Introduction: Navigating the Global Market for steel drink bottles

In the competitive landscape of B2B sourcing, navigating the global market for steel drink bottles presents unique challenges, particularly for international buyers seeking quality, durability, and sustainability. As businesses increasingly prioritize eco-friendly products, the demand for stainless steel water bottles has surged. However, the complexities of sourcing these items—ranging from identifying reliable suppliers to understanding the nuances of product specifications—can be daunting.

This comprehensive guide aims to illuminate the diverse types of steel drink bottles available, including insulated and non-insulated options, and their various applications across different sectors such as hospitality, outdoor recreation, and corporate gifting. Additionally, it delves into crucial aspects of supplier vetting, cost considerations, and market trends that impact purchasing decisions.

By providing actionable insights and expert advice, this guide empowers international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including markets like Germany and Vietnam. Armed with this knowledge, businesses can make informed decisions that not only enhance their product offerings but also align with sustainability goals and consumer preferences. Whether you are looking to establish long-term supplier relationships or simply seeking to understand the market landscape better, this guide serves as a vital resource in your sourcing journey.

Article Navigation

- Top 7 Steel Drink Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for steel drink bottles

- Understanding steel drink bottles Types and Variations

- Key Industrial Applications of steel drink bottles

- 3 Common User Pain Points for ‘steel drink bottles’ & Their Solutions

- Strategic Material Selection Guide for steel drink bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for steel drink bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel drink bottles’

- Comprehensive Cost and Pricing Analysis for steel drink bottles Sourcing

- Alternatives Analysis: Comparing steel drink bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for steel drink bottles

- Navigating Market Dynamics and Sourcing Trends in the steel drink bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of steel drink bottles

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for steel drink bottles

Understanding steel drink bottles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Insulated Stainless Steel Bottles | Double-wall insulation; retains temperature | Outdoor events, corporate gifts | Pros: Excellent thermal retention; durable. Cons: Higher cost; heavier than non-insulated. |

| Non-Insulated Stainless Steel Bottles | Single-wall design; lightweight and portable | Sports, everyday hydration | Pros: Lightweight; cost-effective. Cons: Limited temperature retention; less durable. |

| Kid-Friendly Steel Bottles | Smaller sizes; spill-proof lids; colorful designs | Schools, children’s events | Pros: Safe for children; appealing designs. Cons: Smaller capacity; may not suit adults. |

| Specialty Bottles | Unique features (e.g., built-in straws, filters) | Fitness, outdoor adventures | Pros: Versatile; tailored for specific uses. Cons: Can be more expensive; niche appeal. |

| Customizable Steel Bottles | Options for branding and personalization | Promotional products, corporate gifts | Pros: Enhances brand visibility; unique. Cons: Longer lead times; minimum order quantities. |

What Are Insulated Stainless Steel Bottles and Their B2B Benefits?

Insulated stainless steel bottles feature double-wall construction, which provides exceptional thermal insulation, keeping beverages hot or cold for extended periods. These bottles are ideal for outdoor events, corporate gifts, and promotions, appealing to businesses looking to enhance their brand image while offering practical products. When considering these bottles, buyers should evaluate their thermal performance, customization options, and durability to ensure they meet the needs of their target market.

How Do Non-Insulated Stainless Steel Bottles Compare?

Non-insulated stainless steel bottles are designed with a single-wall structure, making them lighter and more portable than their insulated counterparts. They are commonly used in sports and everyday hydration, offering a cost-effective solution for businesses. Buyers should focus on the weight, size variety, and aesthetic appeal when selecting these bottles, as they cater to a broader audience but lack temperature retention features.

What Makes Kid-Friendly Steel Bottles Unique?

Kid-friendly steel bottles are smaller in size, often equipped with spill-proof lids and vibrant designs to attract children. They find applications in schools and children’s events, making hydration fun and safe for young users. When sourcing these bottles, businesses should consider safety standards, ease of use, and the ability to customize designs to suit different age groups, ensuring they align with educational or recreational objectives.

What Are the Advantages of Specialty Bottles?

Specialty bottles come with unique features such as built-in straws, filters, or specific designs for activities like cycling or hiking. They cater to niche markets, including fitness enthusiasts and outdoor adventurers. Businesses should assess the practicality and specific use cases of these bottles, as they often command higher prices but can enhance customer satisfaction through their tailored functionalities.

Why Should Businesses Consider Customizable Steel Bottles?

Customizable steel bottles offer businesses the opportunity to enhance brand visibility through personalized designs and logos. They are popular as promotional products and corporate gifts, allowing companies to stand out in competitive markets. Buyers need to consider lead times, minimum order quantities, and design options when sourcing these bottles, as effective branding can significantly impact customer loyalty and recognition.

Key Industrial Applications of steel drink bottles

| Industry/Sector | Specific Application of Steel Drink Bottles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Hydration solutions for hiking, camping, and adventure sports | Durable, leakproof, and insulated options enhance user experience | Ensure compliance with safety standards and durability tests |

| Corporate Gifting | Branded steel drink bottles for employee gifts and promotions | Strengthens brand identity and promotes sustainability | Customization options and bulk purchasing capabilities |

| Food and Beverage Service | Reusable bottles for restaurants and cafes | Reduces single-use plastic waste and aligns with eco-friendly values | Sourcing from suppliers with certifications for food safety |

| Education and Childcare | Steel drink bottles for schools and daycare centers | Promotes hydration and environmental responsibility among children | Consider size variations and safety features for kids |

| Travel and Tourism | Customizable bottles for travel agencies and tour operators | Enhances customer experience and promotes brand loyalty | Evaluate bulk order discounts and international shipping options |

How are Steel Drink Bottles Used in Outdoor Recreation?

In the outdoor recreation industry, steel drink bottles serve as essential hydration solutions for activities such as hiking, camping, and adventure sports. These bottles are designed to withstand harsh conditions, providing a reliable source of hydration while being lightweight and portable. The insulated models keep beverages hot or cold for extended periods, addressing the needs of adventurers who require performance and convenience. B2B buyers in this sector should prioritize sourcing durable, leakproof options that comply with safety standards to ensure a positive user experience.

What Role Do Steel Drink Bottles Play in Corporate Gifting?

Steel drink bottles are increasingly used as corporate gifts and promotional items, particularly in sectors focused on sustainability. Companies can brand these bottles with their logos, reinforcing their commitment to environmental responsibility while providing a practical gift to employees and clients. This not only enhances brand identity but also promotes a culture of sustainability within the organization. Buyers should look for suppliers that offer customization options and the ability to fulfill bulk orders efficiently.

How Can Steel Drink Bottles Benefit Food and Beverage Services?

In the food and beverage service industry, reusable steel drink bottles are becoming popular for restaurants and cafes aiming to reduce single-use plastic waste. These bottles not only serve as a sustainable alternative but also enhance the establishment’s eco-friendly image. By offering customers the option to purchase or refill these bottles, businesses can attract environmentally conscious patrons. Key considerations for buyers include sourcing from suppliers who provide food safety certifications and ensuring the bottles meet local regulations.

Why Are Steel Drink Bottles Important in Education and Childcare?

In educational settings, steel drink bottles are used in schools and daycare centers to encourage hydration among children. They are often designed with safety features, such as BPA-free materials and spill-proof lids, making them ideal for young users. By incorporating these bottles into their programs, institutions can promote healthy habits and environmental responsibility. Buyers in this sector should focus on size variations and durability to meet the specific needs of children and ensure long-term usage.

How Do Steel Drink Bottles Enhance Travel and Tourism Experiences?

For travel agencies and tour operators, customizable steel drink bottles can significantly enhance the customer experience. These bottles serve as practical souvenirs that promote hydration during excursions, while also acting as a marketing tool for the agency. By providing high-quality, branded bottles, businesses can foster brand loyalty among travelers. When sourcing, companies should evaluate suppliers that offer bulk order discounts and flexible shipping options to accommodate international buyers.

3 Common User Pain Points for ‘steel drink bottles’ & Their Solutions

Scenario 1: Sourcing Quality Steel Drink Bottles for Diverse Markets

The Problem: B2B buyers often face the challenge of sourcing high-quality steel drink bottles that meet varying international standards and consumer preferences across different markets, such as Africa, South America, and Europe. Inconsistent quality and durability can lead to high return rates and customer dissatisfaction. Additionally, navigating import regulations and certification requirements can be daunting, particularly when dealing with suppliers from multiple regions.

The Solution: To address these challenges, B2B buyers should establish a robust supplier evaluation process that focuses on quality assurance and compliance with local regulations. Start by identifying manufacturers that have proven track records in producing steel drink bottles that conform to international quality standards such as ISO or FDA certifications. Conduct site visits or audits where feasible, or request third-party verification of the supplier’s quality control processes. Additionally, consider leveraging platforms that specialize in international trade, allowing buyers to compare supplier credentials and product specifications easily. By developing strong relationships with reliable manufacturers, buyers can ensure a consistent supply of high-quality products tailored to their specific market needs.

Scenario 2: Understanding the Importance of Insulation in Steel Drink Bottles

The Problem: Many B2B buyers overlook the significance of insulation when selecting steel drink bottles, leading to poor customer experiences, especially in regions with extreme climates. For instance, consumers in hot climates may find that non-insulated bottles do not keep beverages cool, while those in colder regions may struggle with bottles that fail to maintain warmth. This oversight can ultimately affect brand reputation and sales.

The Solution: Educate your purchasing team on the benefits of insulated versus non-insulated steel drink bottles. Insulated bottles typically feature double-wall construction, which provides superior temperature retention for both hot and cold beverages. When sourcing products, prioritize suppliers that offer a range of insulation options, including vacuum insulation technology, which is known for its effectiveness. Additionally, provide your customers with detailed information on the insulation properties of each product to help them make informed choices. Consider conducting market research to identify regional preferences and adjust your inventory accordingly, ensuring that you meet the diverse needs of your customer base.

Scenario 3: Addressing Environmental Concerns with Sustainable Steel Drink Bottles

The Problem: With increasing global awareness about sustainability, B2B buyers face pressure from consumers and regulatory bodies to offer eco-friendly products. Many steel drink bottles are manufactured using processes that may not be environmentally friendly, leading to potential backlash from eco-conscious consumers. Buyers need to ensure that their product offerings align with sustainability standards to maintain market competitiveness.

The Solution: Focus on sourcing steel drink bottles made from recycled materials or produced through sustainable manufacturing processes. Engage with suppliers that prioritize environmental responsibility, such as those using eco-friendly coatings and practices that minimize waste and energy consumption. Consider certifications such as Green Seal or other recognized eco-labels that indicate a product’s sustainability credentials. Additionally, promote the environmental benefits of using steel bottles over single-use plastics in your marketing materials, highlighting features such as recyclability and durability. By aligning your product range with sustainability trends, you can not only satisfy consumer demand but also enhance your brand’s reputation as a responsible and forward-thinking supplier.

Strategic Material Selection Guide for steel drink bottles

What Are the Key Properties of Stainless Steel in Steel Drink Bottles?

Stainless steel, particularly the 18/8 grade (also known as Type 304), is the most common material used for steel drink bottles. This grade boasts excellent corrosion resistance, making it suitable for various beverages, including acidic drinks like fruit juices. Its temperature retention properties are also noteworthy; double-walled insulated versions can keep beverages hot or cold for extended periods. Furthermore, stainless steel is non-reactive, ensuring that the taste of the beverage remains unaltered.

What Are the Advantages and Disadvantages of Using Aluminum for Steel Drink Bottles?

Aluminum is another popular choice for drink bottles, often used in lightweight designs. It is resistant to corrosion and can be anodized for additional protection. However, aluminum bottles are typically less durable than stainless steel and may dent upon impact. The cost of aluminum is generally lower than stainless steel, making it an attractive option for budget-conscious buyers. Nonetheless, aluminum can react with acidic beverages unless lined, which may affect the product’s safety and flavor.

How Do Coatings Impact the Performance of Steel Drink Bottles?

Many steel drink bottles feature specialized coatings, such as powder coating or enamel finishes. These coatings enhance the aesthetic appeal and provide additional protection against scratches and corrosion. However, the manufacturing complexity increases with the application of coatings, potentially raising costs. Coated bottles can be suitable for a variety of applications, but buyers must consider the durability of the coating and its compatibility with the intended media.

What Should International Buyers Consider When Selecting Materials for Steel Drink Bottles?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance standards such as ASTM, DIN, and JIS. These standards ensure product safety and quality, which can vary significantly between regions. Additionally, preferences for material properties may differ; for instance, buyers in colder climates may prioritize insulated options, while those in hotter regions may focus on lightweight designs for portability.

| Material | Typical Use Case for steel drink bottles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Insulated and non-insulated drink bottles | Excellent corrosion resistance and durability | Higher cost compared to aluminum | High |

| Aluminum | Lightweight travel bottles | Lightweight and cost-effective | Less durable, can dent easily | Medium |

| Coated Steel | Aesthetic and protective bottles | Enhanced aesthetics and scratch resistance | Increased manufacturing complexity | Medium |

| Recycled Steel | Eco-friendly options | Sustainable and reduces environmental impact | May have variable quality depending on source | Medium |

This strategic material selection guide aims to provide B2B buyers with essential insights into the materials used in steel drink bottles, helping them make informed purchasing decisions aligned with their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for steel drink bottles

What Are the Key Stages in the Manufacturing Process of Steel Drink Bottles?

The manufacturing of steel drink bottles involves several critical stages, each designed to ensure the final product meets high standards of durability, safety, and functionality. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

Material Preparation: How Are Raw Materials Processed?

The first step in manufacturing steel drink bottles is material preparation. High-grade stainless steel, typically 18/8 (or 304 grade), is selected for its corrosion resistance and durability. The steel is then cut into sheets or coils, depending on the design specifications of the bottles. This initial processing may also involve removing impurities and ensuring that the material meets industry standards.

Once prepared, the steel undergoes surface treatment to enhance its finish and resistance to corrosion. Processes like pickling and passivation are employed to remove any oxides and create a protective layer that prolongs the bottle’s lifespan. This stage is crucial as it directly impacts the product’s quality and compliance with international safety standards.

What Techniques Are Used to Form Steel Drink Bottles?

The next stage is forming, where the prepared steel is transformed into the desired bottle shape. This can involve several techniques:

-

Deep Drawing: This is the primary method for creating the body of the bottle. A punch forces the steel sheet into a die, shaping it into a cylindrical form. This technique ensures uniform thickness and strength throughout the bottle.

-

Hydroforming: In some cases, hydroforming is used to create complex shapes. This process involves using high-pressure fluid to mold the steel, allowing for intricate designs that improve aesthetics and functionality.

-

Welding: After forming, the bottle components are welded together. Techniques such as laser welding or TIG (Tungsten Inert Gas) welding are commonly used to ensure strong, leak-proof seams.

-

Cap and Lid Manufacturing: The caps are often produced separately using injection molding or stamping processes. These caps must fit securely to prevent leaks and maintain temperature control in insulated bottles.

How Are Steel Drink Bottles Finished and Assembled?

The finishing stage involves several processes aimed at enhancing the bottle’s appearance and functionality. This may include:

-

Surface Coating: Bottles can be coated with a powder finish or painted to improve aesthetics and provide additional protection against scratches and wear.

-

Laser Engraving or Printing: Branding and product information are often applied using laser engraving or screen printing techniques. This not only enhances the product’s marketability but also ensures that the information remains durable.

-

Final Assembly: Once the components are finished, they are assembled. This includes attaching caps, lids, and any additional features such as straws or handles.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the manufacturing of steel drink bottles. International standards such as ISO 9001 ensure that manufacturers adhere to quality management principles that enhance customer satisfaction and continuous improvement.

What Are the Key International and Industry-Specific Standards?

For B2B buyers, understanding the relevant certifications can provide assurance of quality:

-

ISO 9001: This standard focuses on effective quality management systems and is essential for manufacturers looking to demonstrate their commitment to quality.

-

CE Marking: This certification indicates that the product meets European health, safety, and environmental protection standards, crucial for markets in Europe.

-

API Certification: For manufacturers targeting specific industries, such as oil and gas, the American Petroleum Institute (API) certification may be required to ensure product integrity.

What Are the Critical Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints designed to catch defects early:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, various tests are conducted to ensure that each stage adheres to quality standards. This includes measuring dimensions, checking weld quality, and validating surface treatments.

-

Final Quality Control (FQC): After assembly, the finished products undergo rigorous testing. This may include pressure testing for leaks, drop tests for durability, and visual inspections for aesthetic quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to ensure that their suppliers maintain robust quality control processes. Here are some strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. This can help identify any gaps in compliance with international standards.

-

Requesting QC Reports: Suppliers should be able to provide detailed QC reports that outline their testing methods, results, and any corrective actions taken in response to defects.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of the supplier’s quality control systems and manufacturing processes. This adds an additional layer of assurance for B2B buyers.

What Nuances Should International Buyers Be Aware Of?

When sourcing steel drink bottles, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

-

Cultural and Regulatory Differences: Different regions may have varying regulations regarding materials and safety standards. Understanding these differences is critical for compliance and market acceptance.

-

Supply Chain Considerations: International shipping can introduce variables such as transit conditions and local customs regulations. Buyers should ensure that suppliers can accommodate these factors.

-

Sustainability Practices: As global demand for sustainable products rises, buyers may want to consider suppliers who prioritize eco-friendly practices in their manufacturing processes, including sourcing recycled materials and reducing carbon footprints.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for steel drink bottles is essential for B2B buyers. By focusing on material preparation, forming techniques, finishing processes, and robust quality control measures, buyers can make informed decisions and ensure the reliability of their suppliers in a competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel drink bottles’

Introduction

In the competitive landscape of B2B procurement, sourcing steel drink bottles requires a strategic approach. This guide provides a step-by-step checklist to assist buyers in navigating the complexities of this market. By following these actionable steps, you can ensure that you make informed decisions that align with your business needs and sustainability goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the steel drink bottles meet your requirements. Consider factors such as size, insulation type (e.g., insulated vs. non-insulated), and material grade (e.g., 18/8 stainless steel). Defining these parameters helps streamline your search and ensures compatibility with your intended use.

Step 2: Identify Your Target Market and Usage

Understanding your target market is crucial in selecting the right product features. Are you catering to outdoor enthusiasts, corporate clients, or health-conscious consumers? Knowing your audience will guide decisions on design, capacity, and additional features like sports caps or ergonomic grips, making your offerings more appealing.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider the following:

– Quality Assurance: Check if they have established quality control processes.

– Production Capacity: Ensure they can meet your volume needs without compromising quality.

Step 4: Verify Compliance with International Standards

Ensure that the steel drink bottles comply with relevant international regulations and standards, such as food safety certifications. This is particularly important for markets in Europe and North America, where regulations are stringent. Ask suppliers for documentation proving compliance, which can mitigate risks associated with importation and consumer safety.

Step 5: Assess Sustainability Practices

Sustainability is increasingly becoming a key factor in procurement decisions. Evaluate suppliers based on their sourcing of materials, manufacturing processes, and packaging. Look for certifications such as ISO 14001 or evidence of eco-friendly practices, which can enhance your brand’s image and appeal to environmentally-conscious consumers.

Step 6: Request Samples for Quality Assessment

Before finalizing your order, request samples to evaluate the quality and functionality of the steel drink bottles. This hands-on assessment allows you to check for durability, insulation performance, and design appeal. Pay attention to aspects like weight, finish, and ease of use, as these will impact customer satisfaction.

Step 7: Negotiate Terms and Establish Clear Communication

Once you’ve selected a supplier, engage in negotiations to establish favorable terms regarding pricing, payment, and delivery schedules. Clear communication is essential to prevent misunderstandings and ensure a smooth transaction process. Document all agreements and maintain an open line for ongoing communication to address any potential issues promptly.

By following this checklist, B2B buyers can navigate the complexities of sourcing steel drink bottles effectively, ensuring a successful procurement process that meets both business and customer needs.

Comprehensive Cost and Pricing Analysis for steel drink bottles Sourcing

What Are the Key Cost Components in Sourcing Steel Drink Bottles?

When sourcing steel drink bottles, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The choice of stainless steel grade (commonly 18/8 for food-grade) significantly impacts pricing. Higher-quality materials can increase initial costs but may lead to longer product lifespans and reduced replacement costs.

-

Labor: Labor costs vary by region and can be influenced by local wage rates. In countries with lower labor costs, such as some parts of Africa and South America, buyers may find more competitive pricing.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce these overheads, thus lowering the overall product cost.

-

Tooling: Custom designs require specialized tooling, which can be a significant upfront investment. However, this cost can be amortized over larger production runs, making it crucial for buyers to consider Minimum Order Quantities (MOQ).

-

Quality Control (QC): Implementing rigorous QC measures is essential for maintaining product standards. The costs associated with QC can vary based on the supplier’s capabilities and the complexity of the products.

-

Logistics: Shipping costs, including freight and insurance, can significantly impact total expenses, especially for international buyers. The choice of Incoterms can also affect financial responsibilities.

-

Margin: Suppliers will typically add a profit margin to cover their costs and risks. Understanding the typical margins in the steel drink bottle market can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of Steel Drink Bottles?

Several factors influence the pricing of steel drink bottles, including:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs carefully to leverage better pricing.

-

Specifications and Customization: Custom designs, colors, or features can lead to higher costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Bottles that meet specific quality standards or certifications (like BPA-free or ISO-certified) may command a higher price. Buyers should weigh the benefits of these certifications against the cost.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer better quality and service but at a premium price.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial. They determine who bears the risk and cost at various stages of shipping, impacting the total landed cost.

What Are Some Negotiation Tips for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies can enhance negotiation outcomes:

-

Research Market Prices: Familiarize yourself with the prevailing prices in your region and globally to establish a baseline for negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and potential replacements.

-

Negotiate on Volume: If possible, consolidate orders to meet or exceed MOQs, which can lead to significant savings.

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Consider long-term partnerships that may yield discounts or favorable payment terms.

-

Be Aware of Pricing Nuances: Understand regional pricing differences and potential tariffs or taxes that may apply. This knowledge can help you negotiate more effectively.

Final Thoughts on Sourcing Steel Drink Bottles

When sourcing steel drink bottles, it is essential to conduct thorough research and analysis of the cost components and pricing influencers. By employing strategic negotiation tactics and considering the Total Cost of Ownership, international buyers can make informed purchasing decisions that align with their business goals. Keep in mind that prices can vary widely based on market conditions, so always seek multiple quotes and remain vigilant during the sourcing process.

Alternatives Analysis: Comparing steel drink bottles With Other Solutions

Understanding Alternatives for Steel Drink Bottles

When evaluating drinkware solutions, it’s essential to consider various alternatives to steel drink bottles. While steel bottles offer durability and insulation, other options may cater to specific needs or preferences, such as weight, cost, or environmental impact. This analysis will compare steel drink bottles with two viable alternatives: plastic drink bottles and glass drink bottles. Each alternative provides unique benefits and challenges that can influence a B2B buyer’s decision.

Comparison Table

| Comparison Aspect | Steel Drink Bottles | Plastic Drink Bottles | Glass Drink Bottles |

|---|---|---|---|

| Performance | Excellent insulation; durable; reusable | Good for short-term use; lightweight | Non-reactive; good insulation with some designs |

| Cost | Higher upfront investment | Low-cost, affordable options | Moderate to high depending on design |

| Ease of Implementation | Simple to use; requires minimal training | Very easy; wide availability | Requires careful handling; heavier |

| Maintenance | Dishwasher safe; resistant to stains and odors | Can stain or retain odors; generally easy to clean | Requires careful cleaning to avoid breakage |

| Best Use Case | Long-term hydration needs; outdoor activities | Daily hydration; casual use | Eco-conscious consumers; stylish branding |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Plastic Drink Bottles?

Plastic drink bottles are a popular choice due to their lightweight nature and low cost. They are easily accessible and come in various designs, making them suitable for daily use. However, while they offer convenience, they often lack durability and can retain odors or stains over time. Additionally, the environmental impact of single-use plastics is significant, which may deter environmentally conscious businesses from opting for this solution.

How Do Glass Drink Bottles Compare in Terms of Performance and Usability?

Glass drink bottles provide an eco-friendly alternative, being fully recyclable and often free from harmful chemicals found in some plastics. They offer a premium feel and are non-reactive, meaning they won’t leach flavors into the beverage. However, glass bottles are heavier and more fragile than both steel and plastic options, which can limit their practicality for outdoor or active uses. The initial investment can also be higher, which might not align with every budget.

How Should B2B Buyers Choose the Right Drink Bottle Solution?

Ultimately, the decision on which drink bottle solution to choose depends on the specific needs and values of the business. For companies prioritizing durability and insulation for outdoor activities or long-term use, steel drink bottles are an excellent choice. However, for businesses focused on budget-friendly options for casual use, plastic bottles may suffice. If sustainability and brand image are paramount, glass drink bottles could be the ideal fit. Each option presents distinct advantages and potential drawbacks, making it crucial for B2B buyers to weigh these factors carefully against their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for steel drink bottles

What Are the Key Technical Properties of Steel Drink Bottles?

When considering steel drink bottles for B2B procurement, understanding their technical properties is essential. Here are some critical specifications:

1. Material Grade

Steel drink bottles are primarily made from food-grade stainless steel, commonly classified as 18/8 or 304 stainless steel. The “18” indicates 18% chromium, while “8” denotes 8% nickel, enhancing corrosion resistance and durability. For B2B buyers, selecting the right material grade ensures product longevity and safety, which can significantly affect customer satisfaction and brand reputation.

2. Insulation Type

Many steel drink bottles feature insulation, typically vacuum insulation, which prevents heat transfer. This is crucial for maintaining the temperature of beverages—keeping drinks cold for up to 24 hours or hot for up to 12 hours. B2B buyers should consider insulation types to meet specific customer needs, such as outdoor activities or daily commutes.

3. Capacity

Steel drink bottles come in various sizes, usually ranging from 12 oz to 64 oz. Understanding the capacity is vital for targeting specific markets, such as athletes, travelers, or families. Offering a range of capacities can help businesses cater to diverse consumer preferences, thereby enhancing market reach.

4. Leak-proof Design

A key feature in steel drink bottles is a leak-proof design, often achieved through silicone seals and threaded caps. This property is essential for preventing spills during transport, which can be a significant selling point for B2B buyers concerned about customer satisfaction and product reliability.

5. Weight

The weight of steel drink bottles varies depending on their design and insulation. Non-insulated bottles tend to be lighter and more portable, making them suitable for travel and outdoor activities. In contrast, insulated models may be heavier but offer superior temperature retention. B2B buyers should evaluate the target market’s preferences for weight and portability.

6. Finish and Coating

The external finish of steel drink bottles can influence both aesthetics and functionality. Options such as powder coating or brushed stainless steel can enhance durability and resistance to scratches. A well-chosen finish not only improves the product’s visual appeal but also aligns with branding strategies aimed at sustainability and style.

What Are Common Trade Terminology and Jargon in the Steel Drink Bottle Industry?

Understanding industry-specific terminology is crucial for effective communication in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by another company, often using their branding. For B2B buyers, partnering with an OEM can streamline product development while minimizing production costs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotations from suppliers for specific products or services. It is a standard practice in B2B procurement, allowing buyers to compare pricing and terms before making decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Knowing these terms helps B2B buyers understand shipping costs, risk, and insurance, facilitating smoother cross-border transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. It is crucial for B2B buyers to understand lead times to plan inventory and ensure timely delivery to customers.

6. Customization

Customization refers to the ability to modify products according to specific client requirements, such as size, color, or branding. This feature is increasingly important in B2B transactions as it allows companies to differentiate their offerings and meet unique customer needs.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they source the right steel drink bottles that meet their business objectives and customer demands.

Navigating Market Dynamics and Sourcing Trends in the steel drink bottles Sector

What Are the Current Market Dynamics and Key Trends in the Steel Drink Bottles Sector?

The steel drink bottles market is experiencing robust growth, driven by increasing consumer awareness regarding health, sustainability, and environmental impact. Global trends indicate a shift towards reusable drinkware as businesses and consumers alike seek alternatives to single-use plastics. This shift is particularly pronounced in emerging markets across Africa, South America, and the Middle East, where the demand for sustainable products is rising. In Europe, particularly in Germany and other environmentally conscious nations, regulations are increasingly favoring eco-friendly products, thereby influencing procurement decisions.

Emerging technologies in manufacturing and supply chain management are reshaping how steel drink bottles are sourced. Innovations such as smart manufacturing and IoT integration facilitate real-time tracking of supply chains, enhancing transparency and efficiency. B2B buyers are also leveraging e-commerce platforms to source products directly from manufacturers, reducing costs and improving supply chain agility. Furthermore, customization options are becoming a key differentiator, with businesses seeking unique designs and features that cater to specific consumer preferences.

How Important Is Sustainability and Ethical Sourcing in the Steel Drink Bottles Market?

Sustainability and ethical sourcing are no longer optional; they are essential components of the steel drink bottles supply chain. The environmental impact of production, from raw material extraction to manufacturing processes, is under increasing scrutiny. International B2B buyers are prioritizing suppliers who adhere to sustainable practices, as this not only mitigates environmental risks but also aligns with consumer expectations for corporate responsibility.

Certifications such as ISO 14001 (Environmental Management) and materials like recycled stainless steel are gaining traction in procurement discussions. These certifications provide assurance that suppliers are committed to reducing their ecological footprint. Additionally, ethical sourcing practices, including fair labor conditions and responsible sourcing of raw materials, are becoming critical criteria for B2B partnerships. Buyers are increasingly conducting audits and assessments to ensure compliance, thereby fostering a more responsible supply chain.

What Is the Brief Evolution of Steel Drink Bottles in the B2B Context?

The evolution of steel drink bottles has been marked by a significant transformation from basic utility items to premium, eco-friendly products. Initially, these bottles were primarily used for industrial purposes or by outdoor enthusiasts. However, as the health and wellness movement gained momentum, the demand for reusable drinkware surged.

Over the past two decades, advancements in technology have led to the development of insulated and lightweight designs, making them more appealing to a broader audience. The introduction of customization options has further enhanced their appeal, allowing businesses to create branded products that resonate with consumers. This evolution reflects a growing recognition of the importance of sustainability and durability in product offerings, which is now a key consideration for B2B buyers in various sectors.

In conclusion, navigating the steel drink bottles sector requires an understanding of market dynamics, a commitment to sustainability, and an appreciation of the product’s evolution. By aligning sourcing strategies with these trends, international B2B buyers can position themselves favorably in a competitive landscape while contributing to environmental stewardship.

Frequently Asked Questions (FAQs) for B2B Buyers of steel drink bottles

-

1. How do I choose the right supplier for steel drink bottles?

Selecting the right supplier involves several key considerations. Start by evaluating their production capacity and quality certifications, such as ISO 9001 or relevant industry standards. Request samples to assess product quality firsthand. It’s also crucial to check their track record, including client testimonials and case studies, particularly in your target market. Additionally, consider their ability to handle customization requests, which can be vital for branding and unique product offerings. Finally, assess their communication responsiveness and support throughout the sourcing process. -

2. What are the key factors to consider when sourcing steel drink bottles internationally?

When sourcing steel drink bottles globally, consider factors such as compliance with local regulations, shipping costs, and import duties. Evaluate the supplier’s experience in international trade, particularly their understanding of customs procedures in your country. Quality assurance is essential, so inquire about their testing methods and quality control processes. Additionally, take into account lead times for production and delivery, as well as the supplier’s ability to provide after-sales support. Understanding these factors can help mitigate risks associated with international sourcing. -

3. What customization options are available for steel drink bottles?

Customization options for steel drink bottles can vary by supplier but generally include size, color, logo engraving, and cap types. Some suppliers may also offer unique finishes, such as powder coating or etching, to enhance branding. Additionally, you can request specific functionalities, like double-wall insulation or different spout designs. When discussing customization, clearly outline your requirements and minimum order quantities (MOQs) to ensure the supplier can meet your needs effectively. -

4. What is the typical minimum order quantity (MOQ) for steel drink bottles?

MOQs for steel drink bottles can vary significantly based on the supplier and the level of customization required. Generally, MOQs can range from 100 to 1,000 units, depending on the product specifications and supplier capabilities. It’s important to discuss your needs with potential suppliers early in the negotiation process. If your order volume is lower than their standard MOQ, some suppliers may offer flexibility or suggest combining orders with other clients to meet the quantity requirements. -

5. How can I ensure product quality when sourcing steel drink bottles?

To ensure product quality, begin by requesting samples before placing bulk orders. Inspect the samples for material durability, finish, and functionality. Additionally, inquire about the supplier’s quality assurance processes, including the use of third-party inspections and testing standards. Establish clear quality criteria in your purchase agreement to hold the supplier accountable. Regular communication during production can also help identify and resolve any quality issues early. -

6. What payment terms should I expect when sourcing steel drink bottles?

Payment terms can vary by supplier, but common practices include a deposit (usually 30-50%) upfront, with the balance paid upon delivery or before shipment. Some suppliers may offer net payment terms based on your relationship and order history. Always clarify payment methods accepted, such as wire transfers, letters of credit, or payment platforms. It’s advisable to negotiate terms that protect your interests, such as escrow services, especially for large orders. -

7. How do I handle logistics and shipping for steel drink bottles?

Effective logistics management involves coordinating with your supplier to determine the best shipping methods and routes. Discuss shipping options, including air freight for urgent orders or sea freight for cost-effective bulk shipments. Understand the associated costs, including freight, insurance, and customs duties. Ensure that all necessary documentation is prepared, such as commercial invoices and packing lists, to facilitate smooth customs clearance. Working with a reliable freight forwarder can also help streamline the logistics process. -

8. What are the environmental considerations when sourcing steel drink bottles?

When sourcing steel drink bottles, consider the environmental impact of production and transportation. Look for suppliers that adhere to sustainable practices, such as using recycled materials or minimizing waste. Certifications like ISO 14001 can indicate a commitment to environmental management. Additionally, assess the product’s lifecycle, including its durability and recyclability, as these factors contribute to sustainability. Promoting eco-friendly products can also enhance your brand’s reputation in markets that value environmental responsibility.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Steel Drink Bottles Manufacturers & Suppliers List

1. Hydro Flask – Insulated Water Bottles

Domain: hydroflask.com

Registered: 2009 (16 years)

Introduction: Insulated & Stainless Steel Water Bottles from Hydro Flask. Labor Day Sale: 25% off summer styles. Free shipping on orders over $39. New Limited Edition Campus Collection available. Various sizes and colors including 16 oz Coffee with Flex Sip™ Lid ($32.95), 21 oz Standard Mouth with Flex Straw Cap ($34.95), and multiple Remix options in 24 oz and 32 oz sizes with Flex Straw Caps, discounted up to…

2. Manna Hydration – Premium Water Bottles

Domain: mannahydration.com

Registered: 2015 (10 years)

Introduction: This company, Manna Hydration – Premium Water Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Klean Kanteen – Stainless Steel Bottles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Klean Kanteen, Yeti, Hydro Flask, Tervis

4. Thermos – Water Bottles

Domain: thermos.com

Registered: 1997 (28 years)

Introduction: Water Bottles from Thermos are tough, leakproof, and dishwasher safe, designed for hydration on the go. Available sizes include 16oz, 18oz, 24oz, 32oz, 40oz, and 64oz. Color options include Beige, Black, Blue, Brown, Green, Grey, Orange, Pink, Purple, Red, Stainless Steel, White, Yellow, Alpine Green, Bright Blue, Bright Lime, Clear, Hyper Green, Mocha, Smoke, Ultra Pink. Lid types include Slide L…

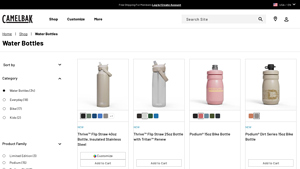

5. CamelBak – Thrive™ Flip Straw 40oz Bottle

Domain: camelbak.com

Registered: 1996 (29 years)

Introduction: CamelBak offers a variety of adventure-ready water bottles, including: 1. Thrive™ Flip Straw 40oz Bottle, Insulated Stainless Steel – $37.99 2. Thrive™ Flip Straw 25oz Bottle with Tritan™ Renew – $17.99 3. Podium® 15oz Bike Bottle – $12.00 4. Podium® Dirt Series 15oz Bike Bottle – $15.00 5. Thrive™ Chug 25oz Bottle, Insulated Stainless Steel – $30.99 6. Thrive™ Chug 20oz Bottle, Insulated Stainles…

6. Hydro Flask – 24 oz Wide Mouth with Flex Chug Cap

Domain: nytimes.com

Registered: 1994 (31 years)

Introduction: This company, Hydro Flask – 24 oz Wide Mouth with Flex Chug Cap, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

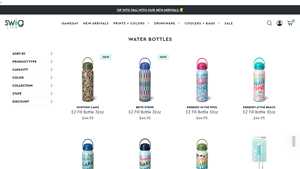

7. Swig Life – Insulated Stainless Steel Water Bottles

Domain: swiglife.com

Registered: 2018 (7 years)

Introduction: Insulated Stainless Steel Water Bottles from Swig Life come in various sizes including 12oz, 16oz, 20oz, 26oz, 30oz, 32oz, and 36oz. They feature a range of prints and colors such as Hunting Camo, Brite Stripe, Candy Crush, Sherbet Stripe, Glacier Stripe, and many more. Prices range from $36.95 to $54.95 depending on the size and design. The bottles are designed for both cold drinks and hot coffee…

Strategic Sourcing Conclusion and Outlook for steel drink bottles

As the global demand for sustainable and innovative drinkware continues to rise, the strategic sourcing of steel drink bottles presents significant opportunities for B2B buyers. Engaging with suppliers who prioritize quality materials, like 18/8 stainless steel, not only ensures durability and performance but also aligns with the growing consumer preference for eco-friendly products. Buyers should focus on partnerships that emphasize sustainability, product innovation, and adaptability to market trends, especially in regions like Africa, South America, the Middle East, and Europe.

The competitive landscape is marked by brands that offer diverse product ranges, from insulated options for adventure enthusiasts to lightweight, non-insulated designs for everyday use. This variety allows businesses to cater to a wide array of customer preferences and usage scenarios, thus maximizing market reach.

Looking ahead, international buyers are encouraged to leverage strategic sourcing to capitalize on the increasing emphasis on health, wellness, and environmental consciousness. By establishing strong relationships with reputable manufacturers, businesses can not only enhance their product offerings but also contribute to a more sustainable future. Make your move today—invest in steel drink bottles that align with your brand values and meet the evolving demands of your customers.