Introduction: Navigating the Global Market for plastic bottles in ocean

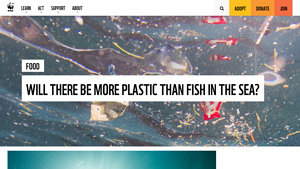

The increasing prevalence of plastic bottles in our oceans poses a significant challenge for international B2B buyers seeking sustainable sourcing options. As pollution levels rise, understanding the complexities surrounding the sourcing and management of plastic bottles becomes crucial. This guide provides a comprehensive overview of the global market for plastic bottles, focusing on their types, applications, and environmental implications. It will also delve into supplier vetting processes, cost considerations, and innovative alternatives that can mitigate the impact of plastic pollution.

By equipping businesses in Africa, South America, the Middle East, and Europe—such as Vietnam and Germany—with actionable insights, this guide empowers informed purchasing decisions. Buyers will gain an understanding of the lifecycle of plastic bottles, from production to disposal, and the role they play in ocean pollution. Additionally, we will explore emerging trends in sustainable packaging and waste management solutions that can help businesses align with eco-friendly practices while maintaining profitability.

Navigating this complex landscape not only addresses the pressing environmental crisis but also opens avenues for innovation and corporate responsibility. As companies increasingly prioritize sustainability, this guide aims to be a vital resource for making strategic choices that benefit both the bottom line and the planet.

Навигация по статье

- Top 8 Plastic Bottles In Ocean Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for plastic bottles in ocean

- Understanding plastic bottles in ocean Types and Variations

- Key Industrial Applications of plastic bottles in ocean

- 3 Common User Pain Points for ‘plastic bottles in ocean’ & Their Solutions

- Strategic Material Selection Guide for plastic bottles in ocean

- In-depth Look: Manufacturing Processes and Quality Assurance for plastic bottles in ocean

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic bottles in ocean’

- Comprehensive Cost and Pricing Analysis for plastic bottles in ocean Sourcing

- Alternatives Analysis: Comparing plastic bottles in ocean With Other Solutions

- Essential Technical Properties and Trade Terminology for plastic bottles in ocean

- Navigating Market Dynamics and Sourcing Trends in the plastic bottles in ocean Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of plastic bottles in ocean

- Важный отказ от ответственности и условия использования

- Strategic Sourcing Conclusion and Outlook for plastic bottles in ocean

Understanding plastic bottles in ocean Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Single-Use PET Bottles | Lightweight, often clear; made from polyethylene terephthalate (PET) | Beverage packaging, consumer goods | Плюсы: Low cost, high availability. Конс: Environmental concerns, limited recycling. |

| Multi-Use HDPE Bottles | Durable, opaque; made from high-density polyethylene (HDPE) | Industrial storage, chemical transport | Плюсы: Long-lasting, reusable. Конс: Higher initial investment, potential for chemical leaching. |

| Refillable Glass Bottles | Heavy, non-reactive; made from glass | Premium beverage markets, health sectors | Плюсы: Eco-friendly, recyclable. Конс: Fragile, higher shipping costs. |

| Biodegradable Bottles | Made from plant-based materials; designed to decompose | Eco-conscious brands, specialty products | Плюсы: Reduced environmental impact. Конс: Limited shelf life, potential higher costs. |

| Cap-Only Plastics | Small, often made from HDPE or polypropylene; caps from single-use bottles | Beverage and consumer goods packaging | Плюсы: Recyclable, lightweight. Конс: Often ends up as litter, difficult to manage recycling. |

What are the Characteristics of Single-Use PET Bottles?

Single-use PET bottles are a prevalent form of plastic in ocean pollution, primarily due to their lightweight and transparent nature. Commonly used in beverage packaging, they are produced at a low cost, making them highly accessible for various industries. B2B buyers should consider the environmental implications of these bottles, as they are often not recycled effectively and contribute significantly to marine debris. The demand for sustainable alternatives is growing, pushing businesses to seek solutions that mitigate their environmental footprint.

How Do Multi-Use HDPE Bottles Compare?

Multi-use HDPE bottles are characterized by their durability and resistance to impact, making them suitable for industrial applications and chemical transport. These bottles can be reused multiple times, offering a more sustainable option compared to single-use plastics. B2B buyers should evaluate the initial investment costs against long-term savings from reduced waste and increased reuse. However, concerns about potential chemical leaching and the need for stringent quality controls can complicate purchasing decisions.

What Makes Refillable Glass Bottles Attractive?

Refillable glass bottles stand out for their eco-friendliness and recyclability. They are commonly used in premium beverage markets and health sectors, appealing to consumers seeking sustainable options. B2B buyers should weigh the benefits of a strong brand image against the higher shipping costs and fragility associated with glass. While these bottles contribute less to ocean pollution, their practicality in certain sectors may be limited due to their weight and breakability.

Why Consider Biodegradable Bottles?

Biodegradable bottles, made from plant-based materials, are designed to decompose over time, reducing their environmental impact. They are increasingly popular among eco-conscious brands and specialty product markets. However, B2B buyers must consider their limited shelf life and potentially higher costs. Understanding the market demand for sustainable products can guide purchasing decisions, especially as consumers become more environmentally aware.

What Are the Challenges of Cap-Only Plastics?

Cap-only plastics, often made from HDPE or polypropylene, represent a small yet significant part of ocean plastic pollution. These caps are lightweight and recyclable, but they frequently end up as litter due to improper disposal. B2B buyers should focus on sourcing solutions that ensure effective recycling processes and consider the implications of these products in their overall sustainability strategies. As the industry shifts towards reducing single-use plastics, exploring innovative packaging solutions can enhance brand reputation and compliance with environmental regulations.

Key Industrial Applications of plastic bottles in ocean

| Промышленность/сектор | Specific Application of plastic bottles in ocean | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Environmental Services | Ocean Cleanup Initiatives | Enhances corporate social responsibility (CSR) image and engages communities | Need for durable, lightweight materials that can withstand harsh marine environments |

| Tourism and Hospitality | Eco-friendly Water Bottles for Tourists | Attracts environmentally conscious consumers and enhances brand loyalty | Sourcing biodegradable or recyclable materials to align with sustainability goals |

| Fishing Industry | Storage for Marine Supplies | Ensures safe transport and storage of essential fishing gear and bait | Requirement for bottles that are resistant to saltwater and UV exposure |

| Производство напитков | Use of Ocean-Recycled PET Bottles | Reduces carbon footprint and appeals to eco-conscious consumers | Need for verified suppliers of recycled materials and compliance with safety standards |

| Packaging and Logistics | Reusable Bottles for Shipping | Decreases waste and shipping costs while improving brand image | Consideration for weight, durability, and recycling options when selecting bottles |

How Are Plastic Bottles Used in Ocean Cleanup Initiatives?

The environmental services sector increasingly utilizes plastic bottles collected from ocean cleanup efforts as part of their recycling and waste management programs. By transforming these bottles into new products, companies not only contribute to reducing ocean pollution but also bolster their corporate social responsibility (CSR) initiatives. For international buyers, particularly in regions with significant ocean pollution, sourcing durable materials that can withstand the marine environment is crucial. This ensures that the bottles used in cleanup efforts remain effective and sustainable over time.

What Role Do Eco-Friendly Water Bottles Play in Tourism?

In the tourism and hospitality industry, eco-friendly water bottles made from ocean-sourced plastics can significantly enhance a brand’s appeal. Tourists are increasingly seeking sustainable options, and offering reusable bottles can attract environmentally conscious customers. Businesses must ensure these bottles are made from biodegradable or recyclable materials to align with sustainability goals. For buyers in Africa, South America, and Europe, it’s essential to source products that comply with local environmental regulations while also being culturally relevant to their markets.

How Are Plastic Bottles Utilized in the Fishing Industry?

The fishing industry uses plastic bottles for storing and transporting marine supplies, such as bait and fishing gear. These bottles provide a lightweight and effective solution for maintaining the quality of supplies during transit. Buyers in this sector should look for bottles that are resistant to saltwater and UV exposure to ensure longevity and performance in harsh marine conditions. Moreover, sourcing from local suppliers can reduce shipping costs and support regional economies.

Why Are Ocean-Recycled PET Bottles Important for Beverage Manufacturing?

Beverage manufacturers are increasingly adopting ocean-recycled PET bottles as part of their packaging solutions. This practice not only helps reduce plastic waste but also appeals to consumers who prioritize sustainability. International buyers should prioritize suppliers who can provide verified recycled materials and ensure compliance with safety standards for food and beverage packaging. This is particularly relevant in markets like Germany and the Middle East, where there is a strong emphasis on environmental responsibility.

How Can Reusable Bottles Improve Packaging and Logistics?

In the packaging and logistics sector, reusable bottles sourced from ocean plastics can significantly decrease waste and shipping costs. These bottles can be used multiple times, improving operational efficiency while enhancing a company’s brand image. Buyers need to consider the weight and durability of bottles, as well as their recycling options, to optimize their supply chain processes. This is especially important for businesses operating in regions with stringent environmental regulations or high logistical costs.

3 Common User Pain Points for ‘plastic bottles in ocean’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Plastic Waste Management

Проблема: B2B buyers in sectors such as manufacturing or retail often face increasing pressure from regulatory bodies to ensure compliance with environmental standards related to plastic waste. For instance, companies operating in Europe may struggle with stringent EU regulations aimed at reducing single-use plastics. This not only complicates supply chain logistics but also leads to potential financial penalties for non-compliance. The challenge is exacerbated in regions with less developed waste management systems, where buyers may find it difficult to source compliant products while maintaining cost efficiency.

Решение: To effectively navigate these regulatory challenges, B2B buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainability and compliance with local and international regulations. This involves conducting thorough due diligence on potential suppliers to ensure their practices align with environmental standards. Additionally, companies can invest in reusable or refillable bottle options, which not only reduce reliance on single-use plastics but also position the business as a leader in sustainability efforts. Implementing a robust waste management strategy that includes recycling initiatives and educating employees about proper disposal methods can further mitigate compliance risks. Buyers should also engage in ongoing training and updates regarding regulatory changes, allowing for agile responses to new laws or standards.

Scenario 2: Managing Brand Reputation Amidst Plastic Pollution Concerns

Проблема: In today’s environmentally conscious marketplace, B2B buyers are increasingly aware of how plastic pollution, particularly from single-use bottles, can damage their brand reputation. Companies that are perceived as contributing to ocean pollution may face backlash from consumers and stakeholders, leading to diminished brand loyalty and sales. This concern is particularly acute for businesses in sectors like tourism, hospitality, and food and beverage, where consumers are more likely to scrutinize sustainability practices.

Решение: To safeguard brand reputation, B2B buyers must proactively integrate sustainable practices into their operations. This can be achieved by sourcing eco-friendly alternatives to single-use plastic bottles, such as biodegradable or compostable packaging options. Collaborating with organizations focused on ocean clean-up efforts can also enhance a company’s image, demonstrating a commitment to environmental stewardship. Additionally, transparent communication about sustainability initiatives and the impact of plastic pollution can resonate with consumers. Leveraging storytelling through marketing campaigns that highlight efforts to reduce plastic waste can further strengthen brand loyalty and attract environmentally conscious customers.

Scenario 3: Addressing Supply Chain Disruptions Caused by Plastic Waste Issues

Проблема: Many B2B buyers are facing disruptions in their supply chains due to increasing scrutiny and regulations surrounding plastic waste management. With rising awareness of plastic pollution, suppliers may encounter delays or increased costs related to compliance with new environmental standards. This can lead to shortages of products or materials, affecting production timelines and ultimately customer satisfaction. Companies in industries such as packaging, food and beverage, or retail are particularly vulnerable to these disruptions.

Решение: To combat supply chain disruptions, B2B buyers should consider diversifying their supplier base to include companies that utilize sustainable materials and practices. This not only mitigates risk but also opens up opportunities for collaboration on innovative solutions to reduce plastic waste. Establishing long-term relationships with suppliers who prioritize sustainability can lead to more reliable product availability and cost stability. Additionally, investing in technology that improves waste tracking and management within the supply chain can enhance efficiency and reduce the risk of bottlenecks. Implementing circular economy practices, such as taking back used bottles for reuse or recycling, can also help create a more resilient supply chain while aligning with consumer expectations for sustainability.

Strategic Material Selection Guide for plastic bottles in ocean

What Are the Key Materials for Plastic Bottles in Ocean Applications?

When selecting materials for plastic bottles that may end up in ocean environments, it is crucial to consider their properties, advantages, disadvantages, and compliance with international standards. The following analysis examines four common materials used in the production of plastic bottles, focusing on their suitability for ocean applications.

How Does Polyethylene Terephthalate (PET) Perform in Marine Environments?

Polyethylene terephthalate (PET) is widely used for beverage bottles due to its excellent strength-to-weight ratio and clarity. PET has a temperature rating of up to 70°C and is resistant to many chemicals, making it suitable for various liquids. However, PET is not biodegradable and can take hundreds of years to decompose in marine environments.

Плюсы: PET is lightweight, durable, and recyclable, which can reduce its environmental impact if properly managed. It is also cost-effective, making it a preferred choice for manufacturers.

Конс: The primary drawback is its environmental persistence. If not disposed of correctly, PET bottles can contribute significantly to ocean pollution. Additionally, while PET is recyclable, global recycling rates remain low, particularly in developing regions.

Влияние на применение: PET is compatible with a wide range of beverages, but its long-term presence in the ocean raises concerns about microplastic formation.

Что относится к полиэтилену высокой плотности (ПЭВП)?

High-density polyethylene (HDPE) is known for its high strength and resistance to impact and moisture. It has a temperature tolerance of around 120°C and is resistant to many solvents. HDPE is also less likely to leach harmful chemicals into its contents compared to other plastics.

Плюсы: HDPE is durable and has a low cost of production. Its resistance to environmental stress cracking makes it suitable for various applications, including those exposed to harsh marine conditions.

Конс: HDPE’s recyclability is limited compared to PET, and it may not be as transparent, which can be a disadvantage for consumer products. Moreover, while HDPE is more resistant to UV radiation than PET, prolonged exposure can still degrade its properties.

Влияние на применение: HDPE bottles are suitable for storing chemicals and liquids, but their long-term environmental impact remains a concern due to their non-biodegradable nature.

How Does Polypropylene (PP) Compare for Ocean Applications?

Polypropylene (PP) offers excellent chemical resistance and can withstand temperatures up to 100°C. It is lightweight and has a high melting point, making it suitable for various applications, including hot-fill products.

Плюсы: PP is highly versatile and can be molded into complex shapes. It is also resistant to many solvents and has a lower environmental impact than other plastics when recycled properly.

Конс: The main limitation of PP is its lower transparency, which may not appeal to consumers. Additionally, while it is recyclable, the infrastructure for recycling PP is less developed in many regions.

Влияние на применение: PP’s chemical resistance makes it suitable for storing a variety of liquids, but like other plastics, it poses a risk of contributing to ocean pollution if not managed properly.

What Role Does Biodegradable Plastic Play in Ocean Applications?

Biodegradable plastics, such as polylactic acid (PLA), are designed to break down more quickly in the environment. They are made from renewable resources and can decompose under specific conditions, making them an attractive alternative.

Плюсы: The primary advantage of biodegradable plastics is their potential to reduce long-term pollution in marine environments. They can decompose into natural substances, minimizing their impact on marine life.

Конс: However, biodegradable plastics require specific conditions to break down effectively, which may not be present in ocean environments. Additionally, they can be more expensive to produce compared to conventional plastics.

Влияние на применение: Biodegradable plastics could be suitable for short-term use applications, but their effectiveness in ocean environments remains uncertain.

Summary Table of Material Selection for Plastic Bottles in Ocean Applications

| Материал | Typical Use Case for Plastic Bottles in Ocean | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Полиэтилентерефталат (ПЭТ) | Beverage bottles, food containers | Lightweight and recyclable | Environmental persistence and low recycling rates | Средний |

| Полиэтилен высокой плотности (ПЭВП) | Chemical storage, household products | Durable and resistant to impact | Limited recyclability and UV degradation | Низкий |

| Polypropylene (PP) | Hot-fill products, chemical containers | Excellent chemical resistance | Lower transparency and less developed recycling | Средний |

| Biodegradable Plastics (PLA) | Short-term use items, packaging | Reduced long-term pollution | Requires specific conditions for decomposition | Высокий |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with sustainability goals while addressing the challenges of ocean pollution.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic bottles in ocean

What Are the Key Stages in the Manufacturing Process of Plastic Bottles?

The manufacturing process for plastic bottles involves several critical stages, from material preparation to finishing. Understanding these stages is essential for B2B buyers looking to ensure quality and sustainability in their supply chains.

Material Preparation: What Raw Materials Are Used?

Plastic bottles are typically made from polyethylene terephthalate (PET) or high-density polyethylene (HDPE). The process begins with the selection of high-quality resin pellets, which are then dried to remove moisture. This step is crucial, as excess moisture can lead to defects in the final product. For sustainable practices, some manufacturers are beginning to incorporate recycled materials into their production, aligning with global efforts to reduce plastic waste and ocean pollution.

Forming: How Are Bottles Shaped?

The next stage is forming, which involves heating the resin pellets until they melt. This molten plastic is then shaped using various techniques such as blow molding or injection molding. Blow molding is commonly used for creating hollow bottles, while injection molding is often employed for caps and closures. The choice of technique can affect the bottle’s strength, weight, and recycling capabilities.

Assembly: What Components Are Integrated?

After the bottles are formed, they may go through an assembly stage where additional components, such as labels and caps, are added. This process can include automated machinery that ensures precision and consistency. Quality at this stage is vital, as any misalignment or defects can lead to product failure, potentially resulting in leaks or contamination.

Finishing: What Final Touches Are Applied?

The final stage, finishing, includes processes such as labeling, printing, and packaging. Bottles may undergo surface treatments to improve adhesion for labels and enhance their resistance to environmental factors. Quality assurance during this phase ensures that the final product meets aesthetic and functional standards.

What Quality Assurance Practices Should Buyers Expect?

Quality assurance (QA) is a critical component of the manufacturing process, especially for international B2B transactions. Buyers should be aware of the various quality standards and checkpoints involved in the production of plastic bottles.

Which International Standards Are Relevant?

For plastic bottle manufacturers, compliance with international standards like ISO 9001 is essential. This standard focuses on quality management systems and ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific applications may also apply.

What Are the Key QC Checkpoints?

Quality control (QC) checkpoints are integral to maintaining high manufacturing standards. These checkpoints include:

- Входящий контроль качества (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- Внутрипроцессный контроль качества (IPQC): Monitoring the manufacturing process to detect and correct defects in real-time.

- Окончательный контроль качества (ОКК): Conducting thorough inspections of finished products before they are shipped.

Each checkpoint serves to minimize defects and ensure that only high-quality products reach the market.

What Common Testing Methods Are Used?

Manufacturers employ various testing methods to evaluate the quality and safety of plastic bottles. Common methods include:

- Visual Inspection: Checking for surface defects, color consistency, and overall appearance.

- Mechanical Testing: Assessing the strength and durability of the bottles under stress.

- Chemical Testing: Ensuring that the materials used do not leach harmful substances, particularly for bottles intended for food and beverage use.

Как покупатели B2B могут проверять контроль качества поставщиков?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is crucial. Here are some actionable steps buyers can take:

What Should Buyers Look for in Audits and Reports?

Buyers should request detailed reports from suppliers that outline their QC processes, test results, and any certifications. Regular audits, either conducted by the buyer or through third-party organizations, can provide an in-depth understanding of the supplier’s practices. During these audits, focus on the following:

- Documentation: Ensure that all QC processes are documented and compliant with international standards.

- Traceability: Check if the supplier maintains traceability for materials and products throughout the manufacturing process.

How Can Third-Party Inspections Enhance Trust?

Engaging a third-party inspection service can provide an unbiased evaluation of the supplier’s manufacturing and QC practices. These services can conduct random sampling and testing to ensure that products meet agreed-upon specifications before shipment. This step is particularly important for buyers operating in regions with varying regulatory standards.

What Are the Nuances of QC for International Buyers?

International B2B transactions come with unique challenges, particularly regarding quality assurance. Buyers should be aware of the following nuances:

What Regional Regulations Should Buyers Be Aware Of?

Different regions may have specific regulations regarding plastic manufacturing and safety. Buyers should familiarize themselves with local laws, such as the EU’s Single-Use Plastics Directive, which aims to reduce plastic waste. Understanding these regulations can help buyers ensure that their suppliers are compliant and that their products will meet market demands.

How Can Cultural Differences Impact Quality Expectations?

Cultural differences can also influence quality expectations and practices. Buyers should engage in open communication with suppliers to clarify quality standards and expectations. Building strong relationships can help mitigate misunderstandings and foster a collaborative approach to quality assurance.

Conclusion: Ensuring Quality in the Global Plastic Bottle Market

In summary, the manufacturing processes and quality assurance practices for plastic bottles are complex and multifaceted. By understanding these elements, B2B buyers can make informed decisions that prioritize quality, sustainability, and compliance with international standards. This proactive approach not only enhances product reliability but also contributes to global efforts to mitigate plastic pollution in our oceans.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic bottles in ocean’

Введение

This guide serves as a practical checklist for B2B buyers looking to procure solutions for addressing the issue of plastic bottles in the ocean. By following these steps, organizations can make informed decisions that not only comply with environmental standards but also contribute to sustainable practices in their supply chains. Understanding the complexities of ocean plastic pollution is crucial for effective sourcing strategies.

Шаг 1: Identify Your Environmental Goals

Establish clear objectives regarding the environmental impact of your procurement. Determine if your focus is on sourcing recycled materials, supporting cleanup initiatives, or investing in innovative alternatives to single-use plastics. Aligning your procurement strategy with your organization’s sustainability goals will help you select suppliers that share your vision.

Шаг 2: Research Suppliers Committed to Sustainability

Look for suppliers that prioritize sustainable practices and demonstrate a commitment to reducing plastic waste. Evaluate their certifications, such as ISO 14001 for environmental management or membership in organizations focused on ocean conservation. Reliable suppliers should be transparent about their sourcing and production processes, showcasing efforts to mitigate their environmental impact.

Шаг 3: Assess Product Specifications and Compliance

Ensure that the plastic bottles you consider meet relevant industry standards and regulations. Check for compliance with local and international guidelines, such as the European Union’s Single-Use Plastics Directive. Understanding the technical specifications, such as recyclability and material composition, will help you select products that align with your sustainability objectives.

Шаг 4: Evaluate Supply Chain Transparency

Investigate the supply chain of potential suppliers to ensure accountability and traceability of materials. A transparent supply chain can help identify the sources of plastic and provide insights into how they manage waste. Request information about their waste management practices and how they contribute to ocean cleanup efforts.

Шаг 5: Consider Innovative Alternatives

Explore suppliers that offer innovative solutions, such as biodegradable or compostable plastic bottles. These alternatives can significantly reduce the environmental impact compared to traditional plastic. Research the effectiveness and market acceptance of these products to ensure they meet your operational needs while also contributing to sustainability.

Шаг 6: Request Samples and Conduct Testing

Before finalizing your procurement, request samples from potential suppliers to evaluate the quality and functionality of their products. Conduct tests to assess durability, performance, and ease of recycling. This step is crucial to ensure that the products you choose not only fulfill your requirements but also uphold your commitment to sustainability.

Шаг 7: Establish Long-Term Partnerships

Finally, foster long-term relationships with suppliers who demonstrate a commitment to sustainability and innovation. Engage in ongoing dialogue about your environmental goals and seek opportunities for collaboration in initiatives aimed at reducing ocean plastic pollution. Building strong partnerships can lead to shared benefits and enhanced impact over time.

Comprehensive Cost and Pricing Analysis for plastic bottles in ocean Sourcing

What Are the Key Cost Components for Sourcing Plastic Bottles?

When sourcing plastic bottles, particularly in the context of ocean-related supply chains, understanding the cost structure is essential for B2B buyers. The main cost components include:

-

Материалы: The primary raw materials for plastic bottles are polyethylene terephthalate (PET) and high-density polyethylene (HDPE). The prices of these materials fluctuate based on global oil prices, production rates, and recycling availability. Buyers should consider sourcing from suppliers who prioritize recycled materials to not only reduce costs but also support sustainability efforts.

-

Труд: Labor costs can vary significantly depending on the region and the local wage standards. Countries with lower labor costs might offer competitive pricing, but buyers should evaluate the skill level and productivity of the workforce to ensure quality.

-

Производственные накладные расходы: This includes costs related to utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, so it’s crucial to partner with suppliers who have streamlined operations.

-

Инструментальная оснастка: Tooling costs refer to the expenses associated with the molds and machinery used to produce plastic bottles. Custom designs or unique specifications may require higher initial investments in tooling, impacting the overall cost structure.

-

Контроль качества (QC): Ensuring the quality of plastic bottles is non-negotiable, especially in markets with strict regulations. Investing in comprehensive QC processes can lead to higher upfront costs but will mitigate risks associated with defective products, which could be costly in the long run.

-

Логистика: Transportation and shipping costs can significantly affect the final price. Factors such as distance, mode of transport, and fuel prices must be considered. Utilizing local suppliers can reduce logistics costs, thereby enhancing overall cost efficiency.

-

Маржа: Suppliers will typically add a profit margin to their costs. Understanding the competitive landscape can help buyers negotiate better terms and find suppliers willing to offer more competitive pricing.

How Do Price Influencers Affect the Cost of Plastic Bottles?

Several factors can influence the pricing of plastic bottles, particularly for international B2B buyers:

-

Объем/МОК: Minimum order quantities (MOQs) can affect pricing. Higher volumes generally lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to optimize order sizes.

-

Технические характеристики и персонализация: Custom designs, sizes, and features can increase costs. Buyers should weigh the benefits of customization against the additional expenses incurred.

-

Materials Quality and Certifications: Bottles made from higher-quality materials or those that meet specific certifications (e.g., food safety standards) often come at a premium. Buyers should ensure that the materials used align with their intended application.

-

Факторы поставщика: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Инкотермс: Understanding international commercial terms is vital for pricing negotiations. Incoterms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect the overall cost.

What Are the Best Buyer Tips for Cost-Efficient Plastic Bottle Sourcing?

International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Эффективно вести переговоры: Leverage your purchasing power by negotiating terms with suppliers. Building long-term relationships can lead to better pricing and service.

-

Оцените общую стоимость владения (TCO): Beyond the initial purchase price, consider factors like shipping, storage, and disposal costs. A lower initial price may not always be the most cost-effective option in the long run.

-

Поймите нюансы ценообразования: Different regions may have varying pricing structures based on local economic conditions and regulations. Familiarize yourself with these nuances to make informed decisions.

-

Research and Compare Suppliers: Don’t settle for the first offer. Conduct market research to compare different suppliers, their offerings, and their pricing to find the best fit for your needs.

-

Будьте в курсе тенденций рынка: Keep an eye on global plastic production and recycling trends. Fluctuations in supply and demand can impact pricing, so being informed will aid in better negotiation.

Disclaimer

The prices and cost structures mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing plastic bottles in ocean With Other Solutions

Introduction to Alternative Solutions for Plastic Bottles in the Ocean

As the issue of plastic pollution continues to escalate globally, particularly concerning plastic bottles in the ocean, it becomes imperative to explore alternative solutions that can mitigate this environmental crisis. B2B buyers, especially those in regions with prevalent plastic waste issues, must consider effective alternatives that not only reduce oceanic plastic waste but also align with their operational and economic goals. This analysis compares plastic bottles in the ocean with two viable alternatives: refillable bottles and biodegradable bottles.

Comparison of Plastic Bottles in the Ocean with Alternative Solutions

| Сравнительный аспект | Plastic Bottles In Ocean | Refillable Bottles | Biodegradable Bottles |

|---|---|---|---|

| Производительность | Long-lasting, contributes to pollution | Durable, reusable, lower waste | Breaks down over time, less pollution |

| Стоимость | High long-term costs due to cleanup | Initial investment, lower costs over time | Higher production cost, variable pricing |

| Простота реализации | No implementation, results from neglect | Requires consumer behavior change | Needs infrastructure for disposal |

| Техническое обслуживание | N/A (pollution issue) | Low maintenance, simple cleaning | Minimal, but requires proper disposal |

| Лучший пример использования | Not a solution; represents pollution | Ideal for urban areas, events | Suitable for short-term use, eco-conscious markets |

Подробный анализ альтернатив

Refillable Bottles

Refillable bottles represent a sustainable alternative that significantly reduces the reliance on single-use plastics. Their durability allows for multiple uses, effectively cutting down on the volume of plastic waste generated. While the initial investment may be higher, the long-term savings from reduced purchasing of single-use bottles can be substantial. However, the success of this solution hinges on consumer behavior and the ability to change habits, which may pose challenges in markets where convenience is prioritized over sustainability.

Biodegradable Bottles

Biodegradable bottles are designed to break down more quickly than traditional plastics, offering a promising alternative to mitigate ocean pollution. They can serve as a transitional solution for companies looking to enhance their environmental credentials. However, they typically come with a higher production cost and may not break down effectively if not disposed of correctly, requiring proper composting infrastructure. This approach is most suitable for businesses in eco-conscious markets where customers are willing to pay a premium for environmentally friendly products.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the right alternative to plastic bottles in the ocean, B2B buyers must consider their specific operational contexts, cost implications, and the environmental impact of their choices. Refillable bottles may be ideal for businesses seeking long-term sustainability benefits and willing to invest in consumer education. In contrast, biodegradable bottles may appeal to those looking to address immediate waste concerns without a complete overhaul of their packaging strategies. Ultimately, the decision should align with the company’s sustainability goals, target market preferences, and the infrastructure available for waste management. By carefully evaluating these factors, businesses can contribute positively to reducing ocean plastic pollution while maintaining operational efficiency.

Essential Technical Properties and Trade Terminology for plastic bottles in ocean

What Are the Key Technical Properties of Plastic Bottles in Ocean Applications?

Understanding the technical properties of plastic bottles is essential for B2B buyers involved in manufacturing, distribution, or recycling efforts related to marine environments. Here are some critical specifications to consider:

1. Класс материала

Plastic bottles are primarily made from various grades of polyethylene terephthalate (PET) and high-density polyethylene (HDPE). The material grade determines the bottle’s strength, flexibility, and resistance to UV light and temperature fluctuations. For marine applications, bottles made from high-grade PET or HDPE are preferred due to their durability and lower likelihood of breaking down into microplastics. B2B buyers should prioritize sourcing bottles made from these materials to ensure longevity and reduce environmental impact.

2. Tolerance

Tolerance refers to the allowable deviation in dimensions, such as thickness and diameter, of the plastic bottles. For instance, a tolerance of ±0.5 mm on a bottle’s neck diameter is crucial for ensuring compatibility with caps and dispensing systems. In the B2B context, tighter tolerances can lead to better sealing and less leakage, which is especially important for products transported over long distances or through harsh marine environments.

3. Barrier Properties

Barrier properties indicate how well a material can prevent the ingress of gases and moisture. For plastic bottles, effective barrier properties can enhance shelf life and protect contents from contamination. This is particularly relevant for bottled water and other liquids intended for human consumption. B2B buyers should evaluate the barrier performance of plastic bottles to ensure they meet safety and quality standards.

4. Recyclability

Recyclability is a vital property for plastic bottles, especially in the context of ocean pollution. Bottles made from recyclable materials can significantly reduce the volume of waste entering marine environments. B2B buyers should focus on sourcing bottles that are not only recyclable but also produced through sustainable practices to align with increasing regulatory pressures and consumer preferences for eco-friendly products.

5. Weight and Volume Efficiency

Lightweight bottles reduce shipping costs and carbon footprints, making them an attractive option for B2B buyers. Additionally, efficient volume design allows for optimized storage and transportation, which is critical when considering the environmental impact of logistics. Buyers should seek bottles that provide a balance between weight and structural integrity to maximize operational efficiency.

What Common Trade Terms Should B2B Buyers Understand?

Navigating the world of plastic bottles also requires familiarity with specific trade terminology that can impact procurement and logistics.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. Understanding OEM relationships is crucial for B2B buyers looking to source custom-branded bottles. It allows for streamlined production and ensures that quality standards are met while leveraging existing manufacturing capabilities.

2. MOQ (минимальное количество заказа)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. This term is significant for B2B buyers to consider their inventory needs and manage cash flow effectively. Knowing the MOQ helps in planning purchases that align with demand without overcommitting resources.

3. RFQ (запрос котировок)

An RFQ is a formal process where buyers request price quotations from suppliers for specific products or services. For B2B buyers, issuing an RFQ for plastic bottles can provide valuable insights into pricing, lead times, and capabilities of various suppliers. This helps in making informed sourcing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is essential for B2B buyers to clarify who bears the risk and costs at various stages of transportation. This knowledge can prevent misunderstandings and ensure smoother transactions.

5. Lead Time

Lead time refers to the time taken from placing an order until it is delivered. For B2B buyers, understanding lead times is critical for inventory management and planning, especially when dealing with perishable goods or products that are in high demand.

In conclusion, comprehending the essential technical properties and trade terminology related to plastic bottles is vital for B2B buyers. This knowledge equips them to make informed purchasing decisions that align with both operational needs and environmental considerations.

Navigating Market Dynamics and Sourcing Trends in the plastic bottles in ocean Sector

What Are the Key Market Dynamics Impacting the Plastic Bottles in Ocean Sector?

The plastic bottles market, particularly in the context of ocean pollution, is shaped by several global drivers and emerging trends. One of the most significant influences is the increasing awareness of environmental issues, which is leading to a shift in consumer preferences towards sustainable packaging solutions. Countries like Germany and Vietnam are implementing stricter regulations on single-use plastics, which are driving innovation in alternative materials and recycling technologies.

Additionally, the rise of circular economy practices is reshaping sourcing strategies, encouraging B2B buyers to seek suppliers who prioritize recycling and the use of biodegradable materials. Technologies such as blockchain are emerging in supply chain management, offering transparency and traceability in sourcing practices, which is crucial for buyers focused on ethical procurement.

Moreover, as the demand for bottled beverages continues to grow, especially in regions with developing economies in Africa and South America, the market for plastic bottles is expected to expand. However, this growth must be balanced with sustainable practices, as improper disposal contributes significantly to ocean pollution. Buyers are increasingly looking for suppliers who can demonstrate compliance with international environmental standards and offer products that minimize ecological impact.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Plastic Bottles Sector?

Sustainability is not just a buzzword; it has become a critical factor for B2B buyers in the plastic bottles sector. The environmental impact of plastic pollution is profound, affecting marine life, coastal economies, and public health. Ethical sourcing practices are essential for mitigating these effects. Buyers should prioritize suppliers who utilize recycled materials and adopt eco-friendly manufacturing processes.

Certifications such as ISO 14001 for environmental management and the Cradle to Cradle certification can serve as indicators of a supplier’s commitment to sustainability. Furthermore, buyers can benefit from sourcing biodegradable alternatives to conventional plastics, such as bioplastics made from natural materials, which can significantly reduce the carbon footprint associated with plastic bottles.

Establishing partnerships with suppliers who have robust waste management practices is also vital. This can help ensure that products are designed for end-of-life recovery, minimizing their potential to become ocean debris. Buyers should actively seek out companies that are engaged in initiatives aimed at reducing plastic waste in oceans, as this can enhance brand reputation and customer loyalty.

What Has Been the Evolution of the Plastic Bottles Market in Relation to Ocean Pollution?

The evolution of the plastic bottles market has been closely tied to the broader narrative of plastic pollution in the oceans. Initially, plastic was heralded as a revolutionary material due to its versatility and durability. However, since the 1950s, the proliferation of single-use plastics, particularly bottles, has led to an alarming increase in ocean pollution.

In response, the late 20th and early 21st centuries saw growing advocacy for environmental stewardship, culminating in international agreements aimed at reducing plastic waste. The emergence of recycling technologies and sustainable materials has also transformed the market landscape. Today, B2B buyers are not only tasked with sourcing products that meet consumer demand but also with addressing the pressing need for sustainable solutions that align with environmental goals. This evolution signifies a critical pivot from convenience to responsibility in sourcing practices, shaping the future of the plastic bottles market.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic bottles in ocean

-

How do I solve the problem of sourcing eco-friendly plastic bottles?

To source eco-friendly plastic bottles, first, identify suppliers who specialize in sustainable materials, such as recycled plastics or bio-based alternatives. Research their certifications, such as ISO 14001 for environmental management. Engage in discussions regarding their manufacturing processes and waste management practices. Consider visiting their facilities or requesting product samples to evaluate quality. Additionally, exploring collaborations with NGOs or environmental organizations can enhance your commitment to sustainability, helping to build a positive brand image while addressing the ocean pollution crisis. -

What is the best type of plastic bottle for reducing ocean pollution?

The best type of plastic bottle for reducing ocean pollution is one designed for multiple uses, such as refillable or reusable bottles made from durable materials like PET or HDPE. These bottles are less likely to contribute to marine debris since they can be used repeatedly and recycled at the end of their life cycle. Furthermore, consider bottles that incorporate recycled materials, which minimize the need for new plastic production and promote a circular economy. Engaging with suppliers that prioritize sustainability will enhance your environmental impact. -

How can I vet suppliers for plastic bottles effectively?

To vet suppliers for plastic bottles, begin by assessing their certifications and compliance with international quality standards such as ISO or FDA regulations. Request references from previous clients to gauge their reliability and product quality. Evaluate their production capacity, lead times, and flexibility in meeting your specific requirements. Conduct on-site visits, if feasible, to inspect their manufacturing processes and quality control measures. Finally, ensure they have a clear commitment to sustainability and responsible waste management practices to align with your environmental goals. -

What are typical minimum order quantities (MOQs) for plastic bottles?

Minimum order quantities (MOQs) for plastic bottles can vary significantly depending on the supplier and the type of bottle. Generally, MOQs may range from 1,000 to 10,000 units for standard models, while custom designs may require higher quantities, often starting around 5,000 to 20,000 units. It’s crucial to discuss your specific needs with potential suppliers, as they may offer flexibility or tiered pricing based on order size. Consider negotiating MOQs to align with your budget and inventory management strategies. -

What payment terms should I expect when sourcing plastic bottles internationally?

When sourcing plastic bottles internationally, payment terms typically range from 30% to 50% upfront, with the balance due upon delivery or within a specified period post-delivery. Common payment methods include bank transfers, letters of credit, or escrow services for added security. Ensure to clarify payment terms in the contract to avoid misunderstandings. Additionally, consider negotiating favorable terms based on your relationship with the supplier and your order volume, as this can enhance cash flow management. -

How do I ensure quality assurance for plastic bottles?

To ensure quality assurance for plastic bottles, implement a robust quality control process that includes pre-production samples, in-process inspections, and final product evaluations. Establish clear specifications and standards for the materials and dimensions of the bottles. Collaborate with suppliers who have established quality management systems and certifications. Consider hiring third-party inspection services for additional oversight, especially for large orders or new suppliers, to ensure the products meet your quality expectations before shipment. -

What logistics considerations should I be aware of when importing plastic bottles?

When importing plastic bottles, consider logistics factors such as shipping methods, customs clearance, and potential tariffs or duties. Evaluate shipping costs and transit times for different carriers to determine the most efficient option. Ensure compliance with international shipping regulations and documentation requirements, including bills of lading and import permits. Additionally, consider partnering with logistics companies experienced in handling plastic products to streamline the import process and mitigate risks associated with delays or damages during transit. -

What are the environmental regulations I need to consider when sourcing plastic bottles?

When sourcing plastic bottles, it’s essential to be aware of environmental regulations in both the sourcing and destination countries. Regulations may include restrictions on single-use plastics, requirements for recycling, and standards for the use of recycled materials. Familiarize yourself with international agreements, such as the Paris Agreement, and regional laws, like the EU’s Single-Use Plastics Directive. Engaging with suppliers who comply with these regulations will not only help your business stay compliant but also enhance your brand’s reputation as a responsible corporate citizen.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимый и тщательный due diligence. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.

Top 8 Plastic Bottles In Ocean Manufacturers & Suppliers List

1. The Ocean Cleanup – Plastic Pollution Solutions

Домен: theoceancleanup.com

Зарегистрирован: 2012 (13 лет)

Введение: This company, The Ocean Cleanup – Plastic Pollution Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. SAS – Plastic Pollution Insights

Домен: sas.org.uk

Зарегистрирован: 1996 (29 лет)

Введение: Plastic pollution facts and figures include alarming statistics such as: Over 1 in 3 fish caught for human consumption now contains plastic; 400 million tons of plastic are produced each year, forecasted to triple by 2060; only 9% of plastic ever produced has been recycled; approximately 11 million tonnes of plastic enter the ocean annually; more than 100,000 marine mammals and 1 million sea birds…

3. Condor Ferries – Ferry Services to Guernsey, Jersey & St Malo

Домен: condorferries.co.uk

Зарегистрирован: 1997 (28 лет)

Введение: Condor Ferries offers ferry services to various destinations including Guernsey, Jersey, and St Malo from ports such as Poole and Portsmouth. Key features include:

– Multiple ferry routes: Poole to Guernsey, Portsmouth to Guernsey, Guernsey to Jersey, and more.

– Options for group travel and vehicle transport, including freight and commercial goods.

– Accessibility services for passengers with …

4. Marine Litter – Plastic Breakdown Insights

Домен: marinelitter.no

Зарегистрирован: 2018 (7 лет)

Введение: A plastic bottle in the ocean will take approximately 450 years to completely break down, although this figure is not verifiable due to the lack of historical data on plastic usage prior to the 1960s. The breakdown process is influenced by factors such as composition, temperature, and exposure to solar UV-radiation. Most plastics are extremely durable and may persist for decades to centuries, with…

5. WWF – Marine Plastic Pollution Campaign

Домен: wwf.org.uk

Зарегистрирован: 1996 (29 лет)

Введение: WWF is campaigning for a global and legally binding UN agreement on ending marine plastic pollution. They encourage actions such as saying no to unnecessary packaging and single-use plastics, picking up litter, reusing and recycling plastic, and participating in challenges like Say no to single use, Say no to plastic, plastic-free routine, Bring a bottle, Reusable bags, and bulk buy.

6. Be the Story – Types of Ocean Plastic

Домен: be-the-story.com

Зарегистрирован: 2018 (7 лет)

Введение: Types of plastic in the ocean include: 1. Biodegradable plastic – decomposes in up to 24 months; found in single-use items (cutlery, plates, cups). 2. Polypropylene – decomposes in 20-30 years; found in bottle caps, straws, yoghurt cups, car bumpers. 3. Nylon – decomposes in 30-40 years; found in toothbrushes, textile fibres, fishing nets. 4. Silicone – decomposes in 20-100 years; found in kitchen…

7. Refill – Combat Plastic Pollution

Домен: refill.org.uk

Зарегистрирован: 2016 (9 лет)

Введение: This company, Refill – Combat Plastic Pollution, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. iStock – Plastic Bottle Ocean Images

Домен: istockphoto.com

Registered: 2000 (25 years)

Введение: 31,500+ Plastic Bottle Ocean Stock Photos, Pictures & Royalty-Free Images

Strategic Sourcing Conclusion and Outlook for plastic bottles in ocean

The issue of plastic bottles in the ocean presents both a significant challenge and an opportunity for strategic sourcing in the B2B landscape. As the global demand for plastic bottles continues to rise, understanding the dynamics of ocean pollution is critical for informed decision-making. B2B buyers must prioritize partnerships with suppliers who emphasize sustainable practices, such as using recyclable materials and promoting reusable alternatives. By doing so, companies can mitigate their environmental impact while also addressing consumer preferences that increasingly favor sustainability.

Furthermore, the disparity in waste management systems across regions highlights the importance of localized sourcing strategies. International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should actively seek to invest in innovative waste management solutions and recycling initiatives within their supply chains. This not only enhances brand reputation but also contributes to a circular economy.

As we move forward, collaboration among stakeholders—manufacturers, suppliers, and consumers—will be essential in combating ocean plastic pollution. By making strategic sourcing choices today, businesses can play a pivotal role in shaping a more sustainable future. Embrace this opportunity to lead the change and connect with suppliers who share your commitment to environmental stewardship.