it

Зарегистрирован: 1997 (28 лет)

Введение: OMSO offers a range of automatic screen printing machines for plastic and glass bottles. Key products include: 1. Servobottle: Automatic screen printing machine for up to 10 colours using UV ink on multi-format containers. 2. Servojet: Digital printing solution for direct printing on objects, capable of printing up to 7 colours with photographic quality. 3. SB021: Fully servo-controlled machine fo…

Strategic Sourcing Conclusion and Outlook for bottle screen printing

How Can Strategic Sourcing Enhance Your Bottle Screen Printing Needs?

In today’s competitive marketplace, strategic sourcing is essential for international B2B buyers looking to optimize their bottle screen printing processes. By partnering with experienced suppliers who offer both high-quality printing and flexible order capabilities, businesses can enhance brand visibility and product appeal. The advantages of screen printing—such as durability, waterproof labeling, and unique design possibilities—make it an attractive option compared to traditional paper labels.

Buyers should focus on suppliers that provide comprehensive services, including design support, quality control, and a range of ink options. This ensures that your branding is not only visually striking but also aligned with your business objectives. Engaging with suppliers that understand regional market dynamics can further enhance the effectiveness of your sourcing strategy, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

As you look to the future, consider how leveraging strategic sourcing in bottle screen printing can differentiate your products in the marketplace. Embrace the opportunity to collaborate with trusted partners who can help bring your unique vision to life, ensuring your brand stands out in a crowded landscape. Take the next step in enhancing your product packaging—reach out to leading suppliers today to explore your options.