Introduction: Navigating the Global Market for standard water bottle ounces

Navigating the global market for standard water bottle ounces presents a unique challenge for international B2B buyers, particularly those sourcing products for diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Nigeria. With a myriad of options ranging from 8 oz to 64 oz bottles, understanding the nuances of each size is essential for making informed purchasing decisions. This guide serves as a comprehensive resource, exploring the various types of water bottles, their applications in different sectors, and critical factors such as supplier vetting and cost considerations.

As hydration needs evolve across different markets, selecting the right water bottle size can significantly impact customer satisfaction and brand loyalty. This guide empowers buyers by breaking down the standard sizes and their specific uses, whether for daily hydration, outdoor activities, or corporate events. Furthermore, it addresses logistical considerations such as packaging, shipping costs, and sustainability practices, which are increasingly important in today’s eco-conscious landscape.

By equipping B2B buyers with actionable insights and a deeper understanding of standard water bottle ounces, this guide enables them to streamline their procurement processes, enhance their product offerings, and ultimately drive business growth. Whether you are a distributor, retailer, or corporate buyer, our comprehensive overview will ensure you navigate this essential market with confidence and clarity.

Article Navigation

- Top 7 Standard Water Bottle Ounces Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for standard water bottle ounces

- Understanding standard water bottle ounces Types and Variations

- Key Industrial Applications of standard water bottle ounces

- 3 Common User Pain Points for ‘standard water bottle ounces’ & Their Solutions

- Strategic Material Selection Guide for standard water bottle ounces

- In-depth Look: Manufacturing Processes and Quality Assurance for standard water bottle ounces

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘standard water bottle ounces’

- Comprehensive Cost and Pricing Analysis for standard water bottle ounces Sourcing

- Alternatives Analysis: Comparing standard water bottle ounces With Other Solutions

- Essential Technical Properties and Trade Terminology for standard water bottle ounces

- Navigating Market Dynamics and Sourcing Trends in the standard water bottle ounces Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of standard water bottle ounces

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for standard water bottle ounces

Understanding standard water bottle ounces Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 8 oz Bottle | Compact size, typically used for single servings | Events, children’s products | Pros: Easy to carry, suitable for kids. Cons: Limited hydration capacity. |

| 16.9 oz Bottle | Standard size for many brands, portable | Retail, vending machines | Pros: Widely accepted, convenient for daily use. Cons: May require frequent refills. |

| 20 oz Bottle | Popular for sports and outdoor activities | Fitness centers, outdoor events | Pros: Balanced size for hydration, fits in most cup holders. Cons: Heavier than smaller sizes. |

| 32 oz Bottle | Larger capacity, ideal for long-duration activities | Gyms, hiking, travel | Pros: Reduces refill frequency, suitable for hydration needs. Cons: Bulkier, less portable. |

| 64 oz Bottle | Maximum hydration capacity, often insulated | Long trips, outdoor adventures | Pros: Ideal for extended use, keeps drinks cold/hot. Cons: Cumbersome to carry, requires planning for transport. |

What Are the Characteristics of an 8 oz Water Bottle?

The 8 oz water bottle is designed for convenience and portability, making it an excellent choice for events, parties, or children’s activities. Its compact size allows for easy distribution and storage, and it can be customized with branding for promotional purposes. However, its limited capacity means that it may not be suitable for prolonged hydration needs, which is a consideration for B2B buyers focusing on event planning or product offerings for kids.

How Does a 16.9 oz Bottle Stand Out in the Market?

The 16.9 oz bottle is considered a standard size, particularly in the bottled water industry. It is widely used in retail and vending machines, making it a familiar choice for consumers. This size strikes a balance between portability and hydration, appealing to a broad audience. B2B buyers should consider its popularity when selecting products for distribution, as it aligns well with consumer expectations and trends.

Why Choose a 20 oz Water Bottle for Sports and Outdoor Activities?

The 20 oz water bottle is favored for sports and outdoor activities due to its manageable size and capacity. It provides enough hydration for workouts or hikes while remaining portable enough to fit in most bags and cup holders. For B2B buyers in the fitness industry, this size is ideal for gyms and outdoor events, as it encourages regular hydration without excessive bulk.

What Advantages Does a 32 oz Bottle Offer for Extended Use?

With a capacity of 32 oz, this bottle is designed for users who require more hydration during prolonged activities. It is particularly suited for gyms, hiking, and travel where access to water may be limited. B2B buyers should consider the trade-off between hydration capacity and portability, as larger bottles can be bulkier and may require additional transport considerations.

When Is a 64 oz Bottle the Right Choice for B2B Buyers?

The 64 oz bottle is the largest option, perfect for long trips or outdoor adventures where refilling isn’t feasible. Often insulated, these bottles keep beverages at the desired temperature for extended periods. B2B buyers catering to outdoor enthusiasts or travelers will find this size appealing, but they must also consider the logistical challenges of transporting larger bottles, ensuring they align with their target market’s needs.

Key Industrial Applications of standard water bottle ounces

| Industry/Sector | Specific Application of Standard Water Bottle Ounces | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Catering events using 8oz and 16.9oz bottles | Enhances guest experience with convenient hydration | Quality of materials, customization options for branding |

| Sports and Recreation | Provision of 20oz bottles for athletes | Supports hydration needs during events | Durability of bottles, ease of transport, and bulk pricing |

| Healthcare | Use of 12oz bottles in patient care | Promotes hydration compliance among patients | Regulatory compliance, safety standards, and ease of use |

| Education | Distribution of 16oz bottles in schools | Encourages healthy hydration habits in students | Cost-effectiveness, branding opportunities, and eco-friendliness |

| Corporate and Events | Use of 10oz bottles for corporate gifting | Enhances brand visibility and employee wellness | Customization for branding, bulk purchase discounts |

How Are Standard Water Bottle Ounces Utilized in the Food and Beverage Industry?

In the food and beverage sector, standard water bottle sizes like 8oz and 16.9oz are commonly used for catering and event services. These sizes provide convenient hydration options for guests, enhancing their overall experience. For B2B buyers, sourcing high-quality bottles that allow for customization with branding is crucial. Additionally, considering the material used in the bottles can impact the product’s perceived value and sustainability, aligning with consumer preferences for eco-friendly options.

What Role Do Standard Water Bottle Ounces Play in Sports and Recreation?

In the sports and recreation industry, 20oz water bottles are a popular choice for athletes participating in events or training sessions. These bottles provide sufficient hydration without being overly cumbersome, allowing athletes to perform at their best. When sourcing, businesses should focus on the durability of the bottles, as they need to withstand rigorous activity. Additionally, bulk pricing and transport logistics are important considerations for organizations looking to provide hydration solutions for large groups.

How Are Standard Water Bottle Ounces Implemented in Healthcare Settings?

Healthcare facilities often utilize 12oz water bottles to promote hydration among patients. This size is manageable for individuals, encouraging compliance with hydration recommendations. For international buyers, sourcing these bottles must include an assessment of regulatory compliance and safety standards, ensuring that the materials used are suitable for medical environments. Ease of use is also a critical factor, as bottles should be accessible for patients of varying mobility.

Why Are Standard Water Bottle Ounces Important in Educational Institutions?

In educational settings, 16oz water bottles are distributed to promote healthy hydration habits among students. These bottles are ideal for school environments as they provide a balance between capacity and portability. B2B buyers in this sector should prioritize cost-effectiveness and the potential for branding opportunities, such as adding school logos. Additionally, eco-friendliness is becoming increasingly important, with many institutions seeking sustainable sourcing options.

How Do Standard Water Bottle Ounces Benefit Corporate Events?

For corporate gifting and events, 10oz water bottles serve as effective promotional items that enhance brand visibility while promoting employee wellness. These bottles can be customized with company logos, making them a great marketing tool. When sourcing for corporate purposes, businesses should consider customization options and seek bulk purchase discounts to maximize value. Additionally, the aesthetic appeal and quality of the bottles can significantly influence brand perception among clients and employees.

3 Common User Pain Points for ‘standard water bottle ounces’ & Their Solutions

Scenario 1: Confusion Over Water Bottle Sizes for Corporate Gifting

The Problem:

B2B buyers, particularly those looking to purchase custom water bottles for corporate events or client gifts, often struggle with the wide array of sizes available. When attempting to select the right size, they face confusion over which ounce capacity will best serve their audience. A common pitfall is choosing bottles that are either too small, requiring frequent refills, or too large, becoming cumbersome for recipients. This indecision can lead to wasted resources, unsatisfactory products, and ultimately, a negative impression of the brand.

The Solution:

To effectively navigate this challenge, buyers should conduct a brief survey or gather data on the preferences of their target audience. For instance, when selecting a standard size for corporate gifts, opting for 16.9 oz (500 ml) bottles is advisable as this is a widely accepted size that balances portability and capacity. Additionally, consider offering a variety of sizes (e.g., 12 oz for kids or 20 oz for adults) to cater to different demographics within the company. Collaborating with suppliers who offer customization options can also enhance the appeal of the bottles, ensuring they align with the company’s branding while being practical for the users.

Scenario 2: Misalignment of Hydration Needs and Bottle Sizes for Events

The Problem:

Event organizers often face the challenge of aligning the hydration needs of attendees with the available water bottle sizes. For example, a sports event may require larger bottles to keep athletes hydrated during intense activities, whereas a corporate seminar might benefit from smaller bottles that are easy to distribute. Misjudging the required size can result in either insufficient hydration for participants or excessive waste if bottles are left unused.

The Solution:

Organizers should analyze the nature of the event and the typical hydration needs of attendees. For high-energy events like marathons or fitness expos, consider sourcing larger bottles (32 oz or more) to minimize the frequency of refills. Conversely, for more formal settings, a standard 16.9 oz bottle can be appropriate. It’s also beneficial to partner with suppliers who understand the specific context of the event and can recommend sizes that align with the expected activities. Additionally, including educational materials on the importance of hydration at the event can encourage proper usage of the bottles provided.

Scenario 3: Challenges with Packaging and Shipping Standard Water Bottle Ounces

The Problem:

B2B buyers involved in wholesale distribution of water bottles frequently encounter logistical challenges related to packaging and shipping. Understanding how many bottles can be efficiently transported based on their ounce capacity can significantly impact shipping costs and operational efficiency. Miscalculating the number of bottles per pallet or case can lead to increased shipping fees or product damage due to improper stacking.

The Solution:

Buyers should familiarize themselves with the packaging specifications provided by suppliers. For example, knowing that a standard case of 16.9 oz bottles holds 24 units can help in planning shipments effectively. Utilizing software tools or spreadsheets to model different shipping scenarios based on bottle sizes and weights can further optimize logistics. It’s also wise to communicate closely with suppliers regarding their packaging methods and pallet configurations to ensure optimal use of space and resources during transport. By understanding the nuances of shipping related to bottle sizes, buyers can reduce costs and enhance their supply chain efficiency.

Strategic Material Selection Guide for standard water bottle ounces

What Are the Key Materials for Standard Water Bottles?

When selecting materials for standard water bottles, it’s essential to consider properties that affect performance, durability, and compliance with international standards. Here, we analyze four common materials: plastic (PET), stainless steel, aluminum, and glass.

How Does Plastic (PET) Perform in Water Bottle Applications?

Polyethylene terephthalate (PET) is a widely used plastic for water bottles, especially for single-use applications. PET has excellent clarity and is lightweight, making it a popular choice for bottled water. It can withstand temperatures up to 120°C (248°F) and is resistant to impact and shattering. However, PET is not suitable for high-pressure applications, and its long-term use can lead to degradation.

Pros: PET bottles are cost-effective, lightweight, and recyclable, making them a preferred choice for mass production. They are also compliant with food safety standards in many regions, including those in Africa and Europe.

Cons: The primary drawback of PET is its susceptibility to leaching chemicals if exposed to high temperatures or prolonged sunlight. Additionally, it is less durable compared to metal options and may not be suitable for long-term use.

What Are the Benefits of Using Stainless Steel for Water Bottles?

Stainless steel is increasingly popular for reusable water bottles due to its durability and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for hot beverages. Stainless steel bottles are also resistant to odors and stains, ensuring a clean drinking experience.

Pros: The key advantage of stainless steel is its longevity and robustness. It is a sustainable option, as it can be reused indefinitely without degrading. Furthermore, stainless steel complies with international health and safety standards, making it suitable for export to various markets.

Cons: The main limitation of stainless steel is its higher cost compared to plastic. Additionally, the manufacturing process can be more complex, requiring specialized equipment and techniques.

Why Choose Aluminum for Standard Water Bottles?

Aluminum is another viable option for water bottles, particularly for those seeking a lightweight and recyclable solution. Aluminum bottles can be treated with a liner to prevent leaching and corrosion, making them safe for various beverages. They are also capable of withstanding moderate pressure.

Pros: Aluminum bottles are lightweight and have a high strength-to-weight ratio, making them easy to carry. They are also recyclable, which appeals to environmentally conscious consumers.

Cons: The primary drawback of aluminum is its susceptibility to dents and scratches, which can compromise the integrity of the bottle. Additionally, the need for a liner can complicate the manufacturing process and increase costs.

What Are the Considerations for Glass Water Bottles?

Glass is a premium material for water bottles, valued for its purity and aesthetic appeal. It is non-reactive, ensuring that no chemicals leach into the water. Glass bottles can handle a wide range of temperatures and are easy to clean.

Pros: The key advantage of glass is its ability to maintain the taste and quality of the water without any interference from the material. Glass is also fully recyclable and can be produced in various designs, appealing to a diverse market.

Cons: The main limitation of glass is its weight and fragility, making it less suitable for outdoor activities or travel. Additionally, the cost of glass bottles is generally higher than that of plastic or aluminum.

Summary Table of Material Selection for Standard Water Bottles

| Material | Typical Use Case for standard water bottle ounces | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic (PET) | Single-use bottled water | Lightweight and cost-effective | Susceptible to leaching | Low |

| Stainless Steel | Reusable water bottles | Durable and corrosion-resistant | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight, portable water bottles | High strength-to-weight ratio | Susceptible to dents and scratches | Medium |

| Glass | Premium reusable water bottles | Maintains taste and quality | Heavy and fragile | High |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions on water bottle materials, ensuring compliance with regional standards and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for standard water bottle ounces

What Are the Key Stages in the Manufacturing Process of Standard Water Bottles?

The manufacturing of standard water bottles involves several critical stages that ensure the final product meets quality and safety standards. Understanding these processes is vital for B2B buyers looking to source reliable products.

1. Material Preparation

The first step in the manufacturing process is the preparation of raw materials. Most water bottles are made from polyethylene terephthalate (PET) or high-density polyethylene (HDPE), which are known for their durability and safety. During this phase, manufacturers acquire high-quality resin pellets, which are then dried to remove moisture that could affect the molding process.

In addition to the primary material, additives may be included to enhance properties such as UV resistance, flexibility, and color. This preparation ensures that the materials meet the specifications required for various bottle sizes, including the popular 8 oz, 10 oz, 12 oz, and 16.9 oz formats.

2. Forming Process

The second stage involves the forming of bottles through techniques like blow molding or injection molding. In blow molding, the dried resin pellets are heated and formed into a parison, which is then inflated into the desired shape using air pressure. This technique is prevalent for producing standard water bottles because it allows for high precision in size and thickness.

For injection molding, the resin is melted and injected into a mold to create the bottle shape. This method is often used for producing bottle caps or other components. Quality control begins at this stage, with checks for dimensional accuracy and defects in the molded components.

3. Assembly

Following the forming process, the assembly stage includes attaching caps, labels, and any additional components. Automation plays a significant role here, with machines handling the capping and labeling to ensure efficiency and consistency. Custom labels can be printed according to the specifications provided by B2B buyers, enhancing brand visibility.

Quality checks during assembly focus on ensuring that all components fit correctly and that the labels are applied accurately. This stage is crucial for maintaining the aesthetic quality of the product, which can influence consumer perception.

4. Finishing Touches

The final stage involves finishing processes such as sanitization, packaging, and labeling. Bottles are typically washed and sterilized to ensure they are safe for food and drink use. Quality assurance teams conduct final inspections to verify that all bottles are free from contaminants and defects.

Packaging is also essential, as it affects shipping efficiency. Bottles are often bundled in cases or shrink-wrapped for protection during transportation. Proper packaging helps mitigate damage and ensures that products arrive in optimal condition.

What International Quality Standards Should B2B Buyers Consider?

Quality assurance is critical in the manufacturing of water bottles, particularly for B2B buyers sourcing products internationally. Several standards and certifications help ensure that manufacturers meet necessary safety and quality benchmarks.

ISO 9001 Certification

ISO 9001 is an internationally recognized standard for quality management systems (QMS). Manufacturers that hold this certification demonstrate their commitment to quality and continuous improvement. B2B buyers should prioritize suppliers with ISO 9001 certification to ensure consistent product quality and reliability.

CE Marking

For products sold in the European market, CE marking is essential. This certification indicates compliance with EU safety, health, and environmental protection standards. B2B buyers from Europe should verify that their suppliers adhere to CE regulations, especially if they are importing water bottles.

API Standards

For buyers in the Middle East and North Africa, the American Petroleum Institute (API) standards may apply, particularly if the bottles are used for industrial applications or in conjunction with petroleum products. Understanding these standards can help buyers assess product suitability and safety.

What Are the Key Quality Control Checkpoints in Water Bottle Manufacturing?

Quality control (QC) is a multi-faceted process that occurs at various checkpoints throughout the manufacturing cycle. Key QC stages include:

Incoming Quality Control (IQC)

At this initial stage, raw materials are inspected before they enter the production process. This includes verifying the quality of resin pellets and any additives. B2B buyers can request IQC reports to ensure that only high-quality materials are used in the production of their water bottles.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC checks focus on monitoring production parameters, such as temperature and pressure during molding. This ensures that the bottles meet the specified dimensions and quality standards. Regular sampling and testing are conducted to identify and rectify issues early in the process.

Final Quality Control (FQC)

Once the bottles are assembled, FQC involves a comprehensive inspection of the final product. This includes checking for defects, ensuring proper labeling, and verifying that the packaging meets shipping standards. B2B buyers should look for detailed FQC reports that outline the testing methods used and the results obtained.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several proactive steps to ensure the quality of their suppliers’ manufacturing processes:

Conduct Supplier Audits

Regular audits of suppliers can provide valuable insights into their manufacturing practices. Audits should assess compliance with international standards and internal QC processes. Buyers can either perform these audits themselves or hire third-party inspection agencies for an unbiased evaluation.

Request Quality Assurance Reports

Suppliers should be willing to provide documentation that outlines their quality control processes, including IQC, IPQC, and FQC reports. Reviewing these documents can help buyers understand the measures in place to ensure product quality.

Engage Third-Party Inspection Services

For international transactions, engaging third-party inspection services can add an extra layer of assurance. These services can conduct independent checks at various manufacturing stages, providing buyers with objective assessments of product quality.

What Specific QC Considerations Should International Buyers Keep in Mind?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific QC nuances:

-

Cultural Differences: Understand that manufacturing standards and practices can vary significantly across regions. Familiarizing yourself with local regulations and standards is crucial.

-

Logistics and Shipping: Ensure that QC measures also consider packaging and shipping practices. Proper packaging can reduce the risk of damage during transport, which is particularly important for international shipments.

-

Regulatory Compliance: Each region may have unique regulations concerning food safety and product standards. Buyers should ensure that suppliers comply with local laws in their respective markets to avoid legal issues.

By understanding the manufacturing processes and quality assurance standards for standard water bottles, B2B buyers can make informed decisions that align with their business needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘standard water bottle ounces’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to procure standard water bottle sizes. Understanding the nuances of water bottle capacities, dimensions, and specifications is essential for making informed purchasing decisions. This checklist will help streamline your sourcing process and ensure you select products that meet your operational needs.

Step 1: Define Your Technical Specifications

Before beginning your procurement process, it’s vital to outline the specific requirements for the water bottles you intend to purchase. Consider factors such as the desired volume (e.g., 8 oz, 16.9 oz, 20 oz), material (plastic, stainless steel, etc.), and design (single-use vs. reusable). This clarity will help you communicate effectively with suppliers and narrow down your options.

Step 2: Understand Market Trends and Consumer Preferences

Research current market trends to identify which water bottle sizes are most popular within your target demographics. In regions like Africa and South America, for instance, smaller bottles (8 oz to 12 oz) may be favored for convenience, while larger sizes (32 oz to 64 oz) may appeal to outdoor enthusiasts. Understanding these preferences will guide your sourcing strategy and product selection.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request detailed company profiles, product samples, and references from other buyers in similar industries or regions. Pay close attention to their manufacturing capabilities, quality control processes, and past performance in delivering standard sizes.

- Key Considerations:

- Certifications (ISO, FDA) that confirm product safety and quality.

- Production capacity to meet your demand.

Step 4: Verify Product Compliance with Regional Regulations

Ensure that the water bottles you are considering comply with local regulations and standards in your target markets. Different regions may have specific requirements regarding material safety, labeling, and environmental impact. This step is crucial to avoid compliance issues that could hinder your distribution efforts.

Step 5: Request Detailed Pricing and Shipping Information

Obtain comprehensive pricing structures from potential suppliers, including volume discounts, shipping costs, and any additional fees. Understanding the total cost of ownership will help you budget effectively and avoid unexpected expenses.

- Important Aspects to Consider:

- Minimum order quantities (MOQs) and lead times.

- Shipping options that suit your logistics strategy.

Step 6: Assess Customization Options

Consider whether you need customized branding or labeling on your water bottles. Many suppliers offer options for bespoke designs, which can enhance brand visibility and appeal to your target audience. Ensure that the supplier can accommodate your specific design requirements and timelines.

Step 7: Conduct a Final Review and Place Your Order

Before finalizing your order, review all details, including specifications, pricing, and delivery timelines. Confirm that all aspects meet your operational needs and align with your business objectives. Once satisfied, proceed with placing your order, ensuring that you have a clear agreement regarding terms and conditions.

By following this checklist, B2B buyers can make informed decisions when sourcing standard water bottle sizes, ensuring that they meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for standard water bottle ounces Sourcing

What Are the Key Cost Components in Sourcing Standard Water Bottles?

When sourcing standard water bottles, understanding the cost structure is essential for effective budgeting and pricing strategy. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials for water bottles include PET for single-use bottles and stainless steel or BPA-free plastics for reusable options. Prices fluctuate based on material quality, availability, and market demand.

-

Labor: Labor costs vary by region and manufacturing scale. In countries with higher labor costs, such as in parts of Europe, the overall manufacturing expense will increase. In contrast, sourcing from regions with lower labor costs, like some areas in Africa or South America, can reduce expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can help mitigate these costs, making it crucial to assess the supplier’s operational efficiency.

-

Tooling: Custom molds and tooling for specific bottle designs can be a significant upfront cost. This is especially relevant if your order requires unique shapes or sizes. Understanding the tooling costs upfront can help you gauge the total investment required.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can incur additional costs. However, investing in quality assurance can lead to long-term savings by reducing returns and enhancing brand reputation.

-

Logistics: Transportation costs are vital in international sourcing. Factors such as distance, shipping methods, and fuel prices can influence overall logistics expenses. It’s important to evaluate freight options and choose the most cost-effective method without compromising delivery timelines.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition and perceived product value. Understanding the margin can help you negotiate better pricing.

How Do Price Influencers Impact Sourcing Decisions for Water Bottles?

Several price influencers should be considered when sourcing standard water bottles, particularly in international markets:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Higher volumes often lead to lower per-unit costs, making it beneficial for businesses that can commit to larger orders.

-

Specifications and Customization: Customized bottles with specific designs or features may incur additional costs. It’s essential to communicate your requirements clearly to avoid unexpected expenses.

-

Material Choices: The type of material chosen affects not only the cost but also the durability and sustainability of the product. Eco-friendly materials may have higher upfront costs but can appeal to environmentally conscious consumers.

-

Quality and Certifications: Bottles meeting specific health and safety certifications may be priced higher. Ensure that your supplier complies with relevant standards to avoid potential legal issues.

-

Supplier Factors: The supplier’s location, reputation, and reliability can influence prices. Suppliers with established track records may charge a premium, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears shipping costs and risks. This knowledge can help you negotiate better shipping arrangements and avoid unexpected charges.

What Buyer Tips Can Help You Optimize Costs in Water Bottle Sourcing?

To navigate the complexities of sourcing water bottles effectively, consider the following tips:

-

Negotiate Wisely: Always engage in negotiations to secure the best possible price. Leverage volume commitments or long-term contracts to gain favorable terms.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership, which includes initial purchase price, shipping, and potential warranty costs. A slightly higher upfront price may lead to lower long-term expenses if the product is of superior quality.

-

Understand Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from Africa, South America, the Middle East, or Europe. Economic conditions, tariffs, and local market demands can influence costs.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and access to exclusive deals.

-

Request Sample Products: Before committing to large orders, request samples to assess quality and ensure that the product meets your specifications. This reduces the risk of costly returns.

Conclusion

In summary, a comprehensive understanding of cost components, price influencers, and strategic buyer tips can empower B2B buyers to make informed decisions when sourcing standard water bottles. Keep in mind that prices may vary widely based on numerous factors, so thorough research and proactive negotiation are key to achieving the best outcomes.

Alternatives Analysis: Comparing standard water bottle ounces With Other Solutions

Introduction to Alternatives in Water Bottling Solutions

In a global marketplace increasingly focused on sustainability and efficiency, B2B buyers are exploring various alternatives to standard water bottle ounces for their hydration needs. While standard water bottles typically range from 8 to 64 ounces, alternative solutions can provide unique advantages in performance, cost, and practicality. This analysis will compare standard water bottles against two alternative solutions: reusable water bottles and water filtration systems. Each option presents distinct benefits and challenges that can impact purchasing decisions.

Comparison Table

| Comparison Aspect | Standard Water Bottle Ounces | Reusable Water Bottles | Water Filtration Systems |

|---|---|---|---|

| Performance | Reliable hydration, portable | Versatile, variable capacity | Provides purified water on demand |

| Cost | Low cost per unit, bulk discounts | Higher upfront cost, savings over time | Initial investment, ongoing filter replacements |

| Ease of Implementation | Easy to store and distribute | Requires education on usage | Requires plumbing or setup |

| Maintenance | Minimal (disposal after use) | Regular cleaning needed | Periodic filter changes |

| Best Use Case | Events, travel, and casual use | Daily hydration, sports, and outdoor activities | Home or office hydration, reducing bottled water reliance |

Detailed Breakdown of Alternatives

Reusable Water Bottles

Reusable water bottles offer a sustainable alternative to standard water bottles. Made from materials like stainless steel or BPA-free plastic, these bottles can hold anywhere from 20 to 64 ounces of liquid. The primary advantage lies in their durability and eco-friendliness, reducing the reliance on single-use plastics. However, they typically have a higher upfront cost and require regular cleaning to maintain hygiene. For businesses promoting environmental responsibility, reusable bottles can enhance brand image while also providing significant long-term savings.

Water Filtration Systems

Water filtration systems represent another viable alternative, allowing businesses to provide purified water directly from taps. These systems can vary in complexity from simple pitcher filters to advanced under-sink units. The primary benefits include a constant supply of clean water without the need for purchasing bottled water. While the initial setup may be more expensive than standard water bottles, the ongoing costs can be lower, especially for businesses with high water consumption. The main drawback is the need for periodic maintenance and filter replacements, which require planning and management.

Conclusion: Choosing the Right Hydration Solution for Your Needs

When selecting the right hydration solution, B2B buyers should consider their specific operational needs, budget constraints, and sustainability goals. Standard water bottles are ideal for short-term needs or events, while reusable bottles and filtration systems offer long-term advantages that align with eco-friendly practices. By carefully evaluating performance, cost, and maintenance requirements, businesses can make informed decisions that enhance their hydration strategies while contributing to a more sustainable future.

Essential Technical Properties and Trade Terminology for standard water bottle ounces

What are the Key Technical Properties of Standard Water Bottle Ounces?

Understanding the technical specifications of water bottles is crucial for B2B buyers, especially when making informed purchasing decisions. Here are some essential properties to consider:

1. Capacity Specifications (Ounces and Milliliters)

Water bottles come in various sizes, typically ranging from 8 oz to 64 oz. The most common size for a standard water bottle is 16.9 oz (500 ml). This specification is vital for determining how much liquid the bottle can hold, which directly impacts consumer usage and marketing strategies. For bulk orders, understanding capacity helps in calculating the total volume needed for distribution and sales forecasting.

2. Material Grade

The material used in water bottle production, such as PET (polyethylene terephthalate), HDPE (high-density polyethylene), or stainless steel, significantly affects product quality, safety, and consumer preference. For instance, PET is lightweight and recyclable, making it suitable for single-use bottles, while stainless steel offers durability and insulation for reusable options. Buyers should ensure that materials comply with local regulations regarding food safety and environmental impact.

3. Dimensions and Tolerances

Each water bottle size comes with specific dimensions, including height and diameter. For instance, a 16.9 oz bottle typically measures 8.25 inches tall and 2.5 inches in diameter. Tolerances refer to acceptable variations in these dimensions, which are crucial for ensuring consistent manufacturing and compatibility with packaging and shipping processes. Understanding these specifications helps in optimizing logistics and storage solutions.

4. Label Size and Customization Options

Label size and the ability to customize them are critical for branding and marketing purposes. The label dimensions often vary by bottle size; for example, a 10 oz bottle might have a label that is 7.75 inches long and 2.25 inches high. Custom labels not only enhance product visibility but also allow businesses to convey important information, such as nutritional content or promotional messages.

5. Weight and Packaging

The total weight of water bottles, including packaging, affects shipping costs and logistics. For example, a case of 24 bottles weighing 30 lbs will have different shipping considerations compared to lighter options. Buyers must evaluate packaging solutions that minimize costs while ensuring product safety during transportation.

What are Common Trade Terms Used in Water Bottle Sourcing?

Familiarity with trade terminology is essential for smooth operations in the B2B landscape. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the water bottle industry, this term is crucial for buyers looking to source bottles from manufacturers who can meet specific design and material requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it can affect cash flow and inventory management. Understanding the MOQ helps businesses plan their purchases according to market demand and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. In the water bottle industry, submitting an RFQ allows buyers to compare costs, delivery times, and terms from multiple manufacturers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and delivery. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and insurance responsibilities when importing water bottles from different regions.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. This term is critical for supply chain management, especially in the water bottle industry, where timely delivery can impact market opportunities and consumer satisfaction.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing standard water bottles, ultimately optimizing their supply chain and enhancing their market offerings.

Navigating Market Dynamics and Sourcing Trends in the standard water bottle ounces Sector

What Are the Key Market Trends Influencing Standard Water Bottle Ounces?

The global water bottle market is experiencing a significant transformation driven by increasing health awareness, environmental concerns, and technological advancements. As consumers across regions such as Africa, South America, the Middle East, and Europe prioritize hydration, the demand for standard water bottle sizes—particularly the 16.9 oz (500 ml) variant—continues to rise. This size is not only convenient for daily use but also aligns with the need for portability in urban settings and outdoor activities.

Emerging technologies are reshaping the sourcing landscape for international B2B buyers. Innovations in manufacturing processes, such as blow molding and injection molding, have improved production efficiency and reduced costs. Additionally, the integration of digital platforms for procurement is streamlining supply chain management, allowing buyers to track orders and manage inventory more effectively. Furthermore, the rise of e-commerce and direct-to-consumer sales channels is influencing traditional distribution models, encouraging suppliers to adapt their strategies to remain competitive.

Market dynamics are also affected by regional preferences and regulations. For instance, in the Middle East, the demand for reusable bottles is growing as governments impose restrictions on single-use plastics. In contrast, Africa’s burgeoning middle class is driving the consumption of bottled water, particularly in urban areas. Understanding these regional nuances is essential for B2B buyers looking to source effectively in diverse markets.

How Can Sustainability and Ethical Sourcing Impact the Standard Water Bottle Sector?

Sustainability has become a pivotal concern in the water bottle industry, prompting B2B buyers to reassess their sourcing strategies. The environmental impact of plastic waste is significant, with millions of tons ending up in landfills and oceans each year. As a result, buyers are increasingly prioritizing suppliers that offer eco-friendly alternatives, such as biodegradable or recycled materials for standard water bottles.

Ethical sourcing practices are also gaining traction among buyers who wish to align their business values with consumer expectations. Brands that demonstrate a commitment to sustainability through transparent supply chains and responsible sourcing are more likely to gain consumer trust. Certifications such as ISO 14001 for environmental management and the Global Recycling Standard (GRS) for recycled materials are becoming critical benchmarks for suppliers.

Moreover, incorporating “green” certifications into procurement strategies can enhance brand reputation and open new market opportunities. Buyers are encouraged to seek partnerships with manufacturers that adhere to environmental regulations and provide proof of sustainable practices, ensuring that their procurement processes contribute positively to both the environment and society.

How Has the Standard Water Bottle Market Evolved Over Time?

The evolution of the standard water bottle market reflects broader societal changes regarding health, convenience, and sustainability. Initially dominated by single-use plastic bottles, the market has transitioned to include a wide range of reusable options, catering to varying consumer needs and preferences. The introduction of stainless steel and glass bottles has expanded the product offering, appealing to environmentally conscious consumers.

In recent years, the rise of fitness culture and outdoor activities has further influenced bottle design and functionality. Consumers now seek bottles that not only meet hydration needs but also fit seamlessly into their active lifestyles. This shift has spurred innovation in features such as insulation, portability, and ease of cleaning.

As the market continues to evolve, B2B buyers must stay informed about emerging trends and consumer preferences. By understanding the historical context and current dynamics, buyers can make strategic sourcing decisions that align with both market demands and their organizational values.

Frequently Asked Questions (FAQs) for B2B Buyers of standard water bottle ounces

-

How do I determine the right size of water bottle for my business needs?

Choosing the right size of water bottle hinges on your target market and usage context. For events or promotional purposes, smaller bottles like 8 oz or 10 oz are ideal for quick hydration and convenience. Larger sizes, such as 16.9 oz or 32 oz, cater to customers looking for extended hydration during sports or outdoor activities. Analyze your audience’s preferences, consider the occasion, and assess shipping costs associated with different sizes to make an informed decision. -

What is the most common size for a water bottle in international markets?

The most widely recognized size for a water bottle globally is 16.9 oz (500 ml), especially for single-use plastic bottles. This size is common in various regions, including Africa, South America, and Europe. However, preferences may vary by market, with some areas favoring larger or reusable options. It’s essential to conduct market research to understand local preferences and adjust your offerings accordingly. -

How can I ensure the quality of water bottles from international suppliers?

To maintain quality, vet suppliers thoroughly by requesting certifications, product samples, and compliance with international safety standards. Evaluate their manufacturing processes and quality assurance measures. Establish clear communication regarding your quality expectations and conduct regular audits to ensure adherence to these standards. Engaging with suppliers who have a proven track record can help mitigate risks associated with quality. -

What customization options are available for water bottles?

Most suppliers offer various customization options, including label design, bottle color, and material choices. Custom labeling can enhance brand visibility, especially for promotional items. Inquire about minimum order quantities (MOQ) for customization and ensure the supplier can accommodate your design requirements. Consider the target audience’s preferences when selecting customization options to maximize impact. -

What are typical payment terms for international water bottle orders?

Payment terms can vary significantly among suppliers. Common arrangements include a deposit (often 30%) upfront with the balance due before shipment. Some suppliers may offer payment upon delivery or through letter of credit for larger orders. Always clarify payment terms upfront to avoid misunderstandings and ensure they align with your cash flow management practices. -

How do I handle logistics for shipping water bottles internationally?

When shipping internationally, partner with experienced logistics providers familiar with customs regulations and import/export requirements in your target countries. Consider shipping methods (air vs. sea) based on cost and urgency. Ensure proper packaging to prevent damage during transit and account for potential delays. It’s also wise to stay updated on tariffs and duties that may apply to your shipments. -

What is the minimum order quantity (MOQ) for standard water bottles?

Minimum order quantities can vary by supplier and product type. Generally, smaller sizes like 8 oz or 10 oz may have lower MOQs compared to larger sizes like 16.9 oz or 32 oz. It’s essential to discuss your needs with suppliers to find a suitable MOQ that meets your budget and storage capacity. Some suppliers may offer flexible MOQs for first-time buyers or larger clients. -

What are the best practices for sourcing water bottles in different regions?

Sourcing water bottles in diverse regions requires understanding local market dynamics, regulations, and consumer preferences. Conduct thorough research on potential suppliers, including their reliability, production capacity, and compliance with local laws. Networking with local trade associations can provide valuable insights and contacts. Additionally, consider attending trade shows to meet suppliers and assess products firsthand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Standard Water Bottle Ounces Manufacturers & Suppliers List

1. Dual Drinks – Dual Tumbler

Domain: dualdrinks.com

Registered: 2023 (2 years)

Introduction: The Dual Tumbler is designed to keep beverages perfectly separated and at their ideal temperature. It allows for two drinks at two different temperatures in one tumbler. The product is currently available for pre-order and is trademark approved with a patent pending status.

2. Airtec – Scarifier Drum ES-200-530

Domain: airtec.com

Registered: 1994 (31 years)

Introduction: Scarifier Drum assembled ES-200-530, SKU: ES-200-530, Category: Working Drums assembled ES-200, Cutter ET-4, Quantity of Cutters: 88 pcs., Shaft Ø: 12 mm, Quantity of Shafts: 4 pcs., CE – approved, Manufacturer Quality Processes and Management ISO 9001:2015 Standards.

3. Owala – FreeSip Water Bottles

Domain: owalalife.com

Registered: 2019 (6 years)

Introduction: Owala offers a variety of water bottles with different sizes and features. Key product details include: 1. FreeSip Water Bottle: – Sizes: 19 oz. (9.88 inches), 24 oz. (10.68 inches), 25 oz. (9.87 inches), 32 oz. (10.66 inches), 40 oz. (11.64 inches) – Materials: Stainless Steel and Tritan Plastic – Features: FreeSip spout with two-way straw, triple-layer insulation, flip-top leakproof lid – Color …

4. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at info@scrapingdog.com for scraping Instagram. Let us know how many pages you want to scrape per month.

5. Water Bottles – 16 oz Bottled Water

Domain: waterbottles.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “16 oz Bottled Water – Standard Label”, “SKU”: “GB-P16-FD”, “description”: “Affordable promotional solution. Perfect for single logo or front and back. Full-color plastic label- which will not come off while in ice for a long time.”, “features”: [“BPA Free”], “min_quantity”: 576, “shipping_info”: “Obtain a shipping estimate to avoid unexpected charges, as bottled water is heavy an…

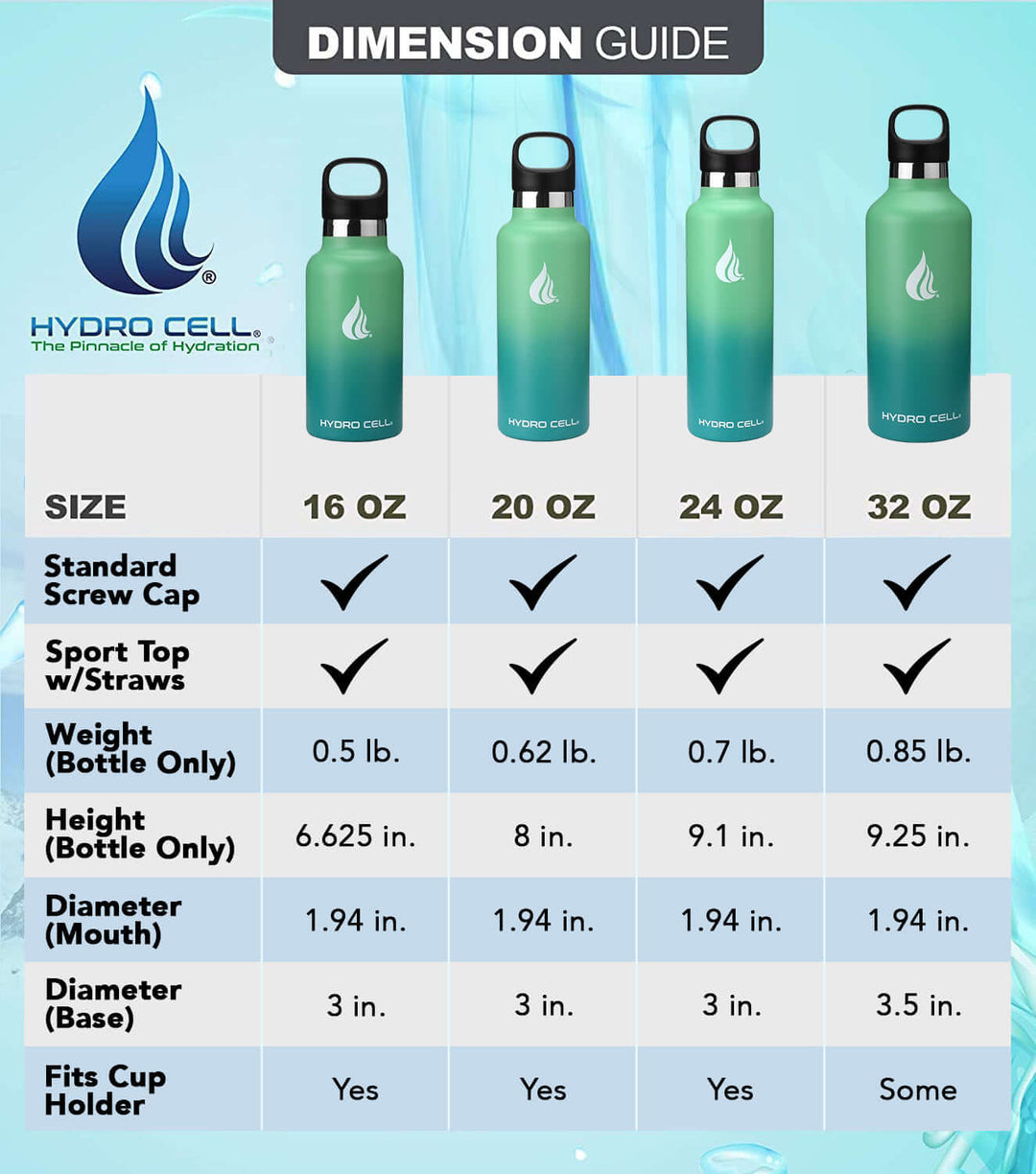

6. Hydrocell – Water Bottle Sizes and Recommendations

Domain: hydrocellusa.com

Registered: 2017 (8 years)

Introduction: Best size of water bottle is 16 to 24 ounces (473 to 708 milliliters) for daily hydration. Options include 10 to 14 ounces for kids, 16 to 20 ounces for everyday use, 20 to 24 ounces for travel, and 40 to 64 ounces for hiking or camping. Stainless steel bottles are recommended for durability and insulation.

7. My Own Water – Premium BPA-Free Water Bottles

Domain: myownwater.com

Registered: 2000 (25 years)

Introduction: We offer several water bottle sizes ranging from 8 oz up to 1 gallon. Our bottles are available in various styles and materials, including:

1. Value Bottles: Ribbed design, made from high-quality BPA-free PET plastic.

– Sizes: 8 oz, 10 oz, 12 oz, 16.9 oz, 23.7 oz, 33.8 oz

2. Modern Bottles: Sleek design without ribs.

– Sizes: 12 oz, 16.9 oz, 23.7 oz, 33.8 oz, 50 oz

3. Aluminum Bottles: 10…

Strategic Sourcing Conclusion and Outlook for standard water bottle ounces

In summary, understanding the variety of standard water bottle sizes—from the compact 8 oz to the widely used 16.9 oz—enables B2B buyers to make informed purchasing decisions tailored to their market needs. Strategic sourcing not only helps optimize supply chains but also ensures that businesses can meet consumer demands for hydration solutions across diverse environments. By carefully evaluating bottle dimensions, weights, and packaging options, international buyers can enhance their logistics efficiency, reduce costs, and improve customer satisfaction.

Looking ahead, the growing emphasis on sustainability and health consciousness presents a unique opportunity for suppliers and buyers alike. As markets in Africa, South America, the Middle East, and Europe evolve, aligning product offerings with local preferences and regulations will be crucial. We encourage B2B buyers to explore innovative sourcing strategies that emphasize quality, sustainability, and customization. By doing so, they can position themselves as leaders in the competitive water bottle market, ready to meet the hydration needs of their customers effectively.