Introduction: Navigating the Global Market for plastic drinking bottles wholesale

In the dynamic landscape of international trade, sourcing plastic drinking bottles wholesale presents both opportunities and challenges for B2B buyers. With increasing demand for sustainable packaging solutions, businesses are tasked with finding high-quality, cost-effective products that comply with regulatory standards while meeting diverse consumer needs. This guide aims to simplify the procurement process by offering a thorough exploration of the global market for plastic drinking bottles, addressing critical aspects such as types of bottles available, their various applications, and essential supplier vetting techniques.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—countries like Brazil and Germany—will benefit from actionable insights designed to enhance their purchasing decisions. The guide covers essential factors, including material specifications, pricing structures, and logistics considerations, empowering buyers to navigate the complexities of global sourcing confidently. Furthermore, it delves into sustainability practices and certifications that ensure compliance with environmental regulations, enabling businesses to align their products with eco-conscious consumer trends.

By providing a comprehensive overview of the wholesale plastic drinking bottle market, this guide serves as a valuable resource for informed decision-making, helping businesses secure reliable suppliers and optimize their product offerings in a competitive marketplace.

Article Navigation

- Introduction: Navigating the Global Market for plastic drinking bottles wholesale

- Top 10 Plastic Drinking Bottles Wholesale Manufacturers & Suppliers List

- Understanding plastic drinking bottles wholesale Types and Variations

- Key Industrial Applications of plastic drinking bottles wholesale

- 3 Common User Pain Points for ‘plastic drinking bottles wholesale’ & Their Solutions

- Strategic Material Selection Guide for plastic drinking bottles wholesale

- In-depth Look: Manufacturing Processes and Quality Assurance for plastic drinking bottles wholesale

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic drinking bottles wholesale’

- Comprehensive Cost and Pricing Analysis for plastic drinking bottles wholesale Sourcing

- Alternatives Analysis: Comparing plastic drinking bottles wholesale With Other Solutions

- Essential Technical Properties and Trade Terminology for plastic drinking bottles wholesale

- Navigating Market Dynamics and Sourcing Trends in the plastic drinking bottles wholesale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of plastic drinking bottles wholesale

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for plastic drinking bottles wholesale

Top 10 Plastic Drinking Bottles Wholesale Manufacturers & Suppliers List

1. Good Start Packaging – BPA-Free Plastic Juice Bottles

Domain: goodstartpackaging.com

Registered: 2010 (15 years)

Introduction: Plastic juice bottles made of BPA-free PET plastic, ideal for fresh juices, cold brew coffees, or sauces. Features include: crystal clear, shatter-resistant, IMS & FDA Certified, HPP compatible, produced in a SQF Certified Facility, and recyclable. Available at wholesale prices with quantity discounts and free shipping on orders over $50. Caps sold separately in various colors. Not intended for fr…

2. General Bottle Supply – Plastic Bottles

Domain: generalbottle.com

Registered: 2005 (20 years)

Introduction: Plastic Bottles – General Bottle Supply offers a range of high-quality, versatile, and durable empty plastic bottle containers suitable for various industrial, commercial, and personal uses. The bottles are manufactured with premium-grade plastic, ensuring longevity and safety for products. The collection includes 156 products categorized by type, material (HDPE, LDPE, MDPE, PET, PVC), capacity/si…

3. Berlin Packaging – PET Plastic Water Bottles

Domain: berlinpackaging.com

Registered: 1997 (28 years)

Introduction: PET Plastic Water Bottles are lightweight and economical, featuring circumferential paneling at the bottom and shoulder for improved strength. They have a generous label panel area for branding. Made from durable PET plastic, these bottles offer excellent gloss, clarity, and impact resistance. They are suitable for personal care, food, beverage, and pharmaceutical products, providing the appeal of…

4. TricorBraun – Plastic Bottles & Jars

Domain: tricorbraun.com

Registered: 1998 (27 years)

Introduction: Plastic Bottles & Jars – Wholesale & Bulk | TricorBraun offers a variety of plastic bottles and jars including: Boston Round Plastic Bottles, Bullet Round Plastic Bottles, Cylinder Round Plastic Bottles, Modern Round Plastic Bottles, Plastic Dropper Bottles, Plastic Liquor & Spirit Bottles, Plastic Packer Bottles, Plastic Sauce Bottles, PET Plastic Bottles, Plastic Jars, Plastic Double Wall Jars, …

5. Container and Packaging – Plastic Bottles

Domain: containerandpackaging.com

Registered: 2001 (24 years)

Introduction: Plastic Bottles – Wholesale PET & HDPE Containers. Suitable for various products including sauces, shampoos, cleaners, and creams. Available in a wide range of styles, colors, and plastic types. Designed for pouring, spraying, or squeezing.

6. BottleStore – Square Plastic Bottles

Domain: bottlestore.com

Registered: 1998 (27 years)

Introduction: Square Plastic Bottles available in various sizes: 16oz (480ml), 8oz (240ml), and 12oz (360ml). Made from clear PET material. Closure options available. Pricing per piece: 16oz – $0.48, 8oz – $0.50, 12oz – $0.53. Carton quantities: 320 pieces for 16oz, 572 pieces for 8oz, and 340 pieces for 12oz. Carton pricing: 16oz – $153.60, 8oz – $287.70, 12oz – $180.20 (as low as $162.11).

7. Totally Promotional – Bulk Water Bottles

Domain: totallypromotional.com

Registered: 2008 (17 years)

Introduction: Blank Water Bottles in Bulk – Wholesale Bulk Water Bottles | Totally Promotional. Options include Plastic Water Bottles, Metal Water Bottles, Glass Water Bottles, BPA-Free Water Bottles, Sustainable Water Bottles, Shaker Bottles, Drink Pouches, and Water Bottle Lids.

8. Restaurantware – Juice Bottles

9. Wholesale Supplies Plus – Bulk Plastic Bottles

Domain: wholesalesuppliesplus.com

Registered: 1999 (26 years)

Introduction: Bulk Plastic Bottles & Containers available at Wholesale Supplies Plus. Offers a variety of plastic bottles suitable for soap making and other DIY projects. Free shipping on orders over $25. Contact information: 216-503-9361. Features include bulk discounts and a wide range of soap making supplies.

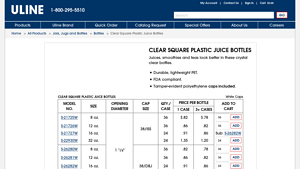

10. Uline – Clear Square Plastic Juice Bottles

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Clear Square Plastic Juice Bottles

– Suitable for juices, smoothies, and teas

– Made from durable, lightweight PET

– FDA compliant

– Includes tamper-evident polyethylene caps

Available Models:

1. Model No: S-21725W

– Size: 8 oz.

– Opening Diameter: 1 1/8″

– Cap Size: 38/ISS

– Quantity/Case: 36

– Price per Bottle: $0.82 (3+ cases: $0.78)

2. Model No: S-21726W

– Size: 12 oz.

-…

Understanding plastic drinking bottles wholesale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PET Plastic Bottles | Lightweight, shatter-resistant, BPA-free | Beverage packaging, sauces, cosmetics | Pros: High recyclability, FDA-approved; Cons: Limited heat resistance. |

| HDPE Plastic Bottles | Durable, resistant to impact and chemicals | Industrial, cleaning products, food storage | Pros: Excellent chemical resistance; Cons: Less transparent than PET. |

| Boston Round Bottles | Classic round shape, available in various sizes and colors | Personal care products, beverages | Pros: Versatile design; Cons: May not be suitable for all beverage types. |

| Square Juice Bottles | Space-efficient design, ideal for cold beverages | Juice and smoothie packaging | Pros: Maximize shelf space; Cons: Not suitable for carbonated drinks. |

| Specialty Bottles | Custom shapes and sizes, often with unique closures | Niche markets (liquor, sauces) | Pros: Stand out on the shelf; Cons: Higher cost and longer lead times. |

What Are the Key Characteristics of PET Plastic Bottles?

PET (Polyethylene Terephthalate) plastic bottles are notable for their lightweight and shatter-resistant properties, making them ideal for a variety of beverages, including juices and cold brew coffees. They are FDA-approved and BPA-free, ensuring safety for food applications. B2B buyers should consider their recyclability, as PET is one of the most widely recycled plastics, appealing to environmentally conscious businesses. However, they have limitations regarding heat resistance, making them unsuitable for hot-filled products.

Why Choose HDPE Plastic Bottles for Industrial Applications?

HDPE (High-Density Polyethylene) plastic bottles are highly durable and resistant to chemicals and impact. This makes them a preferred choice for industrial applications, including cleaning products and food storage. B2B buyers benefit from their robust nature and versatility. However, HDPE bottles are typically opaque, which may limit branding opportunities compared to transparent materials. Buyers should weigh the importance of visibility against the need for chemical resistance based on their product requirements.

What Makes Boston Round Bottles a Popular Choice?

Boston Round bottles are characterized by their classic round shape and are available in a wide range of sizes and colors. This versatility makes them suitable for personal care products, beverages, and more. For B2B buyers, the design’s timeless appeal can enhance brand recognition. However, it’s essential to note that while these bottles are versatile, they may not be the best fit for all beverage types, particularly those requiring specialized pressure management.

How Do Square Juice Bottles Optimize Space?

Square juice bottles are designed to be space-efficient, making them an excellent choice for juice and smoothie packaging. Their shape allows for more efficient storage and transportation, which can significantly reduce shipping costs for B2B buyers. However, these bottles are not suitable for carbonated beverages due to the pressure they generate. When considering square bottles, businesses should focus on their product line to ensure compatibility.

What Are the Advantages of Specialty Bottles in Niche Markets?

Specialty bottles come in unique shapes and sizes, often tailored to specific products like liquor or gourmet sauces. These bottles can help brands stand out on retail shelves, appealing to consumers looking for distinctive packaging. For B2B buyers, the customizability of specialty bottles can enhance brand identity. However, they may come with higher costs and longer lead times, which businesses must consider in their supply chain planning.

Key Industrial Applications of plastic drinking bottles wholesale

| Industry/Sector | Specific Application of plastic drinking bottles wholesale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beverage Manufacturing | Bottling of juices and smoothies | Ensures product safety, shelf stability, and brand visibility | Quality certifications (FDA, HPP compatibility), customization options, and bulk pricing. |

| Food Service & Catering | Use for sauces, dressings, and condiments | Versatility in packaging, enhances customer experience, and reduces waste | Sourcing options for various sizes and shapes, food-safe materials, and reliable supply chain. |

| Personal Care & Cosmetics | Packaging for liquid soaps, shampoos, and lotions | Attractive design options, enhances brand image, and protects product integrity | Availability of eco-friendly materials, customization for branding, and compliance with safety regulations. |

| Pharmaceuticals | Containment for liquid medications | Ensures product safety and compliance with health regulations | Need for tamper-evident seals, compatibility with various liquid types, and certifications. |

| Sports & Fitness | Bottles for hydration and supplements | Promotes brand loyalty, encourages health-conscious consumer behavior | Lightweight design, durability, and options for customization (logos, colors). |

How Are Plastic Drinking Bottles Used in Beverage Manufacturing?

In the beverage manufacturing industry, plastic drinking bottles are primarily used for bottling juices and smoothies. These bottles, often made from high-quality PET plastic, provide a crystal-clear view of the product, enhancing its appeal on retail shelves. They are designed to be shatter-resistant and BPA-free, ensuring the safety of the beverages. International buyers, particularly from regions like Africa and South America, should consider sourcing bottles that are IMS and FDA certified, as these certifications guarantee compliance with food safety regulations and enhance product credibility.

What Role Do Plastic Bottles Play in Food Service and Catering?

Plastic bottles are widely utilized in food service and catering for packaging sauces, dressings, and condiments. Their versatility allows businesses to offer a variety of products in attractive packaging that enhances customer experience. By using these bottles, companies can reduce waste and improve portion control. Buyers must focus on sourcing options that provide various sizes and shapes, ensuring that the materials used are food-safe and compliant with local regulations, especially in diverse markets like Europe and the Middle East.

How Are Plastic Bottles Utilized in Personal Care and Cosmetics?

In the personal care and cosmetics sector, plastic drinking bottles serve as packaging for liquid soaps, shampoos, and lotions. The appeal of these bottles lies in their ability to be customized, allowing brands to enhance their image while ensuring product integrity. For international buyers, especially in Europe and the Middle East, it’s critical to source bottles made from eco-friendly materials that comply with safety regulations. Customization options, such as colors and designs, can significantly impact brand perception and marketability.

Why Are Plastic Bottles Important for Pharmaceuticals?

Pharmaceutical companies use plastic drinking bottles for the containment of liquid medications, ensuring product safety and compliance with health regulations. These bottles often require tamper-evident seals to maintain integrity and consumer trust. For B2B buyers in regions like Africa and South America, it is essential to source bottles that are compatible with various liquid types and come with necessary certifications. This ensures that the products meet stringent health and safety standards while also being cost-effective.

How Do Plastic Bottles Support the Sports and Fitness Industry?

In the sports and fitness industry, plastic drinking bottles are essential for hydration and supplement packaging. They promote brand loyalty by encouraging health-conscious consumer behavior, especially when customized with logos and colors. Buyers should look for lightweight and durable options that can withstand active lifestyles. Sourcing considerations should include the availability of customization, ensuring that the bottles not only serve a functional purpose but also resonate with the target audience’s values and lifestyle.

3 Common User Pain Points for ‘plastic drinking bottles wholesale’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Bottling Operations

The Problem: International B2B buyers often grapple with the challenge of ensuring that the plastic drinking bottles they procure meet stringent quality and safety standards. This is particularly crucial for businesses in regions like Africa and South America, where compliance with local regulations may vary. Buyers may find themselves uncertain about the certifications needed, leading to potential product recalls or reputational damage if subpar materials are used.

The Solution: To navigate this challenge, buyers should prioritize sourcing from suppliers that provide detailed documentation of their quality assurance processes. Look for bottles that are IMS & FDA certified, and manufactured in SQF certified facilities. This guarantees that the bottles meet international safety standards and are suitable for food and beverage applications. Additionally, request samples to evaluate the product firsthand before making a bulk purchase. Engaging in open communication with suppliers about their manufacturing practices and certifications can also ensure that the bottles align with your quality requirements, reducing the risk of compliance issues.

Scenario 2: Managing Supply Chain Disruptions and Lead Times

The Problem: B2B buyers often face unpredictable lead times and supply chain disruptions, especially when sourcing plastic drinking bottles from international suppliers. This can lead to stock shortages, affecting production schedules and customer satisfaction. Buyers from Europe, for instance, may experience delays due to customs clearance or logistical challenges, which can hinder their ability to meet market demand.

The Solution: To mitigate this issue, establish relationships with multiple suppliers to create a diversified supply chain. This strategy can provide alternative options in case of delays or shortages. It’s also advisable to implement a just-in-time inventory system that allows you to order bottles based on real-time demand rather than relying on large stockpiles. Additionally, maintain regular communication with suppliers regarding their production schedules and shipping timelines. Using software solutions for inventory management can enhance visibility into stock levels and order statuses, helping you proactively address potential shortages.

Scenario 3: Understanding the Limitations of Different Plastic Materials

The Problem: Many buyers struggle to understand the differences between various types of plastic used in drinking bottles, which can lead to purchasing errors. For instance, while PET bottles are widely used for cold beverages, they may not be suitable for hot-fill applications or products requiring high-pressure conditions. This lack of knowledge can result in selecting inappropriate bottles that compromise product integrity.

The Solution: To address this, buyers should invest time in educating themselves about the properties of different plastic materials, such as PET, HDPE, and LDPE. Each type of plastic has unique characteristics that determine its suitability for specific applications. For example, PET is great for clear, shatter-resistant bottles, while HDPE is ideal for more robust, opaque containers. Consult with your suppliers about your specific use case and ask for recommendations based on their expertise. Additionally, reviewing product specifications and conducting compatibility tests with your intended beverages can help ensure that you select the right bottle for your needs, ultimately safeguarding your product’s quality.

Strategic Material Selection Guide for plastic drinking bottles wholesale

What Are the Key Materials for Plastic Drinking Bottles in Wholesale?

When selecting materials for plastic drinking bottles, it is crucial to understand the properties, advantages, and limitations of each option. This knowledge empowers B2B buyers to make informed decisions that align with their product requirements and market standards. Below, we analyze four common materials used in the manufacturing of plastic drinking bottles.

How Does PET (Polyethylene Terephthalate) Perform in Plastic Bottle Applications?

PET is one of the most widely used plastics for beverage bottles due to its excellent clarity, strength, and lightweight nature. It has a temperature resistance of up to 60°C (140°F) and is highly resistant to impact and shattering, making it ideal for various applications.

Pros: PET is cost-effective, recyclable, and offers good barrier properties against moisture and gases, preserving the freshness of beverages. It is also FDA-approved for food contact, which is essential for international compliance.

Cons: However, PET is not suitable for high-temperature applications, such as hot-filling or pasteurization, as it can warp or deform. Additionally, while it is recyclable, the recycling rates can vary significantly by region.

Impact on Application: PET bottles are best suited for cold beverages and non-carbonated drinks. Buyers must ensure that their suppliers adhere to local recycling regulations and standards, particularly in regions like Europe, where recycling compliance is stringent.

What Are the Advantages of HDPE (High-Density Polyethylene) for Bottles?

HDPE is known for its excellent strength-to-density ratio and is resistant to many solvents, making it a popular choice for a variety of applications, including dairy and juice bottles. It can withstand temperatures up to 120°C (248°F), making it suitable for hot-fill processes.

Pros: HDPE is robust, lightweight, and resistant to impact and chemicals. Its durability makes it an excellent choice for shipping and storage.

Cons: On the downside, HDPE is less transparent than PET, which may not appeal to brands that prioritize product visibility. Additionally, it has a lower barrier performance compared to PET, which can affect the shelf life of certain beverages.

Impact on Application: HDPE is ideal for products that require durability and moderate temperature resistance. Buyers must consider local regulations regarding food safety and recycling, especially in regions like Africa and South America, where standards may vary.

How Does LDPE (Low-Density Polyethylene) Compare for Bottling Needs?

LDPE is often used for squeeze bottles and flexible packaging due to its low-density structure, which provides excellent flexibility and impact resistance. It can handle temperatures up to 80°C (176°F).

Pros: LDPE is highly resistant to chemicals and moisture, making it suitable for a wide range of beverages. Its flexibility allows for easy dispensing, which is beneficial for sauces and condiments.

Cons: However, LDPE is not as strong as PET or HDPE, making it less suitable for products requiring high durability. Its lower density also means it is less efficient in terms of packaging space.

Impact on Application: LDPE is mainly used for products that require easy dispensing rather than long-term storage. B2B buyers should ensure that LDPE products comply with food safety standards in their respective markets, particularly in Europe, where regulations are strict.

What Are the Benefits and Limitations of PP (Polypropylene) for Bottles?

Polypropylene is increasingly popular for beverage bottles due to its high melting point (up to 130°C or 266°F) and excellent chemical resistance. It is often used for hot-filled products and can withstand sterilization processes.

Pros: PP is lightweight, durable, and has good barrier properties against moisture. It is also recyclable and can be produced in various colors.

Cons: However, PP can be more expensive than PET and HDPE, which may affect overall production costs. Additionally, its clarity is lower than PET, which could impact consumer appeal.

Impact on Application: PP is suitable for both hot and cold beverages, making it versatile for various applications. Buyers must consider the higher cost and ensure compliance with international standards, especially in markets like Germany, where quality assurance is paramount.

Summary Table of Material Properties for Plastic Drinking Bottles

| Material | Typical Use Case for plastic drinking bottles wholesale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET | Cold beverages, juices, and sauces | Excellent clarity and recyclability | Not suitable for hot-filling | Low |

| HDPE | Dairy products, juices, and chemical containers | Strong and impact-resistant | Less transparent | Medium |

| LDPE | Squeeze bottles and flexible packaging | Flexible and moisture-resistant | Lower strength | Low |

| PP | Hot-filled beverages and sauces | High melting point and durability | Higher cost | High |

This guide provides a comprehensive overview of the materials used in plastic drinking bottles, equipping international B2B buyers with the insights needed to make strategic purchasing decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic drinking bottles wholesale

What Are the Main Stages in the Manufacturing Process of Plastic Drinking Bottles?

The manufacturing process of plastic drinking bottles involves several key stages, each crucial to ensuring the final product meets quality and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of appropriate raw materials, typically high-density polyethylene (HDPE) or polyethylene terephthalate (PET). These materials are sourced from certified suppliers to ensure quality. The plastic granules undergo a drying process to remove moisture, which is critical for maintaining the integrity of the final product.

-

Forming: Forming techniques vary based on the bottle design. The most common methods include blow molding and injection molding. In blow molding, air is used to inflate heated plastic into the shape of a mold, creating hollow bottles. Injection molding, on the other hand, involves injecting molten plastic into a mold to form solid parts. Each method has its advantages; blow molding is ideal for producing lightweight bottles, while injection molding allows for complex shapes and designs.

-

Assembly: Once the bottles are formed, they may require additional components such as caps, labels, and handles. This stage often involves automated assembly lines that streamline the process, ensuring efficiency and consistency. Quality checks during assembly are vital to confirm that all components fit correctly and that there are no defects.

-

Finishing: The final stage involves surface treatments and inspections. Bottles may undergo processes such as polishing or coating to enhance their appearance and durability. This stage also includes rigorous quality assurance checks to verify that the bottles meet the required specifications before packaging and shipping.

How Does Quality Control Ensure High Standards in Plastic Bottle Production?

Quality control (QC) is an integral part of the manufacturing process, ensuring that plastic drinking bottles meet international safety and quality standards. Various international and industry-specific standards guide QC processes, including ISO 9001, CE certification, and API standards.

-

International Standards: ISO 9001 is a widely recognized standard that outlines the criteria for a quality management system. Manufacturers seeking this certification must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Compliance with such standards is crucial for B2B buyers, especially those sourcing from different countries, as it indicates a commitment to quality.

-

Industry-Specific Certifications: In addition to ISO standards, manufacturers may also seek industry-specific certifications. For example, the CE mark is mandatory for products sold in the European Economic Area, ensuring they meet safety and environmental requirements. Buyers should verify that suppliers hold relevant certifications to mitigate risks associated with product safety.

What Are the Key Quality Control Checkpoints During Production?

Quality control checkpoints are strategically placed throughout the manufacturing process to identify and rectify issues before the final product is completed. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers must provide certificates of analysis to confirm that materials meet specified standards. Any subpar materials are rejected at this stage, preventing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor production parameters and identify any deviations from standards. This may include measuring dimensions, checking for visual defects, and ensuring that machinery operates within specified tolerances.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is performed. This includes testing for functionality, safety, and compliance with relevant standards. Random sampling is often employed to ensure a representative quality assessment of the entire batch.

What Common Testing Methods Are Used to Ensure Product Quality?

Various testing methods are employed to validate the quality of plastic drinking bottles. These methods help identify potential issues that could affect product performance and safety.

-

Mechanical Testing: This includes tensile strength tests, impact resistance tests, and drop tests to assess the durability of the bottles. These tests help ensure that bottles can withstand handling, transportation, and use without compromising their integrity.

-

Chemical Testing: Bottles are tested for chemical resistance to ensure they do not leach harmful substances into the contents. This is particularly important for food and beverage applications, where compliance with FDA and other health regulations is mandatory.

-

Environmental Testing: Manufacturers may conduct tests to evaluate the bottles’ performance under various environmental conditions, including temperature extremes and exposure to UV light. Such testing ensures that products maintain their quality throughout their lifecycle.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers play a critical role in ensuring the quality of products they source. Here are effective strategies to verify a supplier’s quality control processes:

-

Supplier Audits: Conducting on-site audits allows buyers to directly assess a supplier’s manufacturing processes, quality control measures, and compliance with international standards. This firsthand evaluation can reveal potential risks and reassure buyers about the supplier’s capabilities.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports outlining their QC processes, test results, and any certifications obtained. Buyers should review these documents to ensure they align with their quality expectations.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s production facilities and quality control practices. This can be especially valuable for international buyers who may not have the capacity for on-site audits.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification processes.

-

Regulatory Variations: Different countries have varying regulations regarding food safety and packaging materials. Buyers must familiarize themselves with these regulations to ensure that the products they import comply with local laws.

-

Cultural and Language Considerations: Communication barriers may pose challenges in understanding quality standards and certifications. Engaging a local representative or consultant can facilitate better communication and understanding of regional requirements.

-

Supply Chain Transparency: International buyers should prioritize suppliers that demonstrate transparency in their supply chain practices. This includes clear documentation of sourcing, manufacturing, and quality assurance processes, which can mitigate risks associated with sourcing from overseas.

By understanding the manufacturing processes and quality assurance measures associated with plastic drinking bottles, B2B buyers can make informed purchasing decisions, ensuring that they source high-quality products that meet both their needs and regulatory standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic drinking bottles wholesale’

Introduction

Sourcing plastic drinking bottles at wholesale prices requires a strategic approach to ensure that your business acquires high-quality products that meet regulatory standards and consumer expectations. This checklist provides a clear, step-by-step guide to help international B2B buyers streamline their procurement process, minimize risks, and enhance product offerings.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your plastic drinking bottles. Consider factors such as size, shape, material (e.g., PET, HDPE), and intended use (e.g., cold beverages, juices). Clearly defining these specifications helps you communicate effectively with suppliers and ensures that the products you receive meet your operational needs.

- Material Considerations: Ensure that the chosen material is food-safe and compliant with local regulations.

- Capacity and Design: Consider whether you need standard sizes or custom designs to differentiate your product in the market.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in plastic drinking bottles. Look for manufacturers with a strong reputation and positive reviews in the industry.

- Industry Experience: Prioritize suppliers with significant experience in your specific market segment.

- Geographical Considerations: Consider suppliers located in regions that can efficiently meet your shipping and delivery requirements.

Step 3: ✅ Verify Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with industry standards. This step is crucial to ensure that the products you purchase are safe and of high quality.

- Key Certifications: Look for ISO, FDA, and other relevant certifications that indicate adherence to safety and quality standards.

- Facility Standards: Confirm that the manufacturing facility is certified (e.g., SQF) to ensure hygienic production practices.

Step 4: Request Samples for Quality Assurance

Always request samples before placing a bulk order. This step allows you to assess the quality of the bottles and verify that they meet your specifications.

- Testing for Suitability: Evaluate the samples for durability, clarity, and compatibility with your products (e.g., cold beverages).

- Feedback from Team Members: Involve your team in the evaluation process to gather diverse opinions on the samples.

Step 5: Negotiate Pricing and Terms

Once you’ve selected a potential supplier, engage in negotiations to secure the best pricing and terms. Consider not only the cost per unit but also other factors that could impact your total expenditure.

- Volume Discounts: Inquire about discounts for larger orders or long-term contracts.

- Shipping Costs: Discuss shipping terms to avoid unexpected charges and delays.

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels to ensure that both you and the supplier are aligned on expectations.

- Regular Updates: Schedule regular check-ins to discuss order status, potential issues, and any changes in requirements.

- Crisis Management: Agree on a protocol for handling any discrepancies or quality issues that may arise.

Step 7: Finalize and Place Your Order

After confirming all details and ensuring that both parties are on the same page, finalize your order. Ensure that all contractual obligations are documented clearly.

- Order Confirmation: Get a written confirmation that includes all agreed-upon terms, pricing, and delivery timelines.

- Payment Terms: Clarify payment terms to ensure smooth financial transactions and maintain a good relationship with your supplier.

By following this checklist, you can navigate the complexities of sourcing plastic drinking bottles wholesale with confidence, ensuring quality products that meet your business needs.

Comprehensive Cost and Pricing Analysis for plastic drinking bottles wholesale Sourcing

What Are the Key Cost Components in Plastic Drinking Bottle Manufacturing?

When sourcing plastic drinking bottles wholesale, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of plastic used—typically PET or HDPE—plays a significant role in pricing. PET is often favored for its recyclability and clarity, making it suitable for beverages. Prices can fluctuate based on global oil prices and availability of raw materials.

-

Labor: Labor costs vary by region and manufacturing standards. In areas with lower wage rates, such as parts of Africa and South America, manufacturers may offer more competitive pricing. However, it’s essential to consider the skill level of labor, as higher-quality production may require more skilled workers.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient production facilities can lower overhead costs, contributing to overall price competitiveness.

-

Tooling: Custom molds for unique bottle shapes or sizes can incur significant initial costs. However, these costs are amortized over larger production runs, making high-volume orders more economical.

-

Quality Control (QC): Ensuring that bottles meet safety and quality standards can add to costs but is essential for compliance, especially for food and beverage applications. Certifications like FDA approval or SQF certification can influence pricing.

-

Logistics: Shipping costs depend on the distance from the manufacturer to the buyer, as well as the mode of transportation. Incoterms can significantly affect the total landed cost, with different terms dictating who bears the risk and responsibility for shipping costs.

-

Margin: Suppliers typically add a margin based on their operational costs and market demand. Understanding the competitive landscape can help buyers gauge whether the margins are justifiable.

How Do Price Influencers Affect Wholesale Sourcing of Plastic Bottles?

Several factors can influence the pricing of plastic drinking bottles:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to reduced per-unit prices. Suppliers may set MOQs that can affect smaller businesses, so negotiating these terms is vital.

-

Specifications and Customization: Custom designs or specific features (like color or cap type) can increase costs. Buyers should weigh the benefits of customization against the potential price hike.

-

Material Quality and Certifications: Higher quality materials and certifications generally lead to higher prices. However, these investments may be necessary for ensuring product safety and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their quality assurance processes but can offer peace of mind regarding consistency and compliance.

-

Incoterms: Different shipping terms can impact costs significantly. For instance, FOB (Free on Board) means the supplier covers shipping until the goods are loaded onto the transport vessel, while CIF (Cost, Insurance, and Freight) includes insurance and shipping costs, affecting the overall price.

What Tips Can Help Buyers Achieve Cost-Efficiency in Sourcing Plastic Drinking Bottles?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Don’t hesitate to negotiate on price, especially for larger orders. Building a relationship with suppliers can also lead to better terms over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also shipping, handling, and potential quality issues. A cheaper bottle may end up costing more in the long run if it leads to product failures or compliance issues.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations can impact pricing. Consider hedging strategies or fixed pricing agreements to mitigate this risk.

-

Request Samples: Before placing a large order, request samples to assess quality and functionality. This can prevent costly mistakes and ensure that the products meet your standards.

-

Stay Informed on Market Trends: Keeping an eye on industry trends and changes in raw material costs can help you time your purchases more strategically.

Disclaimer

The prices and terms mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and seek quotes from multiple suppliers to ensure the best pricing and terms for your needs.

Alternatives Analysis: Comparing plastic drinking bottles wholesale With Other Solutions

Understanding Alternatives to Plastic Drinking Bottles Wholesale

In today’s competitive marketplace, businesses must evaluate various packaging solutions to meet their product needs effectively. While plastic drinking bottles are a popular choice due to their versatility and cost-effectiveness, several alternatives exist that may offer unique benefits depending on the use case. This analysis will compare plastic drinking bottles wholesale with two viable alternatives: glass bottles and biodegradable containers.

Comparison Table

| Comparison Aspect | Plastic Drinking Bottles Wholesale | Glass Bottles | Biodegradable Containers |

|---|---|---|---|

| Performance | Lightweight, shatter-resistant | Heavy, breakable; premium feel | Varies by material; often less durable |

| Cost | Generally low-cost | Higher production and shipping costs | Moderate to high, depending on material |

| Ease of Implementation | Easy to source and use | Requires careful handling | May require specialized storage and handling |

| Maintenance | Low maintenance; recyclable | Reusable; requires cleaning | Single-use; compostable or recyclable |

| Best Use Case | Beverages, sauces, and condiments | Premium beverages, cosmetics | Environmentally conscious products, food items |

Pros and Cons of Each Alternative

Glass Bottles

Glass bottles are known for their premium feel and excellent barrier properties, making them ideal for high-end beverages, cosmetics, and specialty foods. Their shatter-resistant versions offer some durability, but they are significantly heavier and more prone to breakage compared to plastic. While glass can be recycled indefinitely, the higher shipping costs and careful handling requirements can deter some businesses from adopting this option. Glass is best suited for brands looking to convey quality and sustainability but may not be practical for all applications, particularly in regions with logistical challenges.

Biodegradable Containers

Biodegradable containers, made from materials like PLA (polylactic acid) or other plant-based substances, are gaining traction among environmentally conscious brands. These containers are designed to break down naturally, reducing landfill impact. However, their performance can vary widely based on the specific material used, and they may not offer the same durability as plastic or glass. Additionally, they often come at a higher cost and may require specific disposal methods to ensure they decompose properly. Businesses focused on sustainability and targeting eco-aware consumers may find biodegradable options appealing, but they should assess whether these containers meet their durability and performance needs.

Conclusion: How to Choose the Right Packaging Solution

Choosing the right packaging solution involves analyzing your specific product requirements, budget constraints, and target market preferences. Plastic drinking bottles wholesale offer a cost-effective and versatile option suitable for a wide range of applications. In contrast, glass bottles provide a premium feel and excellent product protection, while biodegradable containers appeal to eco-conscious consumers but may have limitations in performance. By carefully evaluating these alternatives, B2B buyers can select the packaging that aligns best with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for plastic drinking bottles wholesale

What Are the Key Technical Properties of Plastic Drinking Bottles for Wholesale?

When sourcing plastic drinking bottles, understanding their technical properties is crucial for making informed purchasing decisions. Below are some essential specifications that B2B buyers should consider:

-

Material Grade

The most common materials for plastic drinking bottles include PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene). PET is known for its clarity, shatter resistance, and recyclability, making it ideal for beverages. HDPE, on the other hand, is robust and resistant to impact, which is suitable for products requiring higher durability. Choosing the right material can affect product safety, shelf life, and customer satisfaction. -

Neck Finish

The neck finish refers to the design and size of the bottle opening, which determines the compatibility with closures and caps. Common neck finishes include 24-410 and 38-400. Accurate neck finish specifications ensure that caps fit securely, preventing leaks and maintaining product integrity. This is especially important for products such as juices and sauces, where freshness and safety are paramount. -

Capacity

The capacity of plastic bottles varies widely, typically ranging from 8 oz to 64 oz or more. Selecting the right capacity depends on market demand and the type of beverage. Bottles that are too large may lead to waste, while those that are too small might not meet customer needs. Understanding your target market helps in choosing the appropriate sizes. -

Tolerance Levels

Tolerance levels define the acceptable variations in dimensions during manufacturing. High tolerance levels ensure consistency in production, leading to fewer defects and better quality control. This is vital for maintaining brand reputation and ensuring that products meet regulatory standards. -

Recyclability

The recyclability of plastic bottles is becoming increasingly important for consumers and businesses alike. Bottles made from PET are generally accepted in most recycling facilities. Ensuring that products are eco-friendly not only meets regulatory requirements but also appeals to environmentally conscious consumers.

Which Trade Terms Are Commonly Used in Plastic Bottle Wholesale?

Understanding industry jargon is vital for effective communication and negotiation in the B2B landscape. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of plastic bottles, an OEM might produce custom bottles for a beverage brand. This allows businesses to create unique products tailored to their specifications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. For plastic bottles, MOQs can vary significantly based on the supplier and the complexity of the order. Understanding MOQ helps buyers manage inventory costs and negotiate better pricing. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes for specific products or services. When seeking plastic bottles, an RFQ can include details like quantity, material specifications, and delivery timelines. This process aids in comparing offers from multiple suppliers, ensuring competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. They clarify aspects such as shipping costs, insurance, and risks. Familiarity with Incoterms helps buyers understand their obligations, making logistics smoother and minimizing disputes. -

HPP (High-Pressure Processing)

HPP is a food preservation method that uses high pressure to eliminate pathogens and extend shelf life. For businesses using plastic bottles for juices or other perishable goods, knowing if their bottles are HPP-compatible is crucial for maintaining product safety and quality. -

BPA-Free

This term indicates that the plastic used in the bottles does not contain Bisphenol A (BPA), a chemical linked to health risks. BPA-free bottles are increasingly preferred by consumers and businesses alike, making it an important consideration for brands focused on health and safety.

Understanding these properties and terms can significantly enhance the purchasing process for plastic drinking bottles, allowing B2B buyers to make informed decisions that align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the plastic drinking bottles wholesale Sector

What Are the Key Trends Driving the Plastic Drinking Bottles Wholesale Market?

The plastic drinking bottles wholesale market is experiencing a dynamic shift driven by several global factors. Firstly, the increasing demand for convenience and on-the-go beverages, particularly in developing regions such as Africa and South America, has propelled the need for versatile packaging solutions. The rise of health-conscious consumers is also a significant driver, as products like juices, flavored waters, and functional beverages gain popularity, requiring innovative bottle designs that cater to these needs.

Additionally, technology is reshaping sourcing trends within the industry. Advances in production techniques, such as blow molding and injection molding, enable manufacturers to create lightweight, durable, and aesthetically pleasing bottles that meet varying consumer preferences. Digital platforms are increasingly facilitating B2B transactions, allowing international buyers to source products more efficiently through e-commerce solutions. Furthermore, real-time inventory management systems and data analytics are enhancing supply chain visibility, enabling buyers to make informed purchasing decisions.

Emerging market dynamics, including fluctuating raw material prices and regulatory changes, necessitate that buyers remain agile. Countries in Europe, like Germany, are implementing stricter regulations regarding plastic usage and recycling, prompting wholesalers to adapt their sourcing strategies to comply with these laws. International buyers must stay abreast of these developments to ensure they are sourcing from compliant suppliers.

How Is Sustainability Influencing Sourcing Decisions in the Plastic Drinking Bottles Sector?

Sustainability has become a cornerstone of sourcing decisions in the plastic drinking bottles wholesale market. With increasing scrutiny on environmental impacts, companies are prioritizing eco-friendly materials and practices. Buyers are now more inclined to partner with suppliers that offer BPA-free, recyclable, and biodegradable options. PET (Polyethylene Terephthalate) is particularly favored due to its recyclability and lower environmental footprint compared to other plastics.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are seeking manufacturers that uphold social responsibility by ensuring fair labor practices and transparent sourcing. Certifications such as ISO 14001 for environmental management and the FSC (Forest Stewardship Council) certification for sustainable materials are gaining traction. These certifications not only enhance brand reputation but also meet the growing consumer demand for responsible products.

In regions like the Middle East, where water scarcity is a pressing concern, sourcing trends are increasingly focused on water-efficient production methods. Suppliers that adopt innovative technologies to minimize water usage and waste during manufacturing processes will likely gain a competitive edge. As sustainability continues to shape the market, B2B buyers must evaluate their suppliers based on these criteria to align with global sustainability goals.

What Is the Evolution of the Plastic Drinking Bottles Market?

The evolution of the plastic drinking bottles market has been marked by significant technological advancements and changing consumer preferences. Initially, glass bottles dominated the beverage packaging landscape due to their durability and safety. However, the 1970s saw the introduction of plastic bottles, which quickly gained traction for their lightweight nature and cost-effectiveness.

Throughout the 1990s and early 2000s, innovations in plastic materials and bottle design transformed the market. The introduction of PET as a standard material for beverage bottles marked a pivotal moment, providing manufacturers with a recyclable option that met consumer needs for convenience. The shift towards sustainability began in earnest in the late 2000s, as environmental concerns prompted manufacturers to explore eco-friendly alternatives.

Today, the market continues to evolve, with a focus on enhancing product safety, reducing environmental impact, and embracing digital transformation in sourcing and logistics. As a result, the plastic drinking bottles wholesale sector is poised for further growth, driven by innovation and the increasing demand for sustainable packaging solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic drinking bottles wholesale

-

How do I choose the right plastic drinking bottles for my product line?

Choosing the right plastic drinking bottles involves considering several factors, including the type of beverage, bottle material, size, and design. For cold beverages, PET plastic is ideal due to its clarity and shatter resistance. You should also evaluate the bottle’s compatibility with your production processes, such as high-pressure pasteurization (HPP) if applicable. Additionally, consider sustainability aspects, like recyclability, to align with eco-conscious consumer trends. Request samples from suppliers to test before making bulk purchases, ensuring they meet your quality standards. -

What is the best material for plastic drinking bottles for international shipping?

For international shipping, PET (Polyethylene Terephthalate) is often the best material for plastic drinking bottles. PET is lightweight, durable, and highly recyclable, making it suitable for various beverage types. It also has excellent barrier properties, preserving the freshness of the contents during transport. Ensure that the bottles are manufactured in a facility that meets international quality standards, such as FDA or ISO certifications, to avoid complications with customs and ensure product safety. -

What are the typical minimum order quantities (MOQs) for plastic drinking bottles?

Minimum order quantities (MOQs) for plastic drinking bottles can vary significantly among suppliers, typically ranging from 1,000 to 10,000 units. Factors influencing MOQs include the type of bottle, customization requirements, and the supplier’s production capacity. For international buyers, it’s essential to discuss MOQs upfront to align with your inventory needs and budget. Some suppliers may offer lower MOQs for stock items, while custom designs usually require higher quantities. -

What payment terms should I expect when sourcing plastic drinking bottles wholesale?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer net 30 or net 60 payment terms, especially for established relationships. It’s crucial to clarify payment options and terms during negotiations to avoid misunderstandings. Additionally, consider using secure payment methods, such as letters of credit or escrow services, to protect your investment in international transactions. -

How can I verify the quality and safety of plastic drinking bottles?

To verify the quality and safety of plastic drinking bottles, request certifications from suppliers, such as FDA approval, ISO certifications, and compliance with local regulations. Conducting third-party testing can also provide assurance regarding the materials used and their suitability for food and beverage contact. Consider visiting manufacturing facilities or requesting production samples to evaluate the bottles firsthand. Establishing a good relationship with suppliers can also facilitate transparency in quality assurance processes. -

What customization options are available for plastic drinking bottles?

Customization options for plastic drinking bottles are extensive and can include shape, size, color, labeling, and closures. Many suppliers offer design services to help you create unique packaging that reflects your brand. Depending on the supplier, you may also be able to request custom materials or features, such as UV protection or enhanced barrier properties. Be sure to discuss your specific requirements early in the sourcing process to ensure your needs are met. -

What logistics considerations should I keep in mind when importing plastic drinking bottles?

When importing plastic drinking bottles, consider logistics factors such as shipping methods, freight costs, and lead times. Opt for a reliable freight forwarder experienced in handling plastic goods to navigate customs regulations efficiently. It’s also important to factor in potential tariffs and taxes in your total landed cost. Establish clear communication with your supplier regarding shipping schedules and delivery expectations to avoid disruptions in your supply chain. -

How do I handle customs clearance for plastic drinking bottles imported from overseas?

Handling customs clearance for imported plastic drinking bottles involves several steps. First, ensure all documentation, such as invoices, packing lists, and certificates of origin, is complete and accurate. Familiarize yourself with the specific regulations and tariffs applicable to your product in your destination country. Engaging a customs broker can streamline the process, as they can assist in navigating complex regulations and ensure compliance. Maintain open communication with your supplier to resolve any issues that may arise during clearance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plastic drinking bottles wholesale

In the ever-evolving landscape of plastic drinking bottles wholesale, strategic sourcing emerges as a critical driver for international B2B buyers. By prioritizing quality, compliance with safety standards, and sustainability, businesses can secure reliable suppliers that meet their unique needs. Key takeaways include the importance of selecting bottles made from recyclable materials like PET, ensuring compliance with FDA regulations, and understanding the specific applications for different bottle types—whether for juices, sauces, or other beverages.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality packaging solutions will only grow. Buyers should leverage the competitive pricing and diverse options available from wholesale suppliers to optimize their purchasing strategies. Additionally, embracing innovations in packaging technology, such as High-Pressure Pasteurization compatibility, can provide a significant edge in product quality and shelf life.

Looking ahead, the focus on sustainability and consumer safety will shape the future of packaging. International buyers are encouraged to explore partnerships with reputable suppliers to not only meet current demands but also anticipate future trends. By doing so, they can position themselves for long-term success in a dynamic market.