Introduction: Navigating the Global Market for water bottle length

In the ever-evolving global market, sourcing the right water bottle length can present significant challenges for B2B buyers, particularly those catering to diverse consumer needs across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia. With an increasing focus on sustainability and user experience, understanding the various dimensions and applications of water bottles is critical for making informed purchasing decisions.

This comprehensive guide delves into the myriad types of water bottles available, from compact options for children to larger, more robust models designed for outdoor activities. We will explore the specific applications of different sizes, helping you identify which products align best with your customer demographics. Additionally, this guide will address key considerations for supplier vetting, cost analysis, and the importance of material choices, ensuring that you not only find the right product but also build lasting partnerships with reliable manufacturers.

By equipping international B2B buyers with the insights and tools necessary to navigate the complexities of water bottle sourcing, this guide empowers you to make strategic decisions that enhance your product offerings and meet the demands of your market. Whether you are looking to reduce environmental impact or cater to unique consumer preferences, understanding water bottle length and its implications is essential for success in today’s competitive landscape.

Article Navigation

- Top 6 Water Bottle Length Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water bottle length

- Understanding water bottle length Types and Variations

- Key Industrial Applications of water bottle length

- 3 Common User Pain Points for ‘water bottle length’ & Their Solutions

- Strategic Material Selection Guide for water bottle length

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle length

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle length’

- Comprehensive Cost and Pricing Analysis for water bottle length Sourcing

- Alternatives Analysis: Comparing water bottle length With Other Solutions

- Essential Technical Properties and Trade Terminology for water bottle length

- Navigating Market Dynamics and Sourcing Trends in the water bottle length Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle length

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for water bottle length

Understanding water bottle length Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Small Bottles | Ranges from 6 oz to 12 oz; compact size | Promotional giveaways, children’s events | Pros: Portable, cost-effective; Cons: Limited hydration capacity |

| Medium Bottles | Ranges from 16 oz to 24 oz; versatile for daily use | Corporate gifts, sports events | Pros: Good balance of size and weight; Cons: May require frequent refills |

| Large Bottles | Ranges from 32 oz to 40 oz; designed for outdoor activities | Hiking, camping, and fitness industries | Pros: Reduced need for refills, ideal for hydration; Cons: Bulkier, heavier |

| Specialty Bottles | Unique designs (e.g., wide mouth, insulated) | Outdoor adventures, fitness centers | Pros: Enhanced functionality, diverse uses; Cons: Higher price point |

| Kids’ Bottles | Smaller sizes (e.g., 14 oz); designed for children | Schools, daycare centers | Pros: Ergonomic, appealing designs; Cons: Limited lifespan compared to adult sizes |

What Are the Characteristics of Small Water Bottles?

Small water bottles, typically ranging from 6 oz to 12 oz, are perfect for promotional events and children’s activities. Their compact size allows for easy transport in bags or lunch boxes, making them ideal for giveaways and branded merchandise. B2B buyers should consider the cost-effectiveness and portability of these bottles, although the limited capacity means they may not satisfy hydration needs for longer events or activities.

How Do Medium Water Bottles Serve B2B Needs?

Medium-sized bottles, generally between 16 oz and 24 oz, are versatile and cater to a variety of daily hydration needs. They are commonly used in corporate settings, sports events, and fitness-related promotions. Their balance of size and weight makes them convenient for both consumers and businesses. However, buyers should keep in mind that frequent refills may be necessary, which can be a consideration for high-traffic environments.

What Advantages Do Large Water Bottles Offer?

Large water bottles, ranging from 32 oz to 40 oz, are designed for outdoor enthusiasts and fitness aficionados. They are ideal for activities such as hiking, camping, and gym workouts, where long-lasting hydration is essential. B2B buyers benefit from the reduced need for refills, making them suitable for prolonged events. However, their bulkier nature may deter some consumers who prioritize portability.

Why Consider Specialty Water Bottles?

Specialty water bottles include unique designs such as wide-mouth openings or insulated options, catering to specific needs. These bottles are popular in outdoor adventures and fitness settings, providing enhanced functionality. For B2B buyers, the diverse applications and innovative features can justify the higher price point, although they may not appeal to budget-conscious consumers.

What Makes Kids’ Water Bottles Unique?

Kids’ water bottles, often around 14 oz, are designed with smaller hands in mind and feature fun, colorful designs that attract children. These bottles are commonly used in schools and daycare centers, promoting hydration among younger demographics. While they offer ergonomic benefits and engaging aesthetics, buyers should be aware of their limited lifespan compared to adult-sized options, which may impact long-term purchasing decisions.

Key Industrial Applications of water bottle length

| Industry/Sector | Specific Application of water bottle length | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Custom-sized water bottles for restaurants and cafes | Enhances brand visibility and customer experience | Material quality, customization options, and supply chain reliability |

| Outdoor and Sports | Variable lengths for hydration packs and gear | Meets diverse customer hydration needs during activities | Durability, weight, and compatibility with existing equipment |

| Health and Wellness | Water bottles in varying sizes for fitness centers | Supports health initiatives and promotes hydration among members | BPA-free materials, ease of cleaning, and aesthetic appeal |

| Retail and E-commerce | Standardized sizes for bulk packaging and distribution | Streamlines inventory management and reduces costs | Compliance with local regulations, packaging efficiency, and sourcing sustainability |

| Education and Childcare | Age-appropriate bottle lengths for schools and nurseries | Ensures proper hydration for children, promoting health benefits | Safety standards, ease of use for children, and design features |

How is Water Bottle Length Applied in the Food and Beverage Industry?

In the food and beverage sector, custom-sized water bottles serve as an effective branding tool for restaurants and cafes. Offering various lengths enables establishments to cater to different customer preferences, enhancing the dining experience. For B2B buyers, sourcing high-quality materials that ensure safety and aesthetic appeal is crucial. Additionally, customization options, such as branding and color choices, can significantly impact customer engagement and loyalty, especially in competitive markets across Africa and Europe.

What Role Does Water Bottle Length Play in Outdoor and Sports Applications?

For outdoor and sports industries, varying water bottle lengths are essential for hydration packs and gear used during activities like hiking, cycling, and camping. Different lengths accommodate specific needs, such as lightweight options for long treks or larger capacities for group outings. B2B buyers must consider durability and weight to ensure products can withstand rigorous use. Compatibility with existing equipment, such as hydration systems, is also a key factor, particularly for international buyers in markets like South America and the Middle East.

Why is Water Bottle Length Important in Health and Wellness?

In health and wellness facilities, such as gyms and fitness centers, water bottles of varying sizes promote hydration among members. Providing options that align with daily hydration goals can enhance the overall member experience and support health initiatives. Buyers in this sector should prioritize BPA-free materials and ease of cleaning to ensure safety and convenience. Additionally, aesthetic appeal can attract customers, making it essential to offer visually appealing designs that resonate with health-conscious consumers.

How Does Water Bottle Length Influence Retail and E-commerce?

In retail and e-commerce, standardized water bottle lengths simplify inventory management and distribution processes. Offering a range of sizes enables businesses to meet diverse consumer demands while optimizing storage and shipping efficiency. Buyers should be aware of local regulations regarding product safety and environmental impact, particularly when sourcing materials. Sustainability considerations, such as using recycled plastics, can also enhance brand reputation and appeal to environmentally conscious consumers.

What is the Significance of Water Bottle Length in Education and Childcare?

In educational settings, age-appropriate water bottles are crucial for promoting hydration among children. Different lengths cater to varying age groups, ensuring that young users can easily handle and use the bottles. B2B buyers in this sector must focus on safety standards and ease of use, ensuring that products are designed with children’s needs in mind. Features like spill-proof lids and colorful designs can further enhance usability and appeal in schools and nurseries, particularly in regions with high demand for child-friendly products.

3 Common User Pain Points for ‘water bottle length’ & Their Solutions

Scenario 1: The Challenge of Space Optimization in Distribution

The Problem:

B2B buyers, particularly those managing logistics in beverage distribution, often encounter the issue of space optimization within shipping containers and storage facilities. Water bottles come in various lengths and sizes, which can significantly affect how many units can be transported at once. For instance, if a company primarily orders 40 oz. bottles, they may find that the height limits of standard pallets reduce the number of units they can fit, leading to increased shipping costs and inefficient use of warehouse space.

The Solution:

To combat this challenge, B2B buyers should conduct a thorough analysis of the dimensions of the water bottles they intend to purchase. Prior to placing large orders, it is advisable to request samples of different sizes and conduct a mock-up of pallet configurations. Consideration should also be given to ordering a mix of sizes that complement each other. For example, combining 20 oz. and 32 oz. bottles could maximize space without sacrificing variety for customers. Additionally, investing in specialized pallet racks designed for varying bottle heights can provide more flexible storage solutions. By optimizing the selection and arrangement of bottle sizes, companies can enhance shipping efficiency and reduce costs.

Scenario 2: Consumer Preferences for Bottle Size

The Problem:

In markets such as Africa and South America, consumer preferences for water bottle sizes can vary widely based on cultural habits and lifestyle. A B2B buyer may struggle to meet these diverse demands if they only stock a limited range of bottle lengths. For instance, consumers in urban areas might prefer smaller, portable bottles for convenience, while those in rural settings might favor larger bottles for longer use. Failing to accommodate these preferences can lead to unsold inventory and lost sales opportunities.

The Solution:

To effectively address this issue, B2B buyers should conduct market research to understand regional preferences for water bottle sizes. This could involve surveys or focus groups with target consumers to gather insights on desired bottle lengths. Once the data is collected, buyers can diversify their product offerings by sourcing a range of bottle sizes that cater to different demographics. Collaborating with manufacturers that provide customizable options can also allow businesses to tailor their inventory based on specific market needs. By aligning product offerings with consumer preferences, companies can improve sales and customer satisfaction.

Scenario 3: Regulatory Compliance and Safety Standards

The Problem:

As international regulations around food and beverage packaging continue to evolve, B2B buyers face the challenge of ensuring that water bottles meet safety and compliance standards. Different regions may have varying regulations regarding the materials used in bottle manufacturing, particularly concerning BPA and other harmful substances. If a company imports bottles that do not meet local safety standards, it could face severe penalties, product recalls, and damage to its reputation.

The Solution:

To navigate these regulatory challenges, B2B buyers should prioritize sourcing water bottles from manufacturers that adhere to global safety standards and certifications. Before finalizing purchases, buyers should request documentation that verifies compliance with local regulations, such as FDA approval in the U.S. or EU regulations in Europe. Establishing strong relationships with reliable suppliers who are knowledgeable about international compliance can also be beneficial. Regular audits and checks on the supply chain will help ensure ongoing adherence to safety standards. By proactively managing compliance, businesses can mitigate risks and enhance their reputation in the market.

Strategic Material Selection Guide for water bottle length

What Are the Key Properties of Common Materials Used in Water Bottles?

When selecting materials for water bottles, especially in varying lengths, it is essential to consider their properties that influence product performance. Common materials include stainless steel, Tritan plastic, aluminum, and glass. Each material presents unique characteristics that can affect durability, cost, and suitability for specific applications.

How Does Stainless Steel Perform in Water Bottle Applications?

Stainless steel is renowned for its strength and corrosion resistance. It typically withstands high temperatures and pressures, making it suitable for both hot and cold beverages. The durability of stainless steel means it can endure rough handling, making it ideal for outdoor activities.

Pros: Stainless steel bottles are highly durable, resistant to corrosion, and maintain the temperature of their contents for extended periods. They are also recyclable, appealing to environmentally conscious buyers.

Cons: The primary drawbacks include higher manufacturing costs and weight compared to plastic alternatives. Additionally, stainless steel bottles can be more complex to produce due to the need for specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of beverages, including acidic drinks, without leaching harmful chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial, particularly in regions like Europe and the Middle East where quality regulations are stringent. Buyers should also consider the availability of local suppliers to reduce shipping costs.

What Are the Advantages of Tritan Plastic for Water Bottles?

Tritan plastic is a popular choice due to its clarity, durability, and resistance to shattering. It is lightweight, making it an excellent option for portable water bottles.

Pros: Tritan is BPA-free, dishwasher safe, and resistant to odors and stains, ensuring that the water bottle remains hygienic and visually appealing over time.

Cons: While Tritan is durable, it is less heat-resistant than stainless steel and may warp under high temperatures. Its lifespan is generally shorter than that of metal options.

Impact on Application: Tritan is suitable for a variety of beverages, but users should avoid exposing it to extreme heat to prevent deformation.

Considerations for International Buyers: Buyers in regions like Africa and South America may prefer Tritan for its cost-effectiveness. However, they should ensure compliance with local safety standards to avoid issues related to chemical leaching.

How Does Aluminum Compare as a Material for Water Bottles?

Aluminum is lightweight and offers good thermal conductivity, making it suitable for insulated bottles. It is often coated to prevent reactions with acidic beverages.

Pros: Aluminum bottles are lightweight, making them easy to carry, and they can be produced at a lower cost compared to stainless steel.

Cons: Aluminum is prone to dents and scratches, which can compromise its integrity. Additionally, the lining required to prevent corrosion can add to manufacturing complexity.

Impact on Application: Aluminum is compatible with many beverages but may not be suitable for long-term storage of acidic drinks unless properly lined.

Considerations for International Buyers: Buyers should be aware of the specific coatings used in aluminum bottles to ensure they meet health and safety regulations in their regions.

What Are the Benefits of Glass Water Bottles?

Glass offers an elegant option for water bottles, known for its purity and lack of chemical leaching.

Pros: Glass bottles do not retain flavors or odors, ensuring a clean taste for beverages. They are also fully recyclable.

Cons: The fragility of glass makes it less suitable for active lifestyles, and it is heavier than plastic or aluminum options.

Impact on Application: Glass is ideal for water and non-acidic beverages, but care must be taken to prevent breakage during transport.

Considerations for International Buyers: Buyers should consider the shipping costs associated with glass due to its weight and fragility. Compliance with packaging regulations is also critical to prevent damage during transit.

Summary Table of Material Selection for Water Bottles

| Material | Typical Use Case for Water Bottle Length | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor activities, hot/cold beverages | Highly durable and temperature-retentive | Higher cost and weight | High |

| Tritan Plastic | Everyday use, portable hydration | Lightweight and BPA-free | Less heat resistant | Medium |

| Aluminum | Lightweight, insulated beverages | Cost-effective and portable | Prone to dents and requires lining | Medium |

| Glass | Non-acidic beverages, aesthetic appeal | Pure taste and recyclable | Fragile and heavier | Medium |

This strategic material selection guide provides a comprehensive overview of the considerations necessary for international B2B buyers when choosing the appropriate materials for water bottles of varying lengths.

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle length

What Are the Main Stages in the Manufacturing Process of Water Bottles?

Manufacturing water bottles involves a series of carefully orchestrated stages, each crucial for producing a high-quality final product. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation. Common materials for water bottles include polyethylene terephthalate (PET), Tritan, and stainless steel. Each material offers distinct advantages, such as durability, weight, and recyclability. For instance, PET is lightweight and widely recycled, while stainless steel provides superior insulation and durability. The preparation phase involves sourcing high-grade materials that meet international safety standards, ensuring that they are free from contaminants and suitable for food contact.

Forming

The next stage is forming, where the prepared materials are shaped into the desired bottle structure. For plastic bottles, techniques such as blow molding are commonly used. This method involves heating the plastic until it is malleable and then forming it into a mold using air pressure. For stainless steel bottles, processes like deep drawing or hydroforming are employed to achieve the desired shape without compromising structural integrity. Precision in this stage is vital, as variations in bottle length and diameter can affect compatibility with caps and other accessories.

Assembly

Once the bottles are formed, the assembly phase begins. This may involve attaching components such as caps, straws, and handles. During this stage, manufacturers often utilize automated assembly lines to increase efficiency and consistency. Quality checks are implemented at various points to ensure that all parts fit correctly and operate as intended. For instance, a bottle cap must create a leak-proof seal to maintain the integrity of the contents.

Finishing

The final stage of manufacturing is finishing. This includes processes such as labeling, printing, and surface treatment. Labels must adhere well and withstand exposure to moisture, while printing must be clear and durable. Surface treatments may include polishing stainless steel bottles to enhance aesthetics and resistance to corrosion. The finishing stage is critical, as it not only impacts the bottle’s appearance but also its marketability.

How Is Quality Assurance Managed Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of water bottles, ensuring that products meet both regulatory standards and customer expectations. Various international and industry-specific standards guide these QA processes.

Relevant International Standards

One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system (QMS). Adherence to ISO 9001 ensures that manufacturers maintain consistent quality in their processes and products. Additionally, industry-specific certifications such as CE marking in Europe signify compliance with health, safety, and environmental protection standards.

Quality Control Checkpoints

Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is the first checkpoint, where raw materials are inspected upon arrival. Tests ensure that the materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves continuous monitoring of production to catch any deviations from quality standards. This can include checks for bottle dimensions, weight, and appearance at various stages of production.

-

Final Quality Control (FQC): At the end of the manufacturing process, FQC involves a comprehensive inspection of the finished products. This may include pressure tests for leak-proof functionality and assessments of visual quality.

What Common Testing Methods Are Used for Water Bottles?

Testing methods vary based on the materials used and the intended market. Common tests include:

-

Material Safety Tests: These ensure that the materials used in the bottles are safe for food contact and free from harmful chemicals such as BPA or phthalates.

-

Mechanical Testing: This assesses the strength and durability of the bottles. Tests such as drop tests and compression tests evaluate how well the bottles can withstand impact and pressure.

-

Leak Tests: These tests ensure that bottles maintain their integrity under various conditions. A common method involves pressurizing the bottle and checking for leaks.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensuring product reliability. Here are several strategies:

-

Audits: Conducting regular audits of suppliers’ facilities can help B2B buyers assess adherence to quality standards and manufacturing practices. This can be done through third-party inspection services that specialize in quality audits.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes and results. These reports should outline the methodologies used for testing and the outcomes of various quality checks.

-

Third-party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of a supplier’s manufacturing processes and product quality. This is particularly important for buyers who may not have the resources to conduct on-site inspections.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating quality control and certification can be complex for international buyers, particularly in diverse markets. Here are key considerations:

-

Regulatory Compliance: Each region may have specific regulations regarding water bottle manufacturing. For example, CE marking is essential for products sold in the European Union, while FDA approval is crucial for the U.S. market. Understanding these requirements helps buyers ensure compliance.

-

Cultural Differences in Quality Expectations: Different regions may have varying standards of quality and durability. For example, in arid regions, buyers may prioritize bottles that can withstand high temperatures, while buyers in colder climates may focus on insulation properties. Understanding local market preferences can guide purchasing decisions.

-

Sustainability Certifications: As the demand for eco-friendly products increases, certifications related to sustainability (such as those verifying the use of recycled materials) are becoming more critical. Buyers should consider suppliers who demonstrate a commitment to sustainable practices.

By understanding the intricacies of manufacturing processes and quality assurance for water bottles, B2B buyers can make informed decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle length’

Introduction

This sourcing guide provides a comprehensive checklist for B2B buyers seeking to procure water bottles with specific lengths. Understanding the dimensions of water bottles is essential for catering to diverse consumer needs, optimizing storage and transportation, and ensuring product compatibility with existing offerings. This guide will equip you with actionable steps to make informed purchasing decisions.

1. Identify Your Target Market Needs

Before sourcing water bottles, assess the preferences and requirements of your target market. Different regions and demographics may have varying hydration habits and preferences for bottle size. For instance, buyers in outdoor-oriented markets might favor larger bottles, while urban consumers may prefer compact sizes for portability.

2. Define Your Technical Specifications

Establish clear specifications for the water bottle lengths you need. Consider the volume (e.g., 12 oz, 24 oz, 32 oz) and corresponding heights, as well as any specific design features that may affect usability, such as wide mouths for easy cleaning or carrying loops. This clarity will help streamline the sourcing process and ensure suppliers can meet your exact requirements.

3. Research Material Options

Investigate the various materials available for water bottles, such as Tritan, stainless steel, and recycled plastics. Each material has unique properties that may influence factors like durability, weight, and environmental impact. Opting for sustainable materials can also enhance your brand’s image, particularly in markets increasingly concerned with eco-friendliness.

4. Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can deliver products that meet your specifications. Request company profiles, product samples, and customer testimonials. Focus on suppliers with a proven track record in your target markets, as they are more likely to understand local preferences and regulatory requirements.

5. Check Compliance and Certifications

Ensure that the water bottles comply with relevant health and safety standards in your markets. This may include certifications such as BPA-free, FDA approval, or ISO standards. Compliance is crucial not only for legal reasons but also for building consumer trust in your products.

6. Request Prototypes for Testing

Before placing a large order, request prototypes to evaluate their functionality and quality. Testing the bottles for usability, durability, and consumer appeal can help identify any potential issues early in the process. Gather feedback from focus groups or potential end-users to refine your final product choice.

7. Establish Clear Shipping and Delivery Terms

Discuss and agree on shipping and delivery timelines with your suppliers to avoid disruptions in your supply chain. Consider factors like lead times, shipping methods, and costs. Clear communication at this stage can help mitigate risks associated with delays and ensure a smooth procurement process.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing water bottles with the appropriate lengths, ensuring they meet market demands and enhance their product offerings.

Comprehensive Cost and Pricing Analysis for water bottle length Sourcing

What Are the Key Cost Components in Sourcing Water Bottles by Length?

When sourcing water bottles, particularly regarding length variations, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. Common materials for water bottles include Tritan, stainless steel, and BPA-free plastics. Premium materials may offer better durability and insulation but come at a higher price point. For instance, bottles made from recycled plastics might have slightly elevated costs due to processing.

-

Labor: Labor costs can vary based on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but ensure that quality standards are met. Skilled labor is essential for intricate designs and customizations.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer better pricing.

-

Tooling: Custom molds and tooling can be a significant upfront expense, especially for unique bottle designs or sizes. Understanding the tooling costs is essential if you plan on ordering custom lengths or shapes.

-

Quality Control (QC): Implementing robust QC processes ensures that the final products meet the required specifications. While this incurs additional costs, it is crucial for maintaining product integrity and minimizing returns.

-

Logistics: Shipping costs, including freight and insurance, can vary widely depending on the destination. International buyers should consider these costs in their total budget, especially for larger orders.

-

Margin: Suppliers typically include a markup on their costs to establish a profit margin. This margin can vary based on competition, brand positioning, and market demand.

How Do Price Influencers Affect Water Bottle Sourcing Decisions?

Several factors can influence the pricing of water bottles, particularly when factoring in different lengths:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often result in lower per-unit costs. Buyers should negotiate volume discounts to maximize cost efficiency.

-

Specifications and Customization: Custom designs, colors, or features can increase costs. Buyers should clearly define their requirements upfront to avoid unexpected expenses.

-

Materials: As previously mentioned, the choice of materials significantly affects pricing. Buyers should evaluate the long-term benefits of higher-quality materials against initial costs.

-

Quality Certifications: Certifications (e.g., FDA, ISO) can add to the cost but are essential for ensuring product safety and compliance, especially for international markets.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can impact pricing. Engaging with suppliers who have a proven track record can reduce risks and ensure smoother transactions.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial. These terms dictate responsibilities for shipping costs and risks, which can significantly affect the overall price.

What Are the Best Negotiation Tips for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to substantial savings:

-

Understand Total Cost of Ownership (TCO): Consider all costs associated with sourcing, including shipping, customs duties, and potential tariffs. A lower purchase price might not always equate to savings if these additional costs are high.

-

Leverage Market Research: Knowledge of market prices and competitor offerings can strengthen your negotiating position. Be prepared to discuss alternative suppliers if necessary.

-

Build Long-Term Relationships: Establishing rapport with suppliers can lead to better pricing and terms over time. Suppliers are often more willing to negotiate with trusted partners.

-

Be Open to Alternatives: If a supplier cannot meet your price, discuss alternative materials or design adjustments that could reduce costs without compromising quality.

-

Clarify Payment Terms: Negotiate favorable payment terms to improve cash flow. Options like payment upon delivery or extended payment periods can be beneficial.

Conclusion: Navigating Pricing Nuances for Water Bottle Sourcing

Understanding the comprehensive cost structure and pricing dynamics involved in sourcing water bottles by length is essential for B2B buyers. By considering the key cost components, price influencers, and effective negotiation strategies, buyers can make informed decisions that lead to successful sourcing outcomes. Always remember that indicative prices can vary widely based on the factors discussed, so thorough research and engagement with suppliers are vital.

Alternatives Analysis: Comparing water bottle length With Other Solutions

Exploring Alternative Solutions to Water Bottle Length

In the quest for effective hydration solutions, businesses often consider various methods that can meet their needs. While water bottles of different lengths are popular for their portability and versatility, there are other options available that can serve similar purposes. This section compares the water bottle length against two viable alternatives: hydration packs and water filtration systems. Each option has distinct characteristics that can influence a buyer’s decision based on their specific requirements.

| Comparison Aspect | Water Bottle Length | Hydration Pack | Water Filtration System |

|---|---|---|---|

| Performance | Varies by size (6 oz. – 40 oz.); good for personal hydration. | Provides continuous hydration; holds more water without needing frequent refills. | Ensures clean water; can be used to filter from any water source. |

| Cost | Generally low to moderate; prices vary by material and brand. | Moderate to high; includes costs for the pack and hydration bladder. | Variable; initial purchase may be high but saves on bottled water. |

| Ease of Implementation | Simple to use; just fill and go. | Requires some setup; must adjust straps and ensure bladder is filled. | Requires knowledge of filtering methods and maintenance. |

| Maintenance | Low; occasional cleaning needed. | Moderate; requires cleaning of the bladder and tube. | High; filters need regular replacement and maintenance. |

| Best Use Case | Ideal for individual use, outdoor activities, and daily hydration. | Best for hiking, biking, and prolonged outdoor activities. | Suitable for camping, emergency preparedness, and areas with unreliable water sources. |

Detailed Breakdown of Alternatives

Hydration Packs

Hydration packs are backpacks equipped with a water reservoir and a drinking tube, allowing users to hydrate on the go without stopping. They are particularly advantageous for outdoor enthusiasts who need to maintain hydration during long hikes or bike rides. While hydration packs can hold larger volumes of water compared to standard bottles, they may require a higher initial investment and some technical know-how to set up properly. Maintenance involves cleaning both the reservoir and the tubing to prevent mold and bacteria growth.

Water Filtration Systems

Water filtration systems are designed to purify water from various sources, making it safe for consumption. They offer significant advantages in locations where water quality is a concern. Though the initial cost can be high, these systems reduce the reliance on bottled water, thereby saving money over time. However, they require regular maintenance, including filter changes, which can be a drawback for some users. Additionally, understanding the proper use of these systems is crucial to ensure effective filtration.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a hydration solution, B2B buyers must evaluate their specific requirements, including the intended use case, budget constraints, and maintenance capabilities. For organizations seeking a straightforward, portable hydration option, various lengths of water bottles may suffice. However, for those who engage in prolonged outdoor activities or operate in areas with unreliable water sources, hydration packs or filtration systems may present more effective alternatives. Ultimately, the choice depends on balancing performance, cost, and the ease of integration into existing workflows.

Essential Technical Properties and Trade Terminology for water bottle length

What Are the Key Technical Properties of Water Bottle Length?

When sourcing water bottles for B2B purposes, understanding the essential technical properties is crucial. Here are several specifications that significantly impact product selection and usability.

1. Material Grade

The material used for water bottles, typically plastic (like Tritan) or stainless steel, directly affects durability, weight, and safety. High-grade materials ensure that bottles are BPA-free, resistant to impacts, and can endure various temperatures. For international buyers, knowing the material standards (like FDA compliance for food contact) is vital to ensure product safety and marketability.

2. Height and Diameter

Height and diameter specifications are essential for determining the bottle’s portability and compatibility with standard cup holders or hydration packs. For instance, a 32 oz. bottle may measure approximately 8.25 inches in height and 3.5 inches in diameter. Understanding these dimensions helps buyers optimize storage and transportation logistics, especially when shipping in bulk.

3. Volume Capacity

Volume capacity, measured in ounces or liters, indicates how much liquid the bottle can hold. Common sizes range from 6 oz. to 40 oz. This specification is crucial for targeting specific markets—larger bottles may appeal to outdoor enthusiasts, while smaller sizes may be better suited for children or casual use.

4. Tolerance

Tolerance refers to the permissible limit or variation in dimensions. For example, a height tolerance of ±0.5 inches ensures that products meet quality standards and fit appropriately with lids and accessories. Understanding tolerances is essential for maintaining consistency across batches, which can significantly affect customer satisfaction and brand reputation.

5. Weight

The weight of the water bottle impacts shipping costs and user convenience. Lightweight materials are often preferred for portable products, especially for outdoor activities or travel. B2B buyers should consider how weight influences their logistics and customer preferences, particularly in regions where shipping costs are a significant concern.

6. Leak-Proof Design

A leak-proof design is a critical feature that ensures the bottle maintains its integrity during transport and use. This property not only enhances user experience but also minimizes returns and complaints, making it a vital selling point in B2B negotiations.

What Are the Common Trade Terms Related to Water Bottle Sourcing?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are key terms that every buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the water bottle industry, partnering with an OEM allows buyers to customize products while relying on the manufacturer’s expertise in production and design.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers manage their inventory and cash flow effectively. For example, a supplier might set an MOQ of 500 units for a specific bottle design, which can influence purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific quantities of goods. This process helps B2B buyers compare prices and terms, ensuring they secure the best deals for water bottles.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for understanding shipping costs and risks associated with water bottle procurement.

5. Lead Time

Lead time refers to the period between placing an order and receiving it. This term is crucial for planning inventory and meeting customer demands. Buyers must consider lead times when sourcing water bottles to ensure timely delivery, especially in competitive markets.

By understanding these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing water bottles, optimizing both quality and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the water bottle length Sector

What Are the Key Market Trends Influencing Water Bottle Length Sourcing?

The global water bottle market is experiencing significant transformations driven by health consciousness, environmental concerns, and technological advancements. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe become increasingly aware of hydration’s importance, the demand for diverse water bottle sizes is surging. Notably, reusable water bottles are gaining traction due to their role in reducing plastic waste—an imperative as countries strive to meet sustainability goals.

Emerging trends include the personalization of bottle sizes, catering to varying consumer needs, from compact 6 oz. bottles for children to larger 40 oz. bottles for outdoor enthusiasts. The rise of e-commerce has also reshaped how buyers access products, allowing for direct sourcing from manufacturers, which can streamline procurement processes and reduce costs. Additionally, advancements in materials technology, such as the incorporation of recycled plastics, are becoming increasingly important. This aligns with the global push toward eco-friendly products and resonates particularly well with B2B buyers focused on sustainability.

Moreover, market dynamics are influenced by regional regulations, particularly in Europe and the Middle East, where there is a push for stricter environmental policies. Buyers must stay informed about these regulations to ensure compliance and leverage potential incentives for sustainable practices.

How Is Sustainability Shaping Sourcing Decisions for Water Bottles?

Sustainability is no longer a mere buzzword; it has become a critical factor in sourcing decisions for B2B buyers. The environmental impact of single-use plastics is prompting companies to seek out suppliers who prioritize ethical sourcing and sustainable practices. Buyers are increasingly looking for water bottles made from recycled materials or those that utilize biodegradable options, which can significantly reduce the carbon footprint associated with production and disposal.

The importance of ethical supply chains is underscored by the growing demand for transparency among consumers and businesses alike. Certifications such as ISCC (International Sustainability and Carbon Certification) are becoming essential for suppliers, as they demonstrate a commitment to sustainability and responsible sourcing. International buyers should prioritize partnerships with manufacturers who hold such certifications, ensuring that the products they source not only meet quality standards but also align with their corporate social responsibility goals.

Furthermore, as consumers become more environmentally conscious, products that feature sustainable attributes can enhance brand reputation and customer loyalty. For B2B buyers, sourcing water bottles that reflect these values can lead to competitive advantages in the marketplace, particularly in regions where eco-friendly products are in high demand.

How Has the Water Bottle Industry Evolved Over Time?

The water bottle industry has undergone a remarkable evolution over the past few decades, transitioning from single-use plastic bottles to a diverse array of reusable options. Initially dominated by convenience-driven purchases, the market has shifted focus toward sustainability and health. The introduction of various sizes, from compact bottles ideal for children to larger, insulated options for outdoor activities, reflects an understanding of consumer needs.

Technological advancements have also played a pivotal role in this evolution. Innovations in materials, such as Tritan and stainless steel, have enhanced durability and safety, leading to increased consumer trust. As a result, the market is now characterized by a wide range of products catering to different lifestyles and hydration needs, making it essential for B2B buyers to stay informed about the latest developments and trends in water bottle length and design.

In summary, understanding the dynamics of the water bottle market—especially in terms of sustainability, sourcing trends, and evolving consumer preferences—will enable international B2B buyers to make informed decisions that align with both market demands and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle length

-

How do I choose the right length of water bottle for my target market?

Choosing the right length of water bottle depends on your target demographic and their hydration needs. For regions with hot climates, such as parts of Africa and the Middle East, larger bottles (24 oz and above) may be preferred for outdoor activities. Conversely, in urban settings or for office use, smaller sizes (12 oz to 20 oz) might be more practical. Conduct market research to understand local preferences and align your product offerings accordingly. -

What is the best material for water bottles in international markets?

The best material for water bottles varies by market preferences and regulations. For instance, Tritan plastic is popular for its durability and BPA-free properties, while stainless steel is favored for its insulation and eco-friendliness. In regions like Europe, where sustainability is a priority, bottles made from recycled materials can be appealing. Always check local regulations regarding food-grade materials to ensure compliance. -

What factors should I consider when vetting suppliers for water bottle production?

When vetting suppliers, consider their manufacturing capabilities, quality control processes, and compliance with international standards. Look for certifications such as ISO or relevant environmental certifications. Additionally, assess their experience in exporting to your target regions, as familiarity with local regulations can simplify logistics. Request samples to evaluate product quality before committing to a partnership. -

How can I customize water bottle sizes for my brand?

Customization of water bottle sizes can be achieved by collaborating closely with your manufacturer. Discuss your specific requirements, including dimensions and features (like lids or spouts). Most manufacturers offer flexibility in production runs, allowing for tailored solutions that align with your brand identity. Be prepared to meet minimum order quantities (MOQs) that may vary by supplier. -

What are the typical minimum order quantities (MOQs) for water bottles?

Minimum order quantities (MOQs) for water bottles can range from a few hundred to several thousand units, depending on the manufacturer and the complexity of the design. For custom sizes or materials, MOQs may be higher due to production setup costs. It’s essential to discuss MOQs upfront with potential suppliers to ensure they align with your business strategy and budget. -

What payment terms should I negotiate with international suppliers?

When negotiating payment terms with international suppliers, consider options like a letter of credit, wire transfer, or escrow services for security. Standard practices often include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Ensure that payment terms are clearly outlined in your contract to prevent misunderstandings and protect both parties. -

How can I ensure quality assurance (QA) for my water bottles?

To ensure quality assurance (QA), implement a robust inspection process at various production stages. Establish clear specifications for materials and finishes, and request samples for testing before full production. Consider third-party QA services to conduct audits and inspections. Regular communication with your supplier during production can also help address any quality issues promptly. -

What logistics considerations should I keep in mind when importing water bottles?

When importing water bottles, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner familiar with your target markets to navigate these complexities. Additionally, plan for lead times, which can vary significantly based on the supplier’s location and production schedule. Ensure all documentation is accurate to avoid delays during customs clearance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Water Bottle Length Manufacturers & Suppliers List

1. My Own Water – BPA Free Bottles

Domain: myownwater.com

Registered: 2000 (25 years)

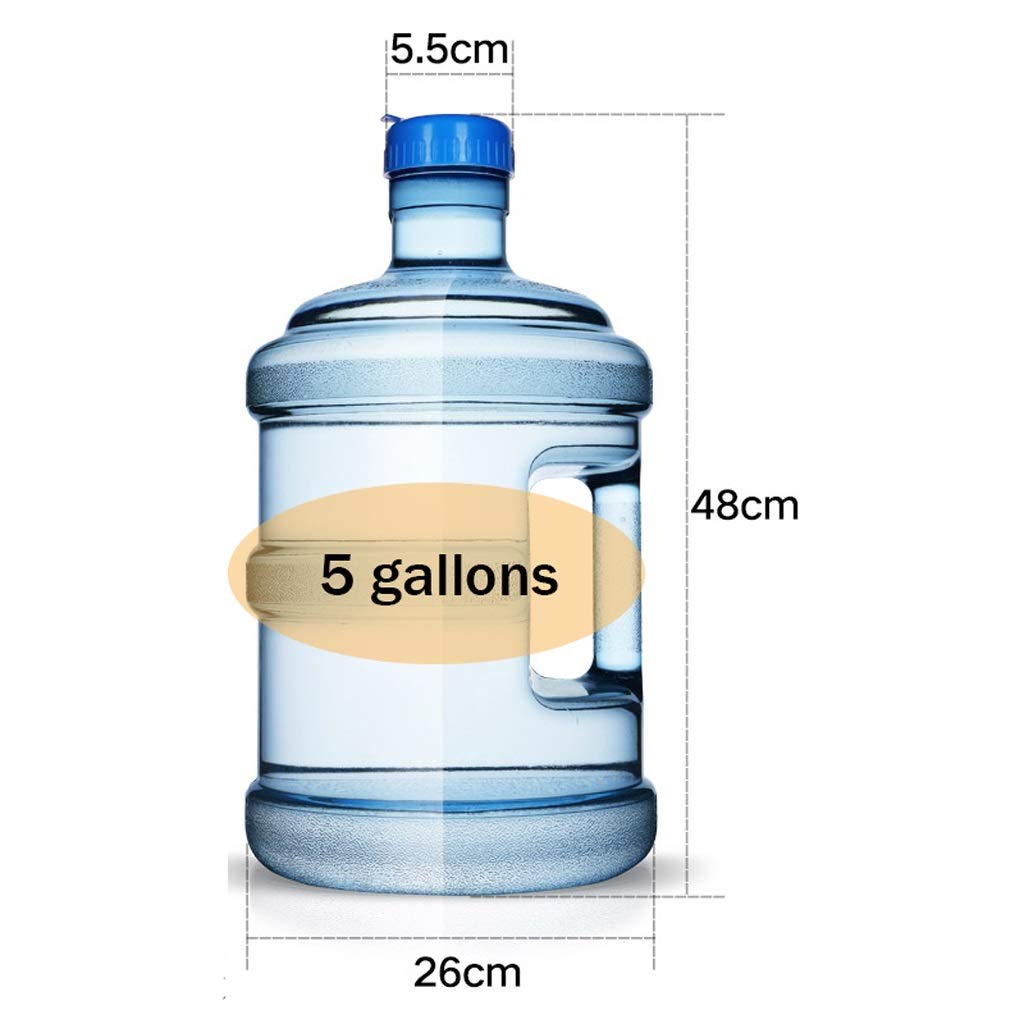

Introduction: We offer several water bottle sizes ranging from 8 oz up to 1 gallon. Our bottles come in a variety of styles, sizes, and materials. Key details include:

– BPA Free: All bottles are made from high-quality BPA free PET plastic.

– Cost Competitive: Best pricing in the industry.

– Durability: Bottles are 3x stronger than comparable grocery store bottles.

– Value Bottles: Ribbed style available in…

2. Reddit – Water Bottle Dimensions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Water bottle dimensions: 8 inches long, 2.5 inches in diameter. Preferred dimensions: 2-3 inches long, 1.15 inches in diameter.

3. Asobu – Insulated Water Bottles

Domain: thewaterbottlestore.com

Registered: 2005 (20 years)

Introduction: Reusable water bottles available in various sizes including 1 Liter/32 oz, 13 oz, 20 oz, and larger options up to 5 Gallon. Materials include BPA-free plastic, stainless steel, and glass. Categories include insulated, infuser, collapsible, and kids water bottles. Brands featured include Asobu, Aquaovo, EarthLust, EcoVessel, KOR, Nalgene, and New Wave Enviro. Replacement caps and accessories are al…

4. I Want My H2O – Custom Water Bottles

Domain: iwantmyh2o.com

Registered: 2007 (18 years)

Introduction: Custom Water Bottle Sizes: 8oz, 12oz, 16.9oz.\n\n8oz Custom Bottled Water: \n- BPA-free\n- Circumference: 8.25 in\n- Height: 4.75 in\n- Diameter: 2.5 in\n- Custom label size varies by region\n- Full clear cap for branding\n- Case holds 24 bottles, ordered in 12-case increments\n- Full pallet: 120–130 cases (2,880–3,120 bottles)\n- 2 cases fit per cardboard box\n\n12oz Private Label Water Bottles: …

5. Juiced Sound – 16.9 Oz Water Bottle

Domain: juicedsound.com

Registered: 2018 (7 years)

Introduction: This company, Juiced Sound – 16.9 Oz Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Bottle Your Brand – Custom Bottled Water

Domain: bottleyourbrand.com

Registered: 2004 (21 years)

Introduction: {“8 oz. Bottled Water”: {“height”: “5 inches”, “diameter”: “2.25 inches”, “label_size”: “2.25 H x 6.375 L”, “case_quantity”: 24, “weight_per_case”: “32 pounds”, “box_dimensions”: “10.75 H x 10.25 W x 16.75 L”, “full_pallet”: “120 cases”}, “12 oz. Bottled Water”: {“height”: “6.25 inches”, “diameter”: “2.25 inches”, “label_size”: “2.25 H x 6.375 L”, “case_quantity”: 24, “weight_per_case”: “22 pounds…

Strategic Sourcing Conclusion and Outlook for water bottle length

What Are the Key Takeaways for B2B Buyers Regarding Water Bottle Length?

In the competitive landscape of water bottle sourcing, understanding the diverse lengths and capacities available is crucial for catering to various consumer needs. From compact 6 oz bottles ideal for children to robust 40 oz options perfect for outdoor adventures, offering a range of sizes not only meets market demand but also enhances brand loyalty. Strategic sourcing of these products allows businesses to reduce costs while ensuring sustainable practices, particularly by opting for materials derived from recycled plastics.

How Can International Buyers Leverage Strategic Sourcing in Their Markets?

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the focus should be on sourcing high-quality, eco-friendly water bottles that align with local preferences and environmental regulations. Collaborating with suppliers who emphasize sustainability can lead to competitive advantages in markets increasingly driven by environmental consciousness.

What’s Next for B2B Buyers in the Water Bottle Industry?

As consumer awareness around sustainability continues to grow, the demand for reusable water bottles will likely increase. Now is the time for B2B buyers to refine their sourcing strategies, ensuring they are well-equipped to meet future demands. Engage with suppliers who prioritize innovation and sustainability to not only fulfill current market needs but also position your brand as a leader in responsible consumption.