Introduction: Navigating the Global Market for water bottle circumference

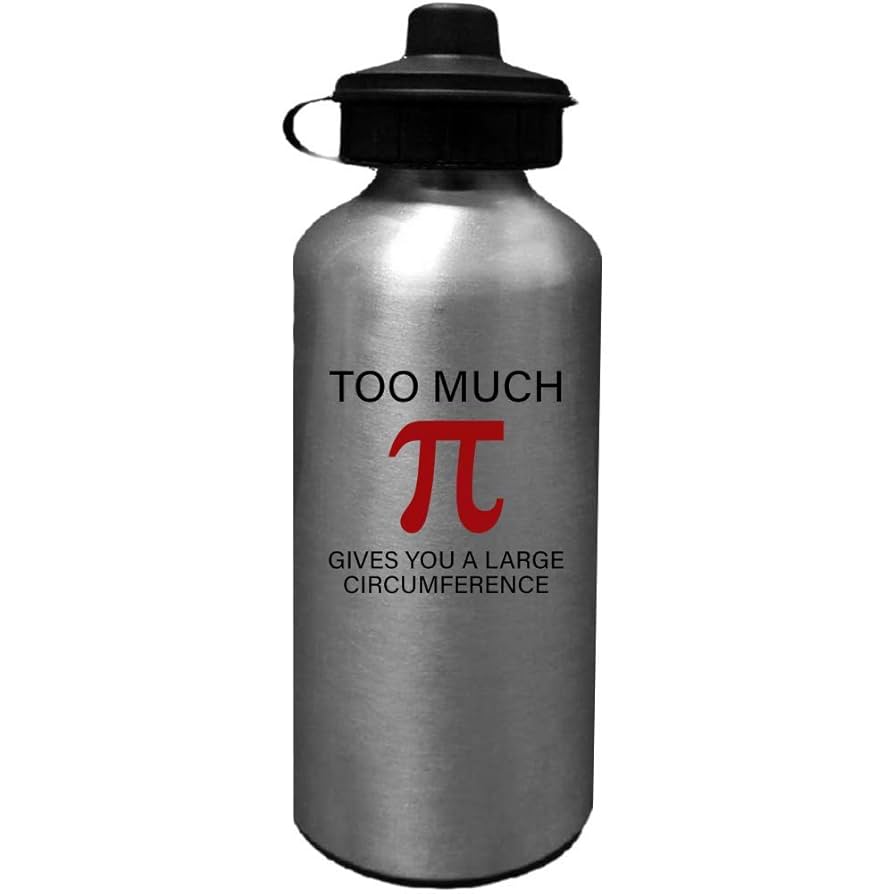

In the ever-evolving landscape of beverage packaging, understanding water bottle circumference is crucial for international B2B buyers. With a growing emphasis on sustainability and consumer preferences, sourcing the right dimensions for water bottles can pose significant challenges. The standard 16.9-ounce (500ml) bottle typically measures between 8 to 10 inches in circumference, but variations abound due to different shapes and sizes. This guide aims to demystify the complexities surrounding water bottle dimensions, offering a comprehensive overview of types, applications, supplier vetting processes, and cost considerations.

Navigating the global market for water bottles involves more than just selecting a size; it requires an informed approach to ensure that products meet regional standards and consumer expectations. This guide is tailored specifically for B2B buyers from Africa, South America, the Middle East, and Europe, including countries like Vietnam and Brazil. By providing actionable insights and expert recommendations, we empower businesses to make strategic purchasing decisions that align with their goals. Whether you are looking to enhance your product offerings or streamline your supply chain, understanding water bottle circumference will play a pivotal role in your success.

Dive into this guide to equip yourself with the knowledge needed to thrive in today’s competitive beverage market.

Навигация по статье

- Top 6 Water Bottle Circumference Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water bottle circumference

- Understanding water bottle circumference Types and Variations

- Key Industrial Applications of water bottle circumference

- 3 Common User Pain Points for ‘water bottle circumference’ & Their Solutions

- Strategic Material Selection Guide for water bottle circumference

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle circumference

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle circumference’

- Comprehensive Cost and Pricing Analysis for water bottle circumference Sourcing

- Alternatives Analysis: Comparing water bottle circumference With Other Solutions

- Essential Technical Properties and Trade Terminology for water bottle circumference

- Navigating Market Dynamics and Sourcing Trends in the water bottle circumference Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle circumference

- Важный отказ от ответственности и условия использования

- Strategic Sourcing Conclusion and Outlook for water bottle circumference

Understanding water bottle circumference Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Standard Single-Use | Height: 8″ (20.3 cm), Diameter: 2.5″ (6.35 cm) | Event catering, travel, vending | Pros: Cost-effective, lightweight; Cons: Environmental concerns, single-use waste |

| Reusable Sports Bottle | Height varies, typically wider diameter for grip | Fitness centers, corporate giveaways | Pros: Durable, eco-friendly; Cons: Higher upfront cost, needs cleaning |

| Настраиваемые бутылки | Various shapes and sizes, often with branding options | Promotions, events, corporate branding | Pros: Brand visibility, tailored marketing; Cons: Longer lead times, higher costs |

| Eco-Friendly Recycled | Made from rPET, often similar dimensions to standard | Sustainability-focused businesses | Pros: Reduced environmental impact; Cons: Limited availability, potential quality variance |

| Bulk Water Containers | Larger capacities (e.g., 5-gallon jugs), varied shapes | Offices, construction sites, events | Pros: Cost-effective per volume, less frequent purchases; Cons: Requires dispensing equipment, space-consuming |

What Are the Key Characteristics of Standard Single-Use Water Bottles?

Standard single-use water bottles are typically 8 inches tall with a diameter of 2.5 inches, holding around 16.9 ounces (500 mL). These bottles are widely used in events, travel, and vending services due to their lightweight and cost-effective nature. However, their environmental impact is significant, as they contribute to plastic waste. B2B buyers should consider the trade-off between cost savings and sustainability when purchasing these bottles.

Why Choose Reusable Sports Bottles for Your Business Needs?

Reusable sports bottles often feature wider diameters for better grip and can come in various heights. They are ideal for fitness centers and corporate giveaways, promoting an active lifestyle while encouraging sustainability. Although they come with a higher upfront cost, their durability and reusability make them a better long-term investment. B2B buyers should evaluate their target audience’s preferences and usage frequency when selecting these bottles.

How Do Customizable Bottles Enhance Brand Visibility?

Customizable bottles vary in shape and size, allowing businesses to incorporate branding and marketing messages. These bottles are particularly effective for promotional events and corporate branding initiatives. While they offer excellent brand visibility, buyers should be aware of longer lead times and higher costs associated with customization. It’s essential to balance marketing goals with budget considerations when opting for these bottles.

What Are the Benefits of Eco-Friendly Recycled Water Bottles?

Eco-friendly recycled water bottles are made from recycled PET (rPET) and often mirror the dimensions of standard bottles. They are increasingly favored by sustainability-focused businesses seeking to minimize their environmental footprint. While these bottles help reduce plastic waste, availability can be limited, and buyers should verify quality standards to ensure product reliability. Considering the growing emphasis on corporate social responsibility, these bottles can enhance a brand’s reputation.

When to Consider Bulk Water Containers for Your Operations?

Bulk water containers, such as 5-gallon jugs, are designed for high-capacity needs and come in various shapes. They are ideal for offices, construction sites, and events, providing a cost-effective solution for hydration. However, they require dispensing equipment and can take up significant space. B2B buyers should assess their operational requirements and space constraints when integrating bulk water containers into their supply chain.

Key Industrial Applications of water bottle circumference

| Промышленность/сектор | Specific Application of Water Bottle Circumference | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Производство напитков | Designing bottle molds for various water sizes | Optimizes production efficiency and reduces waste | Material compatibility, design specifications, and cost |

| Custom Branding | Label design and printing for promotional bottles | Enhances brand visibility and customer engagement | Label dimensions, printing technology, and durability |

| Гостеприимство и мероприятия | Sizing for event-specific bottled water services | Meets diverse customer needs while maintaining quality | Bulk ordering, customization options, and delivery times |

| Retail Distribution | Standardizing packaging for shelf display | Increases shelf appeal and improves inventory turnover | Compliance with local regulations and packaging costs |

| Environmental Sustainability | Developing eco-friendly alternatives | Reduces carbon footprint and aligns with consumer trends | Sourcing recycled materials and assessing lifecycle impacts |

How is Water Bottle Circumference Used in Beverage Manufacturing?

In the beverage manufacturing sector, water bottle circumference is critical for designing molds that produce various bottle sizes efficiently. Accurate measurements ensure that the bottles produced fit standard dimensions for filling and labeling machines, minimizing waste and optimizing production. For international buyers, especially in regions like Africa and South America, understanding local market preferences for bottle sizes can enhance market entry strategies. Additionally, sourcing materials that comply with local regulations is vital to ensure production quality and safety.

What Role Does Water Bottle Circumference Play in Custom Branding?

Custom branding heavily relies on the precise circumference of water bottles to create labels that fit perfectly. This application is particularly valuable for businesses looking to enhance their brand visibility through promotional bottled water. Effective label design can significantly impact customer engagement, making it essential for B2B buyers to consider label dimensions and printing durability. For companies in the Middle East and Europe, aligning label designs with cultural aesthetics can further enhance brand appeal and market penetration.

How is Water Bottle Circumference Relevant for Hospitality and Events?

In the hospitality sector, especially during events, the circumference of water bottles is crucial for offering tailored bottled water services. Event planners often require specific bottle sizes to accommodate various guest preferences and service styles. By understanding the requirements related to circumference, businesses can ensure they meet customer expectations while maintaining product quality. For buyers in Europe and Africa, sourcing options that allow for bulk orders with customization can streamline operations and enhance the overall guest experience.

Why is Standardization of Water Bottle Circumference Important for Retail Distribution?

For retail distribution, standardizing the circumference of water bottles ensures consistency in packaging, which is vital for shelf display and inventory management. A uniform bottle size improves shelf appeal and facilitates easier restocking, leading to better inventory turnover. B2B buyers in South America and Europe must consider compliance with local packaging regulations and the associated costs when sourcing bottles. Understanding market trends and consumer preferences can also guide decisions in selecting the right bottle specifications.

How Can Water Bottle Circumference Contribute to Environmental Sustainability?

The growing emphasis on environmental sustainability makes the circumference of water bottles an important consideration for companies developing eco-friendly alternatives. By focusing on the dimensions of bottles made from recycled materials, businesses can significantly reduce their carbon footprint while appealing to environmentally conscious consumers. International buyers, particularly from regions like Africa and the Middle East, should prioritize sourcing recycled materials and assess the lifecycle impacts of their products to align with global sustainability goals.

3 Common User Pain Points for ‘water bottle circumference’ & Their Solutions

Scenario 1: Confusion Over Standard Sizes for Bottled Water Distribution

Проблема: B2B buyers in the beverage industry often face confusion regarding the standard sizes of water bottles, especially when sourcing for different markets. For instance, a buyer in Brazil may find that the 16.9 oz (500 ml) bottle is popular, but they need to ensure that the dimensions—including circumference—are consistent with local consumer preferences and packaging regulations. This inconsistency can lead to logistical challenges, increased costs, and potential dissatisfaction among retailers and consumers.

Решение: To mitigate this issue, buyers should conduct thorough market research to understand the most common water bottle sizes in their target regions. Utilizing a standardized measurement guide can streamline the sourcing process. Buyers should specify the desired circumference and dimensions in their purchase orders, clearly communicating these requirements to suppliers. Additionally, collaborating with local distributors who understand the market can provide invaluable insights into preferred sizes. Establishing a flexible procurement strategy that allows for adjustments based on local market trends will also enhance operational efficiency.

Scenario 2: Environmental Concerns with Packaging and Circumference

Проблема: Sustainability is increasingly a priority for businesses globally, and buyers are often challenged by the environmental impact of water bottles, especially single-use plastics. The circumference of a bottle can affect its recyclability and the amount of plastic waste produced. Buyers may struggle to find suppliers who offer eco-friendly options while still meeting the size requirements necessary for their branding and distribution needs.

Решение: Buyers should prioritize sourcing bottles made from recycled materials or those that are biodegradable. When evaluating suppliers, they should request detailed information about the materials used, including the environmental impact of the bottle’s circumference. Furthermore, opting for designs that minimize excess plastic without compromising functionality can be beneficial. Engaging with suppliers who have robust sustainability practices and certifications can also reinforce a company’s commitment to environmental responsibility. Implementing a return and reuse system for bottles can further reduce waste and promote a circular economy.

Scenario 3: Custom Labeling Challenges Related to Bottle Dimensions

Проблема: Custom branding through labeling is essential for companies in the beverage sector, yet discrepancies in bottle dimensions—including circumference—can create significant challenges. A company may design a label based on assumed dimensions, only to find it doesn’t fit properly due to variations in bottle size. This can lead to wasted resources and delays in product launches, impacting marketing efforts and sales.

Решение: To address this challenge, buyers should invest in precise measurements of the bottles they intend to use, including circumference and height, before finalizing label designs. Collaborating closely with label manufacturers to understand the recommended label dimensions for specific bottle sizes is crucial. Buyers can also use 3D modeling tools to visualize how the labels will look on the bottles, ensuring a perfect fit. Establishing a proactive communication channel with suppliers regarding any design changes or discrepancies will facilitate smoother production processes and help maintain branding integrity. Regularly reviewing and updating specifications as new bottle designs are introduced will keep the product line fresh and competitive.

Strategic Material Selection Guide for water bottle circumference

What Are the Key Properties of Common Materials Used for Water Bottles?

When selecting materials for water bottles, particularly regarding circumference specifications, several options are commonly considered. Each material presents unique properties that can influence performance, cost, and suitability for various applications. Below, we analyze four prevalent materials: PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), stainless steel, and glass.

How Does PET Perform as a Material for Water Bottles?

PET is widely used for single-use water bottles due to its excellent clarity, lightweight nature, and good barrier properties against gases and moisture. It typically withstands temperatures up to 60°C (140°F) and is resistant to impact, making it suitable for various environments. However, it is not suitable for high-temperature applications, as it can deform or leach chemicals.

Плюсы: PET is cost-effective, lightweight, and recyclable, making it an attractive option for mass production.

Конс: Its single-use nature contributes to environmental concerns, and it may not be durable enough for repeated use.

Влияние на применение: PET bottles are ideal for cold beverages but should not be used for hot liquids.

Соображения для международных покупателей: Compliance with recycling regulations is critical, especially in regions with strict environmental laws, such as Europe. Buyers should also be aware of local recycling capabilities.

What Are the Advantages and Disadvantages of HDPE?

HDPE is another popular choice, especially for reusable water bottles. It offers excellent chemical resistance and can withstand temperatures ranging from -40°C to 60°C (-40°F to 140°F). HDPE is also known for its toughness and resistance to impact.

Плюсы: It is durable, lightweight, and resistant to UV radiation, making it suitable for outdoor applications.

Конс: While it is recyclable, the recycling rates are lower than PET, and it can be more expensive to produce.

Влияние на применение: HDPE is compatible with a wide range of liquids, including acidic beverages.

Соображения для международных покупателей: Buyers should ensure compliance with local food safety standards, as regulations can vary significantly across regions.

Why Choose Stainless Steel for Water Bottles?

Stainless steel is increasingly popular for premium water bottles. It offers exceptional durability, corrosion resistance, and is suitable for both hot and cold beverages. Stainless steel can withstand high temperatures and pressures, making it ideal for various applications.

Плюсы: It is highly durable, reusable, and does not leach harmful chemicals, providing a safe option for consumers.

Конс: The initial manufacturing cost is higher, and it can be heavier than plastic alternatives.

Влияние на применение: Stainless steel is suitable for both hot and cold liquids, making it versatile for diverse markets.

Соображения для международных покупателей: Compliance with food-grade standards is essential, particularly in regions with stringent regulations like the EU.

What Role Does Glass Play in Water Bottle Design?

Glass is a traditional material that offers excellent chemical resistance and does not leach any substances into beverages. It is suitable for both hot and cold liquids and is often preferred for premium bottled water products.

Плюсы: Glass is recyclable and provides an excellent barrier to gases, preserving the quality of the liquid.

Конс: It is fragile and heavier than plastic alternatives, which can increase shipping costs.

Влияние на применение: Glass is ideal for high-end bottled water products but may not be practical for all markets due to its weight and fragility.

Соображения для международных покупателей: Buyers should consider the implications of breakage during transport and ensure compliance with packaging standards.

Summary Table of Material Selection for Water Bottles

| Материал | Typical Use Case for Water Bottle Circumference | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| ПЭТ | Single-use bottled water | Lightweight and recyclable | Limited durability for reuse | Низкий |

| ПНД | Reusable water bottles | Durable and UV resistant | Lower recycling rates | Средний |

| Нержавеющая сталь | Бутылки для воды премиум-класса | Highly durable and safe | Более высокая первоначальная стоимость | Высокий |

| Стекло | High-end bottled water products | Excellent preservation of liquid quality | Fragile and heavier | Средний |

This strategic material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle circumference

What Are the Key Stages in the Manufacturing Process of Water Bottles?

The manufacturing of water bottles, particularly concerning their circumference, involves several critical stages that ensure both quality and consistency. The main processes include material preparation, forming, assembly, and finishing.

-

Подготовка материалов

The primary materials used for water bottles include PET (Polyethylene Terephthalate) and rPET (recycled PET). The first step involves sourcing high-quality resin, which is then dried and melted to remove any moisture. This ensures optimal performance during the forming process. For B2B buyers, understanding the source and quality of materials is vital as it directly impacts the durability and environmental footprint of the bottles. -

Формирование

The forming process typically employs injection molding or blow molding techniques. In blow molding, the melted plastic is formed into a preform, which is then inflated into the desired shape of the bottle. This stage is crucial for achieving the correct circumference and overall dimensions of the bottle. Precision in this step is critical, as any deviation can affect the bottle’s ability to fit standard caps and packaging. -

Сборка

Once the bottles are formed, they may undergo an assembly process where components such as caps and labels are applied. This step often involves automated machinery to ensure efficiency and accuracy. For B2B buyers, it’s important to consider the compatibility of these components with the bottles, as variations can lead to quality issues down the line. -

Отделка

The finishing stage includes quality checks, cleaning, and packaging. Bottles are often treated to enhance clarity and durability. Additionally, they may be printed with branding or labeling as per customer specifications. This stage ensures that the final product meets market standards and customer expectations.

What Are the Quality Assurance Standards Relevant to Water Bottle Manufacturing?

Quality assurance in the manufacturing of water bottles is governed by various international standards and industry-specific regulations. This ensures that the products are safe, reliable, and environmentally friendly.

-

International Standards

ISO 9001 is the most recognized quality management standard worldwide. It establishes a framework for consistent quality in production processes. Compliance with ISO 9001 demonstrates a commitment to continuous improvement and customer satisfaction, which is crucial for B2B buyers looking to establish long-term partnerships. -

Industry-Specific Certifications

Certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the intended use of the water bottles. The CE mark indicates compliance with European safety standards, while API standards could apply if the bottles are used in specific industrial applications. Understanding these certifications can help B2B buyers assess the credibility of suppliers.

What Are the Key Quality Control Checkpoints in Water Bottle Manufacturing?

Quality control (QC) is integral to ensuring that water bottles meet the required specifications and standards. Key checkpoints in the QC process include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Входящий контроль качества (IQC)

IQC focuses on raw materials and components before they enter the production line. This includes inspecting the quality of plastic resins, caps, and labels. For B2B buyers, ensuring that suppliers perform thorough IQC checks can prevent defects in the final product. -

Внутрипроцессный контроль качества (IPQC)

IPQC occurs during the manufacturing process. This involves regular monitoring of the molding and forming processes to detect any deviations from specifications. Techniques such as statistical process control (SPC) can be employed to track production variables. B2B buyers should inquire about the IPQC measures that suppliers have in place. -

Окончательный контроль качества (ОКК)

FQC is conducted after production is complete. This includes testing bottles for dimensions, weight, and functionality (e.g., cap fit). Common testing methods involve dimensional inspection using calipers and performing burst tests to check structural integrity. Buyers should request FQC reports to verify that products meet their specifications.

Как покупатели B2B могут проверить практику контроля качества поставщиков?

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier QC practices is critical. Here are effective methods to ensure supplier reliability:

-

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. These audits can be performed by the buying organization or through third-party agencies that specialize in quality assessments. This not only verifies compliance with standards but also fosters a transparent relationship between buyers and suppliers. -

Запрос отчетов о контроле качества

Suppliers should provide detailed reports on their QC processes, including IQC, IPQC, and FQC results. These documents can offer valuable data on defect rates and corrective actions taken, which can be a good indicator of the supplier’s commitment to quality. -

Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These entities can conduct unannounced checks on production facilities and provide independent assessments of product quality. This is particularly beneficial for buyers who cannot visit suppliers in person.

Каковы нюансы контроля качества и сертификации для международных покупателей B2B?

Navigating the landscape of quality control and certifications can be complex for international B2B buyers. Here are some nuances to consider:

-

Understanding Regional Standards

Different regions may have varying regulations and standards for product safety and quality. For example, products sold in the European Union must comply with CE marking requirements, while products in the United States may need to meet FDA regulations. Buyers should familiarize themselves with these standards to ensure compliance. -

Language and Documentation Barriers

Language differences can pose challenges when reviewing QC documents and certifications. It is essential for buyers to ensure that all relevant documents are available in a language they understand, or to seek assistance from translators or local representatives. -

Cultural Considerations in Business Practices

Different cultures may have unique approaches to business and quality assurance. Understanding these cultural nuances can improve communication and foster better relationships with suppliers, ultimately leading to more reliable quality outcomes.

In summary, the manufacturing processes and quality assurance practices for water bottles are critical components for B2B buyers to understand. By focusing on the key stages of manufacturing, adhering to relevant standards, implementing rigorous QC checkpoints, and verifying supplier practices, buyers can ensure they source high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle circumference’

When sourcing water bottles, particularly for B2B applications, understanding the dimensions, especially the circumference, is crucial for ensuring compatibility with packaging, labeling, and logistics. This guide serves as a practical checklist to help international buyers make informed decisions regarding the procurement of water bottles based on their circumference and other relevant factors.

Шаг 1: Определите технические характеристики

Begin by outlining the specific requirements for the water bottles you need. This includes determining the desired volume (e.g., 16.9 oz or 500 ml), dimensions, and shape. Clearly defined specifications will help streamline the sourcing process, ensuring that suppliers can meet your needs effectively.

- Consider the intended use: Are the bottles for single-use or reusable applications?

- Identify any regulatory requirements: Depending on the region, there may be specific standards for food safety and materials.

Шаг 2: Measure the Circumference Accurately

For optimal packaging and labeling, measuring the circumference of the water bottles is essential. A standard 16.9 oz bottle typically has a circumference of 8-10 inches (20-25 cm).

- Utilize proper measuring tools: A flexible measuring tape can provide the most accurate readings.

- Account for variations: Different bottle shapes may require custom labels or packaging solutions.

Шаг 3: Оцените потенциальных поставщиков

Before committing to a supplier, conduct a thorough evaluation. This includes reviewing company profiles, production capabilities, and prior customer feedback.

- Request samples: It’s beneficial to test the bottles for quality and fit.

- Check for certifications: Ensure that suppliers comply with international standards for food-grade plastics and sustainability practices.

Шаг 4: Assess Sustainability Practices

Given the growing focus on sustainability, evaluate the environmental impact of the bottles you intend to procure. Many suppliers now offer options made from recycled materials.

- Inquire about materials: Look for bottles made from rPET or other recycled plastics.

- Understand the recycling process: Ensure that the supplier has a clear recycling program to minimize waste.

Шаг 5: Determine Logistics and Supply Chain Capabilities

Understanding the logistics of sourcing is vital. Assess the supplier’s ability to deliver within your required timelines and their shipping capabilities.

- Discuss lead times: Knowing how long it will take to receive your order is critical for planning.

- Evaluate shipping options: Determine whether the supplier can accommodate your preferred shipping methods and costs.

Шаг 6: Переговоры о ценах и условиях оплаты

Once you have identified a suitable supplier, engage in negotiations regarding pricing and payment terms.

- Consider bulk discounts: Many suppliers offer reduced rates for larger orders.

- Review payment flexibility: Ensure the terms align with your financial capabilities and cash flow.

Шаг 7: Finalize Contracts and Agreements

Before making any commitments, ensure all agreements are documented. This includes specifications, pricing, delivery schedules, and any warranties or guarantees.

- Consult legal expertise: Having legal oversight can protect your interests in the contract.

- Establish clear communication channels: Define who will be responsible for updates and changes during the order process.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing water bottles based on their circumference and other critical specifications, ultimately ensuring a successful procurement process.

Comprehensive Cost and Pricing Analysis for water bottle circumference Sourcing

What Are the Key Cost Components in Sourcing Water Bottle Circumference?

When sourcing water bottles, particularly those with specific circumferences, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Материалы: The type of plastic used (e.g., PET, rPET) significantly impacts costs. Sustainable materials often incur higher initial expenses but can provide long-term savings through brand positioning and compliance with environmental regulations.

-

Труд: Labor costs vary based on the manufacturing location. Countries with lower labor costs can reduce overall expenses, but this might compromise quality if not managed properly.

-

Производственные накладные расходы: This includes utilities, rent, and equipment depreciation. Efficient production lines and energy-efficient practices can help minimize these costs.

-

Инструментальная оснастка: The initial cost of molds and other tooling equipment can be substantial, especially for customized bottle shapes. However, these costs can be amortized over larger production volumes.

-

Контроль качества: Implementing strict QC measures ensures product consistency and compliance with safety standards, which is particularly important for international markets. While this adds to costs, it can prevent costly recalls and reputational damage.

-

Логистика: Transportation costs can vary greatly depending on the origin of the materials and the destination of the finished products. Incoterms should be clearly defined to avoid unexpected charges.

-

Маржа: Suppliers typically mark up prices to ensure profitability. Understanding the competitive landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect Water Bottle Circumference Sourcing?

Several factors influence the pricing of water bottles, particularly regarding circumferences:

-

Объем/МОК: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to reduced per-unit costs, making it essential for buyers to assess their capacity and demand.

-

Технические характеристики и персонализация: Custom designs or unique specifications can lead to higher costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Материалы: The choice of materials, including recycled options, can influence costs. While eco-friendly materials may be pricier upfront, they can appeal to consumers and enhance brand reputation.

-

Качество и сертификация: Bottles that meet certain quality standards or certifications (e.g., FDA approval) may command higher prices. Buyers should consider the long-term benefits of investing in quality.

-

Факторы поставщика: Supplier reliability, reputation, and historical performance can affect pricing. Building strong relationships with suppliers can lead to better pricing and terms.

-

Инкотермс: Understanding shipping terms and responsibilities is crucial in international transactions. The choice of Incoterms can significantly impact total costs and risk exposure.

What Tips Can B2B Buyers Utilize for Cost-Efficiency in Water Bottle Sourcing?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing can lead to substantial cost savings:

-

Negotiate Terms: Leverage your order volume and the competitive landscape to negotiate better pricing and payment terms with suppliers.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, storage, and potential waste costs. A lower upfront price might not always result in savings in the long run.

-

Поймите нюансы ценообразования: International buyers should be aware of currency fluctuations, tariffs, and local regulations that can affect pricing.

-

Evaluate Supplier Diversification: Avoid dependency on a single supplier by diversifying your supplier base. This can protect against price hikes and supply chain disruptions.

-

Monitor Market Trends: Stay informed about market conditions, such as material costs and regulatory changes, to anticipate price changes and adapt your sourcing strategy accordingly.

Заключение

Understanding the cost components and pricing influencers in water bottle circumference sourcing is essential for B2B buyers. By employing strategic negotiation techniques and evaluating total costs, companies can optimize their sourcing strategies and achieve better financial outcomes. While prices may fluctuate, informed decisions based on comprehensive analysis will lead to sustainable sourcing practices that meet both business objectives and consumer demands.

Alternatives Analysis: Comparing water bottle circumference With Other Solutions

Exploring Alternatives to Water Bottle Circumference

In the landscape of beverage packaging, particularly for water, the dimensions of containers play a crucial role in usability, distribution, and consumer appeal. While the standard water bottle circumference often dictates its market viability, it’s essential for B2B buyers to consider alternative solutions that may offer competitive advantages in performance, cost, and environmental impact.

| Сравнительный аспект | Water Bottle Circumference | Eco-Friendly Water Pouch | Reusable Water Bottles |

|---|---|---|---|

| Производительность | Standardized dimensions suitable for vending and retail | Lightweight, flexible design allows for easy storage | Durable and customizable, suitable for repeated use |

| Стоимость | Moderate, with high production and recycling costs | Lower production costs, but may have higher logistics costs | Initial higher cost, but savings over time due to reusability |

| Простота реализации | Established supply chains and processes | Requires new logistics and handling approaches | Well-understood market with existing infrastructure |

| Техническое обслуживание | Minimal; recycling is key | Single-use, leading to disposal challenges | Requires cleaning, but promotes sustainability |

| Лучший пример использования | Retail and vending machines | Outdoor events, festivals, and emergency supplies | Corporate gifting, promotional products, and everyday hydration |

Подробный анализ альтернатив

Eco-Friendly Water Pouch

Eco-friendly water pouches are a modern alternative that offers a flexible, lightweight solution for hydration. These pouches typically have a smaller circumference than standard bottles, making them easier to transport and store. While their production costs are generally lower, logistics can become complex due to their unique handling requirements. The single-use nature of these pouches raises environmental concerns, as they contribute to waste despite being made from recycled materials. They are particularly well-suited for outdoor events and festivals, where convenience is paramount.

Reusable Water Bottles

Reusable water bottles present a compelling alternative for businesses focused on sustainability and long-term cost savings. These bottles come in various shapes and sizes, and while they may have a higher initial purchase price, they can significantly reduce costs over time as they eliminate the need for single-use packaging. They require maintenance, as regular cleaning is essential, but this promotes a sustainable practice among consumers. Reusable bottles are ideal for corporate gifting and branding opportunities, enhancing customer loyalty through environmentally friendly practices.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between water bottle circumference and its alternatives, B2B buyers should assess their specific operational needs and market demands. If your focus is on sustainability and long-term cost efficiency, investing in reusable water bottles may be the best route. Conversely, for events requiring high-volume distribution with minimal logistics hassle, eco-friendly water pouches could offer a practical solution. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their business goals and environmental commitments.

Essential Technical Properties and Trade Terminology for water bottle circumference

What Are the Key Technical Properties of Water Bottle Circumference?

Understanding the technical specifications of water bottle circumference is essential for B2B buyers in the beverage industry. Below are critical properties to consider:

1. Diameter and Circumference Measurements

The diameter of a water bottle directly influences its circumference, which is vital for packaging, labeling, and compatibility with dispensers. For instance, a standard 16.9 oz (500 mL) bottle typically has a diameter of 2.5 inches (6.35 cm), resulting in a circumference of approximately 8-9 inches (20-23 cm). Accurate measurements are crucial for logistics and inventory management, ensuring that bottles fit within designed spaces.

2. Класс материала

Water bottles are commonly made from various materials, such as PET (Polyethylene Terephthalate) and rPET (recycled PET). The choice of material affects not only the bottle’s durability and weight but also its recyclability and environmental impact. B2B buyers should prioritize suppliers offering high-grade materials that meet industry standards, especially as sustainability becomes a key purchasing criterion.

3. Уровни толерантности

Tolerance refers to the allowable deviation from specified measurements. For water bottles, maintaining tight tolerances in diameter and height is critical for ensuring that caps fit securely and that bottles are consistent in shape. Tighter tolerances can lead to reduced production waste and better overall quality, which is essential for maintaining brand reputation.

4. Объемная емкость

The volume capacity of a water bottle is directly linked to its dimensions. Understanding the relationship between circumference and volume is essential for inventory planning and customer demand forecasting. A well-defined volume specification helps buyers select bottles that meet market needs, whether for single-use or multi-pack offerings.

5. Weight Specifications

The weight of a water bottle affects shipping costs and consumer handling. Lighter bottles can reduce transportation expenses, making them attractive for bulk purchases. Additionally, consumers often prefer lighter bottles for convenience. B2B buyers should consider weight specifications to optimize logistics and enhance the customer experience.

What Are Common Trade Terms Related to Water Bottle Circumference?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of water bottles, an OEM might supply the bottles to beverage companies that brand and sell them. Understanding OEM relationships can help buyers negotiate better prices and ensure product quality.

2. MOQ (минимальное количество заказа)

MOQ is the smallest order a supplier is willing to accept. This term is vital for B2B buyers to understand their purchasing capabilities and to manage inventory effectively. Knowing the MOQ helps businesses plan their procurement strategies and avoid excess inventory costs.

3. RFQ (запрос котировок)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. It is a critical step in the procurement process for water bottles, enabling buyers to compare options and make informed decisions based on cost and quality.

4. Инкотермс (международные коммерческие термины)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, risk, and costs. Familiarity with these terms helps B2B buyers understand shipping logistics and negotiate better terms, ensuring smooth transactions across borders.

5. Параметры настройки

Customization refers to the ability to modify the design, size, or labeling of water bottles. Understanding customization options is crucial for businesses looking to differentiate their products in competitive markets. Buyers should inquire about available modifications to meet specific branding needs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, streamline procurement processes, and enhance their competitive advantage in the beverage market.

Navigating Market Dynamics and Sourcing Trends in the water bottle circumference Sector

What are the Current Market Dynamics and Key Trends in the Water Bottle Circumference Sector?

The global water bottle market is experiencing significant growth, driven by increasing demand for convenient hydration solutions and heightened awareness of environmental issues. In regions such as Africa, South America, the Middle East, and Europe, the rise of health-conscious consumers and a growing inclination towards sustainable products are shaping market dynamics. The standard 16.9-ounce (500 mL) water bottle, with a typical circumference of 8-10 inches (20-25 cm), remains a popular choice among consumers and businesses alike.

Emerging B2B tech trends are influencing sourcing practices in the water bottle sector. Digital platforms are streamlining procurement processes, allowing international buyers to connect with manufacturers more efficiently. Additionally, advancements in manufacturing technologies are enabling the production of customizable bottles, catering to specific branding needs while adhering to desired dimensions. As sustainability becomes a priority, there is a noticeable shift towards sourcing bottles made from recycled materials and developing eco-friendly designs that comply with regulatory standards across different regions.

In response to the fluctuating global supply chain dynamics, international B2B buyers are increasingly focusing on diversifying their supplier networks. This approach mitigates risks associated with geopolitical uncertainties and supply disruptions, ensuring a stable supply of water bottles tailored to varying circumference specifications.

How is Sustainability Influencing Sourcing Decisions in the Water Bottle Industry?

The environmental impact of single-use plastic bottles has prompted a reevaluation of sourcing practices in the water bottle sector. Ethical supply chains are crucial as businesses seek to minimize their carbon footprint and comply with stringent environmental regulations. The use of recycled PET (rPET) in bottle production exemplifies a sustainable approach, as it reduces the need for virgin plastic and conserves natural resources.

B2B buyers are increasingly prioritizing suppliers that offer ‘green’ certifications, such as the Global Recycle Standard (GRS) or the Cradle to Cradle certification, which validate sustainable practices. These certifications not only enhance brand reputation but also appeal to a growing segment of environmentally-conscious consumers. Furthermore, companies are exploring alternative materials, such as biodegradable plastics and plant-based resins, to align with sustainability goals.

Incorporating sustainability into sourcing decisions can lead to long-term cost savings, improved brand loyalty, and compliance with international regulations, making it a pivotal factor for B2B buyers in the water bottle circumference sector.

How Has the Water Bottle Sector Evolved Over Time?

The evolution of the water bottle sector reflects broader societal changes and advancements in technology. Initially dominated by glass and metal containers, the introduction of plastic bottles in the 1970s revolutionized the industry by providing a lightweight, cost-effective alternative. Over the years, the standard dimensions of water bottles, particularly the 16.9-ounce size, became widely accepted due to their convenience and portability.

As consumer awareness regarding environmental sustainability grew, manufacturers began innovating with materials and designs that reduce waste and enhance recyclability. The transition towards rPET and the emphasis on ethical sourcing practices signify a pivotal shift in the industry, aligning product offerings with the values of modern consumers. This evolution underscores the importance of adaptability in sourcing strategies, as businesses navigate the complexities of a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle circumference

-

How do I determine the appropriate circumference for my water bottle design?

To determine the appropriate circumference for your water bottle, first consider the target market and usage. For standard single-use bottles, a circumference of approximately 8-10 inches (20-25 cm) is typical for a 16.9 oz (500 ml) bottle. If your design includes additional features like grips or custom shapes, measuring prototypes is crucial. Collaborate with manufacturers who can provide samples or mock-ups to ensure the circumference aligns with ergonomic and aesthetic preferences. -

What are the most common sizes for water bottles in international markets?

The most common sizes for water bottles globally include 500 ml (16.9 oz), 750 ml, and 1 liter. The 500 ml size is widely used in both single-use and reusable bottles, making it a popular choice among consumers. When sourcing, consider regional preferences; for instance, larger bottles may be favored in South America, while smaller sizes might be more popular in Europe. Understanding local trends can enhance your product’s market acceptance. -

What customization options should I consider for water bottle circumference?

Customization options for water bottles can include varying diameters, materials, and shapes. Consider offering eco-friendly options made from recycled plastics or biodegradable materials, as these are increasingly preferred in many markets. Additionally, you can provide customizable labels that fit the specific circumference of your bottles, allowing businesses to enhance branding. Collaborate closely with your supplier to explore innovative designs that cater to specific customer needs. -

What are the minimum order quantities (MOQs) for water bottles from suppliers?

Minimum order quantities can vary significantly among suppliers, typically ranging from 1,000 to 10,000 units for custom water bottles. For smaller businesses or startups, seeking suppliers with flexible MOQs is advisable. Negotiate terms that allow for trial orders or smaller batch productions to assess market demand. Understanding the supplier’s capabilities and their production cycles can also facilitate better planning for your inventory needs. -

How can I vet suppliers for water bottle production effectively?

Vetting suppliers involves assessing their production capabilities, quality control processes, and compliance with international standards. Request samples to evaluate material quality and craftsmanship. Additionally, check for certifications such as ISO or FDA compliance, particularly for food-grade products. Establish communication with previous clients to gather insights about the supplier’s reliability and service. Engaging in trade shows or industry forums can also provide valuable networking opportunities to identify reputable suppliers. -

What payment terms are standard in B2B water bottle transactions?

Standard payment terms in B2B transactions often include a deposit upfront, typically 30% to 50%, with the balance due upon shipment or delivery. Some suppliers may offer net terms, allowing payment within 30, 60, or even 90 days post-delivery. It’s essential to discuss and agree on these terms before finalizing contracts. Ensure that you have a clear understanding of the payment methods accepted, such as bank transfers, letters of credit, or online payment systems. -

What quality assurance measures should I implement when sourcing water bottles?

Implementing robust quality assurance measures is crucial in water bottle sourcing. Start by defining quality standards based on your target market’s regulations. Conduct regular inspections during production, and consider third-party quality control services to verify compliance with specifications. Request detailed documentation, including material safety data sheets (MSDS) and certificates of analysis (COA). Establish a return policy for defective products to minimize losses and maintain customer satisfaction. -

How should I approach logistics for international shipping of water bottles?

When planning logistics for international shipping of water bottles, consider factors such as shipping methods, customs regulations, and lead times. Work with freight forwarders experienced in handling beverage products to ensure compliance with local laws. Evaluate different shipping options, including sea freight for larger orders or air freight for urgent shipments. Calculate total landed costs to understand the financial implications, and ensure that your supply chain is resilient enough to handle potential disruptions.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимый и тщательный due diligence. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.

Top 6 Water Bottle Circumference Manufacturers & Suppliers List

1. Owala – FreeSip 32 oz Bottle

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Owala FreeSip 32 oz bottle has a diameter of approximately 3.43 inches and a circumference of about 10.78 inches.

2. Bottle Your Brand – Water Bottle Labels & Sizes

Домен: bottleyourbrand.com

Зарегистрирован: 2004 (21 год)

Введение: Bottle and Label Size Information: 1. Water Bottle Labels Only: – Narrow water bottle label: 1 3/4″ H x 8 1/4″ W – Wide water bottle label: 2 1/8″ H x 8″ W 2. Bottled Water Orders: – 12 oz. Bottled Water: – Height: 7″ – Diameter: 2.25″ – Label size: 1.83″ H x 7.25″ L – Case: 24 bottles, Weight: 22 lbs, Box dimensions: 8″ H x 10″ W x 15″ L – 16.9 oz. Bottled Water: – Height: 8″ – Diameter: 2.5″ – L…

3. Facebook – Water Bottle Measurement

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: This company, Facebook – Water Bottle Measurement, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Owala – FreeSip Water Bottle

Домен: owalalife.com

Зарегистрирован: 2019 (6 лет)

Введение: {‘FreeSip_Water_Bottle’: {‘sizes’: [{‘size’: ’19 oz.’, ‘height’: ‘9.88 inches’}, {‘size’: ’24 oz.’, ‘height’: ‘10.68 inches’}, {‘size’: ’25 oz.’, ‘height’: ‘9.87 inches’}, {‘size’: ’32 oz.’, ‘height’: ‘10.66 inches’}, {‘size’: ’40 oz.’, ‘height’: ‘11.64 inches’}], ‘materials’: [‘Stainless Steel’, ‘Tritan Plastic’], ‘colors’: {‘Tritan’: 3, ‘Stainless_Steel’: 6}}, ‘Flip_Water_Bottle’: {‘sizes’: [{‘s…

5. Answers – Water Bottle Circumference

Домен: answers.com

Зарегистрирован: 1996 (29 лет)

Введение: The circumference of a typical 20 oz plastic water bottle is approximately 8.63 inches, based on an average diameter of 2.75 inches. The diameter can vary between 2.5 to 3 inches depending on the specific design of the bottle.

6. Math Answers – Height Specification

Strategic Sourcing Conclusion and Outlook for water bottle circumference

What Are the Key Takeaways for B2B Buyers on Water Bottle Circumference?

Understanding the circumference of water bottles is crucial for international B2B buyers aiming to optimize their product offerings and supply chain strategies. The standard dimensions, such as the 16.9 oz bottle typically measuring between 8-10 inches in circumference, provide essential insights for packaging and shipping logistics. When sourcing water bottles, consider not only the size but also the environmental impact, as single-use plastics contribute significantly to global waste. Opting for bottles made from recycled materials can enhance sustainability initiatives and appeal to environmentally conscious consumers.

How Can Strategic Sourcing Enhance Your Business?

Strategic sourcing allows businesses to streamline their procurement processes, reducing costs while ensuring compliance with quality and sustainability standards. By aligning sourcing strategies with market demands and environmental regulations, companies can gain a competitive edge in diverse regions such as Africa, South America, the Middle East, and Europe.

What Should B2B Buyers Do Next?

As the global landscape evolves, it is imperative for B2B buyers to remain proactive. Engage with suppliers who prioritize innovation and sustainability in their water bottle designs. Leverage this knowledge to not only meet current market demands but also anticipate future trends. By making informed sourcing decisions today, your business can thrive in tomorrow’s marketplace, contributing positively to both the economy and the environment.